- Drilling and installing casing pipes - a guide for beginners

- The main methods of drilling wells under water

- Auger drilling

- Rotary drilling method

- Multilateral method

- Manual drilling of a well under water

- impact method

- Rope percussion drilling

- Homemade devices for drilling wells

- Choose the type of well

- Advantages of hydrodrilling wells

- Drilling methods

- Peculiarities

- Assembling a spoon drill

- Manual well drilling

- rotary method

- screw method

Drilling and installing casing pipes - a guide for beginners

The manual drilling procedure is simple. Its scheme is as follows:

- Pour water into the pit and knead the clay in it to the consistency of kefir. The operation is performed by a mixer. Such a solution during drilling will form a kind of container with smooth walls in the well.

- Start the pump. It pumps flushing fluid into the hoses, which flows to the drilling rig through the rod. Then the water goes into the first pit. In it, the liquid from the well, saturated with soil particles, is filtered out (suspensions settle to the bottom). The drilling fluid becomes clean and passes to the next sump. It can be reused for drilling.

- In cases where the length of the drill string is not enough to reach the water layer, install additional rods.

- Having reached the coveted aquifer, you supply a large volume of clean liquid into the well to thoroughly rinse it.

- Remove rods and install pipes (casing).

Typically, tubular products are used with a cross section of 11.6–12.5 cm with walls having a thickness of about 6 mm. It is allowed to install any casing pipes - plastic, made of asbestos cement, steel.

It is desirable to provide casing pipes with filters. Then the water from the well will have a higher quality. You can purchase ready-made filtering devices. But there is a more economical option - to make the simplest filters with your own hands.

Casing pipes with filters

Drill many small holes in the bottom of the casing with a drill. Wrap the product with geofabric, fixing it with suitable clamps. The filter is ready! Believe me, such a simple design will make the water from the well much cleaner.

Also, after installing the casing, it is recommended to fill it with a little gravel (about half a regular bucket). This building material in this case will serve as an additional filter.

After the casing is installed, the well is flushed again. The procedure makes it possible to wash out the aquifer, which, in the course of drilling operations, was saturated with flushing fluid. Such an operation is done as follows:

- install the head for the well on the tubular product;

- carefully fasten the hose coming from the motor pump;

- supply clean water into the well.

All work has been completed. Lower the pump into the well and enjoy clean water.

The main methods of drilling wells under water

Drilling a well with your own hands is quite realistic and affordable if you have the necessary hydrogeological information.Having chosen a method for drilling a well for water, you should correctly determine the place for its installation. Nearby there should be no sewerage, drain holes, other communications that may pollute the water. It is also necessary to take into account the distance from the housing where it is planned to supply water.

There are a lot of types of manual drilling, using various mechanisms, devices, complex equipment: from the simplest clogging to hydraulic drilling.

Percussive drilling is the cheapest and easiest way to provide a site with drinking water

Methods for drilling water wells differ depending on the technology used to destroy the rock. There is drilling:

- shock;

- rotational;

- mixed type.

Auger drilling

This method is used for sand wells. Usually, auger drilling of water wells is carried out in relatively soft, loose or frozen soil. The auger is a pipe wrapped with a metal tape. Through rotation, the helical device deepens, giving out the selected soil to the surface. Often, with this technology, a casing pipe is lowered behind the auger-screw, which clogs the walls and prevents the earth from crumbling. This method has a number of advantages:

- good speed;

- no need for flushing;

- the walls of the well are compacted.

If auger drilling is carried out in an area with soft or loose soil, then the bit blades should be positioned at an angle of 30 to 60 degrees relative to the bottom. If drilling of wells by this method is carried out on denser deposits, which are based on gravel and pebbles, then the blades should be at an angle of 90 degrees relative to the bottom. It is necessary to determine the angle during work, depending on the hardness of the soil with which it is supposed to work.

Of all the methods of self-drilling, auger can be considered the least effective.

The depth of auger drilling of a well is carried out by the size of one rod, which then rises to the top and is increased by an additional rod. After that drilling can be continued. The diameter of the screw hole is from 6 to 80 cm.

Rotary drilling method

Rotary drilling refers to rotary methods: a rotor located on the surface drives a bit lowered into the well. The bit is additionally weighted ("loaded") with pipes to increase the degree of soil grinding.

Using this technology, it is possible to destroy almost any rock in terms of hardness. This is an expensive method used for artesian wells.

In rotary drilling, flushing is mandatory. This process quickly removes waste rock while leaving the hole clean, allowing for unobstructed casing insertion.

There are two types of flushing: direct and reverse. Direct flushing is carried out with a clay solution, which quickly removes waste rocks and strengthens the walls, since clay eliminates formation clogging. Backwashing with water is used to clean the annulus from slag.

The rotary method of drilling wells is one of the varieties of rotary technology

Benefits of rotary drilling:

- the power of the equipment used, which allows breaking rocks of any hardness;

- durability of the drilled well (wall strength);

- the ability to drill in a limited area due to the small size of the drilling rig.

The disadvantages of this technology can be considered the difficulty of working at sub-zero temperatures and the low drilling speed.

Multilateral method

This method consists in conducting two shafts from the main bottomhole glass, while the main shaft is used more than once.

In this case, the working area and the filtration surface increase, but the volume of drilling work in the surface formation decreases.

Depending on the auxiliary shafts, the following types of multilateral design are possible:

- Radial - horizontal main shaft and radial - auxiliary.

- Branched - consists of two inclined trunks and an inclined main.

- Horizontally branched - similar to the previous type, but the angle of the auxiliary trunks is ninety degrees.

The choice of the type of multilateral design is determined by the shape of the auxiliary wellbores and their placement in space.

Manual drilling of a well under water

Drilling a well manually only for an unprepared person will seem an extremely difficult process, requiring large physical costs. With certain knowledge and preparation, it is realistic and feasible to make a drill for a well with your own hands. Depending on the conditions of occurrence of groundwater, you can use several methods of self-drilling wells.

To carry out drilling work, specialists are usually invited, but if desired, they can be done independently.

impact method

In this way, the simplest well-needle is installed - the Abyssinian well. This method is actively used by home craftsmen, punching a well for water in the country.The design of the "drilling rig" is a shaft, consisting of pipe sections, and a tip that cuts the soil layers. A weighty woman serves as a hammer, which rises and falls with the help of ropes: when pulled, a kind of hammer rises to the top of the structure, when weakened, it falls on a podbaka - a device of clamps arranged symmetrically. After the trunk enters the ground, it is built up with a new segment, the bollard is attached to the new part, and clogging continues until the tip enters the aquifer by 2/3 of the reservoir.

The barrel-pipe serves as an opening for water to exit to the surface.

The advantage of this well is that it can be drilled in the basement or other suitable room. This creates ease of use. The price is also attractive, breaking a well for water in this way is inexpensive.

Percussion drilling can be used on any type of soil

Rope percussion drilling

The most commonly used method. This method involves breaking up the soil by lowering a heavy drilling tool from a height of two meters. The design used in this type of drilling consists of the following elements:

- tripod, which is placed above the drilling site;

- block with a winch and a cable;

- driving cup, rod;

- bailers (for passing through loose layers of soil).

The glass is a piece of steel pipe, beveled inward, having a strong lower cutting edge. On top of the driving glass is an anvil. A barbell strikes on it. The lowering and lifting of the driving glass is carried out using a winch. The rock that enters the glass is held in it due to the force of friction.In order to penetrate as deep as possible into the ground, a shock rod is used: it is thrown onto an anvil. After filling the glass with soil, it is lifted up, after which it is cleaned. The operation is repeated until the required depth is reached.

Well drilling on loose soils is carried out using a bailer. The latter is a steel pipe, at the lower end of which a delay valve is installed. After the bailer enters the soil, the valve opens, as a result of which the soil enters the pipe. When the structure is lifted, the valve closes. After being removed to the surface, the bailer is cleaned, the actions are repeated again.

Rope-impact equipment for drilling wells

The auger method described above is also effectively used for self-drilling. It does not make sense to explain how to drill a well with your own hands using an auger - the basic principle is preserved.

Advantages of manual drilling:

- economical way financially;

- repair and maintenance of a hand drill is easy;

- the equipment is not bulky, so there is no need to use heavy equipment;

- the method is applicable in hard-to-reach places;

- effective, does not require a lot of time.

The main disadvantages of manual drilling can be considered to be lowering to a shallow depth (up to 10 m), where the layers mainly pass, the water of which needs to be cleaned, and the inability to crush hard rocks.

Percussion-rope scheme with a bailer and a punching bit

Homemade devices for drilling wells

The simplest water intake device is the well of the Abyssinian well. To arrange it, you do not need sophisticated equipment or fixtures at all.It is enough to get a "woman", and this is a load of 20 - 25 kilograms and make a bollard - in fact, a clamp that securely covers the pipe being clogged.

An elementary device for punching Abyssinian wells is shown in Fig. 1, where:

1. Clamp for fastening blocks.

2. Block.

3. Rope.

4. Baba.

5. podbabok.

6. Driving pipe.

7. Water intake pipe with a filtering device. At the front end, it is equipped with a spear-shaped tip, the diameter of which is larger than all other components. Raising and sharply lowering the woman, two people reach the water carrier at a depth of up to 10 meters in one light day.

Drawing fig.1 does not include a tripod

Without denying the effectiveness of this method, we draw your attention to the fact that it is easier to control the direction of immersion with a tripod, because the pit must be strictly vertical. A tripod is easy to make with your own hands from improvised materials

Drilling of classic wells for water can be carried out by shock-rope method, the equipment for the implementation of this technology is so simple that it “asks” to be made by hand.

The simplest small-sized installations of this type allow drilling wells for water to a depth of 100 meters. A characteristic disadvantage of this method is the low productivity during penetration, since the process is associated with constant lifting of the tool to unload the soil from the wells after every 5–8 strokes. At the same time, the shock-rope method enables the most high-quality opening of aquifers.The simplest device shown in Fig. 1 can be easily upgraded by installing a drive on a winch with a reset clutch, as well as installing an additional manual lifting mechanism for assembling casing pipes, which can be done by hand at home.

Self-made installations for drilling water wells using auger tools are popular. This is a whole range of solutions from a simple garden drill, on which it is possible to increase the length of the drill rod, to quite complex mechanisms that fit the MGBU classification. They already use electric or internal combustion engines.

If you wish, you can make a simple auger drill with your own hands, because it is useful not only for drilling water wells, but also when building site fences and when creating a pile grillage foundation, significantly reducing the amount of earthwork. To do this, you can use the drawing from Fig. 3, if necessary, changing the dimensions in accordance with the preferences of the manufacturer.

More complex devices for drilling holes in this way include a drilling derrick, which is a traditional tripod.

One worker can do the job, but there is a danger of the drill string deviating from the vertical. Therefore, they usually work together, evenly loading both sides of the lever.

Given the complexity of the work, it is advisable to mechanize the drilling process as much as possible. There are all conditions for this, a field of short searches in the construction markets, you can purchase any parts or assemblies and make a drill yourself.

As can be seen from Fig. 6, many industrial designs cannot be compared with such a home-made product in terms of the elegance of execution and layout of such an installation. Judging by the type of conductors, the electrical circuit was designed and executed for a voltage of 220 volts. The size of the drilling tool shows that the rig is capable of drilling medium and high production wells.

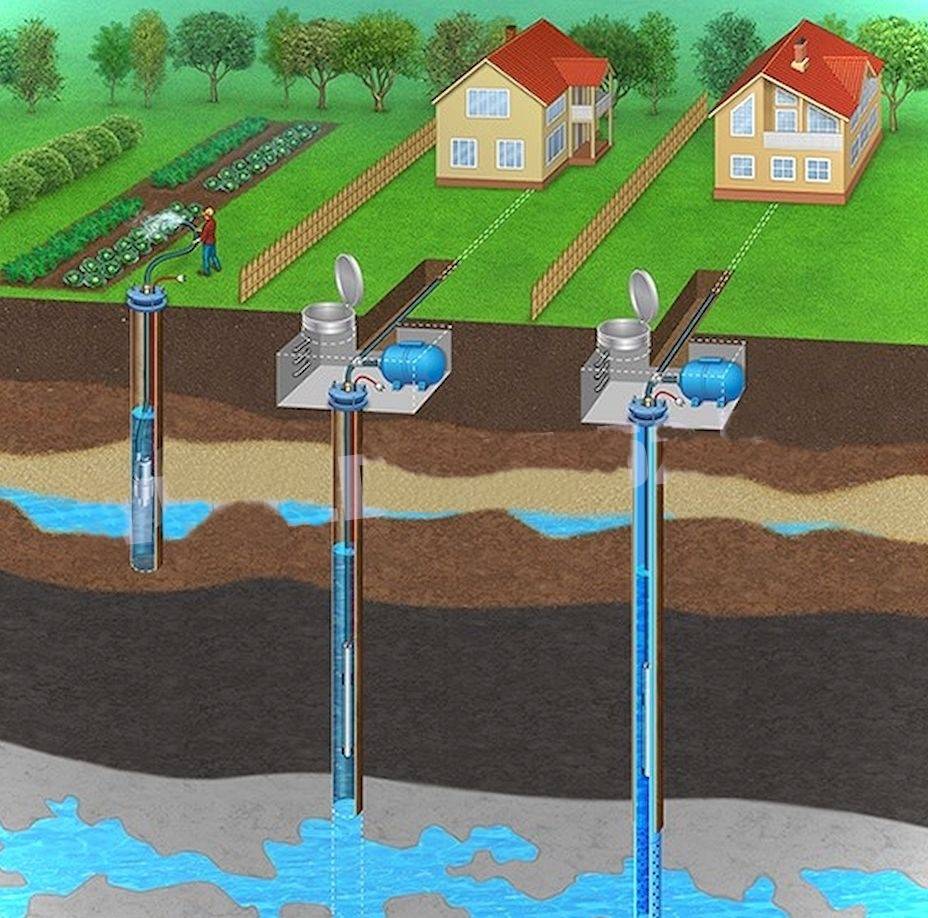

Choose the type of well

When choosing a well, proceed not only from the possibilities, but also from the expediency. Opportunities are of two types: natural resources and finance. In the first case, you need to answer the question - is there water here, in the second - how much does it cost to get it.

The next stage is the definition of the type of well. The cheapness of a well with your own hands consists only in the fact that you do not have to pay for hired labor and the purchase of special equipment. However, in drilling a well, you will have to invest your own labor, time and costs for the partial purchase of a tool. So you still have to think about saving.

If a well is needed only for watering plants and maintaining a small country house, then an Abyssinian well is enough. If the house is intended for year-round living of a large family, then at least a sand well is needed, and preferably an artesian one. You will have to choose the latter option if the water flow should exceed 10 m3 per hour.

Drilling an artesian well will take some sweat, but it can provide water to several homes. For its drilling, arrangement and operation, it makes sense to combine the efforts of several homeowners. Conclude an agreement, form a common budget and use common water.

As for the reserves and depth of water, you can learn about them from special maps and the results of hydrological studies.Data on water resources are usually available from municipal authorities. In addition, it is necessary to assess the degree of soil pollution, and find out the location of sources of harmful emissions. This is not true only for an artesian well - usually pollution does not penetrate to such a depth.

From the point of view of pollution, the water extracted from the Abyssinian well is most at risk. It can become contaminated from the nearest septic tank, it can even get pesticides used in the garden. For this reason, water from the Abyssinian well is most often used for irrigation and other household needs.

After you have decided on the natural possibilities of your land, assessed the scope of work for different types of wells, correlated all this with financial capabilities, you can decide on the type of well and start working.

Advantages of hydrodrilling wells

The technology of hydro-drilling for water among the people has gained popularity relatively recently, therefore it has many misinterpretations. First, it is a misconception that the method is only suitable for small wells. This is not true.

If desired, and with appropriate technical support, it is possible to hit wells with more than 250 meters by hydraulic drilling. But the most common depth of domestic wells is 15-35 meters.

The opinion about the high cost of the method is also not supported by calculations. Good speed of work reduces financial costs.

The obvious advantages of the method also include:

- compactness of the equipment;

- the possibility of drilling in an extremely limited area;

- minimum technological operations;

- high speed of work, up to 10 m per day;

- safety for landscape and ecological balance;

- the possibility of self-drilling;

- minimum cost.

Perhaps the most significant advantage of hydrodrilling is still the ability to drill in landscaped areas without significant aesthetic troubles.

The technology of hydraulic drilling on the MBU machine allows you to carry out a cycle of work on a small site and does not violate the landscaping of the site

The advantages of hydrodrilling are also very clear when compared with dry drilling technology, where it is necessary to constantly remove the working tool from the hole for cleaning and load it again.

Most of all, this technology is adapted to work with fine-clastic sedimentary soils, which are most easily removed from the well using a bailer. And the drilling fluid allows you to do without gelling.

Of course, for a good result of the enterprise, it is necessary to purchase the appropriate means of mechanization, because one home-made drill, even at shallow depths, is not enough.

Drilling methods

Before starting work, you should decide how to work, since you can punch a well with your own hands in several ways:

- Rotary drilling method - the rotation of the drilling tool to deepen it into the rock.

- Percussion method - the drill rod is driven into the ground, deepening the projectile.

- Shock-rotational - driving the rod into the ground twice or thrice, then rotating the rod and driving again.

- Rope-percussion - the drilling tool rises and falls, regulated by a rope.

impact method

impact method

These are dry drilling methods. There is also a technology of hydrodrilling, when drilling is carried out using a special drilling fluid or water, which are used to soften the soil.The hydropercussion method requires high costs and special equipment. If manual drilling is carried out, a simplified version is used, pouring water over the soil to soften it.

Peculiarities

The key difference between hydrodrilling wells for water is the presence of two drilling processes. First of all, when choosing this method, the rock is destroyed with the help of special devices. Next, pieces of earth are extracted with water under pressure. In other words, hydrodrilling involves washing out the soil with a powerful jet of water.

The peculiarity of the method is that the stages are carried out simultaneously, which allows you to get a high-quality result as soon as possible. To destroy the rock, special drilling equipment is immersed in the ground, and the cleaning is carried out by equipment that pumps water into the ground and delivers it to the body of the well being built in the process.

Another feature of hydraulic drilling is that the fluid from the equipment is used not only to wash out the rock destroyed by the drilling equipment. Additional functions of the supplied fluid:

- the possibility of carrying out the destroyed rock to the surface;

- cooling of tools that are used for drilling;

- grinding the well from the inside, preventing its collapse in the future.

There are quite a few advantages of hydrodrilling wells in suburban areas.

- Reducing financial costs. Work on drilling wells with the help of a hydraulic drilling rig can be done by hand without inviting specialists and special skills.

- The ability to install compact small equipment to work in small areas.For the arrangement of the well, small-sized equipment is used.

- convenience of the method. For drilling, you do not need to carry out any preliminary calculations, purchase a huge range of equipment and tools. The modern technique is simple and understandable to anyone who decides to try this method.

- Fast drilling and well completion time. Work can be completed in a maximum of a week.

It is also worth noting the environmental safety of the method and the minimal impact on the landscape. It is possible to carry out work on drilling wells even in landscaped areas. However, this method is not always suitable.

Assembling a spoon drill

It is necessary to prepare a pipe with a wall thickness of at least 5 mm. An incision is made on the side wall. Its width depends on the type of soil: the looser it is, the smaller the gap. The lower edge of the pipe is rounded with a hammer. This edge is bent so that a helical coil is formed. On the same side, a large drill is fixed. On the other hand, attach the handle.

The spoon drill includes a long metal rod with a cylinder at the end. The cylinder has 2 components, which are located along or in the form of a spiral. A sharp cutting edge is located along the bottom of the cylinder.

Manual well drilling

Most often, summer residents are interested in how to drill a well with their own hands, and not just a well. You will need such equipment for drilling wells as a drill, a drilling rig, a winch, rods and casing pipes. The drilling tower is needed for digging a deep well, with its help, the drill with rods is immersed and lifted.

rotary method

The simplest method of arranging a well for water is rotary, carried out by rotating the drill.

Hydro-drilling of shallow wells for water can be carried out without a tower, and the drill string can be removed manually. Drill rods are made from pipes, connecting them together with dowels or threads.

The bar, which will be below all, is additionally equipped with a drill. The cutting nozzles are made of sheet 3 mm steel. When sharpening the cutting edges of the nozzle, it must be taken into account that at the moment of rotation of the drill mechanism, they must cut into the soil in a clockwise direction.

The tower is mounted above the drilling site, it must be higher than the drill rod in order to facilitate the extraction of the rod during lifting. After that, a guide hole is dug for the drill, about two spade bayonets deep.

The first turns of rotation of the drill can be done independently, but with a greater immersion of the pipe, additional forces will be required. If the drill cannot be pulled out the first time, you need to turn it counterclockwise and try to pull it out again.

The deeper the drill goes, the more difficult the movement of the pipes. To facilitate this task, the soil must be softened by watering. When moving the drill down every 50 cm, the drilling structure must be taken out to the surface and cleaned from the soil. The drilling cycle is repeated anew. At the moment the tool handle reaches the ground level, the structure is increased with an additional knee.

As the drill goes deeper, the rotation of the pipe becomes more difficult. Softening the soil with water will help facilitate the work. In the course of moving the drill down every half meter, the drilling structure should be brought to the surface and freed from the soil. The drilling cycle is repeated again.At the stage when the tool handle is level with the ground, the structure is extended with an additional knee.

Since lifting and cleaning the drill takes most of the time, you need to make the most of the design, capturing and lifting up as much of the soil as possible. This is the principle of operation of this installation.

Drilling continues until an aquifer is reached, which is easily determined by the condition of the excavated land. Having passed the aquifer, the drill should be immersed a little deeper until it reaches a layer that is located below the aquifer, waterproof. Reaching this layer will make it possible to ensure the maximum inflow of water into the well.

It is worth noting that manual drilling can only be used to dive to the nearest aquifer, usually it lies at a depth not exceeding 10-20 meters.

In order to pump out dirty liquid, you can use a hand pump or a submersible pump. After two or three buckets of dirty water are pumped out, the aquifer is usually cleared and clean water appears. If this does not happen, the well needs to be deepened by about another 1-2 meters.

screw method

For drilling, an auger rig is often used. The working part of this installation is very much like a garden drill, only much more powerful. It is made from a 100 mm pipe with a pair of screw turns welded onto it having a diameter of 200 mm. In order to make one such turn, you need a round sheet blank with a hole cut in its center, the diameter of which is slightly more than 100 mm.

Then, a cut is made at the workpiece along the radius, after which, at the place of the cut, the edges are parted in two different directions, which are perpendicular to the plane of the workpiece. As the drill sinks deep, the rod on which it is attached increases. The tool is rotated by hand with a long handle made of pipe.

The drill must be removed approximately every 50-70 cm, and due to the fact that the more it goes deep, it will become heavier, so you will need to install a tripod with a winch. Thus, it is possible to drill a well for water in a private house a little deeper than the above methods.

You can also use the manual drilling method, which is based on the use of a conventional drill and a hydraulic pump: