- homemade press

- Manual

- From the jack

- Do-it-yourself steps for making sawdust briquettes

- Raw material preparation

- Pressing process

- Drying and application

- Basic properties and classification of the material

- Advantages of briquettes

- How to make briquettes with your own hands

- Main advantages

- Briquette production

- Manufacturing steps

- Manufacturing Equipment

- Advantages and disadvantages

- 4 Equipment for the manufacture of eurofirewood

- Advantages of fuel briquettes

- Waste briquetting device

- Briquettes for furnaces and boilers

- What is more profitable to use

homemade press

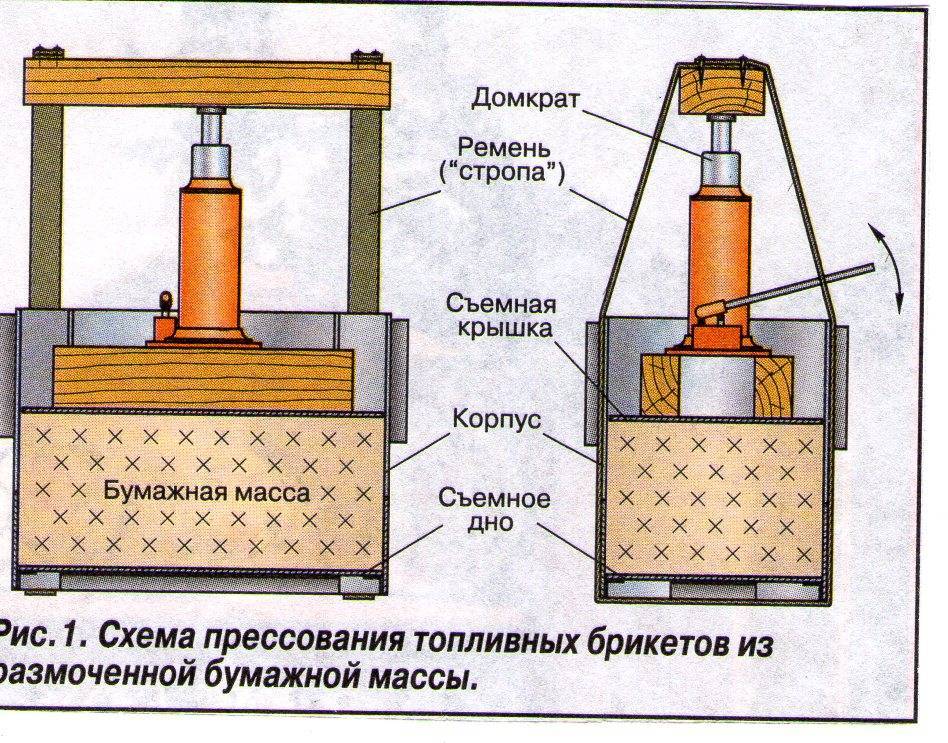

If you have a drawing and certain design skills, you can make a press for fuel briquettes with your own hands.

Home-made devices for briquetting are of two types - functioning from a jack and with a manual drive.

A description of the assembly of the structure will help you understand how to make a press, and which option is best to use.

Manual

To make a hand press, a punch is required. It is constructed from a thick metal sheet. A pressure lever is attached to the material, and the structure is fixed with hinges.

The punch is installed in a special mold. Usually it is made square. A mold is made from metal.Holes are drilled with a thin drill in the lower part and on the sides, which ensure the release of moisture during the pressing process.

To collect the released water, a container is used in which the finished press is installed.

From the jack

To obtain better quality solid fuel and improve the design of the press, a hydraulic jack is used.

The manufacturing process of such equipment consists of the following stages:

1. The base for the press is formed from the channels. All metal parts are fastened by welding.

2. Racks are attached to each corner of the prepared base in a vertical position. Each support is taken 1.5 meters high.

3. A mixer is welded to the racks. The drum can be made from a pipe with a large diameter or you can take a finished part from an old washing machine.

4. A galvanized steel tray is fixed under the mixer, from which the raw materials will penetrate into a special mold.

5. Holes are created in the thick-walled pipe intended for the matrix. They should be evenly spaced throughout the round contraction. The width of each opening should be from 3 to 5 millimeters.

6. At the bottom of the mold, a flange is fixed with a welding machine, to which the bottom is screwed.

7. The finished form is connected to the base.

8. After that, a punch is cut out of the steel sheets. It must have the same shape as the matrix. Using a rod, the punch is connected to a hydraulic element.

The assembled mechanism is fixed above the form to the racks. The tray is attached to the bottom.

To speed up the process of extracting pressed briquettes, it is recommended weld disc and spring to the bottom of the matrix. It must match the diameter of the punch.Such a mechanism will automatically eject finished products after turning off the hydraulics.

Pressed wood raw materials require drying. The lower the humidity of the briquettes, the better they burn. In addition, dry briquettes have a higher heat transfer.

Do-it-yourself compact fuel can significantly reduce the cost of heating a house. Ready-made briquettes can be used both for the boiler and for the furnace. But it should be borne in mind that the quality of products largely depends on the density index.

It is almost impossible to make pressed firewood using home-made equipment that will burn for a long time and give off a large amount of heat.

Therefore, if it is necessary to use fuel with high performance, then it is better to purchase it in specialized stores.

Do-it-yourself steps for making sawdust briquettes

The process of home pressing sawdust is as follows:

- drying of raw materials if it has high humidity;

- grinding of raw materials in a crusher or manually;

- mixing crushed sawdust raw materials with clay or cardboard;

- press loading;

- pressing into molds;

- unloading and air drying;

- film packaging.

The quality of drying can be checked by breaking the briquette, it should be tight and dry on the cut.

If there is no suitable crusher, you can use a perforator.

The film must be shrinkable so that moisture does not penetrate into the finished product and its shape is preserved.

Raw material preparation

At the next stage, they are preparing raw materials, but first you need to choose the right one.To compress high-quality paper and cardboard briquettes, you must first soak them in water, then squeeze them well to remove all moisture residues, and after that they can be placed in the pressing mechanism.

Pressing process

Processing of the prepared material is the most important stage in production. Work begins with the assembly and testing of raw materials. After that, it is necessary to clear the place where the finished pressed blocks will be stored. Immediately it should be noted that after pressing the briquettes will be wet and sticky. So that they do not stick together and do not lose their correct shape, they need to be folded not too close to each other. It is best to lay plywood sheets or flat slate between the pressed material.

Using a similar method, other materials are processed and pressed. The main thing is not to forget to carefully fold them in a prepared place on a completely flat surface. For an hour of such work, about 60 home-made briquettes can be produced.

Drying and application

After the pressing process is completed, the finished products are sent for drying. At home, you can simply lay out the material on a sunny lawn, but make sure that it does not accidentally fall into the rain, otherwise the drying process will be delayed. When the briquettes have lost the maximum amount of moisture, they can be moved to permanent storage, moreover, you can already fold them as you like and not be afraid that they will stick together.

It’s worth adding right away that such home-made blocks weigh a little, this is due to a lack of pressure during production. Actually, after that you can test the briquettes and flood the bath with them or light the fireplace.It is better to carry out these activities using a special ignition or put some paper in the firebox, since it will be quite difficult to do this in the usual way.

By the way, if desired, such a pressing apparatus can be modernized, for example, by purchasing a factory press, then the resulting briquettes will be of better quality and denser, and their output will increase significantly.

Basic properties and classification of the material

Briquettes are made from various waste products of woodworking and agricultural enterprises:

- from sawdust, bark, branches;

- from straw;

- from vegetable waste;

- from the husks of grains;

- from reeds;

- from peat;

- from waste from flax processing;

- from screenings of coal;

- from the vine.

Due to its versatility, this type of fuel can be used in various areas: in boiler rooms; for heating houses, baths, saunas, greenhouses and many other objects.

Externally, the briquettes are similar to ordinary firewood, their diameter is 10 cm, and the length is about 25 cm. The strength of this material is given by the substance lignin, which, under the influence of pressure and temperature, begins to melt and bind its particles.

Advantages of fuel briquettes:

- The release of a small amount of soot and smoke, the ash content of Eurowood does not exceed 1.5%. If peat briquettes are processed, the ash can subsequently be used as phosphorus or lime fertilizer.

- The burning time of wood briquettes is three times longer than that of ordinary firewood, so they do not need to be loaded into the oven often.

- Affordable cost.

- Compact and easy to transport.

- During combustion, environmentally friendly fuel does not emit harmful substances.

Depending on the manufacturing technology of briquettes, they can have a different shape:

- NESTRO is eurofirewood, which is made in the form of a cylinder. For their production, a shock press is used.

- Pini & Kay - multifaceted products with holes. For their manufacture, a special press is used, which has a working surface pressure of 1100 bar. After pressing, they undergo a heat treatment procedure, as a result of which they acquire a dark brown hue.

- Briquettes ruf (ruf) after processing take the form of a rectangle. They are produced using a hydraulic press having a pressure of 400 bar.

Advantages of briquettes

When wondering which type of fuel to choose for purchase or production, one should compare the price market and the characteristics of materials. Fuel briquettes in the twenty-first century are many times superior to other combustible energy sources due to a number of advantages:

- high density and low humidity allow to achieve a heat release of 5 kW per hour

- uniform combustion with a minimum of smoke

- low percentage of ash at complete combustion (> 10%)

- the cost of briquettes is more profitable than the cost of pellets and coal

- production costs are also lower than the production costs of other materials

- the best alternative to other combustible fuels without changing the furnace

- environmental friendliness

- convenient for storage and transportation

The use of recycled wood firewood has become a significant step both for the environment and for modern businessmen. The future is behind alternative fuels, so the competition for the production of fuel briquettes is increasing every day.Even at home, people try to capitalize on waste and make homemade briquettes. By opting for sustainable materials, everyone makes a significant contribution to a cleaner future.

How to make briquettes with your own hands

Jack press.

To make a briquette from sawdust, you need a press. You can buy a ready-made hydraulic press, to which you still need to buy a compressor. Production on such equipment is faster and easier, but the device consumes a lot of electricity, since it has a dryer. Consumption depends on the model, the range is from 5 to 35 kW. There are also hand presses, where pressure is created through a lever or by winding. In the first case, it will not be possible to properly squeeze the briquettes from moisture. In the second case, the process takes a long time.

The best option is to use a car hydraulic jack as a press. Their carrying capacity is different, at least 2 tons. It is necessary to prepare a strong metal frame, a jack is attached to the upper beam with bark (upside down). That is, the force of the jack will be directed downwards, where the form filled with raw materials is located.

Algorithm for making fuel briquettes with your own hands:

- soak the crushed cardboard;

- mix wet cardboard with sawdust - proportion 1:10;

- place the mass in a press and squeeze out moisture;

- remove the briquettes from the molds and dry

To see with your own eyes how fuel briquettes are made you can do it yourself in the video below:

You can mix sawdust with a concrete mixer or a mixer. You can dry ready-made briquettes in the sun or on an oven. The moisture content of the fuel must be kept to a minimum. For example, in factory briquettes, the moisture content is 8-10%. At home, at least reach the level of ordinary firewood 18-25%. Most solid fuel boilers and pyrolysis ovens on fuel, the moisture content of which is not more than 30%. The less moisture in the fuel, the less heat energy will be used to evaporate it. Accordingly, a dry energy carrier will give more thermal energy to heat the room.

Main advantages

Fuel briquettes are a modern type of alternative fuel. They can be used in any stoves, fireplaces, boilers, barbecues, barbecues. Eurobriquettes are cylindrical blanks resembling firewood, or rectangular bricks. Small dimensions allow to place them in furnaces of any size.

What are briquettes made of? Most often, wood is used (sawdust, shavings, dust), but straw, paper, peat, coal, seed or nut husks, and even manure are also used. The composition of the eurobriquette can vary significantly, depending on which technology is used in the production.

A home-made eurobriquette can be used to kindle a sauna stove or heat a house. Since the raw material is compressed quite strongly and the amount of moisture is minimal, the fuel briquette burns for a long time, constantly releasing a large amount of heat. An interesting point was noticed by people who are already actively using such fuel: if you melt your barbecue with eco-wood and fry food on it, it does not ignite if it gets on the briquettes of fat.

Warehouse for handicraft ready-made ecro-briquettes

For solid fuel stoves, boilers and fireplaces, sawdust briquettes are an excellent option. They slowly flare up, but after burning for a long time and emit a large amount of heat. This is explained by the high density of the pressed wood product.The heat transfer from briquettes significantly exceeds the level of heat obtained by burning even the driest firewood, the storage and drying of which took at least a year.

Humidity of fuel briquettes is 8-9%, dry firewood, in turn, has an indicator of 20%. It turns out that a briquette made from the same wood burns better than the wood itself. This effect is formed due to the fact that during combustion, fuel briquettes do not need to evaporate a large amount of moisture.

The briquette burns with a stable fire, without splashes, sparks, cod, and the amount of smoke emitted during combustion can be described as small. It is extremely convenient to lay such fuel in the furnace, since all products have the same regular shape.

Placement in the furnace of ecological self-made fuel briquettes

Like any product, fuel briquettes are not without disadvantages:

- First of all, it is worth noting that they are very vulnerable to moisture, therefore they are sold in cellophane packaging.

- Briquettes are not able to withstand mechanical stress, especially products made using the RUF technology that are not fired on the outside.

- If you want to set up the manufacture of such things at home, it will cost you a pretty penny, although there will certainly be a benefit in the long run. The fact is that you will have to purchase a grinding plant, a dryer and a press machine in order to carry out the entire cycle of work with raw materials. With the right equipment, it will be possible to set up handicraft production of fuel briquettes even in your own garage.

Briquette production

The raw materials for the manufacture of briquettes are all kinds of waste from agricultural enterprises, woodworking, furniture production and other industries that use wood and plants.The technology for the production of fuel briquettes from sawdust makes it possible to use up to four cubic meters of waste to create one cubic meter of the finished product, which has a positive effect on the environment. Companies that produce sustainable firewood rid the planet of a huge amount of garbage.

The cost of raw materials for briquetting varies depending on its type and quality, as well as on the region from which it is delivered. The quality of the supplied raw materials is one of the main factors for the success of the production of environmentally friendly clean fuel.

It is important to have reliable suppliers who, according to laws and regulations, ensure environmental safety in their production. Numerous agricultural complexes and farms, woodworking enterprises and sawmills become such suppliers.

The technology for the production of environmentally friendly fuel is divided into several stages. Each of them uses special equipment, and the established temperature and pressure standards are observed. But the main element in the creation of briquettes is the binder. The connecting components are melted during the production process and bind together the fractions of the raw materials.

Waste wood from deciduous trees does not need the addition of binders, because it already contains resin, which becomes a binder during heating. Agricultural waste, on the other hand, requires additional substances such as lignin. Lignin is considered the basic component in fuel briquettes. In terms of composition, it is environmentally friendly, as it is obtained only from the remains of parts of plants.

The production of sustainable firewood begins with the preparation of the dryer and setting the desired temperature inside the fan. After that, the bunker with auger feed is loaded, feeding the material into the drying chamber. Moisture is removed by air currents, so only ordinary steam escapes into the atmosphere. No harmful substances are released during the drying of the material, which is why the production of fuel briquettes is called environmentally friendly.

Manufacturing steps

The main stages of production:

- Grinding / crushing of raw materials to a fraction of not more than 3 mm. Waste is shredded in a chipper. The rotating drum of the device, equipped with sharp knives, crushes the chips and separates the larger ones for re-grinding to the required size.

- Drying. The heat generator dries the fractions with hot air. The amount of moisture in the raw material should not exceed 15%.

- Briquetting. In the extruder, the line for briquetting wood waste begins, and not only. The prepared mixture is sent for pressing. Under conditions of high pressure and at a special temperature, the raw material is squeezed out of the extruder and cut into individual briquettes.

- Package. The briquettes are hermetically packed, after which they are sent to the warehouse.

Manufacturing Equipment

The main equipment for the manufacture of fuel briquettes are an extruder and a press.

An extruder is a machine that softens / melts materials and gives them the desired shape by extruding a compressed mass through a die.The machine consists of several main fragments: a body with a heating element, a main screw and an extrusion head for creating briquettes of a certain shape at the exit from the machine.

The press is an apparatus for squeezing the prepared mixture of fractions to a high density and ergonomic consistency. Pressing allows you to form the most compact and suitable for long-term storage and use of briquettes.

There are several types of press:

- Manual press for briquettes. This is a simple metal structure, which includes a mold, a support part, a piston and a handle. This type of press is light weight and easy to transport.

- Hydraulic Press. The hydraulic press includes a variable displacement piston pump, an electric motor and a hydraulic oil tank. It is used only in rooms with maintaining a positive temperature.

- Impact mechanical press. Forms briquettes according to the principle of impact extrusion. The press piston is placed horizontally inside the cylindrical pump.

Advantages and disadvantages

To understand how good fuel briquettes are, you should consider their positive and negative sides.

The pros are as follows:

- Since eurofirewood has the correct shape, it is very convenient to store them.

- Fuel briquettes are much more calorific than firewood. This results in savings on raw materials.

- Suitable for all ovens and gas boilers. Due to the long burning of compressed sawdust, the addition of new portions of raw materials occurs much less frequently.

- Burning is even and silent, small coals do not fly around. When using raw materials, the emission of smoke and the formation of tar, ash is insignificant.This leads to a reduction in labor costs for cleaning and cleaning chimneys.

- Depending on the method of manufacturing eurofirewood, their shelf life is from one to 5 years.

- The bars do not contain chemicals, therefore they are considered an environmentally friendly product.

- During one heating season, 1.5-2 times less briquette fuel is used compared to conventional firewood.

- Combustion of eurobriquettes occurs slowly and gently. This releases a lot of heat.

In addition to positive qualities, compressed products have some disadvantages:

- Avoid contact with water during storage.

- Some species are stored for no more than one year.

- The cost of raw materials is quite high.

4 Equipment for the manufacture of eurofirewood

The main element of production is the press. First you need to decide what shape the finished elements will be and, depending on this, choose equipment. The most commonly used briquettes are round or cylindrical.

Professional presses include:

- Screw. Produces octagonal pellets with a hole in the center. They have a maximum density, as a result of which they show a high duration of burning. It is convenient to pass a cord or rope through the hole to hang the pellets in sunlight to dry.

- Hydraulic. It can be used to produce rectangular elements. Their density is minimal, so the material consumption is quite large.

- Shock-mechanical. Allows you to get briquettes of any shape. Density is medium.

With the help of these devices it is possible to produce high quality eurofirewood. Nowadays, there are many companies specializing in the production, delivery and installation of equipment for the manufacture of compressed fuel.The only negative is the price of such devices is quite high.

Therefore, if it is not planned to manufacture a large amount of material for sale, it is more profitable to make the device with your own hands.

To do this, you need a form, for which you can use, for example, an old sewer pipe with thick walls. To allow excess liquid and air to escape, holes are made in the pipe. It is in this form (matrix) that the mixture will be pressed into pellets.

The die attaches to any lever or screw type hand press or to a hydraulic jack.

The raw material is put into the mold, compressed by a press, after which the finished product is pushed out with the help of a metal rod.

Advantages of fuel briquettes

Fuel briquettes are distinguished by the ability of high heat transfer. Their calorific value is 4600-4900 kcal/kg. For comparison, dry birch firewood has a calorific value of about 2200 kcal/kg. And birch wood of all types of wood has the highest heat transfer rates. Therefore, as we see, fuel briquettes give 2 times more heat than firewood. In addition, throughout the combustion, they maintain a constant temperature.

Long burning time

Briquettes are also characterized by a rather high density, which is 1000-1200 kg/m3. Oak is considered the most dense wood applicable for heating. Its density is 690 kg/cu.m. Again, we see a big difference in favor of fuel briquettes. Good density just contributes to the long-term burning of fuel briquettes. They are able to give a steady flame from laying to complete combustion within 2.5-3 hours.With the supported smoldering mode, one portion of high-quality briquettes is enough for 5-7 hours. This means that you will need to add them to the stove 2-3 times less than if you fired wood.

Low humidity

Humidity of fuel briquettes is no more than 4-8%, while the minimum moisture content of wood is 20%. The briquettes have such a low moisture content due to the drying process, which is an essential step in the production.

Due to their low humidity, briquettes reach a high temperature during combustion, which contributes to their high heat transfer.

Minimum ash content

Compared to wood and coal, the ash content of briquettes is much less. After burning, they leave only 1% ash. Burning coal leaves up to 40% ash. Moreover, the ashes of the briquettes can still be used as fertilizer, and the ashes of coal will still have to be disposed of.

The advantage of heating with briquettes is that the cost of cleaning and maintaining the fireplace or stove is much reduced.

Environmental friendliness

The choice of fuel briquettes for heating in the house is a great option for people who care about their health. Briquettes practically do not emit smoke and other harmful volatile substances, so you can fire the stove without charcoal even with a low chimney draft.

Unlike coal, the combustion of briquettes does not form dust that settles in the room. Also, since briquettes are fuel produced from waste, there is less damage to the environment.

Ease of storage

Fuel briquettes are convenient both to use and store. Unlike shapeless firewood, briquettes have a fairly regular and compact shape.Therefore, even if you try to put firewood as carefully as possible into a compact woodpile, they will still take up 2-3 times more space than briquettes.

No condensation on chimneys

Since firewood has a higher moisture content, during combustion, it forms condensate on the walls of the chimney. Depending on the moisture content of the wood, there will be more or less condensation, respectively. What is bad about condensate in a chimney is that it narrows its working section over time. With heavy condensate, after one season you will notice a strong drop in draft in the chimney.

8% humidity of the briquettes practically does not form condensate, consequently, the chimney's working capacity is maintained longer.

Waste briquetting device

homemade press

In the event that heating briquettes are supposed to be used for winter heating of a country house in winter or as an alternative fuel in an individual house, it is rather laborious to make them manually.

In this case, it is advisable to make a simple machine that will speed up and facilitate the work. Today, various modifications of machine tools are commercially available. They differ in functionality, the number of cells in the forms, the type of drive - manual or mechanical.

All models have one thing in common - they allow you to mechanize the most laborious process - the compaction of the wet mass in the cells of the form.

The simplest machine is a metal frame welded from a corner, on which a wooden tabletop painted with moisture-resistant paint is fixed. A “P” is welded to the frame - a shaped bracket, between the uprights of which a swinging lever is fixed - a rocker arm, the compression force depends on the length of which.

A punch is pivotally mounted on the lever, the dimensions of which are slightly smaller than the dimensions of the cells. The form filled with the briquette mass is placed on the countertop and pressed with a punch until the briquettes are given the desired density. Moving the mold over the tabletop, the compression operation is repeated for each cell.

Some "craftsmen" abandon the welded structure, and put together a bracket and frame from boards and thick bars. It all depends on the volume of production.

In order for the press to last long enough, after each pressing operation, it should be cleaned of adhering mass.

If the gardener has the opportunity to get or make a vibrating plate, then a press is not required. Compaction of sawdust-clay mass is carried out due to vibration.

Briquettes for furnaces and boilers

As an alternative firewood fuel briquettes have a number of advantages:

- Firewood burns longer, gives more heat;

- No sparks, much less smoke;

- Very economical, because you can make briquettes with your own hands from waste, that is, there will be virtually no costs;

- Ash does not need to be thrown away, it will be an excellent fertilizer for the beds;

- When stored, the same briquettes take up less space than a traditional firewood shed;

- It can be used not only for a fireplace and stove, but also for solid fuel boilers.

In general, as experts note, the production of fuel briquettes can become a profitable business.

For the production of fuel briquettes, you can use a variety of materials, and the vast majority are waste that is in every household:

- Waste paper. Newspapers, cardboard boxes, scribbled notebooks - everything that is lying around at home;

- Agricultural waste. For example, straw, sunflower husks, dry plant stems;

- Waste from the garden. Fallen leaves are also used, as well as tops of root crops, dry grass, uprooted weeds;

- Branches, shavings, wood chips, sawdust, that is, all wood waste, including those left after pruning trees on the site.

Important! Some owners add plastic bags, film to the plant and wood mass. Experts are against this approach, because in this case, briquettes can no longer be called environmentally friendly fuel.

And don't use ash as a fertilizer. In general, there are no official recommendations regarding the addition of polyethylene film to briquettes, everything is at the owners' risk.

To get started, you will need to grind raw materials, everything except sawdust, seed husks and small chips. For this purpose, a garden shredder is used, the choice of which we have already written. All branches, sticks, leaves, wood chips, dry grass, straw are thoroughly crushed to obtain prepared raw materials for fuel briquettes.

Important! An ordinary garden shredder will not cope with paper, waste paper. It will have to be torn by hand, cut, use a shredder

Clay and starch, as well as wax are most often used as binders in a mixture for fuel briquettes. Portland cement is sometimes added, but it greatly increases the ash content of the fuel. Sugar and molasses are also an option, but they are expensive. If it is possible to find waste from pulp and paper production, you can use sulphite-yeast mash. However, it contains too much moisture.

Important! If fuel briquettes are made from sawdust and other wood waste, then binders are not needed.They are lignin, a natural polymer contained in wood initially and released at high temperature and under pressure.

But this rule applies if baking is used, and not natural drying.

In addition, binders are not needed if the mixture contains paper. It softens with water, and in itself serves as a good adhesive that holds all the other components of the briquette.

If clay acts as a binder, then its proportion with waste should be 1:10, no more. Water is added little by little so that the whole mixture acquires the consistency of a paste, which will be easy to shape.

To mix the mixture, you can use a concrete mixer or a construction mixer. This will speed up the process and make the mixture homogeneous. Next, you need a mold for pressing. Sometimes summer residents even use old pots, wooden boxes, and other items that are no longer needed in everyday life.

The easiest way is to manually press the mixture into the shape of your choice and then dry it in the sun, naturally. But manual efforts may not be enough to get a high-quality, non-scattering fuel briquette. Therefore, home craftsmen usually use various mechanized presses. If there is a vibrating table, then the press is not needed.

The process of creating a mixture for fuel briquettes and their pressing-molding is simple, but time-consuming. That is why many people prefer to either buy ready-made briquettes or buy special machines that greatly facilitate production. In addition, we admit that factory briquettes, which are formed under 20-ton presses, are much denser, and therefore they will burn longer.

If you have any questions on this topic, ask them to specialists and readers of our project here.

What is more profitable to use

It is best to start the comparison with the price of fuel, because it worries us the most. If we take average indicators, then 1 cubic meter of fuel briquettes costs about 2 times more than ordinary firewood. As we know, fuel briquettes can be created from different materials, but the price of firewood is highly dependent on from the type of wood. If you choose the most expensive fuel briquettes and the cheapest wood, the cost may differ by 3 times.

Note that most often on the market there are products of two types of quality. High-quality briquettes are more dense without cracks and chips, often burned on the outside. Lower quality briquettes have a lower density, they are characterized by a multilayer structure, which is weakly vulnerable to damage. Such briquettes burn faster and release less energy.

Popular fuel for stoves in homes and baths

Let's compare the indicators at work:

- How long fuel briquettes burn - usually 2 hours, while simple firewood is about an hour.

- The heat transfer from fuel briquettes is noticeably higher, since the fire in the furnace is stable throughout the entire burning time. Firewood usually flares up quickly and gives off maximum heat immediately, and then gradually fades out.

- After using firewood, a lot of coal and ash appears in the firebox, while practically nothing remains of eurowood.

The main task of fuel briquettes is heating. They burn for a long time, emit a lot of heat, and at the same time do not take up much space in the house, do not litter, they are also environmentally friendly and safe to use like firewood is common.At the same time, they do not create a full-fledged atmosphere of comfort, do not crack, and often emit a more unpleasant odor when burned. No wonder they have the prefix "euro" in their name, this type of fuel was created primarily to save on heating.

If you use fuel briquettes for heating a house, then such a replacement for firewood for a stove is quite relevant, but for kindling a bath, such a choice will not always be justified. As well as for a fireplace, the task of which is not only to heat the house, but also to create an appropriate entourage, with which a substitute for firewood clearly cannot cope.

To evaluate the effectiveness of fuel briquettes in each case, experiments should be carried out, too many factors affect their work. Only after you are convinced of the merits of this alternative type of fuel, you can give it some assessment.

Recently, a lot of positive reviews have appeared on the network, indicating that it is more profitable to heat a house with eurowood than ordinary ones. We attribute this to the growing popularity of alternative fuels.