- The principle of operation of an electric instantaneous water heater

- Design features

- Making a tank

- What is an indirect heating boiler and what are they

- Kinds

- Which boilers can be connected to

- Tank shapes and installation methods

- What is an indirect heating boiler and what are they

- Kinds

- Which boilers can be connected to

- Tank shapes and installation methods

- What is a single-circuit boiler

- Optimum operating mode of the electric boiler

- How an indirect heater works

- Advantages and disadvantages of the system

- Pros and cons of a double-circuit boiler

- Indirect heating boiler pros and cons

- Heat accumulator for heating boilers: features of the device and connection

- Heat accumulator device and rational connection of external devices

- Principle of operation

- Features of piping an indirect heating boiler

- What pipes are suitable for tying

- How to choose an indirect heating boiler

- Calculation of the volume of the storage tank

- Connection diagrams for the heating system

The principle of operation of an electric instantaneous water heater

Flow heaters have a simple design. For almost all models, a single concept is used, in which the liquid passes through the body of the thermal equipment, receiving heat from the heating elements.At the moment when the user opens the tap, a special pressure switch starts, followed by a heater. Its task is to quickly heat the water to a predetermined temperature.

The design has a breaker, the function of which is to force the power off. This occurs when pressure drops in the system or when the degree of water heating is exceeded. An additional fuse is a stabilizer. Its task is to ensure the normalization of pressure when critical values are reached.

Design features

The main component of electric water heaters is the heating element. The alloy of this part provides heat transfer when an electric current passes through it. Spirals are isolated to prevent corrosion, for which they are placed in a special plastic block. When the heating element is heated, the generated heat is taken away by the cold water passing through it.

Loading

The design of the active block eliminates residual heat. This is due to the small volume of fluid passing through and the mass of the device itself. The formation of scale on the spirals does not occur, which significantly extends the service life of products.

Note! If you look at the water heater in a section after many years of use, you can see only a small coating on the surface of the spirals. In flow-through installations of a closed modification, the heating element coils are enclosed in copper or brass modules

This structure provides fire safety

In flow-through installations of a closed modification, the heating element coils are enclosed in copper or brass modules. This structure ensures fire safety.

Considering how the boiler works, one should distinguish between the type of control.Hydraulic manipulation occurs manually, through six power steps. More precise control of the actions of technology is electronic. Such a system works autonomously, the degree of water heating in the boiler is controlled under the temperature set by the user. This principle is better than hydraulics, since all processes are electronically controlled, regardless of the pressure.

Due to stereotypes, the name "boiler" is often associated with an electric hot water tank. Although there are other versions of household appliances that provide autonomous hot water supply to private houses and apartments. Under certain conditions, the use of gas appliances and indirect heating tanks is much more profitable and comfortable. To choose a storage water heater, it is worth comparing the principle of operation of boilers of various types, connection nuances and operation features.

Making a tank

The material for the tank is better to take anti-corrosion, stainless steel or aluminum alloys are suitable. Alternatively, a gas cylinder is used, but it should be well cleaned and primed. If this is not done, the hot water will have a gasy smell and taste.

To connect the tank to the water supply system and its installation, five holes should be made:

- two - for installing a spiral pipe;

- one for the incoming tube;

- one more - from above for water intake;

- the last one is from below for the drain tap.

If you plan to use the boiler not only during the heating season, it is recommended to prepare a place for installing a heating element. To do this, it is necessary to drill a hole at the bottom of the tank, and while the heating element is not installed, put plugs there.

What is an indirect heating boiler and what are they

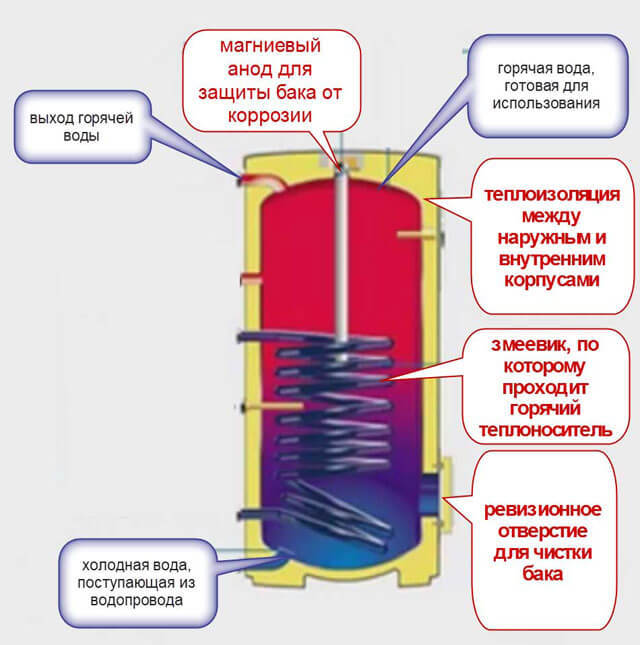

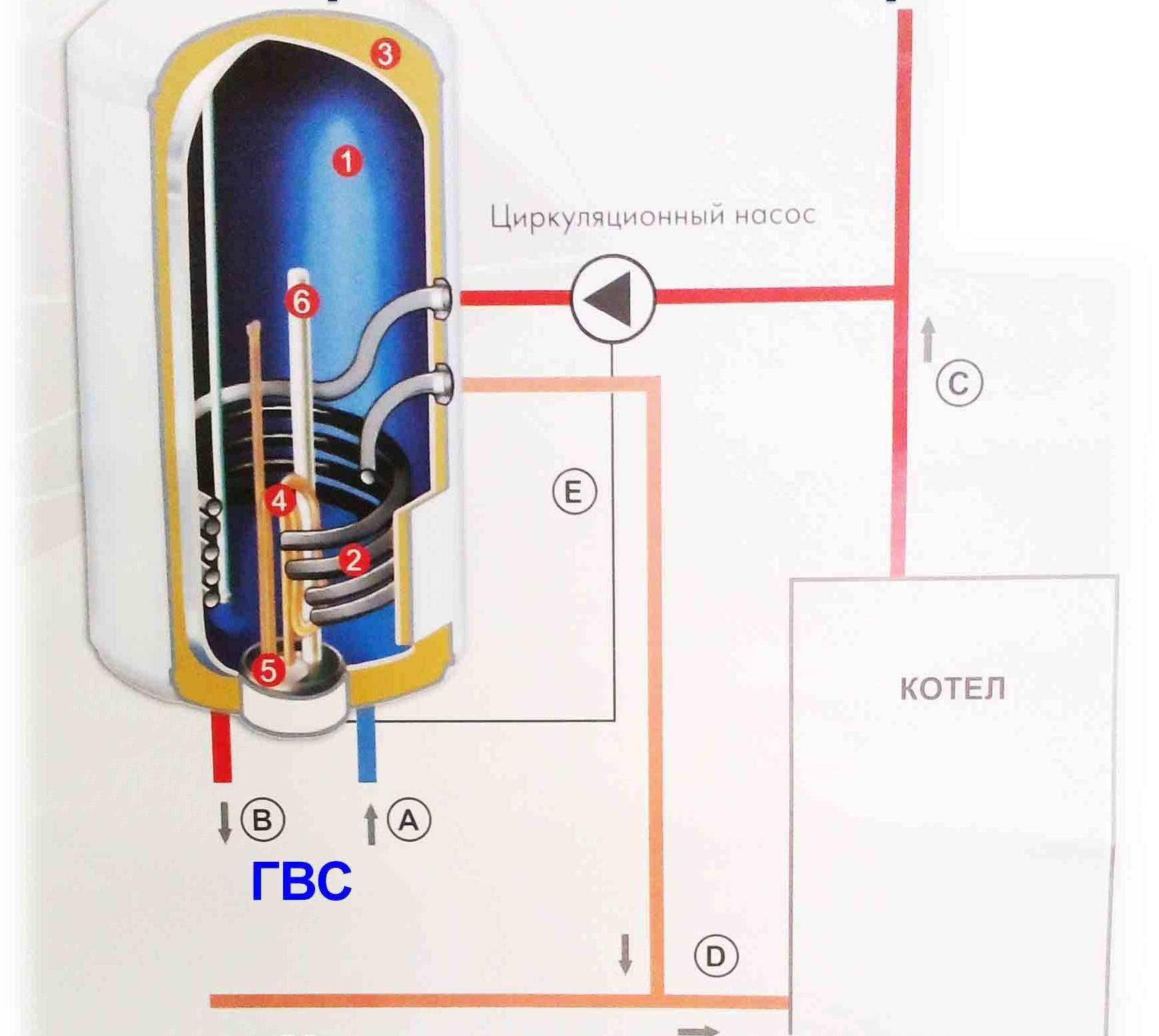

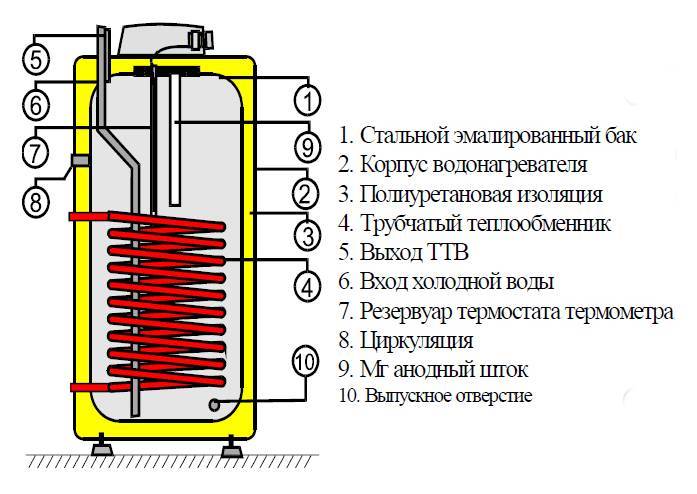

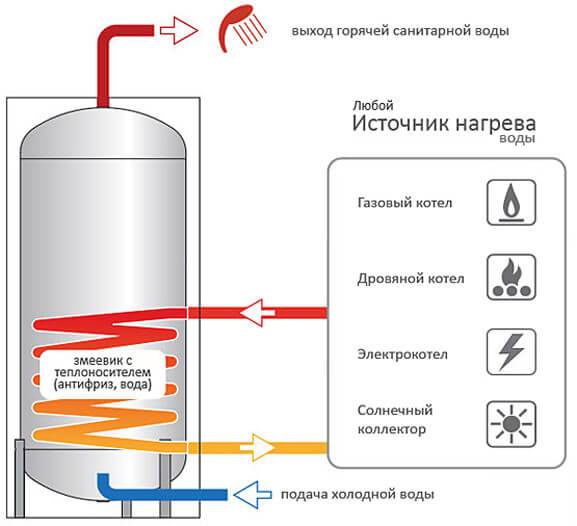

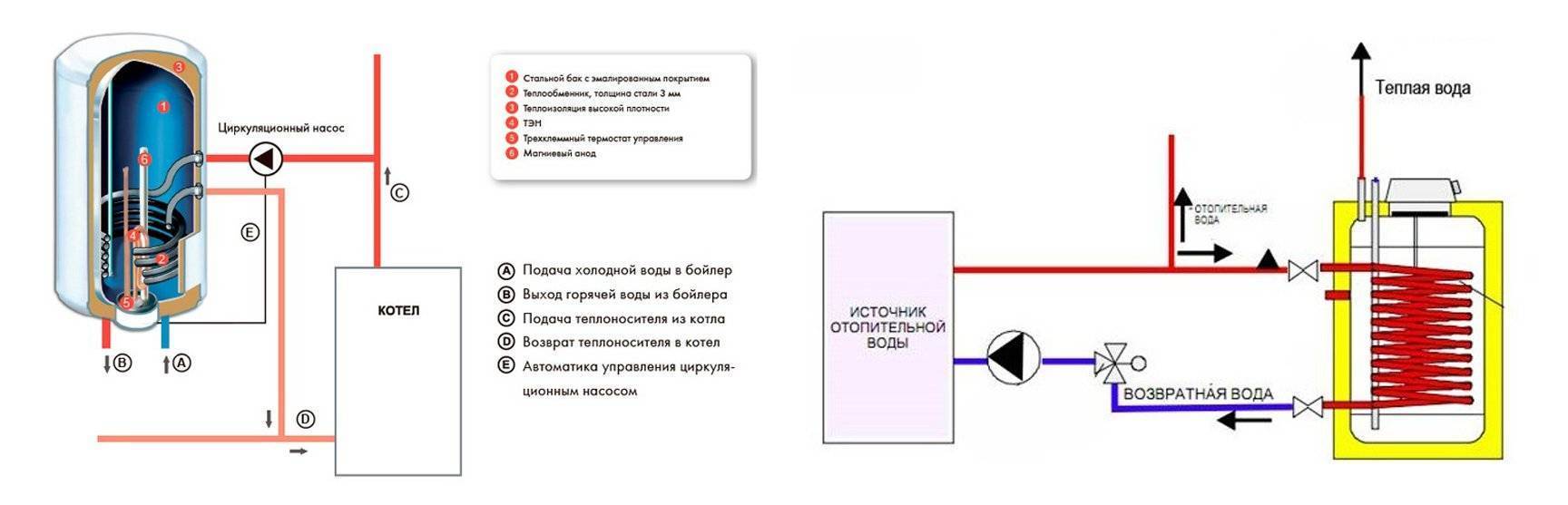

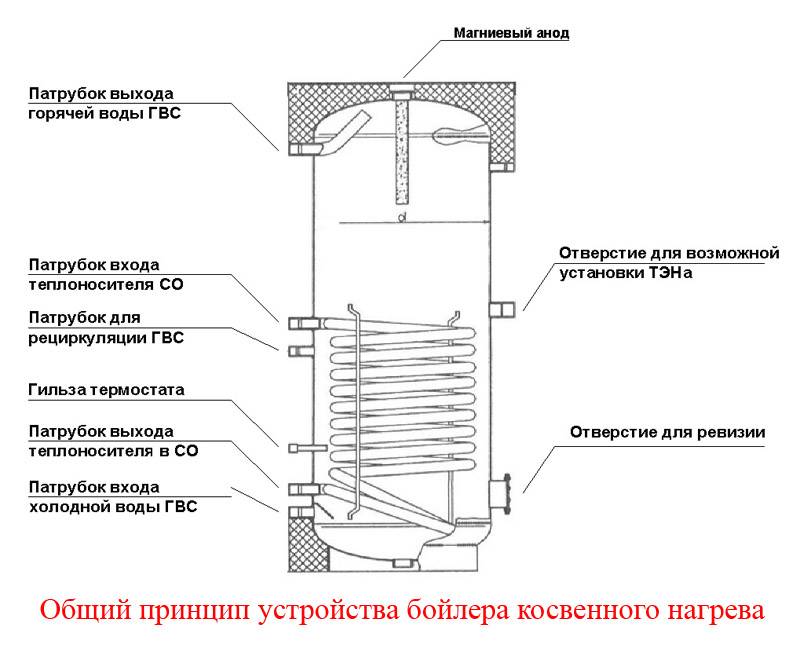

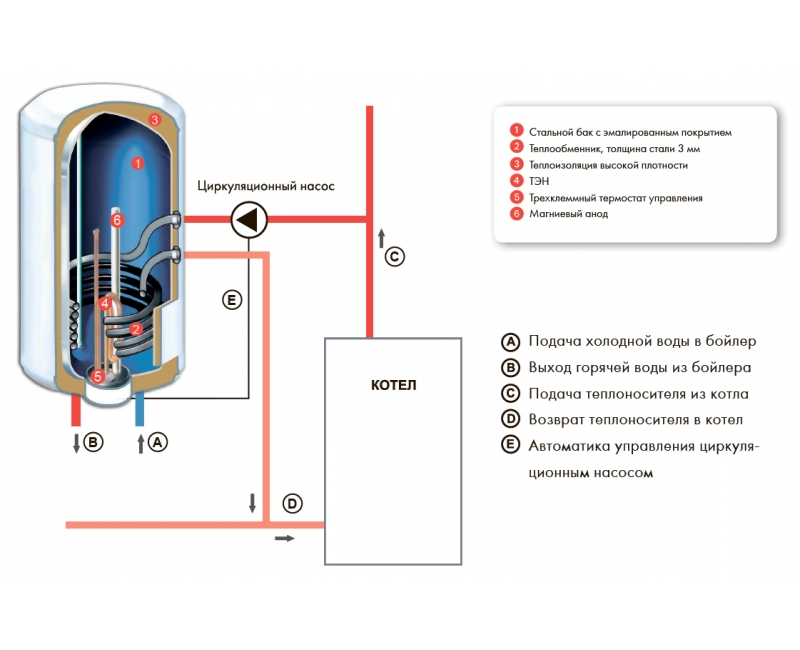

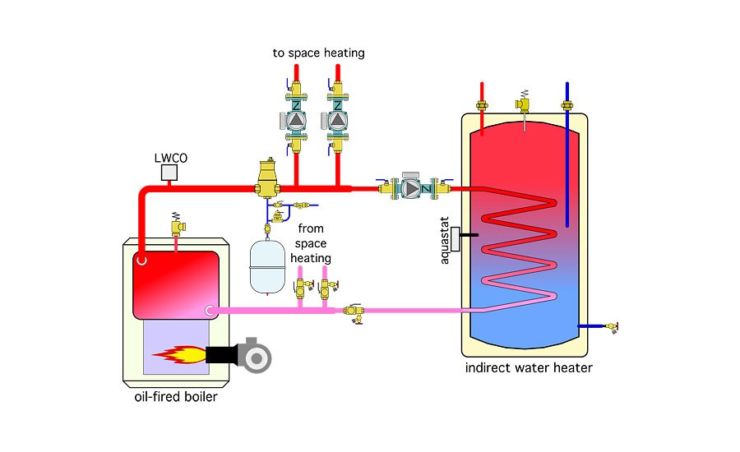

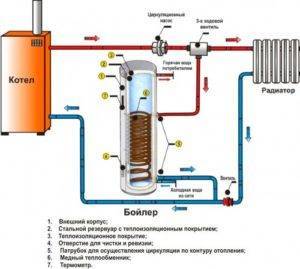

A water heater or an indirect exchange boiler is a tank with water in which a heat exchanger is located (a coil or, according to the type of water jacket, a cylinder in a cylinder). The heat exchanger is connected to a heating boiler or to any other system in which hot water or other coolant circulates.

Heating is simple: hot water from the boiler passes through the heat exchanger, it heats the walls of the heat exchanger, and they, in turn, transfer heat to the water in the tank. Since the heating does not occur directly, then such a water heater is called "indirect heating". The heated water is used for household needs as needed.

Indirect heating boiler device

One of the important details in this design is the magnesium anode. It reduces the intensity of corrosion processes - the tank lasts longer.

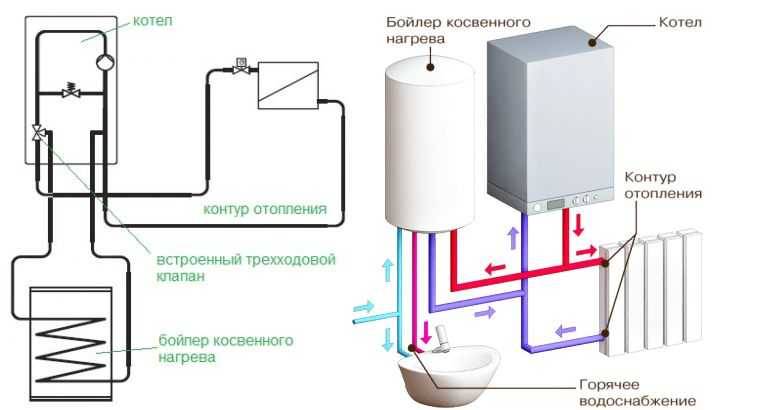

Kinds

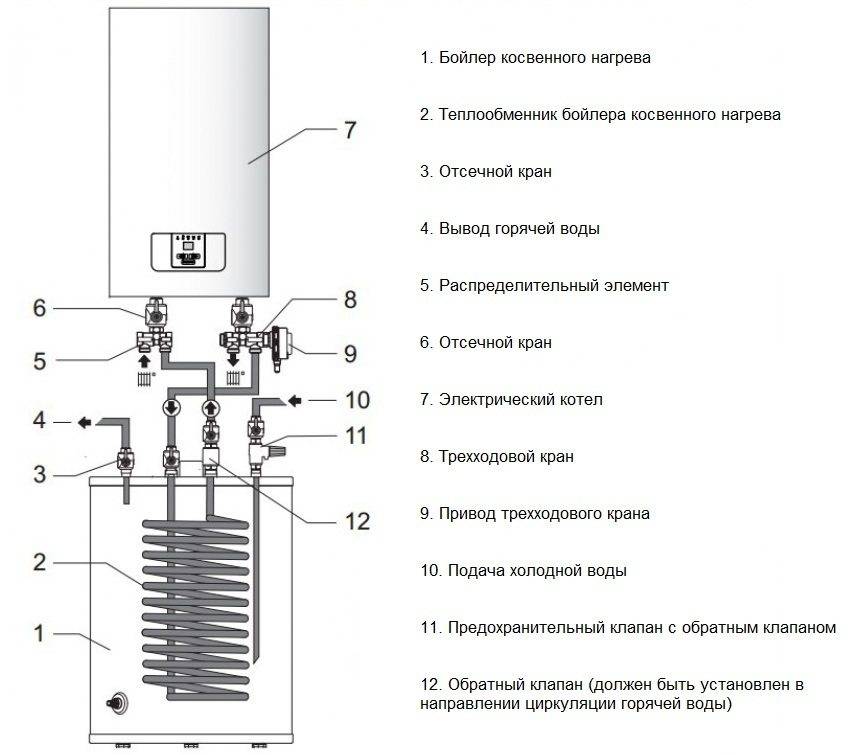

There are two types of indirect heating boilers: with built-in control and without. Indirect heating boilers with built-in control are connected to a heating system powered by boilers without control. They have a built-in temperature sensor, their own control that turns on / off the supply of hot water to the coil. When connecting this type of equipment, all that is needed is to connect the heating supply and return to the corresponding inputs, connect the cold water supply and connect the hot water distribution comb to the upper outlet. That's all, you can fill the tank and start heating it.

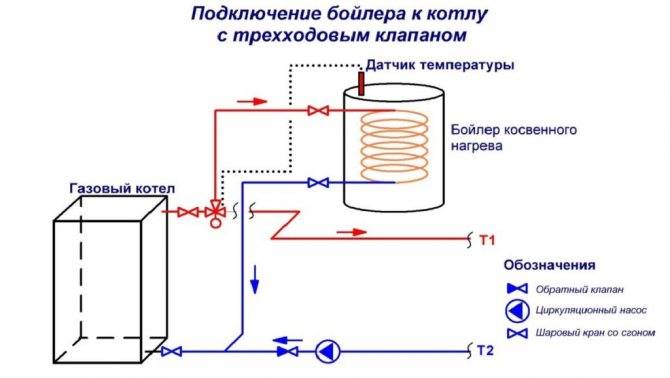

Conventional indirect heating boilers work mainly with automated boilers. During installation, it is necessary to install a temperature sensor in a certain place (there is a hole in the body) and connect it to a certain boiler inlet.Next, they make the piping of the indirect heating boiler in accordance with one of the schemes. You can also connect them to non-volatile boilers, but this requires special schemes (see below).

What you need to remember is that the water in the indirect heating boiler can be heated just below the temperature of the coolant circulating in the coil. So if your boiler works in low-temperature mode and produces, say, + 40 ° C, then the maximum temperature of the water in the tank will be just that. You can't heat it up anymore. To get around this limitation, there are combined water heaters. They have a coil and a built-in heating element. The main heating in this case is due to the coil (indirect heating), and the heating element only brings the temperature to the set one. Also, such systems are good in tandem with solid fuel boilers - the water will be warm even when the fuel has burned out.

What else can be said about the design features? Several heat exchangers are installed in large-volume indirect systems - this reduces the time for heating water. To reduce the time of heating water and for slower cooling of the tank, it is better to choose models with thermal insulation.

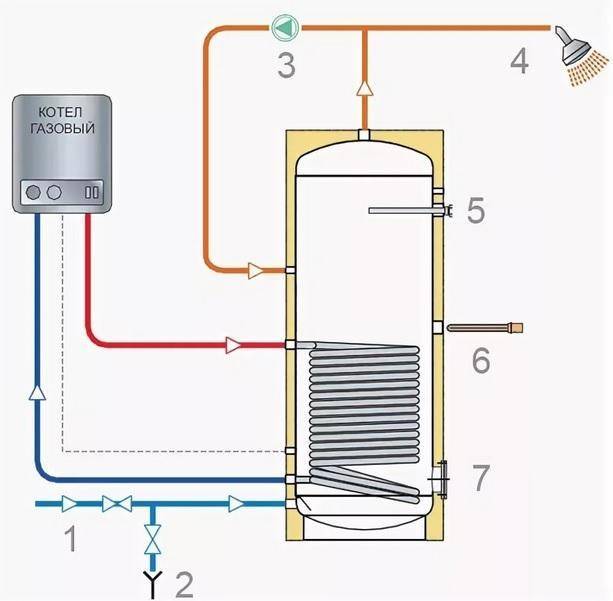

Which boilers can be connected to

Boilers of indirect heating can work with any source of hot water. Any hot water boiler is suitable - solid fuel - on wood, coal, briquettes, pellets. It can be connected to any type of gas boiler, electric or oil-fired.

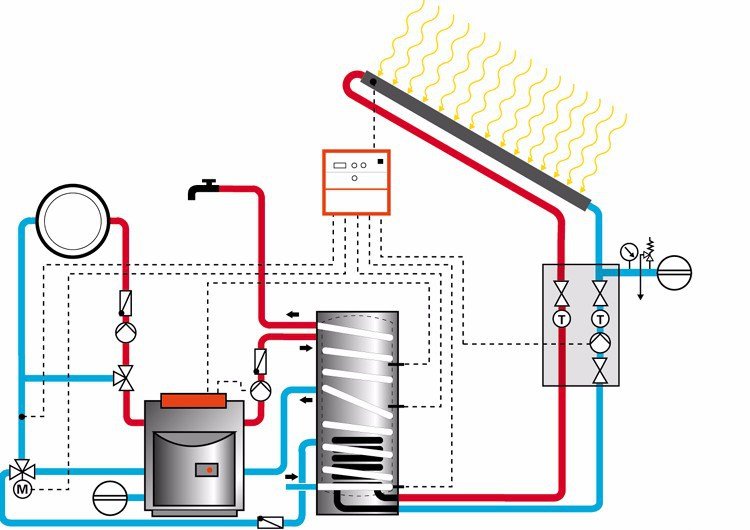

Scheme of connection to a gas boiler with a special outlet for an indirect heating boiler

It’s just that, as already mentioned above, there are models with their own control, and then installing and tying them is a simpler task.If the model is simple, it is necessary to think over a system for controlling the temperature and switching the boiler from heating radiators to heating hot water.

Tank shapes and installation methods

The indirect heating boiler can be installed on the floor, it can be hung on the wall. Wall-mounted options have a capacity of no more than 200 liters, and floor options can hold up to 1500 liters. In both cases, there are horizontal and vertical models. When installing the wall-mounted version, the mount is standard - brackets that are mounted on dowels of the appropriate type.

If we talk about the shape, then most often these devices are made in the form of a cylinder. In almost all models, all working outputs (pipes for connection) are brought out at the back. It is easier to connect, and the appearance is better. On the front of the panel there are places for installing a temperature sensor or a thermal relay, in some models it is possible to install a heating element - for additional heating of water in case of a lack of heating power.

By type of installation, they are wall-mounted and floor-mounted, capacity - from 50 liters to 1500 liters

When installing the system, it is worth remembering that the system will work effectively only if the boiler capacity is sufficient.

What is an indirect heating boiler and what are they

A water heater or an indirect exchange boiler is a tank with water in which a heat exchanger is located (a coil or, according to the type of water jacket, a cylinder in a cylinder). The heat exchanger is connected to a heating boiler or to any other system in which hot water or other coolant circulates.

Heating is simple: hot water from the boiler passes through the heat exchanger, it heats the walls of the heat exchanger, and they, in turn, transfer heat to the water in the tank. Since the heating does not occur directly, then such a water heater is called "indirect heating". The heated water is used for household needs as needed.

Indirect heating boiler device

One of the important details in this design is the magnesium anode. It reduces the intensity of corrosion processes - the tank lasts longer.

Kinds

There are two types of indirect heating boilers: with built-in control and without. Indirect heating boilers with built-in control are connected to a heating system powered by boilers without control. They have a built-in temperature sensor, their own control that turns on / off the supply of hot water to the coil. When connecting this type of equipment, all that is needed is to connect the heating supply and return to the corresponding inputs, connect the cold water supply and connect the hot water distribution comb to the upper outlet. That's all, you can fill the tank and start heating it.

Conventional indirect heating boilers work mainly with automated boilers. During installation, it is necessary to install a temperature sensor in a certain place (there is a hole in the body) and connect it to a certain boiler inlet. Next, they make the piping of the indirect heating boiler in accordance with one of the schemes. You can also connect them to non-volatile boilers, but this requires special schemes (see below).

What you need to remember is that the water in the indirect heating boiler can be heated just below the temperature of the coolant circulating in the coil.So if your boiler works in low-temperature mode and produces, say, + 40 ° C, then the maximum temperature of the water in the tank will be just that. You can't heat it up anymore. To get around this limitation, there are combined water heaters. They have a coil and a built-in heating element. The main heating in this case is due to the coil (indirect heating), and the heating element only brings the temperature to the set one. Also, such systems are good in tandem with solid fuel boilers - the water will be warm even when the fuel has burned out.

What else can be said about the design features? Several heat exchangers are installed in large-volume indirect systems - this reduces the time for heating water. To reduce the time of heating water and for slower cooling of the tank, it is better to choose models with thermal insulation.

Which boilers can be connected to

Boilers of indirect heating can work with any source of hot water. Any hot water boiler is suitable - solid fuel - on wood, coal, briquettes, pellets. It can be connected to any type of gas boiler, electric or oil-fired.

Scheme of connection to a gas boiler with a special outlet for an indirect heating boiler

It’s just that, as already mentioned above, there are models with their own control, and then installing and tying them is a simpler task. If the model is simple, it is necessary to think over a system for controlling the temperature and switching the boiler from heating radiators to heating hot water.

Tank shapes and installation methods

The indirect heating boiler can be installed on the floor, it can be hung on the wall. Wall-mounted options have a capacity of no more than 200 liters, and floor options can hold up to 1500 liters.In both cases, there are horizontal and vertical models. When installing the wall-mounted version, the mount is standard - brackets that are mounted on dowels of the appropriate type.

If we talk about the shape, then most often these devices are made in the form of a cylinder. In almost all models, all working outputs (pipes for connection) are brought out at the back. It is easier to connect, and the appearance is better. On the front of the panel there are places for installing a temperature sensor or a thermal relay, in some models it is possible to install a heating element - for additional heating of water in case of a lack of heating power.

By type of installation, they are wall-mounted and floor-mounted, capacity - from 50 liters to 1500 liters

When installing the system, it is worth remembering that the system will work effectively only if the boiler capacity is sufficient.

What is a single-circuit boiler

Of the two existing types of boilers, differentiated by the number of built-in heating circuits, the single-circuit one differs in that it is endowed with only one useful function - heat supply to the batteries to increase the room temperature. Its design itself is not capable of supplying hot water to the tap, so the role of the mixer in this case is reduced to zero. Boilers are electric (heating elements, induction, electrode) and gas, which is due to different methods of heating, power, consumption.

The electric boiler has the following nomenclature: a central tank that acts as a heat exchanger, tubular heating elements (heaters), inlet and outlet pipes in the lower part of the body, a circulation pump for water circulation in the system, a thermostat, indicators.In the induction boiler, instead of heating elements, coils are placed, which are driven by electromagnetic induction, the outlet pipe with hot water is installed on the top cover of the structure. Electrode boilers operate, respectively, by means of the poles of a closed electrical circuit (anode and cathode) installed in parallel, forming an electrical voltage and heat generation.

The gas single-circuit boiler is equipped with a heat exchanger, a combustion chamber for the incoming fuel from a gas burner, a three-code valve, a circulation pump, an expansion tank, a valve for connecting to a gas pipeline.

All modern models of single-circuit boilers, in addition to the water inlet-outlet pipe, have pipes for connecting to external water heating units. Thus, the possibility of synthesizing a single-circuit boiler with an indirect heating boiler is realized to create a multifunctional heating and hot water supply system at home.

Optimum operating mode of the electric boiler

Setting the temperature to the minimum allowable is highly discouraged for the following reasons:

- Reducing the efficiency of water heating equipment;

- The temperature of the liquid is 30-40⁰ C - an ideal environment for the formation, reproduction of bacteria, mold fungus, which will certainly fall into the water;

- The rate of scale formation increases.

These devices are often equipped with the option of an economy mode, marked with the letter E. This mode of operation means heating the liquid inside the tank to a temperature of +55 ° C, which allows you to extend the period of use before maintenance.That is, at this temperature regime, scale is formed the slowest of all, respectively, it is less often necessary to clean the heating element. This does not apply to energy savings.

How an indirect heater works

There is a hollow spiral in the tank. A coolant circulates inside, which distributes heat throughout the system. Its constant movement provides a circulation pump. As soon as the thermometer indicates that the specified temperature has been reached, the pump switches off automatically. Due to the heat-insulating layer, heat loss during shutdown is only 3-4 degrees per day.

Inlet and outlet pipes are connected to the tank, through which hot water goes to the boiler.

Scheme of work:

What to look for when choosing:

- Power. It must match the parameters of the heating system. Otherwise, the system may not be able to cope with the load or, conversely, the power will not be enough for normal heating.

- Accommodation. If the heating boiler is placed on the floor, then it is better to choose a floor boiler. In other cases, give preference to the wall.

Experts recommend purchasing a boiler and a boiler of the same brand. Then installation and connection will be easy and smoothly.

heat exchanger consumption. The values are indicated in the documents for the technique. Ideally, the indicator should not exceed 40% of the total volume of liquid in the tank.

Advantages and disadvantages of the system

For what reasons it is worth installing an indirect boiler:

- Provides plenty of hot water.

- Uniform pressure at several points of the fence at once.

- Low cost of heating, no electricity consumption.

- Possibility to additionally turn on gas, electricity if necessary.

Flaws:

- Expensive setup. Since, in addition to the boiler, you need to buy and connect the boiler.

- While the water is being heated, the temperature in the rooms will decrease.

- The design takes up a lot of space, you will need to allocate a separate room.

Having understood the principle of operation of the equipment, you can adequately assess the profitability of the purchase

When choosing, pay attention to the technical specifications and calculate the appropriate power

Pros and cons of a double-circuit boiler

A double-circuit heating device has many advantages. The main advantage of this device is that thanks to such a boiler, you can simultaneously heat the room and use hot water. Using a double-circuit boiler will save you from the additional costs that may be associated with the purchase of a boiler. Also, the external attractiveness of double-circuit heating devices should be attributed to the indisputable advantages. These boilers look aesthetically pleasing not only in the boiler room, but also in any other room.

Modern double-circuit heating devices have a high efficiency, which can significantly reduce utility costs. Double-circuit boilers allow you to ideally adjust the temperature inside the room, as well as adjust the temperature of the water in the DHW pipeline.

These heating devices are not without several disadvantages, the list of which includes:

- turning off the heating at the time of hot water disassembly;

- relatively low productivity in the preparation of hot water.

Indirect heating boiler pros and cons

The advantages of using an indirect heating boiler in the hot water system of a private house include:

- Comfort in use. DHW as in an apartment;

- Rapid heating of water (due to the fact that all 10-24 or even more kW of boiler energy are used);

- No scale in the system. Because heating is carried out through a heat exchanger, and its temperature does not exceed the boiling point of water. Of course, the problem is not completely solved, but its education is significantly reduced. Also, storage water heaters can be equipped with anodes made of various materials (aluminum, magnesium, titanium). Which also contributes to the resistance to corrosion of the tank itself and prevents the formation of scale.

- Possibility to organize a water recycling system. Hang towel warmers. No need to wait and drain a large amount of water until hot water flows. You can't do that on a double boiler.

- The ability to get a large amount of hot water, which is enough for all needs at the same time. With a double-circuit boiler, the flow of hot water is limited by the capacity of the boiler - its power. You can't wash dishes and use the shower at the same time. There will also be clear temperature fluctuations.

As always, there are cons:

- Naturally, the cost in relation to a double-circuit boiler is greater;

- Takes up a decent amount of space;

- Additional troubles for connecting and configuring the system;

- With a recirculation system, additional costs (faster cooling of the system, pump operation, etc.), which will lead to an increase in the DC in payment for energy carriers (gas, electricity);

- The system needs to be serviced regularly.

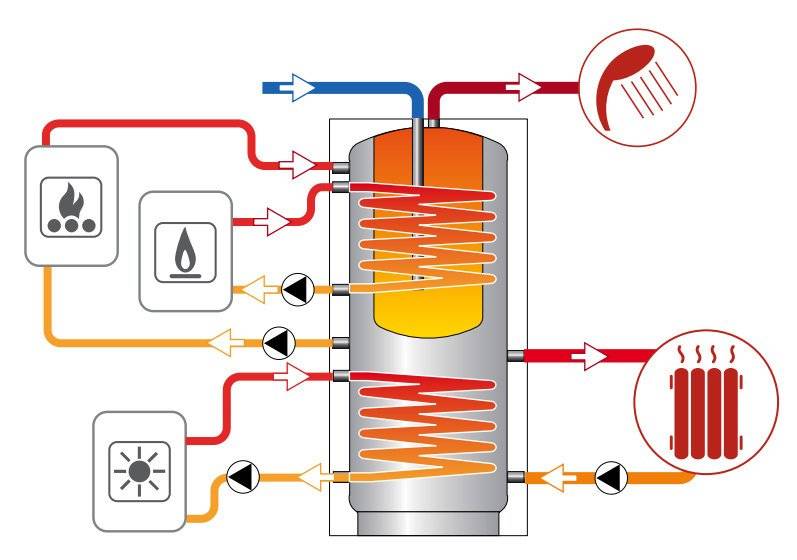

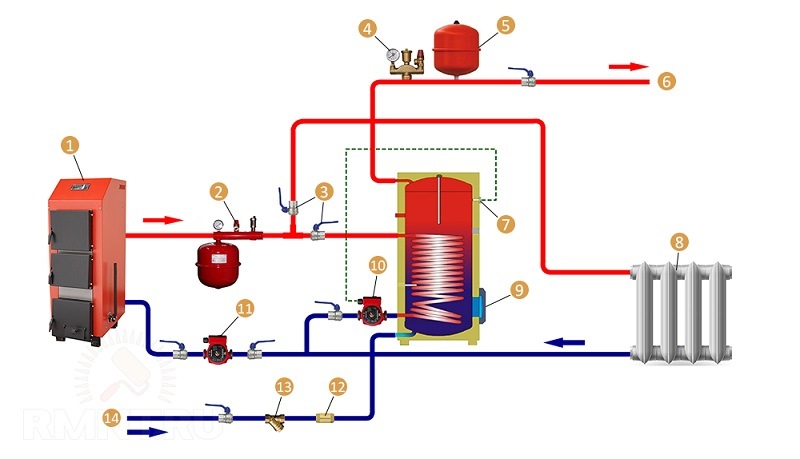

Heat accumulator for heating boilers: features of the device and connection

The purpose of using this unit is to collect and store the coolant heated to a certain temperature for its further transfer to the system when the need arises. Being connected to the water circuit of the room, this type of battery provides support for the temperature regime, even if the heat source is turned off.

Useful advice! If the water heating of the house is produced from electricity, registration of a night tariff with a reduced cost of 1 kW / h. will save you money on bills. The heating system will be sufficiently heated at night, and during the daytime the heat accumulator will work.

The heat accumulator is used to maintain water heated to a certain temperature.

This device also performs other functions. The main ones include:

- reduces fuel consumption by almost a third. At the same time, the efficiency of the fuel plant increases;

- protects heating devices from overheating, collecting excess heat;

- heats water for the domestic hot water system. That is, in fact, this is one of the varieties of an indirect heating boiler. The price of this unit varies over a very wide range: from 13 to more than 300 thousand rubles;

- the heat accumulator tank can connect several heat sources operating on different types of energy or fuel;

- the design of the device allows the selection of coolant of different temperatures.

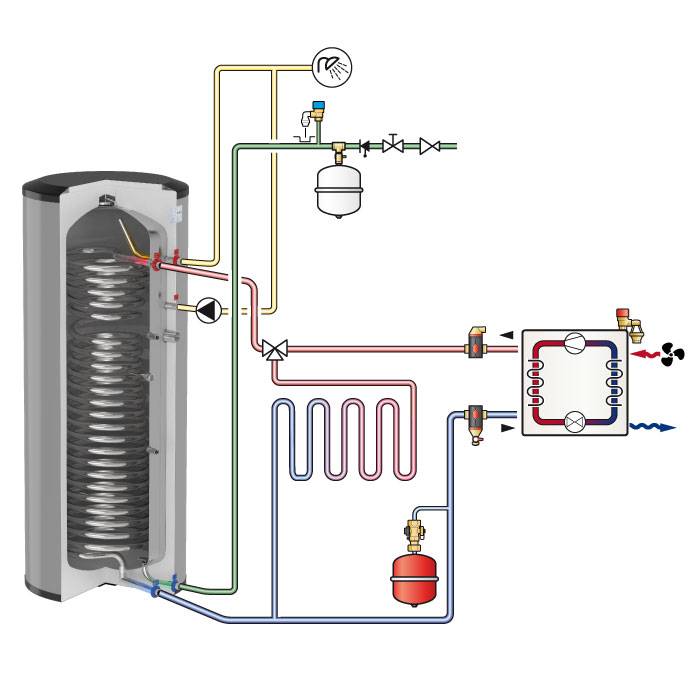

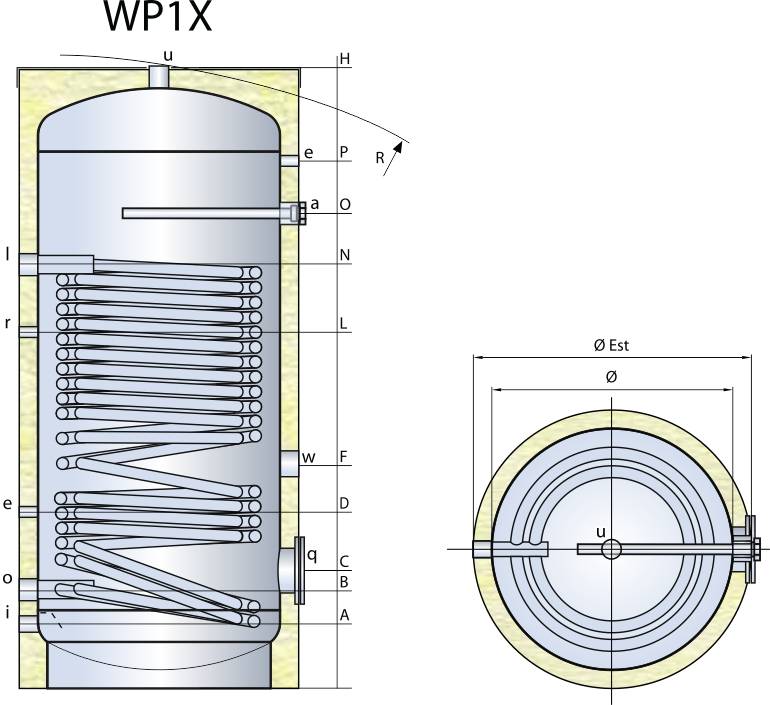

Heat accumulator device and rational connection of external devices

The main part of this unit is a cylindrical stainless tank filled with a liquid characterized by a high heat transfer coefficient. Its strapping is carried out with a heat-insulating material.In combination with the installation of the upper jacket, such a constructive solution increases the cooling time of the heat accumulator. Inside the cylindrical tank are placed from 1 to 3 heat exchangers. The number of coils is determined by the capabilities and needs of homeowners.

Heated water from solid fuel or gas boilers enters the cavity of the accumulator tank from above, and the cooled liquid settles closer to the bottom and is pumped back into the boiler for heating.

Scheme of the heat accumulator device with the ability to connect to alternative energy sources

The lower compartment usually has a temperature of the order of 35-40°C. Therefore, it is advisable to connect it to the underfloor heating system. The temperature of the middle part is 60-65°C. Therefore, heating devices should be connected to it. The upper part of the tank is connected to the hot water supply. The water temperature there reaches 80-85°C.

Principle of operation

The operation of an indirect boiler is a fairly simple process. To do this, cold water enters the lower part of the tank, it is heated by a heat exchanger. Already warm water comes for use from its upper part. The system includes a magnesium anode, which ensures a longer life of the boiler, as well as a thermostat.

The boiler may or may not have a coil. There are models where there is a large capacity, and another capacity is inserted into it, but smaller. Hot water from the boiler enters the larger tank, as a result of which the cold water in the smaller tank is heated. The existing distance between the walls of the cylinders is the heat exchanger.

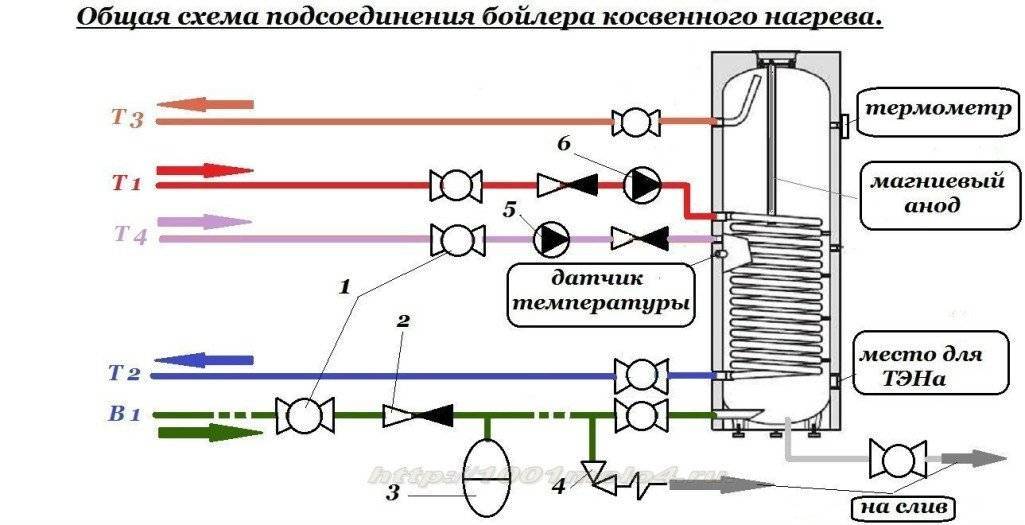

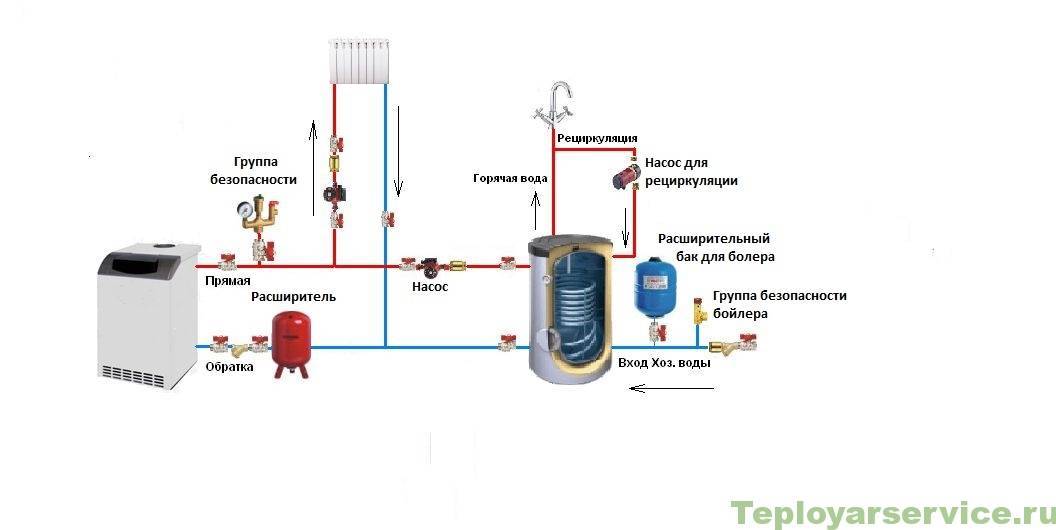

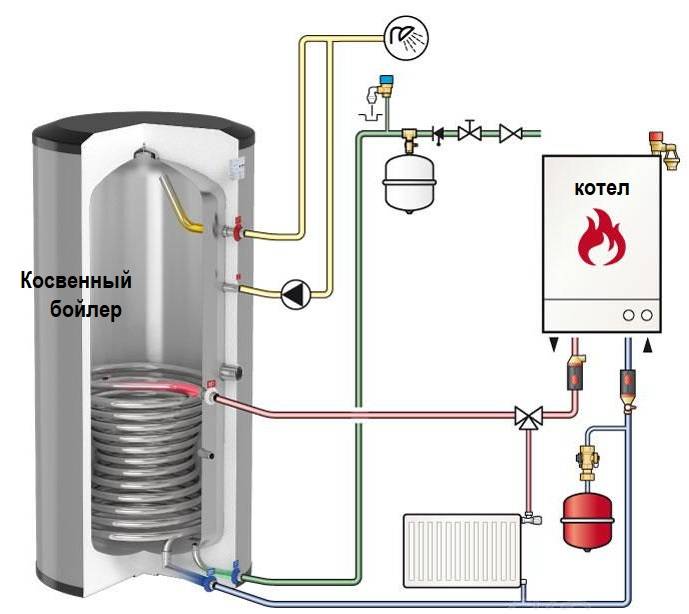

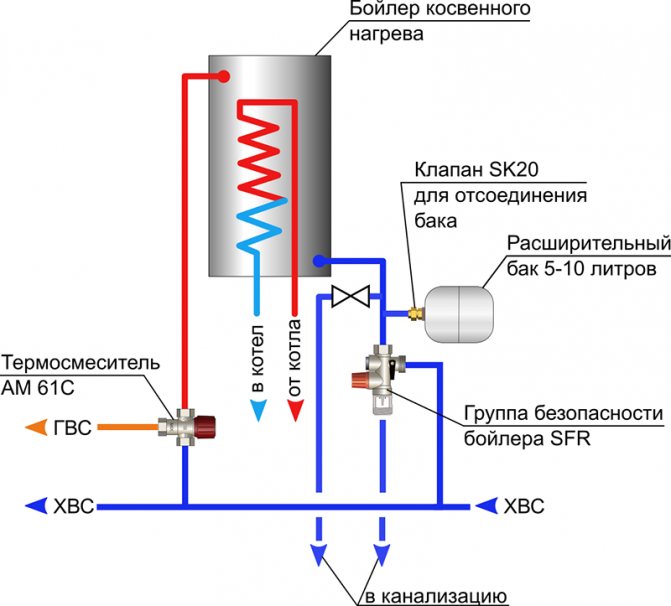

Features of piping an indirect heating boiler

It is easier to do wiring and piping if the KN boiler is installed together with the boiler, pumps and other equipment involved in the assembly of the DHW system. Embedding an additional device into an already existing network is much more difficult.

In any case, for the normal operation of the devices, you will have to follow a number of rules:

- choose the right place for installation - as close as possible to the boiler;

- provide a flat surface for mounting the boiler;

- to protect against thermal expansion, install a membrane accumulator (at the outlet of heated water), the volume of which is at least 1/10 of the volume of the BKN;

- equip each circuit with a ball valve - for convenient and safe maintenance of devices (for example, a three-way valve, a pump or the boiler itself);

- to protect against backflow, install check valves on the water supply pipes;

- improve water quality by inserting filters;

- correctly position the pump (or several pumps) - the motor axis must be in a horizontal position.

For safety reasons, do not attempt to mount heavy devices on plasterboard or thin wooden partitions. Concrete and brick walls are suitable. Brackets or other types of holders are fixed with brackets, anchors, dowels.

Regardless of the type of device - floor or wall - if possible, it is mounted above the level at which the boiler is installed, or at the same level. For outdoor, you can make a pedestal or a solid stand up to 1 m high

When installing, the nozzles are directed towards the boiler (even if they are masked in the back or behind a false wall).Do not use unreliable equipment, such as corrugated hoses that cannot withstand the pressure and pressure of water.

For normal operation of the storage water heater of indirect heating, the following functional devices must be included in the piping:

- A complex technical system must be equipped with pumps that supply hot sanitary water to the taps and stimulate the movement of the coolant along the heating branch, as well as along the water heating circuit in the boiler

- Cold water coming from a public or autonomous water supply must be cleaned through a sump or filter system that destroys lime salts before being supplied to the boiler. Filtration will prevent the formation of mineral sediment

- After the sump or water filtration system, there must be a pressure reducer. However, it is only needed if the pressure in the branch exceeds 6 bar

- Before entering cold water into the boiler, a check valve is required to prevent reverse flow.

- In order for the heating water to have a reserve for expansion during the period when it is not used, an expansion tank and a pressure relief valve are included in the piping

- To prevent excessively hot water from entering the taps, threatening burns, a three-way mixing valve must be installed in the circuit. It will mix portions of cold water with hot water, as a result, there will be water at the required temperature for the user

- In order for the heat carrier from the heating to enter the "jacket" heating the sanitary water only when it is needed, a two-way thermostat is installed. Its server is connected to the water heater temperature sensor

- If the hot water consumption in the house is large enough, it is advisable to purchase a boiler with a built-in additional instantaneous water heater or buy a separate device and include it in the hot water supply branch. In case of its shortage, a miniature protochnik will turn on and save the situation.

What pipes are suitable for tying

To connect the boiler and heating wiring, it is better to take metal-plastic or polypropylene pipes. They will cost less than galvanized or copper counterparts.

Sequential wiring of radiators is carried out using metal-plastic pipes on press fittings or polypropylene pipes with aluminum reinforcement. However, each of these options has its drawback. Press fittings are sensitive to the quality of installation and leakage can occur at the slightest displacement. Polypropylene, on the other hand, has a high coefficient of elongation when heated to more than 50°C. For wiring the "warm floor" system, metal-plastic on press fittings, polyethylene or thermomodified polyethylene are used.

How to choose an indirect heating boiler

Making the right choice of a suitable indirect heating boiler model is a difficult task for a beginner. However, there is nothing overwhelming here, you just need to take into account a few important nuances:

When choosing a water heater with indirect heating for an apartment or a private house, the first step is to determine the optimal volume of the storage tank. In order for all family members to have enough hot water, they calculate taking into account the approximate consumption of 100 liters per day by one person.

Cost-effective indirect water heating boiler for a family of four or more people

With this number of people, the approximate consumption of hot water is 1.5 l / min.

Paying attention to the volume of the tank, take into account the heating time. Large capacity will take longer to heat up. It may be worth giving preference to a model with two heat exchangers or a tank-in-tank system.

The composition of the thermal insulation determines how long the water will remain hot after the boiler is turned off.

Cheap water heaters come with foam. Porous material poorly retains heat and quickly decomposes. The optimal thermal insulation is mineral wool or polyethylene foam.

To make the right choice, you need to compare the power of the indirect water heater and the heating boiler. If the latter is characterized by weak parameters, the boiler will become an unbearable load.

When buying any model, be sure to pay attention to the presence of a thermostat, valve and other security elements.

It may be worth giving preference to a model with two heat exchangers or a tank-in-tank system.

The composition of the thermal insulation determines how long the water will remain hot after the boiler is turned off. Cheap water heaters come with foam. Porous material poorly retains heat and quickly decomposes. The optimal thermal insulation is mineral wool or polyethylene foam.

To make the right choice, you need to compare the power of the indirect water heater and the heating boiler

If the latter is characterized by weak parameters, the boiler will become an unbearable load.

When buying any model, be sure to pay attention to the presence of a thermostat, valve and other security elements.

When the issue is resolved with all the important nuances, you can pay attention to the form, design, manufacturer and other details.

Calculation of the volume of the storage tank

To make an approximate calculation of the volume of the storage tank, you can use a simple reading of the water meter. When the same number of people constantly arrive at the house, the daily consumption will have the same data.

A more accurate calculation of the volume is based on counting the water points, taking into account their purpose and the number of living family members. In order not to go into complex formulas, the hot water consumption is taken from the table.

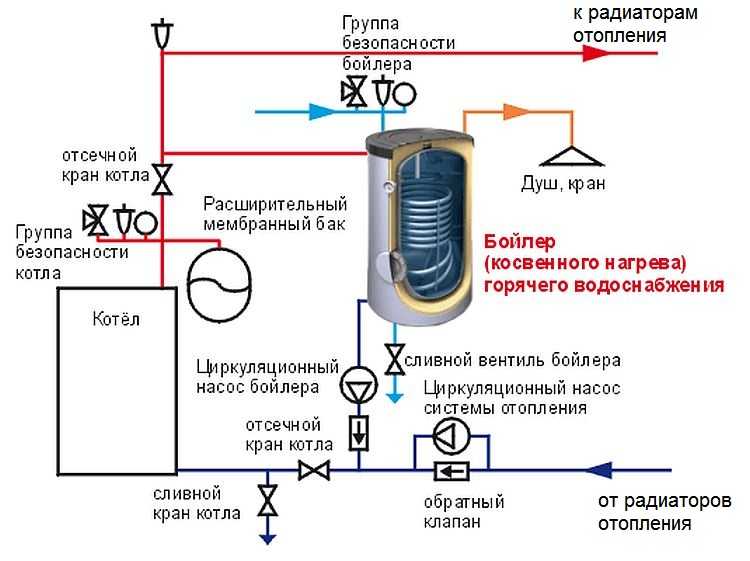

Connection diagrams for the heating system

When choosing a connection scheme for an indirect boiler for heating water, the location of the device in the house, as well as the features of the heating system wiring, are taken into account.

A simple and commonly used scheme is based on connecting an indirect device through a three-way valve. As a result, two heating circuits are formed: heating and hot water. After the boiler, a circulation pump crashes in front of the valve.

If the need for hot water is small, a system diagram with two pumps is suitable. The indirect water heater and the boiler form two parallel heating circuits. Each line has its own pump. The scheme is suitable for country houses where hot water is rarely used.

The connection diagram is more complicated if the house has a “warm floor” system installed along with radiators. To distribute pressure across all lines, and together with an indirect boiler they will get three, a hydraulic distributor is installed. The node normalizes the circulation of water through the "warm floor", water heater and radiators. Without a distributor, pumping equipment will fail.

In indirect water heaters with recirculation, three nozzles come out of the body.Traditionally, two outputs are used to connect to the heating system. A looped circuit is led from the third branch pipe.

If the indirect water heating device does not have a third branch pipe, and recirculation must be done, then the return line circuit is connected to the cold water pipe and the recirculation pump is additionally inserted.

Recirculation allows you to get hot water at the outlet of the tap even before the liquid in the storage tank of the boiler is completely heated.