- List of tools for the job

- Types of water intake workings and soils

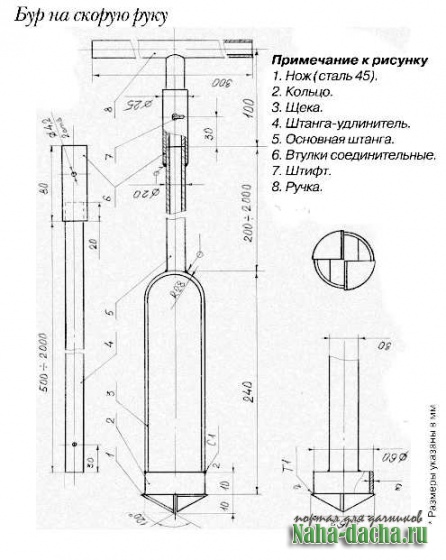

- Do-it-yourself drill for percussion-rope drilling

- Do-it-yourself drill for wells

- Other types of wells

- How to make a drill for a well with your own hands: instructions with drawings

- DIY manufacturing

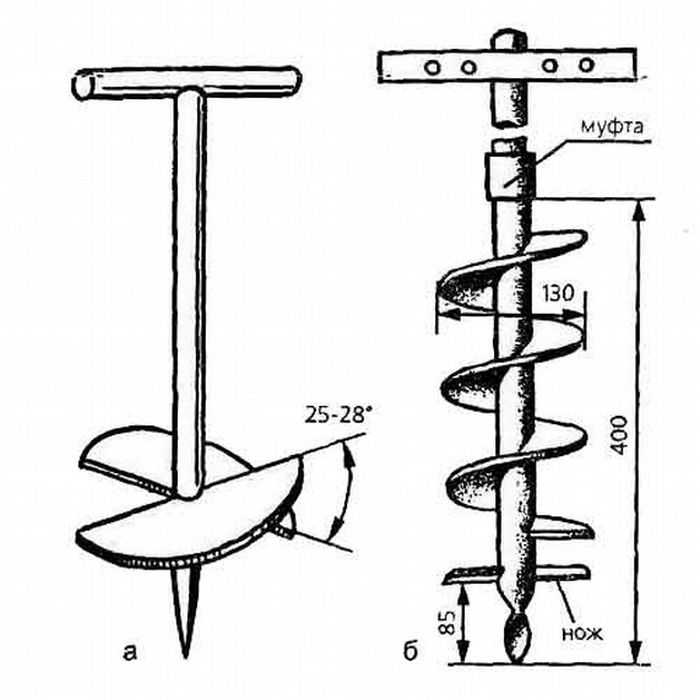

- Homemade disc drill

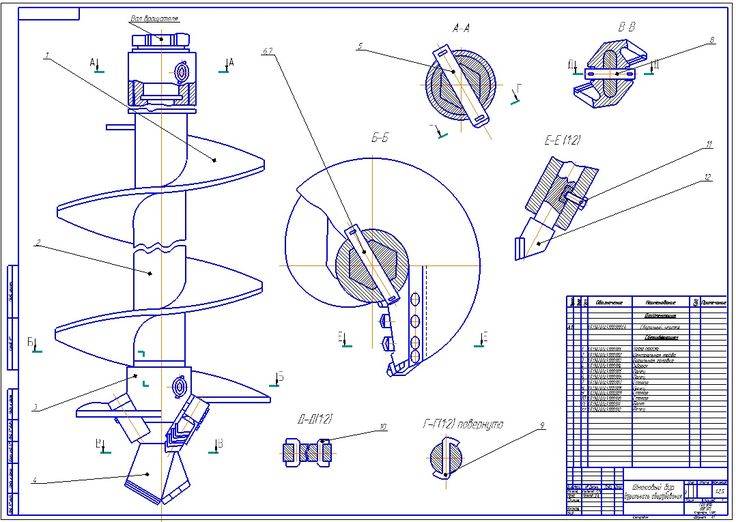

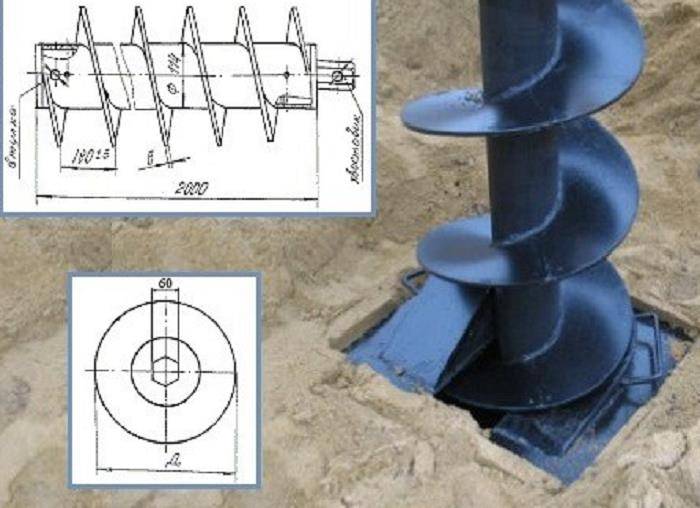

- Screw tool

- Shovel drill

- Well Depth Determination

- Do-it-yourself drill for wells

- Other types of wells

- Advantages of self-drilling

- Conclusions and useful video on the topic

List of tools for the job

Let's try to consider the shock-rope method of drilling wells with our own hands. It has the following advantages:

- Keeps a significant part of the useful soil layer in its original state.

- When using special equipment, landings on the site do not suffer.

- There are no restrictions on the drilling area. A hand drill can be used in almost any part of the territory.

- Extreme ease of operation of the unit and a minimum of requirements in relation to the qualifications of the worker.

To successfully cope with the work, you need to stock up on the necessary tools. You will need a shovel, a drill, in which the cutting part will be reinforced.

You can strengthen the unit by adding cutters to the screw. File elements can play their role. Cutters can be sharpened using a grinder.You will also need a “baby” type pump with a hose, a cart for removing soil, and a container of water. You also need steel wire for the filter, a pipe, gravel or gravel as a pillow, wire for mounting the bottom filter.

Types of water intake workings and soils

Before starting drilling, you should study the composition of the soil at the site in order to at least roughly imagine your future well.

Depending on the characteristics of the aquifer, there are three types of wells:

- Abyssinian well;

- filter well;

- artesian well.

The Abyssinian well (or well-needle) can be arranged almost everywhere. They punch it where the aquifer lies relatively close to the surface and is confined to the sands.

For its drilling, driving technology is used, which is not suitable for the construction of other types of wells. All work can usually be completed within one business day.

This scheme allows you to study the features of the device of various wells in order to better understand the technology of their drilling and choose the appropriate method (click to enlarge)

But the flow rate of such wells is small. To provide the house and the plot with enough water, it sometimes makes sense to make two such wells on the site. The compact dimensions of the equipment make it possible to arrange such a well right in the basement without any problems.

Filter wells, which are also called "sand" wells, are created on soils where the aquifer lies relatively shallow - up to 35 meters.

Usually these are sandy soils that lend themselves well to drilling. The depth of the filter well usually varies between 20-30 meters.

This diagram clearly shows the device of the filter well.A filter must be installed at the bottom of it to prevent sand and silt from entering the water.

Work in a good scenario will take two to three days. The filter well needs good maintenance, since the constant presence of sand and silt particles in the water can cause silting or sanding.

The typical life of such a well can be 10-20 years. The period may be longer or shorter, depending on the quality of the well drilling and its further maintenance.

Artesian wells, they are wells “for limestone”, are the most reliable, since the water carrier is confined to bedrock deposits. Water contains numerous cracks in the rock.

Silting of such a well usually does not threaten, and the flow rate can reach about 100 cubic meters per hour. But the depth to which drilling is to be carried out usually turns out to be more than solid - from 20 to 120 meters.

Of course, drilling such wells is more difficult, and it will take much more time and materials to complete the work. A professional team can cope with the work in 5-10 days. But if we drill a well on the site with our own hands, it may take several weeks, and even a month or two.

But the effort is worth it, because artesian wells can last half a century, or even more, without problems. Yes, and the flow rate of such a well allows you to supply water not only to one house, but also to a small village. Only manual drilling methods are not suitable for a device of such development.

The physical and mechanical properties of soils are also of great importance when choosing a drilling method.

In the course of work, it may be necessary to go through a variety of layers, for example:

- wet sand, which can be drilled in almost any way relatively easily;

- water-saturated sand, which can only be removed from the trunk with the help of a bailer;

- coarse-clastic rocks (gravel and pebble deposits with sandy and clay aggregates), which are drilled with a bailer or a glass, depending on the aggregate;

- quicksand, which is fine sand, supersaturated with water, it can only be scooped out with a bailer;

- loam, i.e. sand with abundant inclusions of clay, plastic, well amenable to drilling with an auger or core barrel;

- clay, a plastic rock that can be drilled with an auger or a glass.

How to find out what soils lie under the surface, and at what depth is the aquifer? Of course, you can order geological studies of the soil, but this procedure is not free.

Almost everyone chooses a simpler and cheaper option - a survey of neighbors who have already drilled a well or built a well. The water level in your future water source will be at about the same depth.

Drilling a new well a short distance from an existing facility may not follow exactly the same scenario, but it will most likely be very similar.

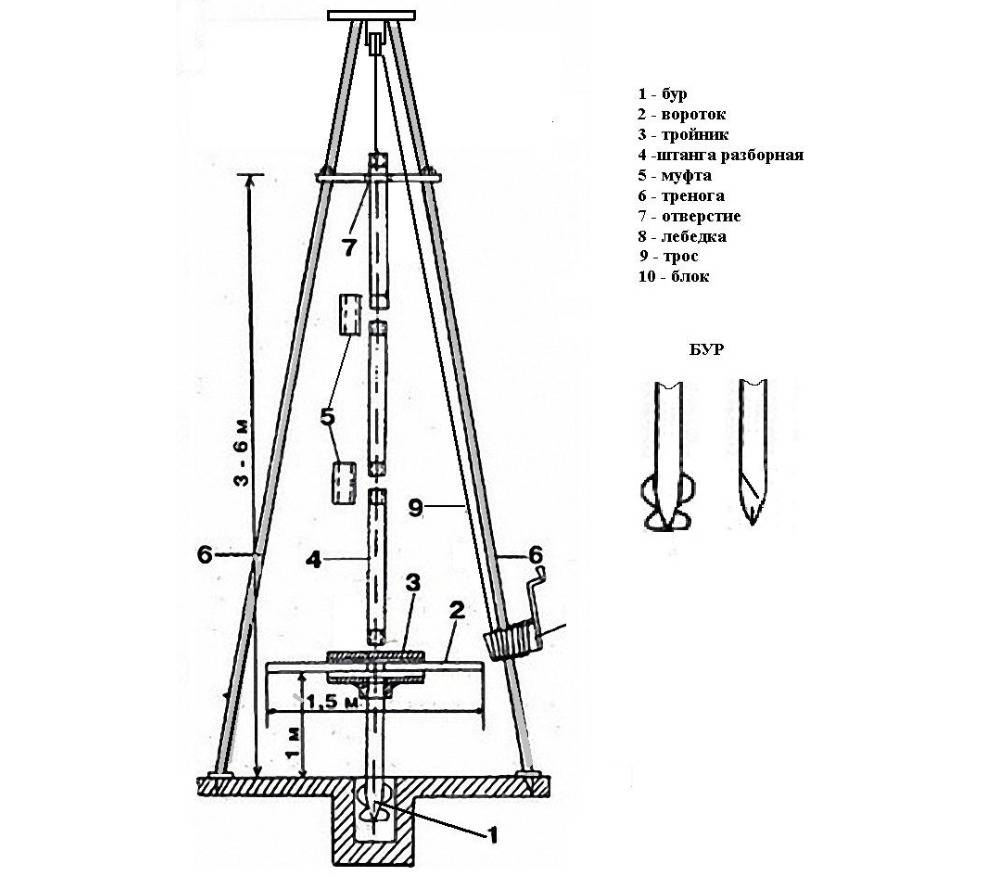

Do-it-yourself drill for percussion-rope drilling

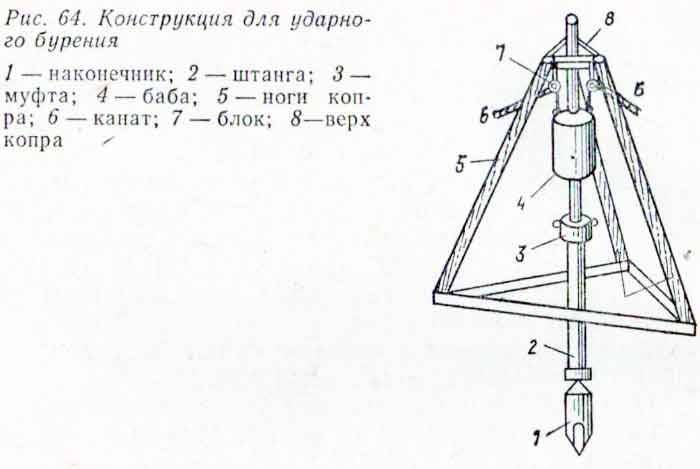

It is possible to drill a well in the area not only by rotating the drill, but also by the shock-rope method. For this type of work, a special installation is needed, which can also be done independently from improvised materials.

With such equipment, all work can be done without assistants at all, so we will also consider the process of making an impact drill.

In order to understand what and how we will make, we will consider in general terms the essence of shock-rope work.

From a great height, a projectile pipe, a bailer for a well, is dropped into the place of the future water intake point indicated with a shovel or auger. At the top, an eye for a cable is welded to the drill.

A hole is cut on the side in the upper part to extract the drilled rock.

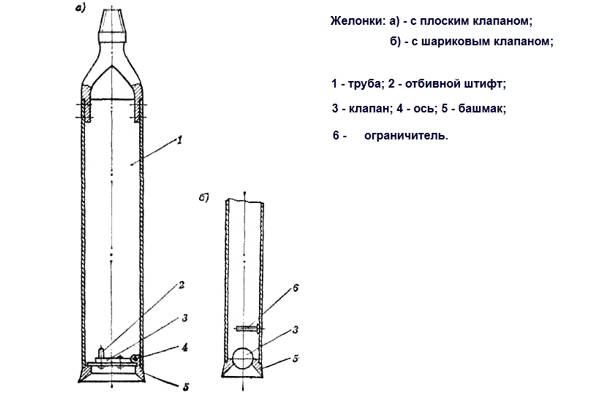

- A bailer is a drilling tool, for the manufacture of which a pipe with a diameter of 80 to 160 mm is needed. Convenient for self-drilling length 1.2 - 1.5 m.

- At the bottom of the bailer, a valve is arranged that moves when the soil is pushed into the cavity. Having captured the drilled rock, the valve closes the hole.

- At the top of the bailer, a device is arranged for connecting the projectile to the cable. It is necessary to extract the drill from the well.

- To unload the rock held by the valve, a window is cut out in the pipe. The bailer removed from the well is turned over and freed from the soil.

The lower edge is sharpened or equipped with teeth that optimize the loosening of the soil. At 5 - 7 cm above the conditional bottom, a ball or petal valve is arranged inside the pipe to capture and hold the loosened rock.

Incoherent soil particles are retained inside the bailer thanks to a valve located at the bottom of the body. The screw, bell, glass do not have such advantages.

The filled bailer is removed from the barrel with a winch, turned down with a hole and cleaned with blows of a heavy hammer.

Then the process of shock-rope drilling resumes and repeats until a well of the depth that was planned to be obtained is formed at the site of the fall of the drill.

It is not necessary to buy a ready-made installation - you can make your own bailer for drilling and cleaning.

It makes no sense to create one drill in this case, so we will tell you how to build the entire drilling rig along with the projectile.

- We choose the place where, according to our calculations and assumptions, the well should be located. We outline it by making a small indentation with a conventional shovel.

- We install a tripod 2-3 meters high above the hole. We equip the top of the tripod with a well-fixed block for the rope. You will also need a winch, which we attach to the supports. It's good if you have an electric winch, but a manual one will work too.

- We are preparing the percussion drill itself. For this purpose, we will need a thick-walled pipe, the diameter of which corresponds to the size of the shaft of the future well.

To make a drill, we take a strip of thick metal and weld it to the upper end of the pipe, placing it perpendicular to the longitudinal axis of the projectile.

Along the center line of our pipe in a welded metal strip, we drill a hole corresponding to the thickness of the rope on which the projectile will be fixed.

The lower end of the pipe also needs to be processed: you can make a gear or ring sharpening on it. If you have a muffle furnace, you can harden the drill in it after the sharpening procedure.

A drill for percussion-rope drilling is not so easy to clean from the soil that has accumulated in it. To speed up this routine operation, you can make not a window-hole, but a vertical slot, passing through almost 2/3 at the top of the pipe.

So, if its power still allows, the projectile can be made heavier by placing removable metal weights in the upper part of the pipe.

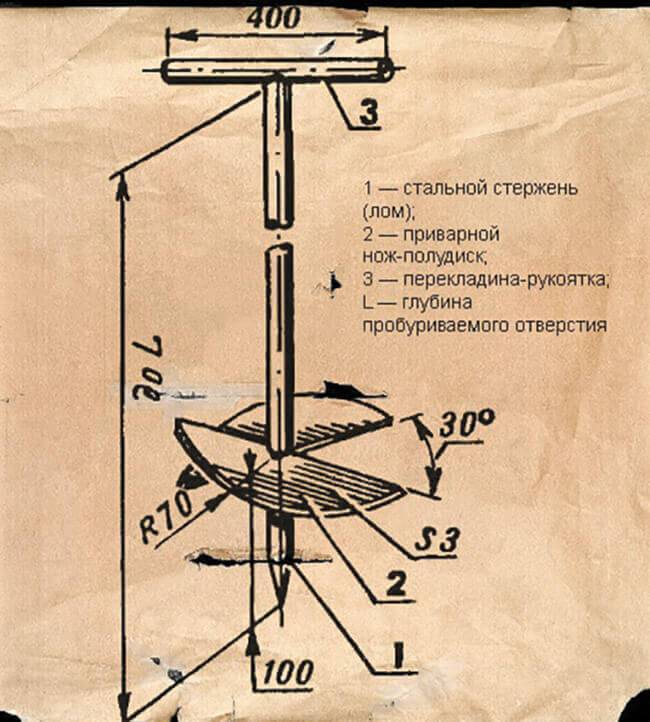

Do-it-yourself drill for wells

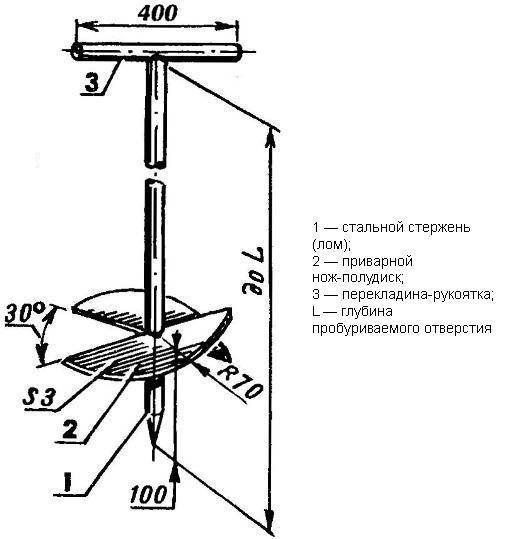

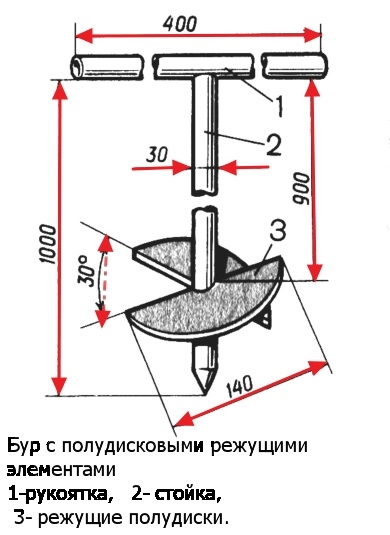

The drill for wells is made of metal. The drill itself is a structure made of a metal rod with a sharpened end. Knives are attached to the sides of the drill.For knife cavities, halves from a metal disk about 15 cm thick can be used. Then the knives must be welded to the rod with an inclination of approximately 22 degrees. The disk halves are placed opposite each other. Between parallel blades, the slope should be 44 degrees.

You can make a spoon drill for wells. It has the shape of a cylinder with a longitudinal section on the side. The length of this drill is about 800 mm. This drill can be made from sheet steel, which must be rolled to the required size and fixed by welding.

To make it easier to overcome various layers of soil, use the following drills:

- drill spoons are used for sandy soil;

- a drill bit is used for loosening hard rocks;

- a spiral drill (also called a serpentine) is used for clay soils;

- the bailer makes it possible to raise the earth to the surface.

Other types of wells

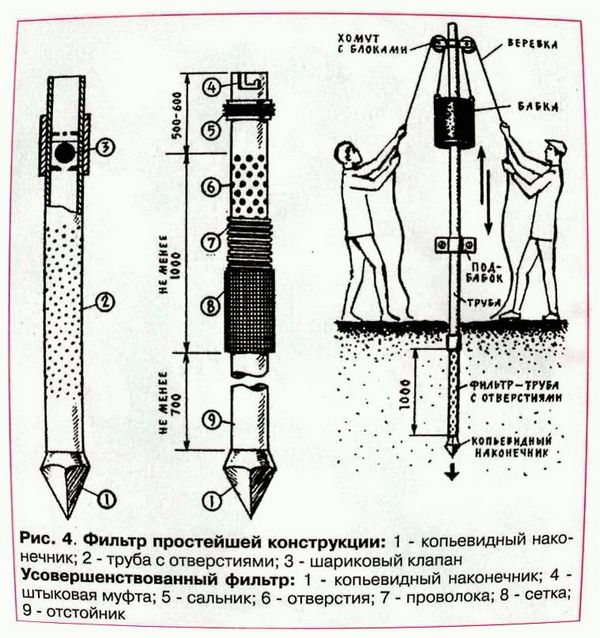

There are other varieties of these sources of water supply. It is absolutely not necessary to drill to a great depth: for example, you can make a well up to 20 meters if you build an Abyssinian well. It is done in this way.

The earth makes its way to the required depth to the aquifer. For what you can use an inch pipe with a thin tip at the end. A self-priming pump is attached to the driven pipe, it will create a vacuum. If this well does not produce enough water, several Abyssinian wells can be installed on the site.

To punch a well, it is desirable to find a light sandy soil. Do not forget that the Abyssinian well can not be built in any area. For it to work, the water must be no deeper than 7 meters. Naturally, you can dig even more.Also keep in mind that such a well will not work on stony soil. For the Abyssinian well, plastic or metal pipes are usually used. It is best to cut them into two meters. Pipes are brought into the ground gradually and fastened with threads. You can use oil paint to seal joints or plumbing tape.

Couplings can also be used to secure the connection. If the structure is not airtight, then it will simply tear. Do not forget that the diameter of the tip must be larger than the diameter of the pipe. At the end of the pipe, you need to install a filter needle. It is necessary to ensure the supply of clean water and protect the well system from debris. The needle is preferably made of metal or directly from the material of the pipe. To make a filter needle, it is necessary to make holes in the pipe with a diameter of 7 mm. Holes must be in a checkerboard pattern. A stainless steel mesh is attached to the holes. Instead of a lid, a sharp tip is attached to the end of the pipe, which must be slightly wider than the pipe itself. For a spear, it is best to choose tin.

Lead should not be used as it heavily contaminates the water and will simply make it unfit for consumption.

A well-needle can be constructed in different ways: it can be hammered or drilled. To drive the structure into the ground, you will need a driving headstock, and you need to pour water directly into the pipe all the time. Then, when the water abruptly goes into the ground, the structure can be buried in the ground. When it drops another 50 cm, you can connect the pump.

With the driving method, there is a chance to damage the structure on a stone or not get into the aquifer. Drilling is more reliable in this regard, but you will need special equipment.

First you need to determine the location. The well can be located both on the street and in the basement of the room. After you need to dig a hole with a width and depth of one meter. The top layer of soil can be removed with a drill. After that, you can start hammering a pipe into the ground. This will require a load of approximately 35 kg. Suitable pancakes from the bar. The pipe must be directed in the middle of the pit. When the pipe enters the ground, it is necessary to screw the second segment and continue working. Upon reaching the aquifer, you need to rinse the filter. Dirty water must be removed with a pump. The site near the well is concreted. Then you can connect the well to the water supply.

The Abyssinian well is the simplest do-it-yourself water structure in arranging, which does not require significant costs and is quite easy to do indoors or on the site.

Summing up, it must be said that if you need to make a well in the country for some purpose, then you need to prepare all the required materials and tools, determine the soil, analyze the possibilities of the upcoming design, study various types of drills and drilling equipment, and make them yourself.

How to make a drill for a well with your own hands: instructions with drawings

For owners of private houses, the issue of organizing water supply is relevant. Water is also needed in summer cottages, where it is used for personal needs, watering garden plants. The easiest way to get water is to drill a well. You can contact a company that provides such services, or do everything yourself. Usually employees of companies work quickly and professionally.But paying for their work is an expensive pleasure, and sometimes a deep well is not needed. You can buy a drill for a well or make it yourself: drawings, photos and videos are on the Web. With a homemade tool, you will successfully drill a shallow (up to 20 meters) well and provide access to water.

DIY manufacturing

If necessary, this tool can be made independently with some mandatory tools. To work, you will need a grinder, a welding machine, a locksmith set, an electric drill and a grinding wheel

The most important thing in making a homemade drill is to make a fairly comfortable handle and good blades, which can be based on circular saw blades.

Homemade disc drill

This design is the easiest to manufacture and requires a minimum amount of materials.

For work you will need:

- Metal fittings for a rod with a length of 1.5 meters.

- A piece of pipe for the handle.

- Blade circular disk.

- A thick drill that will act as a tip.

Having selected the desired diameter of the disc, it should be cut in half, and it is advisable to grind off the existing cloves to avoid cuts during work. The handle is welded to the top of the rod, as a result of which the structure takes on a T-shape. A drill is welded to the opposite part of the rod in the center, and blades at some distance from it

It is important to observe the angle of inclination between the blades at 25 degrees

You can make a disk drill with interchangeable blades, for which, instead of the blades themselves, you need to weld metal landing pads at the same angle and come up with a way to fix the disks.Bolted mounting is ideal, for which a hole is drilled in the site to the size of the required bolt and the desired thread is cut.

This modification allows you to select the required diameter of the working discs as the work is being done.

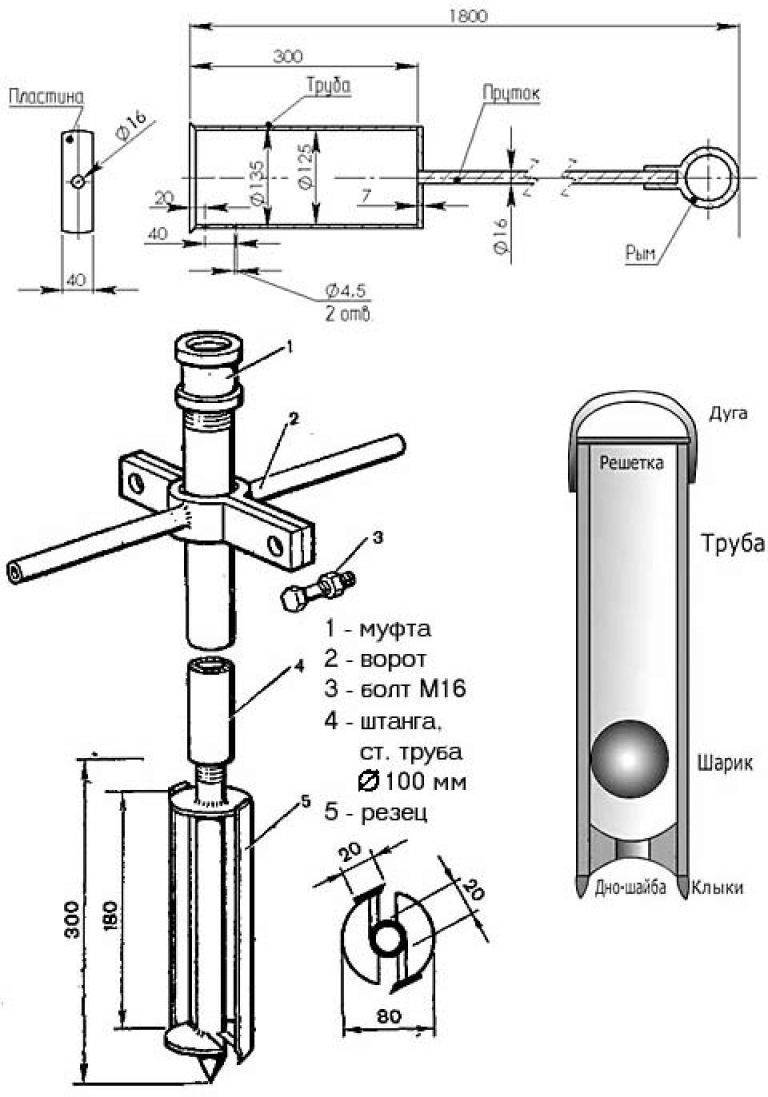

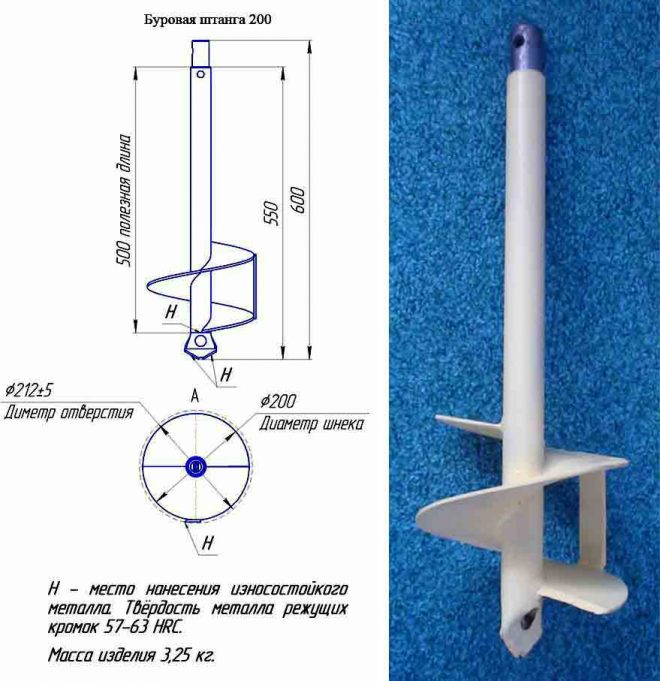

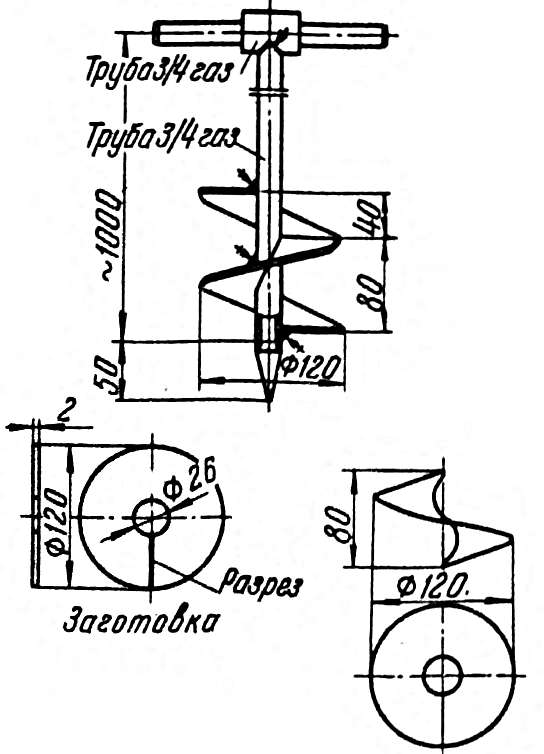

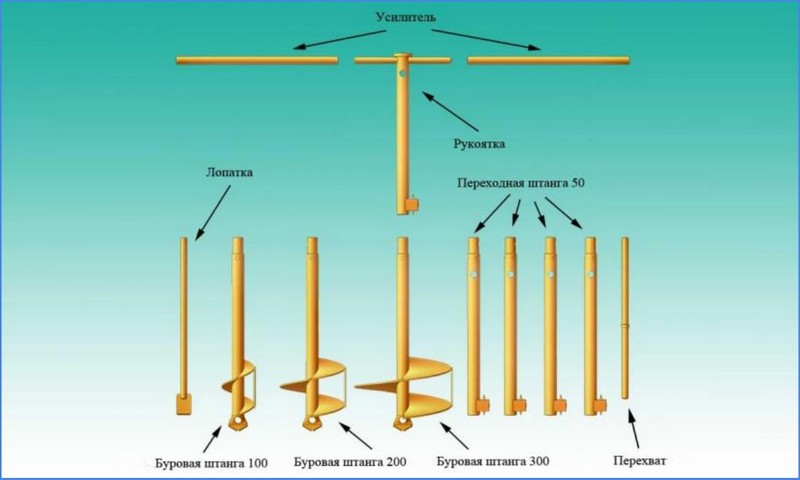

Screw tool

The design of the auger is more difficult to manufacture and use, but it is easier to dig narrow diameter holes with it. For its manufacture, the same materials will be required as for a disk drill, but instead of a cutting wheel, for a circular it is better to take ordinary round metal disks in the amount of several pieces of equal thickness and diameter.

The design of the auger is more difficult to manufacture and use, but it is easier to dig narrow diameter holes with it. For its manufacture, the same materials will be required as for a disk drill, but instead of a cutting wheel, for a circular it is better to take ordinary round metal disks in the amount of several pieces of equal thickness and diameter.

First, the rod, handle and drill are welded together as described above in the manufacture of a disk drill. Then an auger should be made from the existing disks.

To do this, in the center of each of the available disks, drill a hole with a diameter equal to the diameter of the rod. After that, a small sector is cut out of a part of each disk, and the disks are welded in such a way that a spiral structure is obtained.

The rod is installed inside the resulting spiral, which is then stretched along the rod. Upon obtaining the required shape and height of the screw, it is welded to the rod, starting from the upper and lower disks.

Shovel drill

To work with soft loose soils, you can make a garden drill from a shovel. To do this, cut lines are marked on the shovel blade according to the existing drawing, then the canvas is cut according to the markings with a grinder, and the resulting edges are bent in different directions. Moreover, the ends of the canvas are slightly curved upwards.

The resulting design has a small weight and dimensions, resembles a brace and is ideal for planting plants on the land.

Well Depth Determination

A medium-deep well (up to seven meters) will allow you to have drinking water. To make a drilling rig with your own hands, in addition to the drill, you will need a shovel and time to equip the pit. A pit measuring 2x2x2 meters is used to facilitate the process of drilling to great depths. To facilitate the work, it can be fixed with boards or plywood. After completion of work, the pit falls asleep. Water is taken in by a pump.

A deep well (more than seven meters) will make it possible to fully cover the need for water for all residents of a cottage or private house. Moreover, there will be enough water not only for individual use, but also for technical purposes, irrigation, sanitary requirements, maintenance of a pond or pool.

In general, the choice of the type of water intake will be determined after a geological survey of the well construction site. We propose to study in more detail the last option - the construction of a deep well with your own hands, as the most difficult of those described.

Do-it-yourself drill for wells

The drill for wells is made of metal. The drill itself is a structure made of a metal rod with a sharpened end. Knives are attached to the sides of the drill. For knife cavities, halves from a metal disk about 15 cm thick can be used. Then the knives must be welded to the rod with an inclination of approximately 22 degrees. The disk halves are placed opposite each other. Between parallel blades, the slope should be 44 degrees.

You can make a spoon drill for wells. It has the shape of a cylinder with a longitudinal section on the side. The length of this drill is about 800 mm.This drill can be made from sheet steel, which must be rolled to the required size and fixed by welding.

To make it easier to overcome various layers of soil, use the following drills:

- drill spoons are used for sandy soil;

- a drill bit is used for loosening hard rocks;

- a spiral drill (also called a serpentine) is used for clay soils;

- the bailer makes it possible to raise the earth to the surface.

Other types of wells

There are other varieties of these sources of water supply. It is absolutely not necessary to drill to a great depth: for example, you can make a well up to 20 meters if you build an Abyssinian well. It is done in this way.

The earth makes its way to the required depth to the aquifer. For what you can use an inch pipe with a thin tip at the end. A self-priming pump is attached to the driven pipe, it will create a vacuum. If this well does not produce enough water, several Abyssinian wells can be installed on the site.

To punch a well, it is desirable to find a light sandy soil. Do not forget that the Abyssinian well can not be built in any area. For it to work, the water must be no deeper than 7 meters. Naturally, you can dig even more. Also keep in mind that such a well will not work on stony soil. For the Abyssinian well, plastic or metal pipes are usually used. It is best to cut them into two meters. Pipes are brought into the ground gradually and fastened with threads. You can use oil paint to seal joints or plumbing tape.

Couplings can also be used to secure the connection. If the structure is not airtight, then it will simply tear. Do not forget that the diameter of the tip must be larger than the diameter of the pipe. At the end of the pipe, you need to install a filter needle. It is necessary to ensure the supply of clean water and protect the well system from debris. The needle is preferably made of metal or directly from the material of the pipe. To make a filter needle, it is necessary to make holes in the pipe with a diameter of 7 mm. Holes must be in a checkerboard pattern. A stainless steel mesh is attached to the holes. Instead of a lid, a sharp tip is attached to the end of the pipe, which must be slightly wider than the pipe itself. For a spear, it is best to choose tin.

Lead should not be used as it heavily contaminates the water and will simply make it unfit for consumption.

A well-needle can be constructed in different ways: it can be hammered or drilled. To drive the structure into the ground, you will need a driving headstock, and you need to pour water directly into the pipe all the time. Then, when the water abruptly goes into the ground, the structure can be buried in the ground. When it drops another 50 cm, you can connect the pump.

With the driving method, there is a chance to damage the structure on a stone or not get into the aquifer. Drilling is more reliable in this regard, but you will need special equipment.

First you need to determine the location. The well can be located both on the street and in the basement of the room. After you need to dig a hole with a width and depth of one meter. The top layer of soil can be removed with a drill. After that, you can start hammering a pipe into the ground. This will require a load of approximately 35 kg. Suitable pancakes from the bar.The pipe must be directed in the middle of the pit. When the pipe enters the ground, it is necessary to screw the second segment and continue working. Upon reaching the aquifer, you need to rinse the filter. Dirty water must be removed with a pump. The site near the well is concreted. Then you can connect the well to the water supply.

The Abyssinian well is the simplest do-it-yourself water structure in arranging, which does not require significant costs and is quite easy to do indoors or on the site.

Summing up, it must be said that if you need to make a well in the country for some purpose, then you need to prepare all the required materials and tools, determine the soil, analyze the possibilities of the upcoming design, study various types of drills and drilling equipment, and make them yourself.

Advantages of self-drilling

Manual drilling with self-made fixtures has the following advantages over automatic penetration methods using special drilling equipment by individuals and organizations:

Cheapness. Making a drill with your own hands from improvised materials and drilling a well without the involvement of third-party assistants, specialists, organizations is the most profitable option from a financial point of view, if other ways of employment in your free time do not bring cash income.

Versatility. Independent drilling by hand is universal due to the following features:

- Manual drilling in many situations is the only possible option for carrying out work if it is impossible to enter the site of special equipment or the well is located in a built room.

- Narrow borehole channels are laid manually without the use of casing strings of standard diameter, which significantly reduces the cost of organizing and arranging water supply at an individual site.

- Manual drilling is carried out to a depth of 5 to 35 m, which corresponds to the characteristics of the Abyssinian and sand wells.

- The made drill can be used for other economic purposes, if it is necessary to make holes in the ground - when constructing fences, planting garden plants, installing pile foundations and other household work. As unnecessary, the structure can always be disassembled and used on the farm at your discretion.

Prefabricated manual twist drill kit

Flexibility of application. Depending on the depth of the water reservoir, the quality of the soil and the dimensional parameters of the borehole channel, various drilling technologies, designs of drilling devices, or combinations thereof are used. With individual production, it is always possible, through experiments, to independently make a drill for a well, the most convenient and effective for specific conditions.

Work can be carried out at any time convenient for the owner, without reference to the season, time of day, weather, hired specialists or organizations. If electricity is not supplied to the area to be equipped, it is possible to drill wells manually mechanically without its presence.

Of course, for the cheapness of the manual method, you will have to pay for the speed of work and intensive physical labor, the latter are to some extent useful in terms of improving health.

Pipes and couplings for threaded connection

Conclusions and useful video on the topic

Drilling a well with a shock-rope method:

The subtleties of making a screw with your own hands:

For those who want to know how to competently drill a water well manually, we have given proven methods in practice. It is necessary to choose the optimal method of drilling, to seriously approach the choice of the necessary equipment, and when drilling, strictly follow the advice of experienced craftsmen.

The result of the efforts made will be a self-equipped source of water supply, providing clean water to all households.

Would you like to tell how you drilled a well in your own area? Have questions or interesting facts about the topic of the article? Please write your comments in the box below.