- Indirect heating boiler device

- Project development

- Calculation of the volume of the manufactured boiler

- What material is the container made of?

- Coil Sizing Calculation

- What material is the heat exchanger made of?

- Wiring diagram

- Possible mistakes

- Briefly about the main

- Connecting the boiler to a gas boiler

- To a single gas boiler

- To a double-circuit gas boiler

- Advantages and disadvantages, the choice of BKN

- We recommend reading:

- Optimum operating mode of the electric boiler

- Storage water heaters

- We make a boiler with our own hands

- Boiler tank preparation

- Manufacturing and processing of the coil

- Production and binding of BKN

- thermal insulation

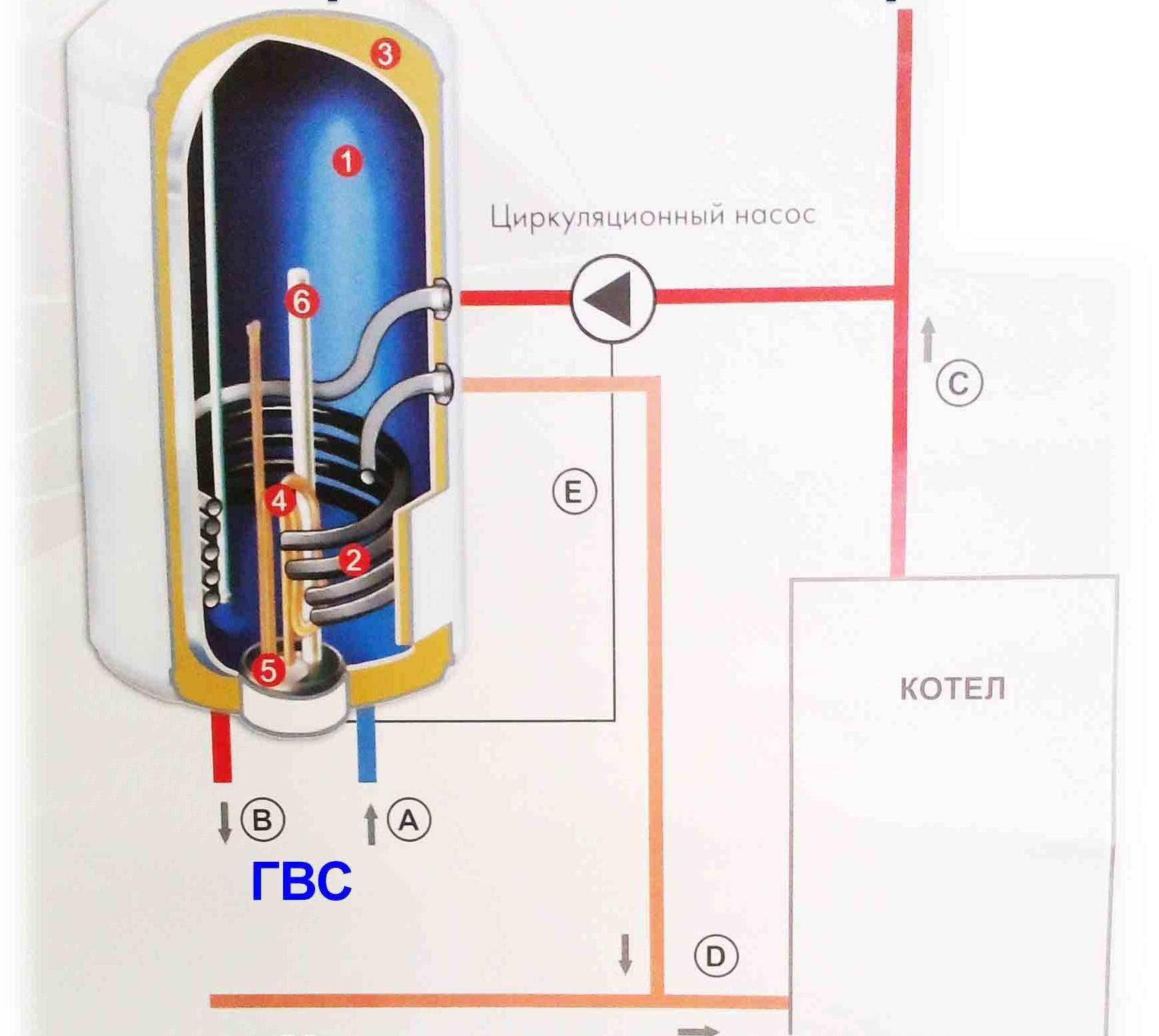

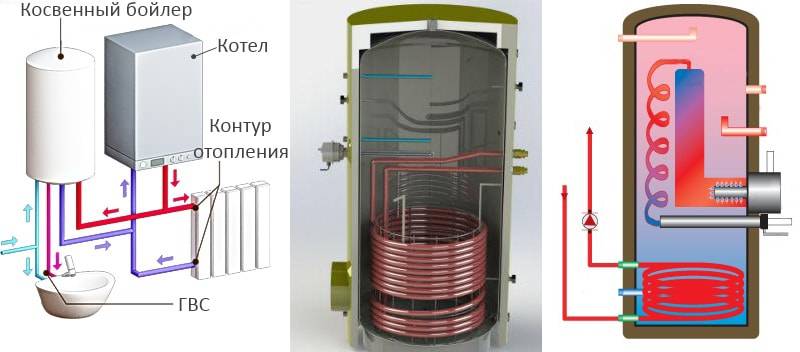

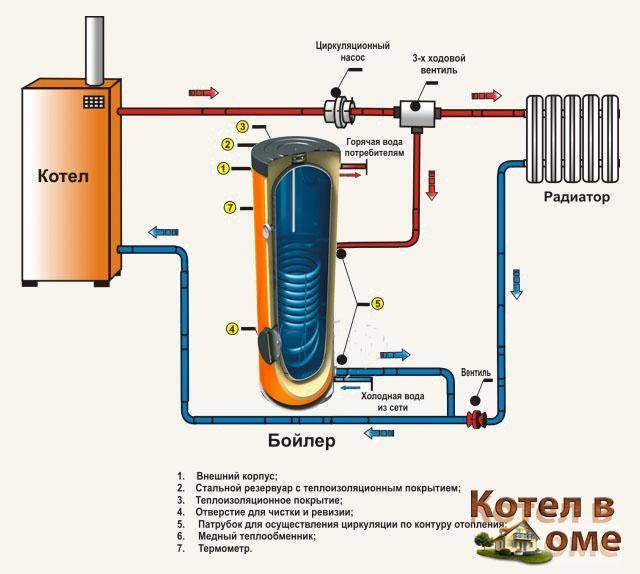

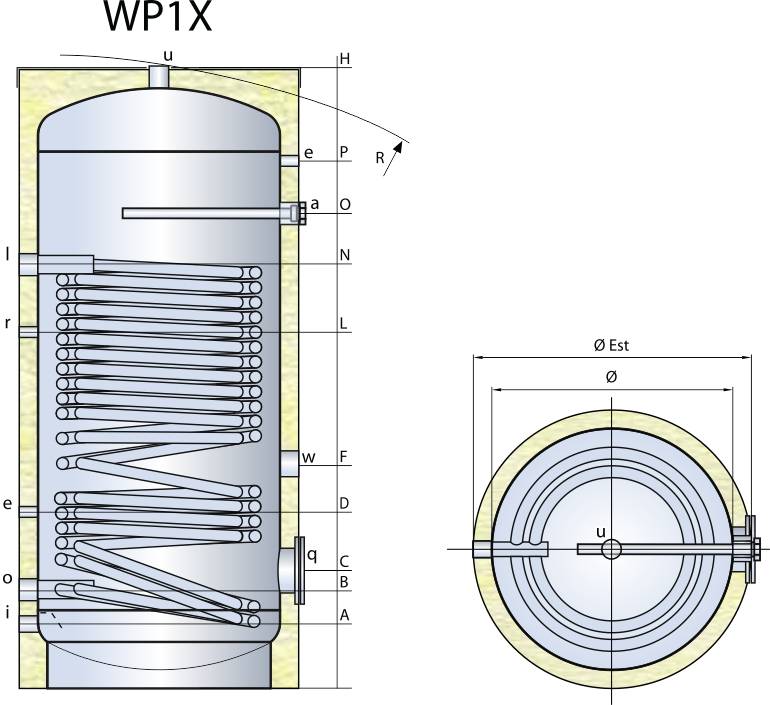

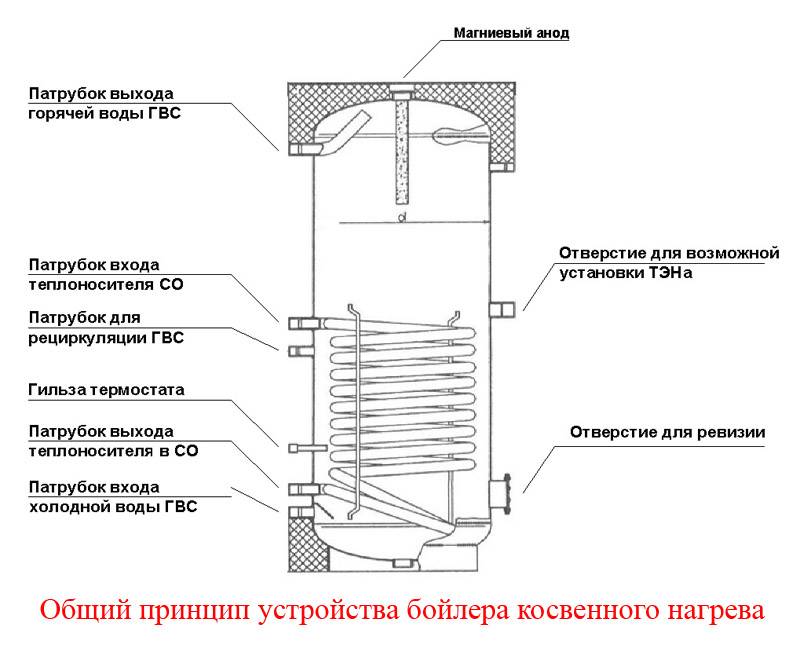

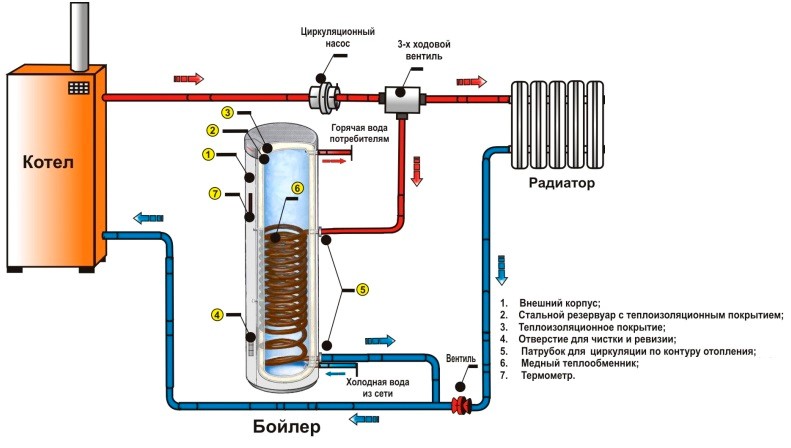

Indirect heating boiler device

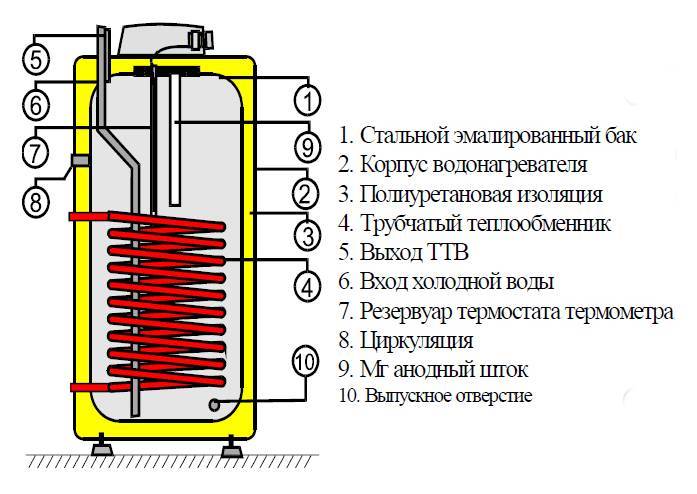

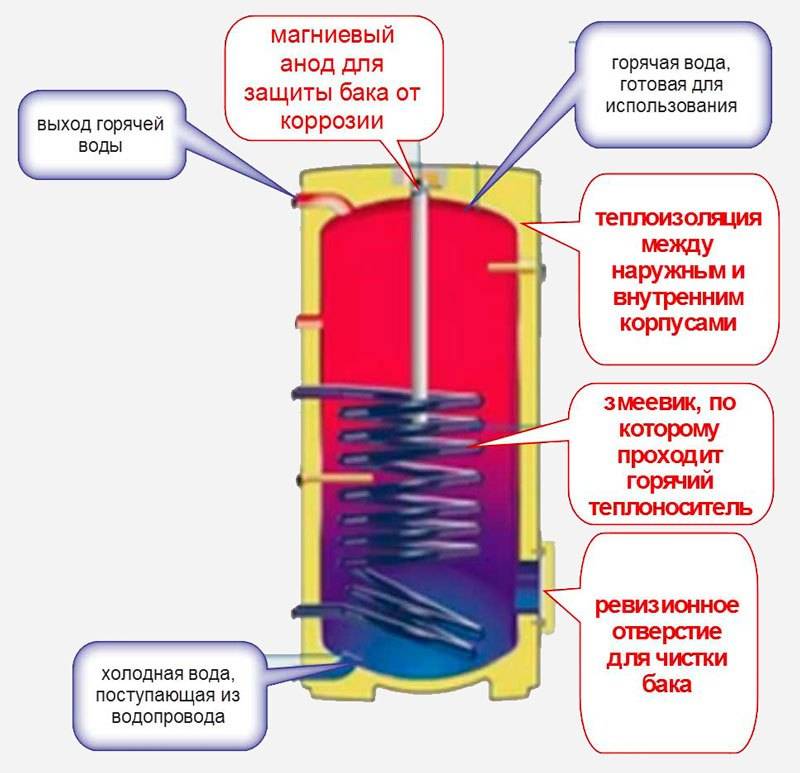

The structure of the boiler design includes the following main elements:

- Capacity;

- Coil or built-in tank;

- Thermal insulation layer;

- outer casing;

- Fittings (pipes) for connection;

- magnesium anode;

- TEN (not always);

- Thermal sensor;

- Temperature control system;

Tanks for boilers are usually cylindrical, less often rectangular. They are made from carbon (ordinary) or high-alloy (stainless) steel.In the case of using conventional steel grades, the inner surface of the container is covered with a layer of special enamel or glass-ceramic, in all cases a magnesium (or titanium) anode is installed.

The magnesium anode is a consumable item and needs to be replaced regularly as it gets used. The corrosion rate of the material of the main tank due to the anode is reduced several times.

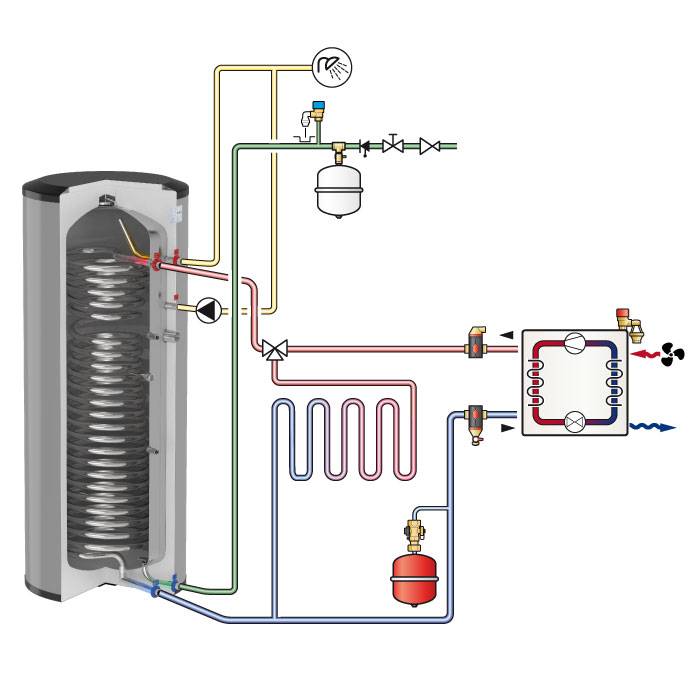

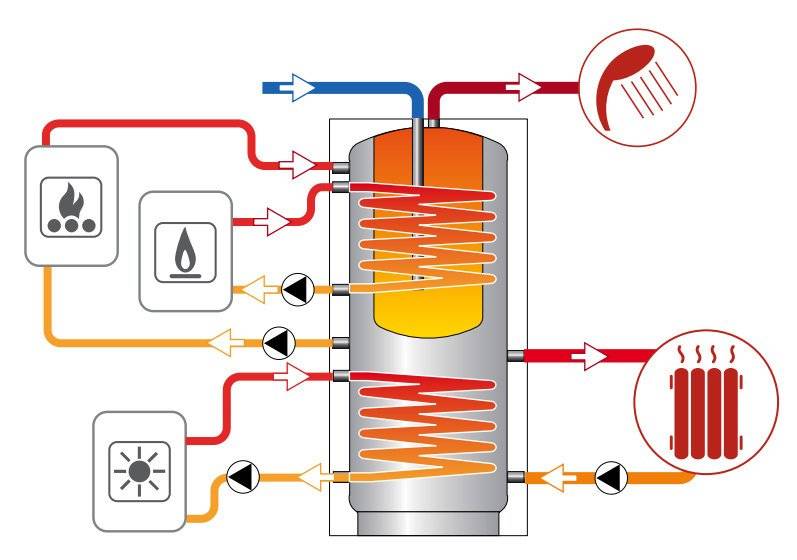

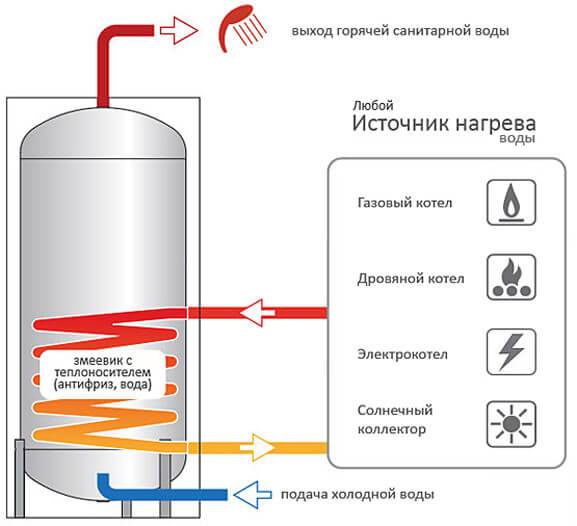

The main modification of the BKN is a container with a built-in spiral coil; for large volumes, the device can be equipped with several coils, and they can be connected to various heat generating sources - a boiler, a heat pump, a solar collector.

Stainless Steel Boiler Spiral Heat Exchanger

The material of the coil is usually copper, less often - ordinary or stainless steel. The ends of the coil are equipped with threads for connecting valves and pipelines.

Second variety boilers KN - units with built-in capacity. The tank also has layers of a protective coating or is made of stainless steel, equipped with nozzles that extend beyond the main tank.

To reduce heat losses, the container is insulated with high quality - polyurethane and other thermal insulation materials are used for this. The insulated container is enclosed in a decorative and protective casing - it is made of steel or high-strength plastic.

Many BKN models are equipped with removable heating elements. They are designed to increase the performance of the boiler or act as the main heating element (during the warm season, in the absence of heating).

Tanks are equipped with hatches for internal inspection and equipment cleaning.Units with built-in tanks are equipped with self-cleaning systems and usually do not have hatches.

BKN capacity varies from 50 to 1500 liters. According to the method of placement, the device is divided into 2 types:

- Wall-mounted - up to 200 liters;

- Floor.

A separate type of BKN is built-in. They are placed directly in the same building with the boiler, controlled by its automation system. Built-in heaters have volume limitations - this is due to the presence of common overall characteristics with the boiler.

It should be noted that wall placement implies the presence of a main wall or the construction of reinforcing structures. According to the orientation of the tank, boilers are divided into vertical and horizontal.

The main control element of the BKN is a temperature sensor, it is installed in the middle zone of the tank in a special sleeve. The control system sets the required hot water temperature, sensor when changing (heating or cooling) delivers water temperature appropriate commands to turn off the actuators - a pump or a three-way valve.

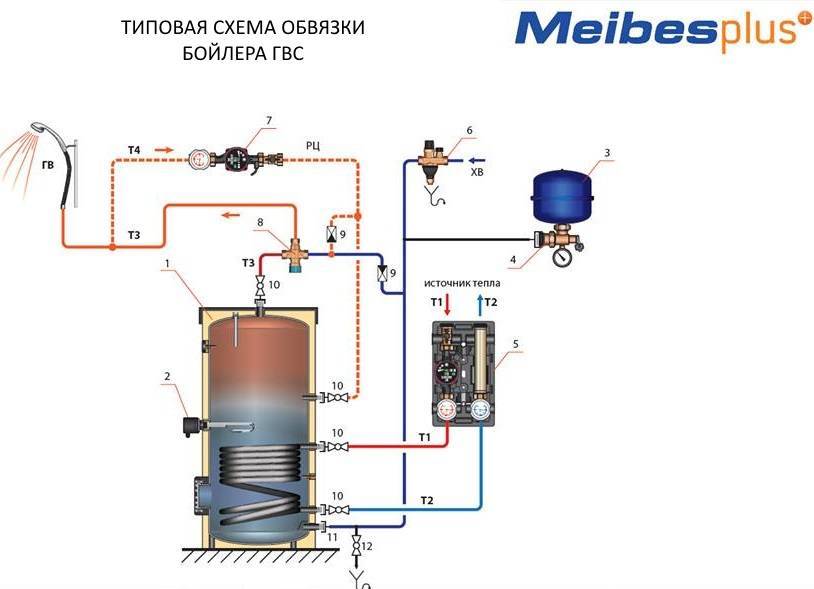

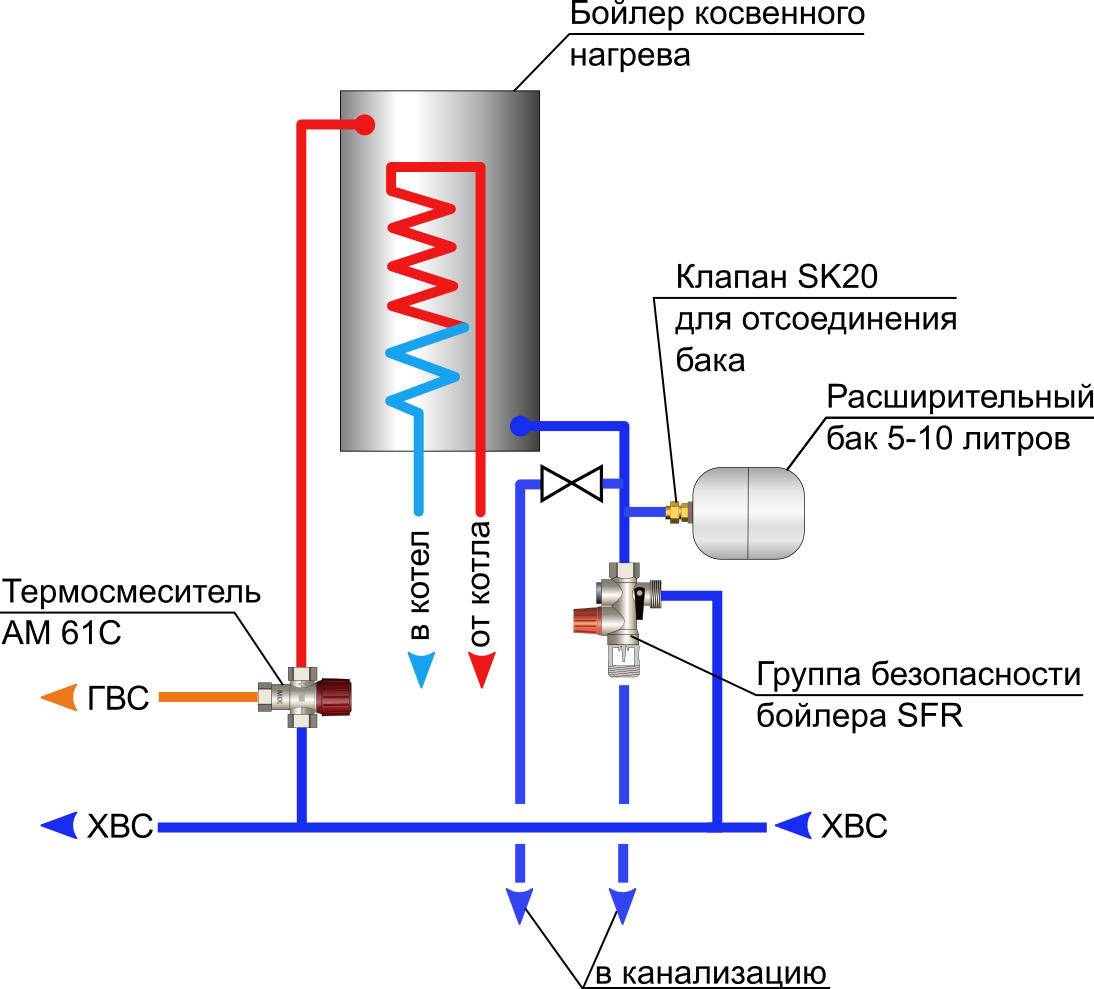

In the upper part of the boiler there is a branch pipe for connecting an air vent or a safety group. Most often, a safety group is installed here, while the response pressure of the safety valve is 6.0 kgf / cm2. In addition to the GB, an expansion valve is necessarily integrated into the BKN piping. membrane type tank - its volume is selected at the rate of 10% of the boiler capacity.

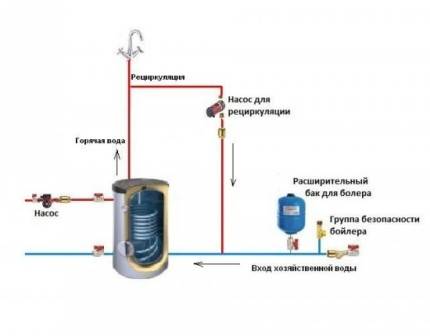

At the bottom of the BKN there is a threaded fitting for draining water from the device. Cold water is supplied to the bottom of the device, hot water is taken from the top.Most BKN models are equipped with a branch pipe for organizing a recirculation circuit, it is located in the middle part of the device.

Project development

Boiler BKN is carried out according to the project, which is based on the executive drawings. They are made independently, taken on the Internet according to the required tank volume and coolant temperature, or borrowed from users who have successfully installed and operate the required volume of BKN. The project performs thermal and hydraulic calculations and determines the specification of the necessary equipment.

Main design parameters of BKN:

- hourly volume of DHW water consumption, m3;

- coil location;

- coil configuration;

- coil heating area.

In addition, a section “automation” is being prepared, which provides for emergency shutdown of the BKN and automatic maintenance of operating temperature DHW in the boiler.

When choosing the parameters of the tank and the coil, you should not get carried away with the large dimensions of the structure, since this will lead to a decrease in the overall efficiency of the installation due to an increase in heat losses.

Calculation of the volume of the manufactured boiler

In the event that the boiler is already installed in a private house and is designed for heating, the tank volume must be calculated based on the maximum operation of the boiler for heating and the remaining power reserve for the DHW service. If this balance is violated, then the system will start to work with subcooling both in the heating system and in the DHW.

For example, an indirect heating boiler Thermex 80, with a volume of 80 liters, will require a boiler power reserve of 14.6 kW at a boiler water temperature of at least 80 C.

The load on the hot water supply is determined by the volume of water use, the practical ratio between the volume of the NBR tank and heat load on DHW:

- 100 l - 16 kW;

- 140 l - 23 kW;

- 200 l - 33 kW.

In order to carry out more accurate calculations, a formula is used that is based on the heat balance:

Vbkn \u003d P x.v (tk - tx.v): (tbkn - tx.v).

Where:

- Vbkn is the estimated capacity of the indirect heating tank;

- P h.v - hourly consumption of hot water;

- tk is the temperature of the boiler heating water from the primary external heating source, usually 90 C;

- th.v. - the temperature of cold water in the pipeline, in summer it is taken 10 C, in winter 5 C;

- t bkn - the temperature of the water heated by the BKN is set by the user from 55 to 65 C.

What material is the container made of?

The BKN tank is usually selected from available materials, usually it is made independently from sheet steel, large-sized pipes, or used liquefied gas cylinders are used.

Sheet steel

Sheet steel

In this case, the masters do not have much choice. When choosing a material for a tank, one must proceed from its durability and strength, since it functions in a highly corrosive environment and under pressure.

In the world, the best indirect heating boilers, presented by European manufacturers, are devices with a glass-ceramic coating. Stainless steel tanks, although more durable, are less popular due to their high cost. In addition, there are budget BKN with a protective layer of enamel, but they have the shortest period of operation.

Coil Sizing Calculation

The calculation of the heating area is the basic one for creating a BNC with the required thermal power. It is determined by the length of the tube in accordance with the formula:

l \u003d P / n * d * DT

In this formula:

- P is the power of the heat exchanger, taken at the rate of 1.5 kW for every 10 liters of tank volume;

- d is the diameter of the coil, usually 0.01 m;

- n is the number of pi;

- l is the estimated length of the coil tube, m;

- DT is the temperature difference at the inlet 10 C and the outlet 65 C. As a rule, it is taken as 55 C.

What material is the heat exchanger made of?

To make a BKN water heater in the form of a coil, take a copper / brass tube D from 10 to 20 mm. It is twisted in a spiral and an interturn gap of 2-5 mm is left. The gap is performed in order to compensate for the thermal expansion of the pipe.

With this version of the spiral, a good contact of the heat carrier with the heating pipe surface is formed. In the distribution network you can find ready-made copper spirals, which can initially be released for process equipment

This is not so important if the dimensions of the coil correspond to the necessary calculations.

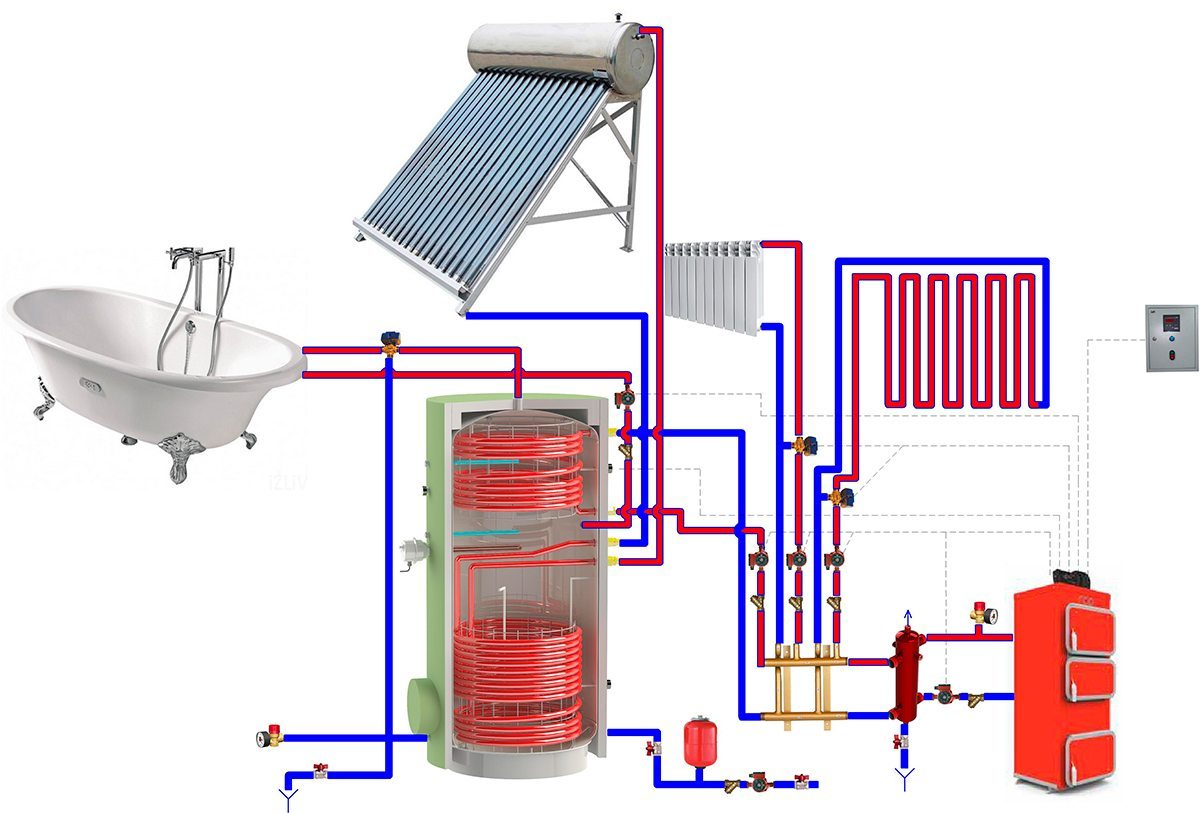

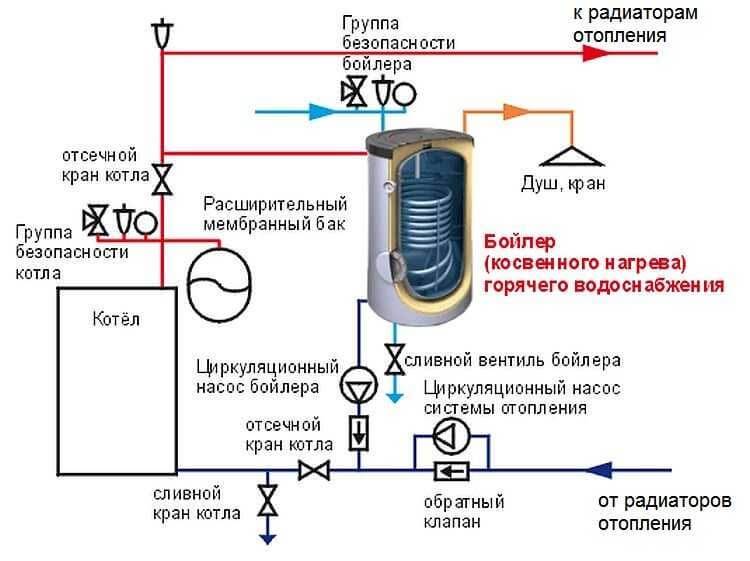

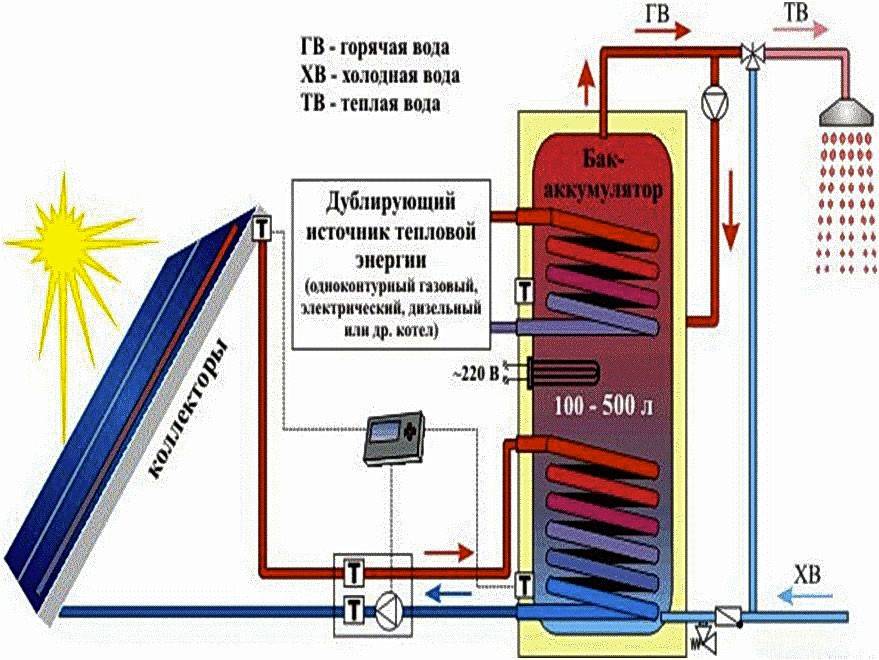

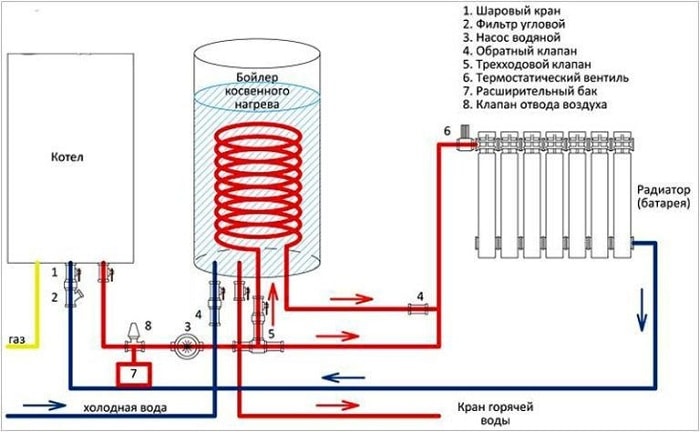

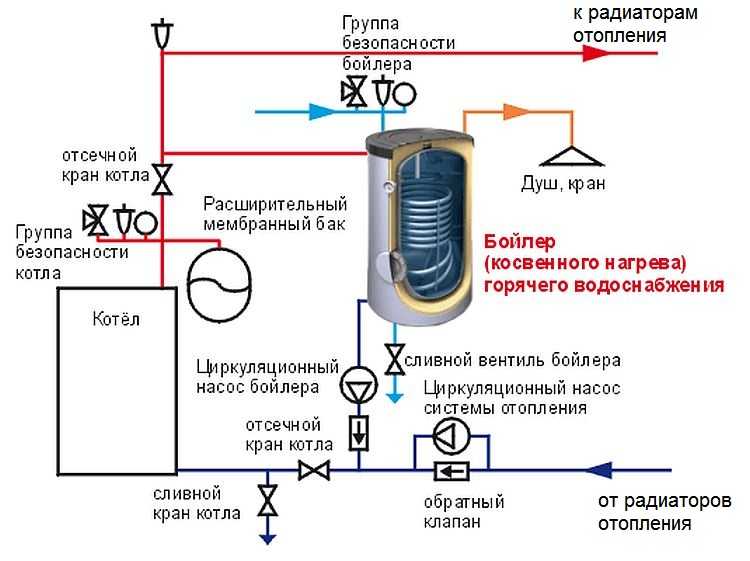

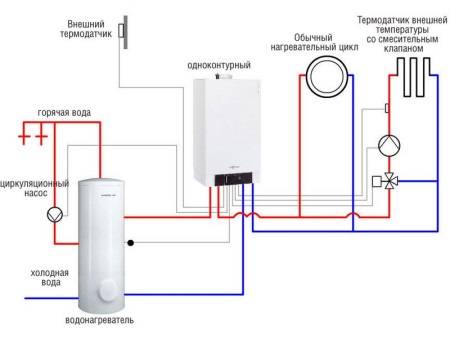

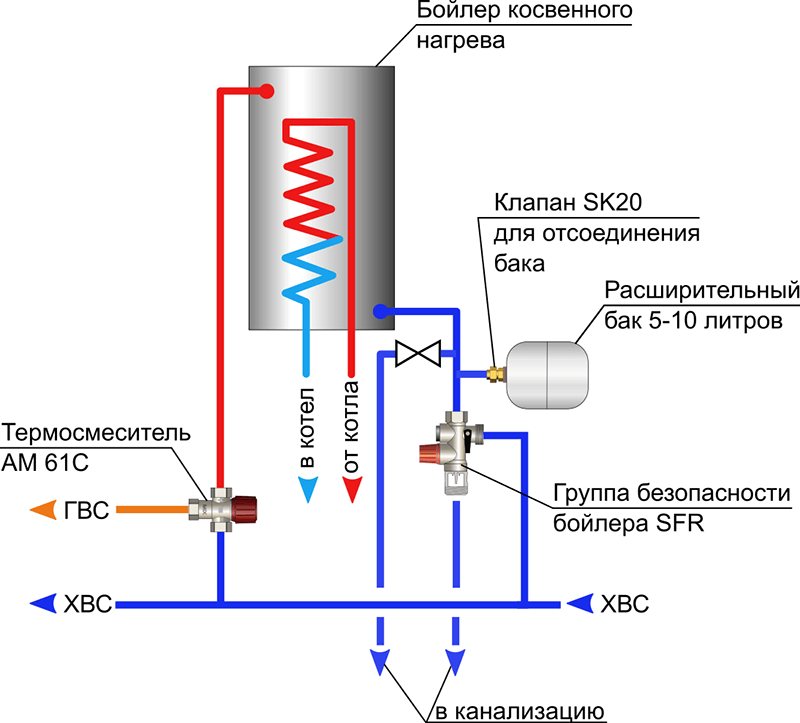

Wiring diagram

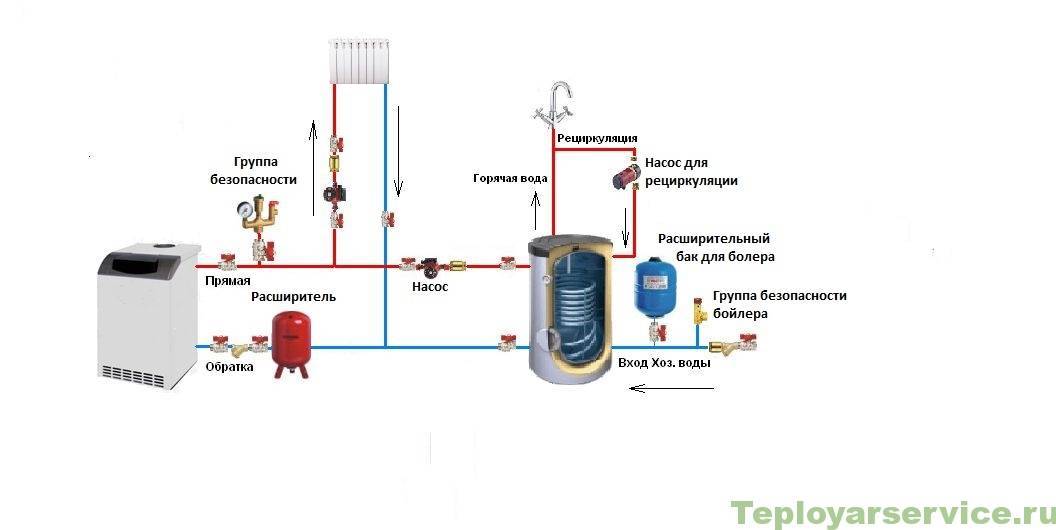

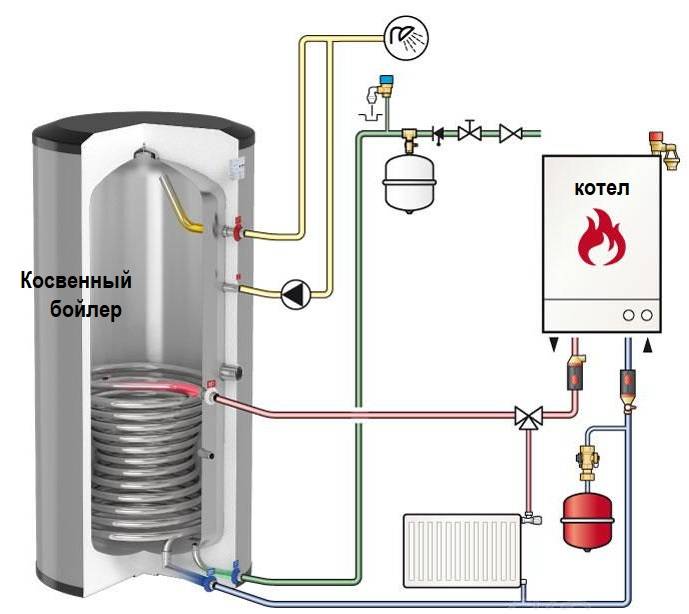

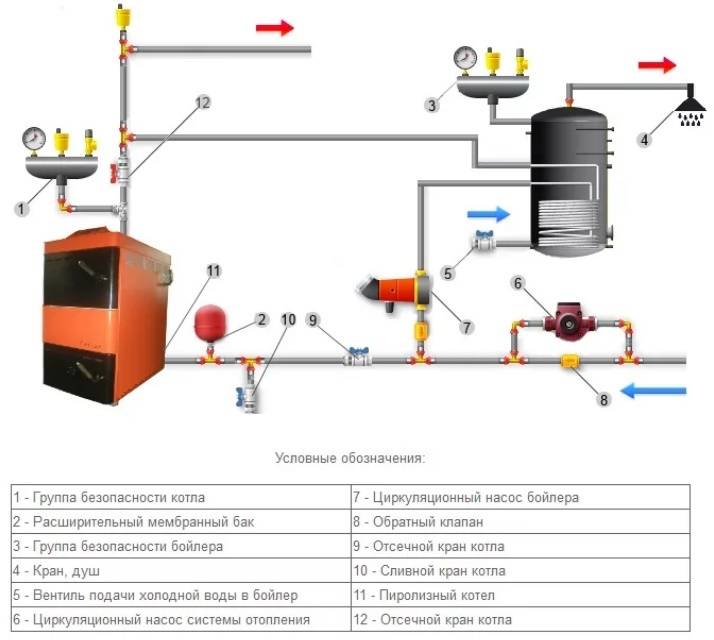

Boiler connection indirect heating to a single-circuit boiler of any type is performed according to the same schemes: with or without priority. In the first case, the coolant, if necessary, changes the direction of movement and stops heating the house, and all the energy of the boiler is directed to heating. This method allows you to quickly heat a large volume of water.

At the same time, the heating of the house is suspended. But the boiler, unlike from double boiler, heats water for a short time and the rooms do not have time to cool down.

Features of connecting an indirect heating boiler depend on the material of the pipes:

- polypropylene;

- metal-plastic;

- steel.

The easiest way is to connect the equipment to polypropylene communications that are not sewn into the walls.In this case, the master will have to cut the pipe, install tees, use couplings to connect the pipes going to the boiler.

To connect to hidden polypropylene communications, it is necessary to additionally install branch pipes leading to pipes in the walls.

There is no technology for hidden installation of a metal-plastic water supply system, so the connection will be identical to the connection of polypropylene open communications.

Properly installed indirect heating boiler

Connecting the boiler in the video:

When installing a water heater, it is necessary first of all to choose the right location in accordance with the requirements:

- Quick access to the connecting links of the water supply for quick repairs.

- Proximity of communications.

- The presence of a solid load-bearing wall for mounting wall models. In this case, the distance from the fasteners to the ceiling should be 15–20 cm.

Water heater placement options

When a place for equipment is found, it is necessary to select a boiler piping scheme. Connection with a three-way valve is very popular. The scheme allows you to connect several heat sources in parallel to one water heater.

With this connection, it is easy to regulate the temperature of the water in the boiler. For this, sensors are installed. When the liquid in the tank cools, they give a signal to the three-way valve, which shuts off the supply of coolant to the heating system and directs it to the boiler. After heating the water, the valve works again, resuming the heating of the house.

When connecting distant water intake points needs to be recycled. This will help keep the temperature of the liquid in the pipes high.When the taps are opened, people will immediately receive hot water.

Connecting a boiler with recirculation

Connecting with recirculation in this video:

Possible mistakes

When connecting an indirect heating boiler, people make several common mistakes:

- The main mistake is the incorrect placement of the water heater in the house. Installed far from a heat source, the device requires laying pipes to it. This leads to an increase in costs. At the same time, the coolant going to the boiler cools down in the pipeline.

- Incorrect connection of the cold water outlet reduces the efficiency of the appliance. It is optimal to place the coolant inlet at the top of the device, and the outlet at the bottom.

To increase the life of the system, it is necessary to properly connect and then perform periodic maintenance of the equipment.

It is important to clean the pump and keep it in good working order. Option for proper placement and connection of the water heater

Option for the correct placement and connection of the water heater

Briefly about the main

An indirect heating boiler is an economical way to organize a hot water system at home. The equipment uses the energy of the heating boiler for heating, this does not lead to additional expenses.

The water heater is a durable equipment, so you should choose a quality installation. Best of all, stainless steel tanks with a brass coil showed themselves. They quickly heat water and are not afraid of corrosion.

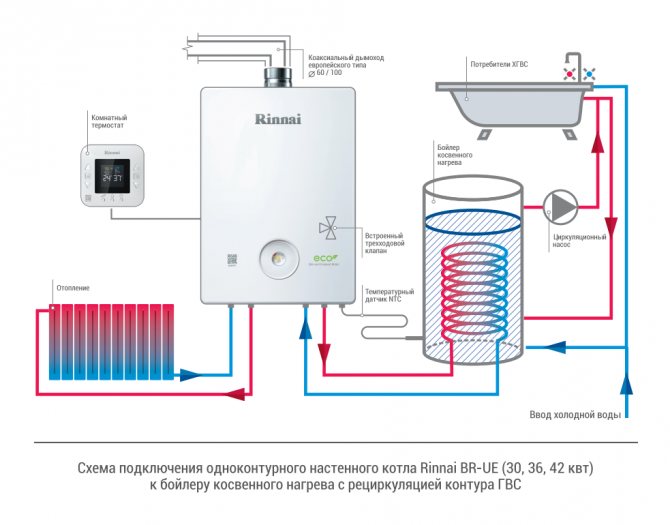

Connecting the boiler to a gas boiler

For the correct functioning of a boiler with a gas boiler, it contains a temperature sensor. In order for them to work together, a three-way valve is connected. The valve regulates the flow between the main circuit and the DHW circuit.

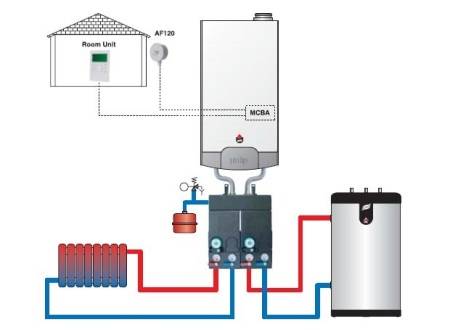

To a single gas boiler

For such a connection, a harness with two pumps is used. It is she who is able to replace the circuit with a three-way sensor. The main thing is to separate the coolant flows. In this case, it would be more correct to say about the synchronous operation of the two circuits.

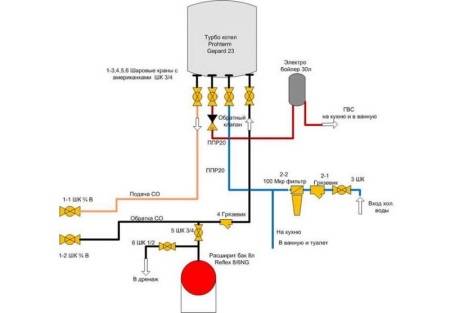

To a double-circuit gas boiler

Main in this the connection diagram will become two magnetic valve. The bottom line is that the boiler is used as a buffer. Cold water enters from the water supply network. The DHW inlet valve is closed. If you open it, then at first water will flow from the buffer, which is the boiler. The buffer contains heated water, the consumption of which is regulated by the capacity of the boiler and the set temperature.

Advantages and disadvantages, the choice of BKN

Boilers of indirect heating have a number of the following advantages:

- Availability of hot water supply;

- Do not require permission to install (unlike a gas boiler);

- Simplicity of device and operation;

- Ability to use different heat sources;

- Possibility of self-manufacturing (if you have the equipment and skills);

- High-quality provision of hot water at any point of water intake (in the case of a recirculation circuit).

The equipment has few drawbacks, but still they are:

- Large overall dimensions and weight of roomy models;

- Dependence on the availability of electricity;

- The initial heating of water takes a certain time, while the power supplied to the heating system is significantly reduced.

In the case of having its own boiler, BKN is clearly considered the best solution for meeting the needs of hot water supply. It is not required to purchase water heaters that have a more complex design, requiring the conditions for installation, the availability of other energy resources - gas or electricity. Compared to most water heating equipment, indirect heating boilers are considered the best in terms of the level and quality of hot water supply.

The choice of the BKN model depends on the following factors:

- Intensity of hot water consumption;

- Manufacturing materials;

- Possibility of integration with heat generators;

- manufacturer's reputation;

- Price.

The main selection criterion is volume and frequency of water consumption. The volume of the BKN tank is usually determined by average indicators hot water consumption:

| Number of persons | BKN tank volume, liters | Note. |

| 1 | 2 | 3 |

| 1 | 50 | |

| 2 | 50 — 80 | |

| 3 | 80 — 100 | |

| 4 | 100 or more | |

| 5 or more | 120 - 150 and more |

An important technical indicator is the power of the heat exchanger. It depends on the rate of water heating. The recommended value is at least 70 - 80% of the nominal power of the heat generator. At lower values, the duration of the initial heating increases, this negatively affects the operation of the heating system.

The service life of the equipment directly depends on the quality of the materials of manufacture. It is recommended to purchase boilers made of materials that are little susceptible to corrosion or with maximum protection against it. Corrosion is the main negative process affecting the integrity of the equipment.

You should also pay attention to the possibility of integration (mutual operation) of a boiler and a boiler from different manufacturers. This possibility is not always available - for joint work, it may be necessary to purchase additional automation and complicate the circuit. An important factor is the reputation of the manufacturer and the cost of the device.

The issue of price depends on the financial capabilities of the buyer. As for the manufacturer, it is recommended to purchase units of reputable brands. BKN have a decent cost - so it would be irrational to purchase a low-quality product

An important factor is the reputation of the manufacturer and the cost of the device. The issue of price depends on the financial capabilities of the buyer. As for the manufacturer, it is recommended to purchase units of reputable brands. BKN have a decent cost - so it would be irrational to purchase a low-quality product.

(Views 791 , 1 today)

We recommend reading:

Operation of the heating system

Water convectors: types, device, principle of operation

Water heated floors

Which radiator is better for heating

Aluminum heating radiators

Underfloor heating system

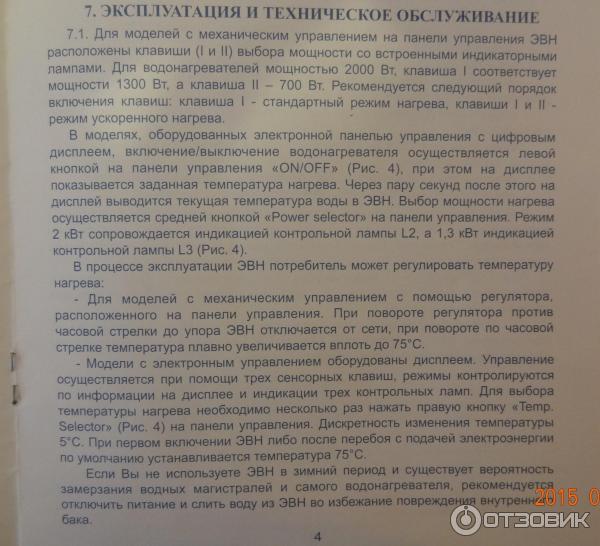

Optimum operating mode of the electric boiler

Setting the temperature to the minimum allowable is highly discouraged for the following reasons:

- Reducing the efficiency of water heating equipment;

- The temperature of the liquid is 30-40⁰ C - an ideal environment for the formation, reproduction of bacteria, mold fungus, which will certainly fall into the water;

- The rate of scale formation increases.

These appliances are often equipped with an economy mode option, denoted by the letter E.This mode of operation means heating the liquid inside the capacitive tank to a temperature of +55⁰ C, which allows you to extend the period of use before maintenance. That is, at this temperature regime, scale is formed the slowest of all, respectively, it is less often necessary to clean the heating element. This does not apply to energy savings.

Storage water heaters

By the principle of operation and structure, they resemble electric types of water heaters. The outer metal case, the inner tank also has a protective coating, only a gas burner acts as an energy source. Such equipment provides for operation on liquefied or main gas, including on a weak flow, does not require connection to the electrical network.

It is worth noting that this type is less popular than its electric competitor. This is due to the high price, large dimensions and the possibility of installation not in all houses. But, according to experts, the high price of such equipment will pay off during its operation, since gas, as a source of energy, is much more economical than electricity.

Depending on the features of the structure, such equipment is divided into two types:

- with a closed combustion chamber;

- with an open combustion chamber.

As well as electric boilers, they can be:

- wall-mounted - from 10 to 100 liters (for example, Ariston SGA series models);

- floor-standing - from 120 liters or more (like Ariston models of the NHRE series).

The gas design also provides a control system with a choice of temperature, equipped with a thermostat to maintain the required temperature, shows how much hot water is left in the tank. Such equipment must be equipped with a security system.

But this is where bandwidth limitations come into play. Already for a water heater with a power of 8 kW, the cross section of the copper wire should be 4 mm, and for aluminum, with the same cross section, the maximum load is 6 kW.

At the same time, in big cities the mains voltage is almost always 220V. In villages, small towns or summer cottages, it often falls much lower. That's where the water heater comes in.

We make a boiler with our own hands

Water heaters with indirect heating can have a wide variety of designs and configurations. Most importantly, they must be made exactly to the calculations, using high quality materials and in accordance with established processing technology, in order to obtain a product capable of operating under conditions of high temperatures and pressure. The production process is divided into several important stages.

Boiler tank preparation

When choosing a tank design, you need to pay attention to how the coil will be wound into the body. If there is a mounting cover in the housing, then there will be no problems for the master with tying the heat exchanger

AT when the container is integral, then you will need to make the cover yourself, cutting off the upper part and fixing it bolted throughout circumference with pre-installed rubber gasket.The most convenient option for installation is considered to be a design that has two covers - top and bottom.

Next, two holes are drilled on the body for the end sections of the coil. The diameter of the holes must be consistent with the thread diameter of the fittings plus 1-2 mm. Fittings are passed into technological holes, with pre-installation of sealing rings.

Further, on the outside of the body, turn the opposite fittings and tighten them strongly. Such a connection gives stability to the coil structure, which is further reinforced with supports inside the casing to prevent vibration and noise during the circulation of the heat exchanger.

Branch pipes for the inlet/outlet of the heated medium and drainage lines are pressed into the vessel body, on which shut-off and safety valves are installed. On the case, the location of the insert for the pointer thermometer is determined.

Manufacturing and processing of the coil

It is not difficult for an experienced craftsman to make a heat exchange coil on his own. In this method, the main condition is to produce high-quality winding.

It is desirable to perform it from pipes with good heat transfer and anti-corrosion properties: copper and stainless steel. Although the latter option is difficult to bend and give the desired shape.

Finished coil

Finished coil

Preferential for these purposes is a copper tube, which bends without preheating the burner. For winding, a drum of the desired material is used with a smaller diameter of the working capacity of the water heater by 8-12%. After winding, coils of pipes are pushed apart between up to 5 mm.

Production and binding of BKN

First of all, a self-made indirect heating boiler is connected to an external source of heating: central heating pipes or to an independent circuit of an autonomous heating boiler unit.

The manufactured spiral is placed inside the housing and tied with the supply coolant. Before closing the housing with a lid, pressurize the heating circuit. To do this, start the circulation of the coolant by opening the valve on the supply and return and carefully inspect the coil for leaks.

BKN piping scheme

BKN piping scheme

Further, according to the scheme, the structure is tied with the DHW line through the shut-off and control valves. According to the scheme, the tank is connected with cold water supply, hot water outlet with an internal hot water pipeline going to mixers and drainage lines, for draining water during repairs and maintenance. A thermometer and a pressure gauge are mounted at the outlet of the BNS so that the parameters of the heated water can be controlled.

If the tank has an automatic control and protection system, install primary temperature sensors and pressure to protect the BKN from high heating parameters.

thermal insulation

In order to reduce heat losses from the BKN and provide it with accumulative thermal properties, external thermal insulation of the structure is performed.

The heat insulator is fixed using mounting glue, wire ties or otherwise. It is of great importance that the case is completely protected, since the efficiency of the system will depend on the quality of the thermal insulation, and how long the tank can store hot water.

Very often, in practice, thermal insulation is performed using a second tank of larger diameter, into which a working container is inserted, and the space between them is filled with insulation.