- Advantages and disadvantages

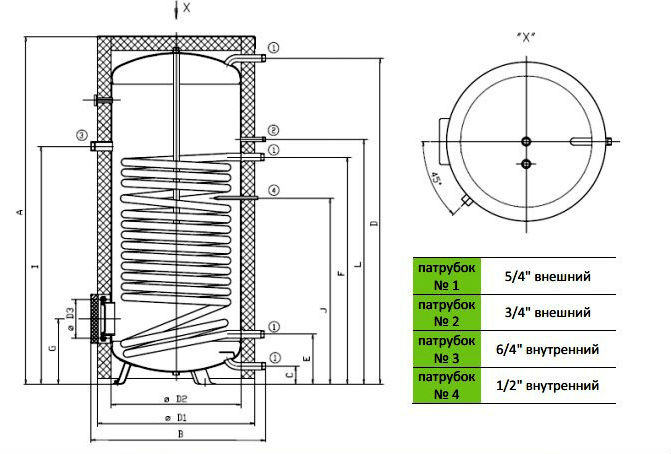

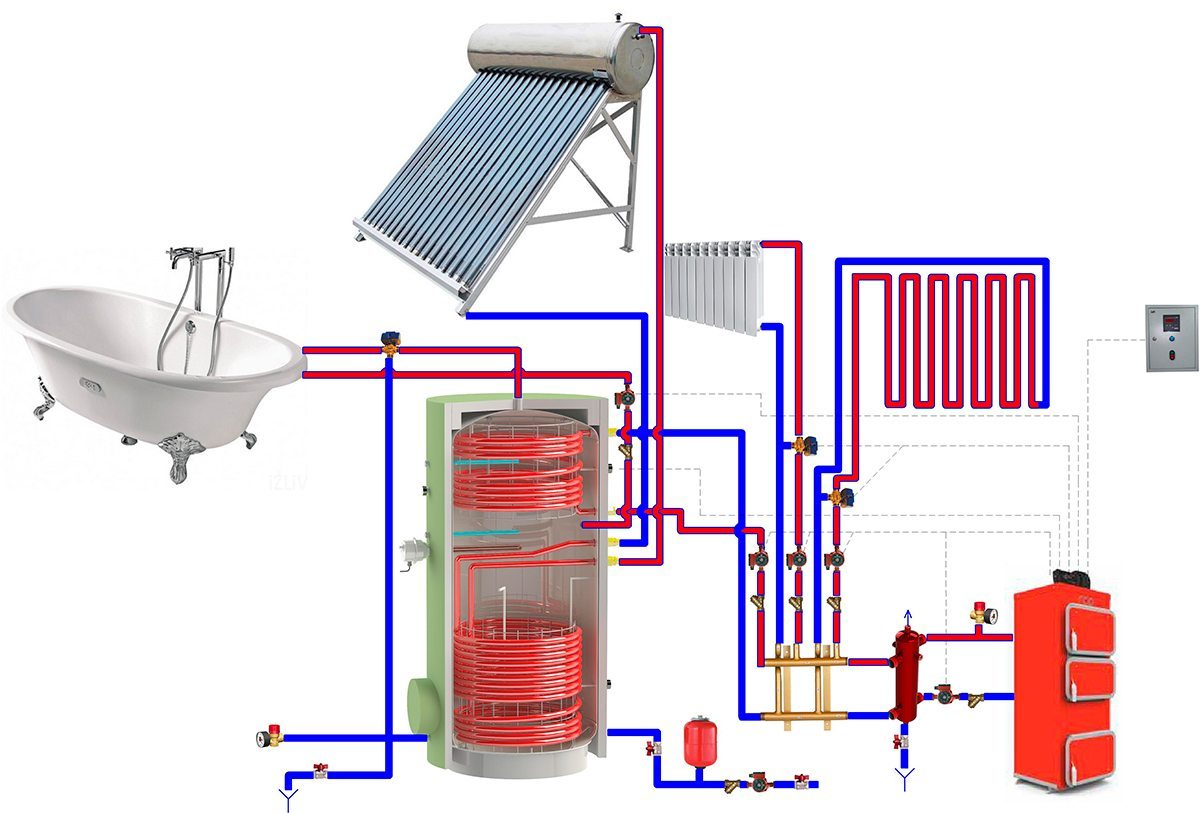

- Connection diagrams for indirect heating tanks Drazice

- About Drazice

- Unique technologies

- Types of Drazice boilers

- Types of breakdowns of Drazice boilers

- Popular Models

- Boiler Drazice OKC 200 NTR

- Boiler Drazice OKC 300 NTR/BP

- Boiler Dražice OKC 125 NTR/Z

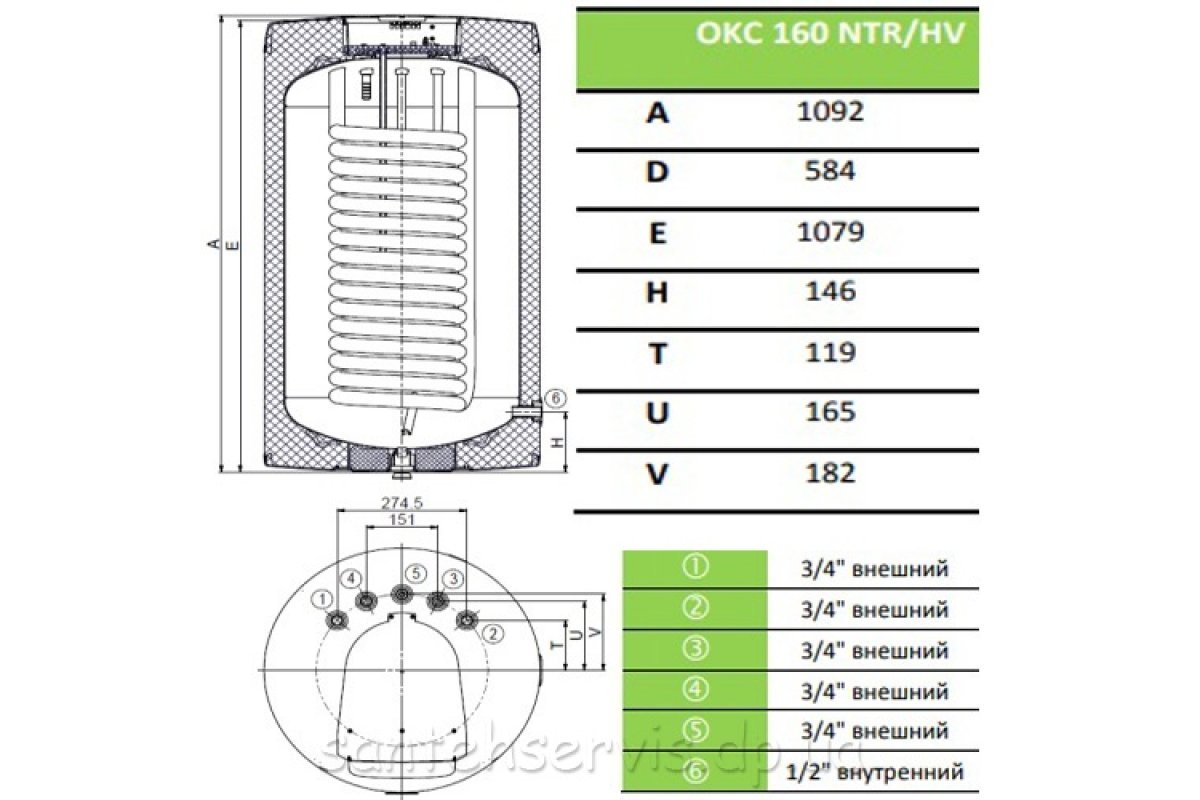

- Boiler Dražice OKC 160 NTR/HV

- Mounting

- Description of the model range

- The best models with a heat exchanger

- Baxi Premier Plus–150

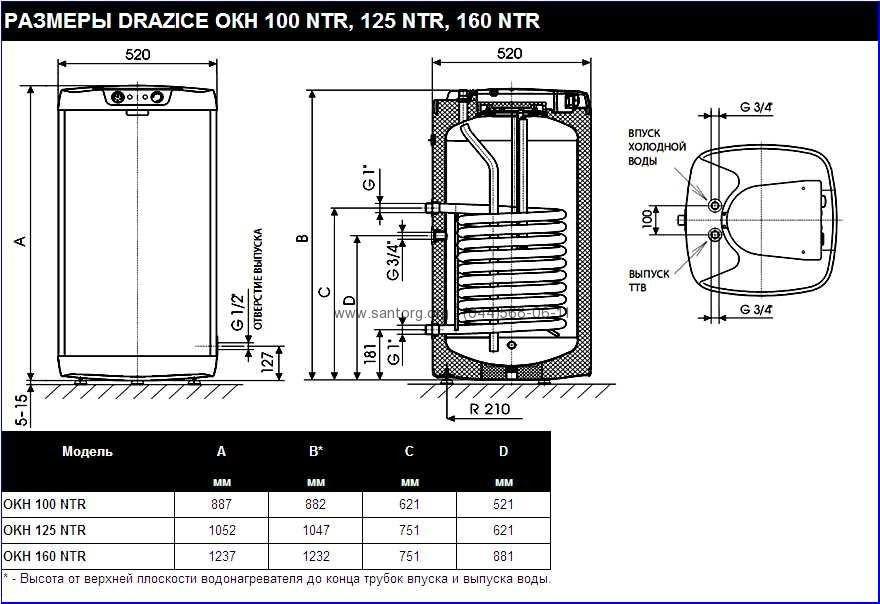

- Drazice OKC 125 NTR

- Gorenje GV 120

- Protherm FE 200/6 BM

- Bosch WSTB 160-C

- Selection Options

- Volume of the tank

- Heat exchanger device

- The presence of heating elements

- tank material

- Operating pressure

- Technical description of the water heater Drazice OKC 200 NTR

Advantages and disadvantages

Any hot water system is not without flaws. Absolutely perfect equipment does not exist in nature. To the credit of DRAZICE, its indirect heating boilers have practically no drawbacks, on the contrary, if you analyze customer reviews, the system is almost perfect. However, we managed to find a fly in the ointment in this barrel of honey, but let's start traditionally with sweets.

Advantages:

Saving. The cost of a cubic meter of cold water is much lower than hot water. At the same time, indirect heating boilers do not require the connection of additional power sources and heating elements.

Benefit.Thanks to such a system, it is possible to provide the family with a large volume of hot water in a relatively short time - the capacity of devices for continuous heating of water varies within 10-200 liters.

Practicality. The coolant for such a system can be obtained from any external source.

Safety. The coolant is reliably protected from contact with water. In addition, the system is reliably protected from overheating and short circuits.

Convenience. The boiler provides water return to several points of selection while maintaining a stable temperature. In comparison, storage water heaters usually cannot handle such a load. If one person takes a shower, and another opens the faucet in the kitchen, the first person will most likely be doused with a stream of ice water or boiling water.

Flaws:

The cost is usually higher than any similar equipment.

It takes quite a long time to heat the water in the tank. In this regard, storage water heaters with built-in heating elements look more advantageous.

Problems with connection in the summer. At this time, the heating systems are turned off, so there are problems with the coolant intake. The problem is solved by using built-in heating elements, which eliminates the savings advantage.

In addition, for the efficient operation of the system, the boiler must be installed in close proximity to the source of the coolant. Considering that the equipment has impressive dimensions, this can be difficult to do. For example, when connecting a boiler to a gas boiler in a private house, a separate technical room will be required.

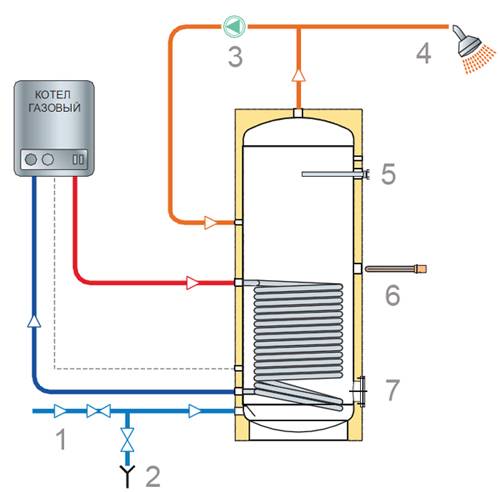

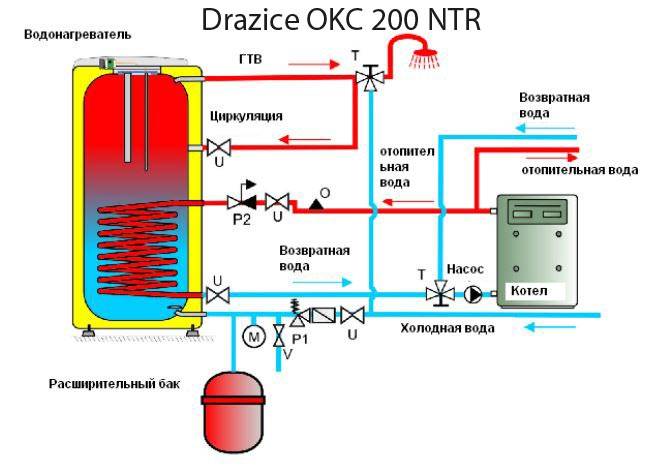

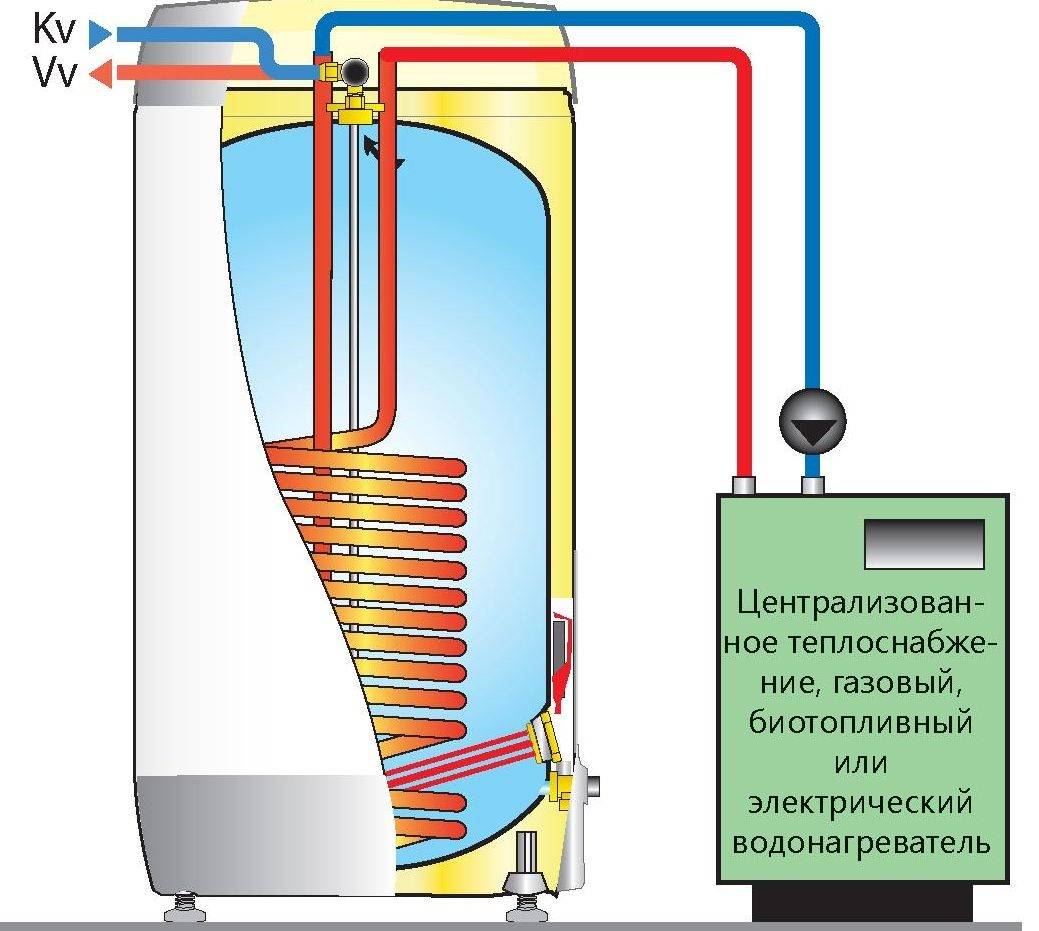

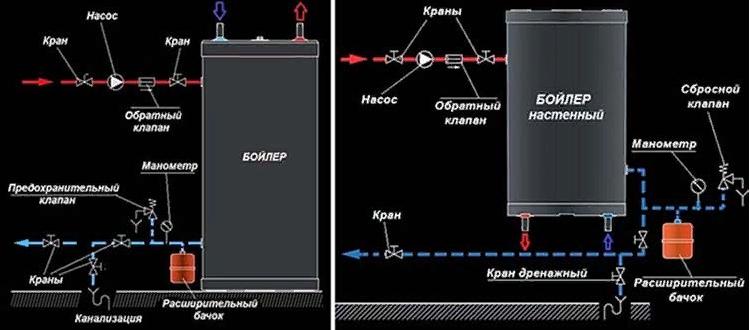

Connection diagrams for indirect heating tanks Drazice

Basics:

- The first stage is the connection of cold water:

- Through the bottom entrance to the supply line.

- Wiring is connected to the upper branch pipe to the points of water intake.

- The second stage - to the coolant:

A special option is a scheme with a 3-way valve, an automatic two-circuit system is created:

- Main heating.

- BKN outline.

Equipment operation with three way valve: the node controls the system according to the thermostat commands. The thermostat device allows you to set values for the heating element operation algorithm. When t° drops in the hot water supply to the set minimum on the device, the controller is triggered, the hot flow is redirected to the coil. When fixing the set values, the device acts in reverse - the coolant flows to its source.

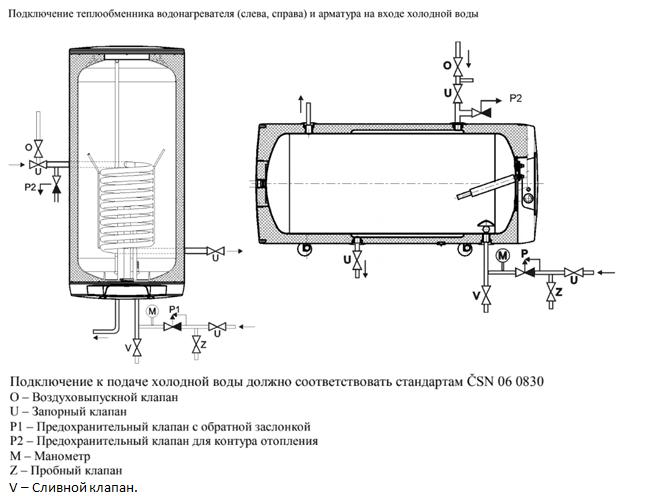

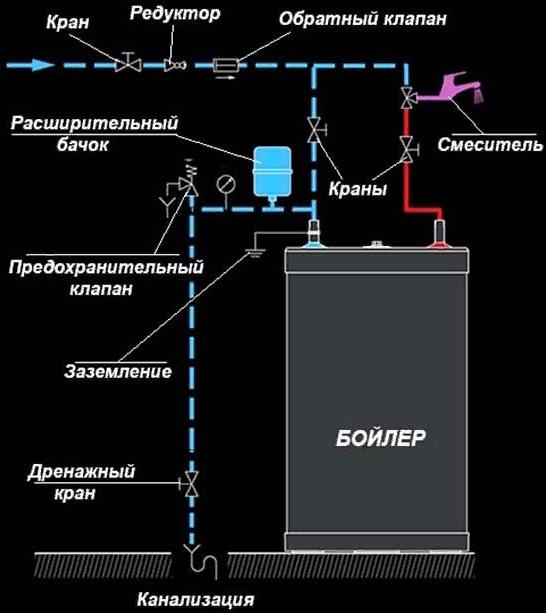

A complete scheme for installing an indirect heating boiler Dražice to a heating and water supply system:

At the inlet / outlet of the coolant put cut-off valve for dismantling the boiler. All such nodes are located closer to the BKN to reduce heat losses. Installing a filter in the circuit (pre-washed) is mandatory to protect against system clogging. Thermal insulation of all lines is important. When connecting to the water supply, a drain valve must be installed, and a safety valve (on the branch) is mandatory in all cases.

Scheme of connecting the indirect heating tank Drazice with recirculation to solid fuel boiler (shut-off valves are not shown, but they are required to turn off the water heater before maintenance):

When connecting a tank with a belt jacket, an expansion tank and safety units at the coolant outlet are recommended, since the DHW tank expands / contracts.

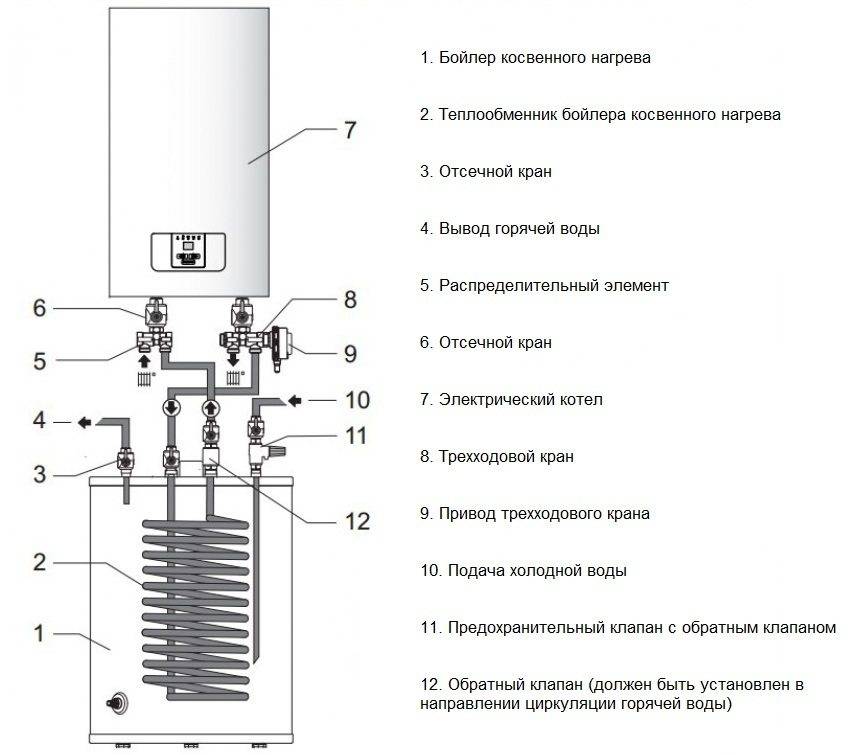

The easiest way is to tie the BKN with mounted boilers with a special fitting. Other heat generators are connected to the tank through a three-way switch, which is switched by an electric drive, controlled by the boiler thermostat.

Drazice boiler piping diagram with 3-way valve for boilers with 2 circuits:

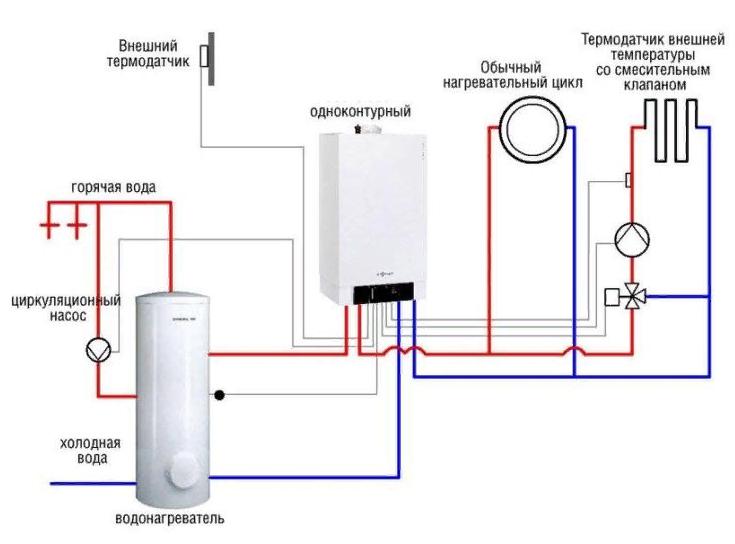

Scheme of connecting the indirect heating tank Dražice to a single-circuit boiler:

It is also appropriate to connect with a pair of pumps: the flows will go along two lines. The first place is occupied by the warm water circuit. Under the scheme, the BKN is set up in conjunction with a single-circuit boiler. Multi-temperature flows do not change the characteristics, since check valves are placed in front of the pumps. Hot liquid is supplied only by the boiler.

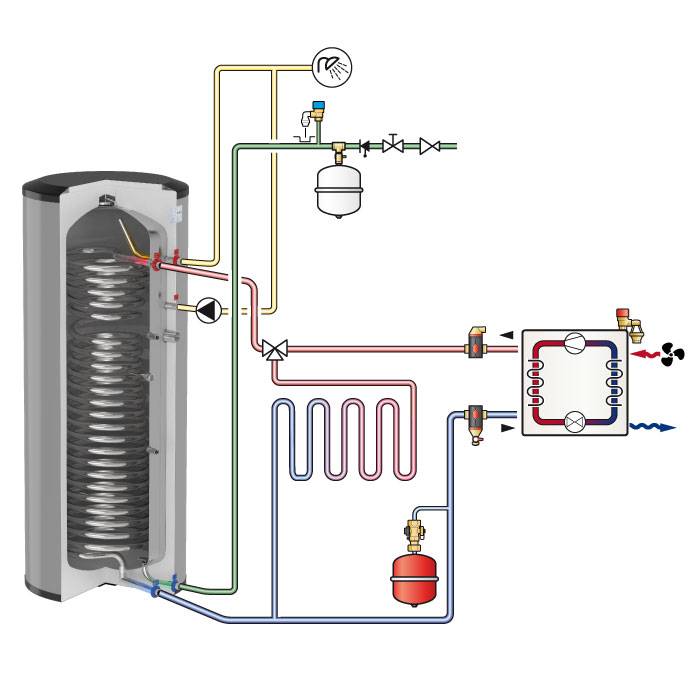

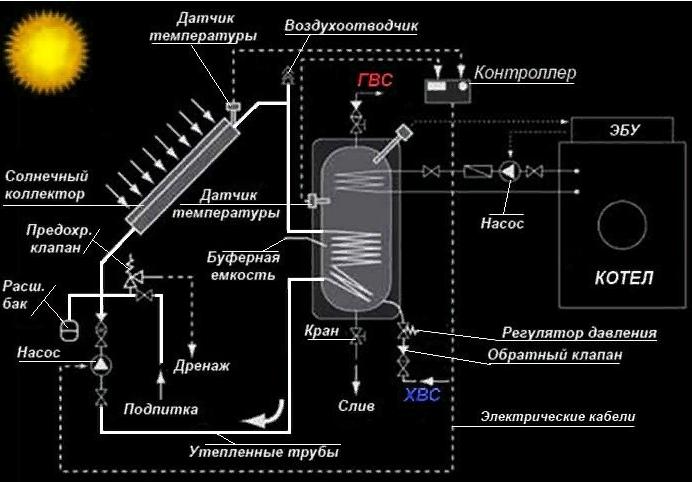

Connecting with solar energy to the second coil of the water heater creates a complete closed cycle with hydroaccumulator, pump and safety units. A separate control unit for manifold sensors is required.

Connection on the water supply side if the dismantling devices are close. The drain pipe is left filled so that when the drain is opened, the liquid flows out. The piping includes an expander (6 - 8 bar), of the same size as for water supply.

When consumers are at a distance, they make a recirculation pipeline with a pump, a check valve. If the BKN is without a fitting for connection, then a return pipe is cut in at the cold inlet.

Connecting to the electrical network is a separate stage, the standard scheme is as follows:

About Drazice

The history of the Czech company begins in 1900, and the production of water heating systems of various types and volumes was established half a century ago. The company's products are exported to dozens of countries around the world, it is well known outside of Europe. Drazice consistently occupies one of the first places in the ranking of water heater manufacturers.

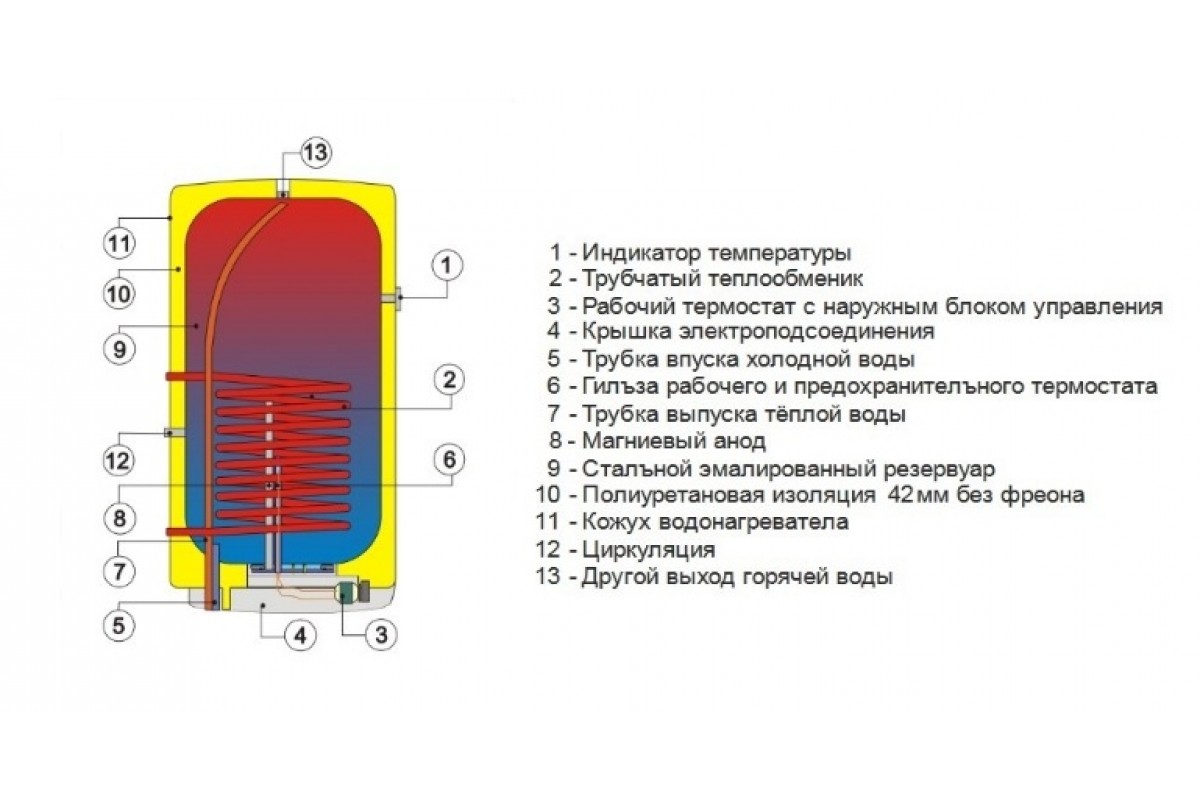

Unique technologies

Czech boilers - energy-saving technologies, the best materials and strict quality control. But their main advantage is the fuel cell system.Instead of a heating element immersed in water, a dry ceramic tube is used, placed in a metal sleeve, made of the same steel as the tank. Since the materials are the same, there is no galvanic reaction, which means that corrosion is defeated.

Ceramics is extremely resistant to aggressive water environment, so Czech heaters are very durable. If scale and deposits are removed periodically, operating costs can be reduced. The magnesium anode, which prevents corrosion, also helps to extend the life of the tank. The devices are equipped with service hatches - for comfortable maintenance work.

All products are designed and manufactured in the Czech Republic.

Types of Drazice boilers

Design features of heaters:

- control and selection of temperature in the range of 5-77 °С;

- auto protection against freezing and overheating;

- minimal heat loss.

The company manufactures water heaters:

- Indirect heating - 100-1000 l.

- Combined - 80-200 liters.

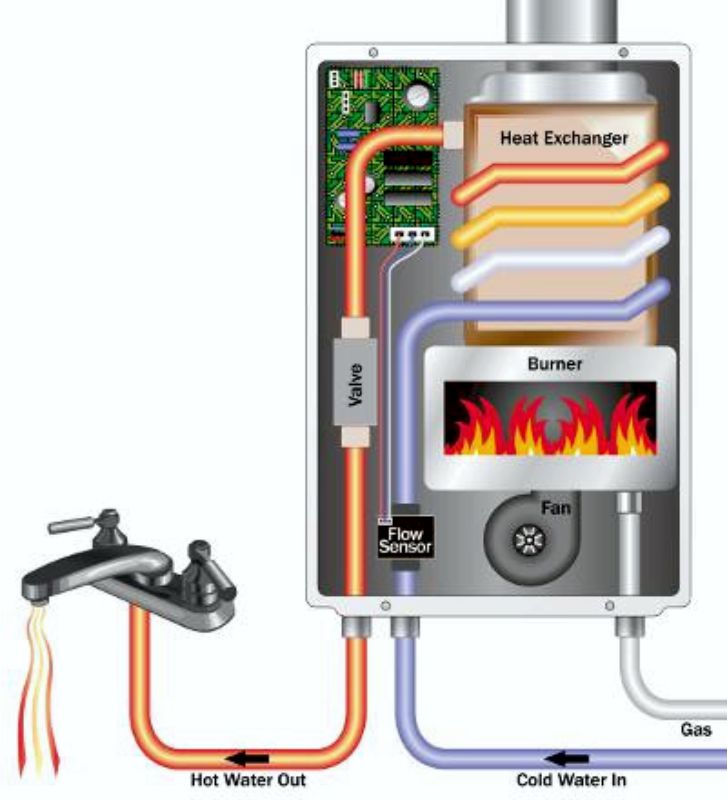

Boilers of indirect and combined heating - what is the difference?

Such heaters, in fact, are storage devices, inside which a liquid circulates, heated by a boiler or other heat source. To connect the device to the boiler, a special pipeline is used, and the circulation of the coolant is maintained using pumps and mixers.

Pros:

- no need to spend money on heating the coolant;

- high efficiency;

- power grids are not loaded;

- stable volumes of hot water - even if there are several points of water intake.

The main disadvantage of indirect heaters, which confuses many consumers, is the binding to the heating unit. It turns out that in order to heat the water, you need to turn on the heating even in warm weather

If this heating principle does not suit you, pay attention to combined type boilers

The fundamental difference between combined heaters is that in addition to the tubular heat exchanger, they have an electric heating element. The device can heat water autonomously, even if the heating system is turned off.

Types of breakdowns of Drazice boilers

Heating element with scale

Heating element with scale

Even the most reliable water heaters need care and maintenance. The bottom line is to flush the tank, replace the magnesium anode and heating element, remove scale. Czech technology has been uninterrupted for up to 15 years if the strapping is done correctly. But sometimes unexpected breakdowns occur, in which case it is necessary to contact the official service center.

The main types of breakdowns of Drazice boilers include:

- malfunction or leakage of the tank;

- failure of the heating element;

- slow heating or no heating.

Tank leakage is a problem with all storage water heaters. The inner surface of the tank is constantly in contact with water, so sooner or later traces of use and corrosion will appear. Long-term use is reflected in the welds, they can leak, sometimes holes are formed. In this case, the tank is beyond repair. But if a leak is detected from the bottom of the water heater, the malfunction lies in the depressurization of the internal container. The installer will change the gasket and the machine can be used again.

The cause of a boiler failure is often the formation of scale on the heating element or a malfunction of its electrical component. If the thermostat fails, the part must be completely replaced. Sometimes the heating element fails due to improper connection of the water heater. Therefore, the binding of the device must be carried out by an experienced installer.

If the device heats water slowly or does not do so at all, it is necessary to check all boiler automation. The reasons may be:

- breakdown of the thermostat or safety valve;

- defective electronic unit;

- the heating element switch has failed.

If the inspection of the boiler shows that the power indicator is off, you will have to call a repairman. Without the help of technicians, the problem cannot be fixed.

Popular Models

Let's see which models of indirect heating boilers from Drazice are valued by Russian buyers. We will touch on both the most expensive samples and simple ones - of a limited volume.

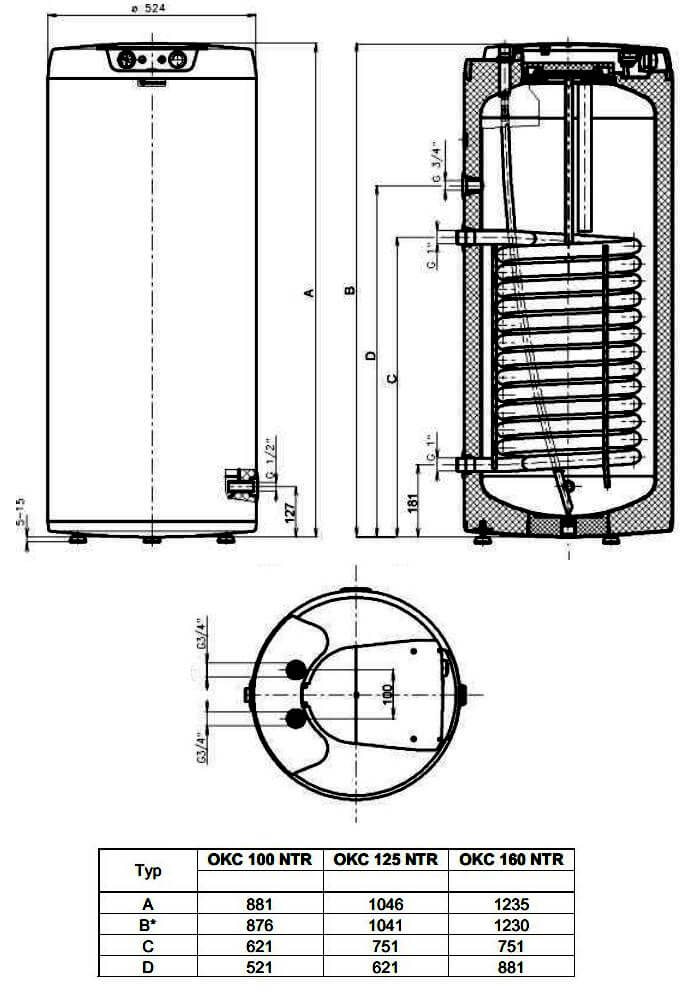

Boiler Drazice OKC 200 NTR

Before us is one of the most popular models in Russia. Its enameled tank holds 208 liters of water. Indirect heating is carried out using two heat exchangers with an area of 1.45 square meters. m. Such an impressive area made it possible to achieve a thermal power of 32 kW. The water in the tank can be heated to a temperature of +90 degrees. The supply of pipes from the heating system is carried out from the side, the boiler itself is oriented to the floor installation.

This boiler is distinguished by a minimum time for heating water - after all, it is indirect. The time to reach a temperature of +60 degrees from a mark of +10 degrees is only 14 minutes. However, such a high performance is typical for almost all indirect units. The working pressure in the tank can reach 0.6 MPa, in the heat exchangers - 0.4 MPa. The weight of the water heater excluding water is about 100 kg. Estimated price - 25-28 thousand rubles.

An analogue of this boiler is the Drazice OKC 160 NTR model, which has a similar design (there is one heat exchanger) and a volume of 160 liters.

Boiler Drazice OKC 300 NTR/BP

Quite an impressive indirect heating water heater, designed for a large number of household consumers or for commercial use. For example, it can be installed in a large cottage with two bathrooms. The device will be able to easily fill two bathtubs with hot water, plus it will remain for the rest of the residents. If someone does not have enough water, there is nothing to worry about - literally in 20-25 minutes the next portion will be ready (and this is as much as 296 liters).

Device features:

- Built-in circulation pump control system.

- Possibility of installing an electric heater (in addition to indirect heating).

- Large area spiral heat exchanger.

- Corrosion protection - enamel and magnesium anode.

- Water heating temperature - up to +90 degrees.

- Lots of positive feedback from buyers.

- Overpressure protection.

The estimated cost of the device is 45 thousand rubles.

Boiler Dražice OKC 125 NTR/Z

Before us is an indirect heating boiler Drazice, designed for wall mounting. Its capacity is only 120 liters, but given the rapid heating, this is more than enough. The main scope of application is household. The device can heat water up to +80 degrees, temperature control is carried out using a thermometer located on the front panel of the case in the upper part. All connections are made from the bottom side, here are the controls and indications.

Boiler Dražice OKC 160 NTR/HV

Inexpensive, floor-standing, with top piping - this is how we can characterize the Dražice boiler for 160 liters. Before us is a model of exclusively indirect heating, without the possibility of installing a heating element to work during periods of heating shutdown.However, in the warm season it is enough to turn off the heating system, leaving the circulation exclusively to the water heater itself - this is quite realistic and very economical (gas costs a little more than electricity, but it gives 4-5 times more heat).

This boiler is made in a floor form factor and is equipped with a simple enameled tank. An additional stage of corrosion protection, in addition to enamel, is implemented by a magnesium anode. The heat exchanger is made of stainless steel, which makes it more durable. Responsible for indirect heating, it has a power of 32 kW. This ensures reaching a temperature of +60 degrees in just 10-15 minutes. The cost of the device is about 25 thousand rubles.

Mounting

To install the indirect heating boiler Dražice, we need the following tools: puncher, tape measure, level, adjustable wrench, pliers and screwdrivers. From the materials you will need anchors, metal-plastic pipes, flexible hoses, clips, tees and sealing tape or tow. Also, when connecting, you will need a three-way valve or a circulation pump, depending on the selected scheme.

Circulation pump

Circulation pump

Before installing a hinged boiler, the strength of the wall is checked. It must be brick or concrete. If the wall is made of more fragile materials such as gypsum, it must be reinforced with reinforcement. It is most convenient to locate the water heater near the boiler in order to further simplify its connection.

Mounting points on the wall are marked, holes are drilled. It is necessary to buy an anchor or a dowel with self-tapping screws in advance, since the fasteners are not included in the delivery of the Dražice water heater. Depending on the volume, the section and length of the fasteners are selected.For devices up to 100 l, anchors with a diameter and length of 6-10 mm are suitable, over 100 l 12-14 mm. Fasteners are screwed into the holes and the boiler is hung.

If the model is vertical, it is installed at a height of at least 600 mm from the floor; if it is horizontal, the right end should be at a distance of more than 600 m from the opposite wall.

Boiler Drazice 100l

Boiler Drazice 100l

This is necessary for unhindered access to the nodes during connection, further maintenance and repair. Also, you can not hang the boiler close to the ceiling, ten centimeters are left in order to hang it on hooks.

Floor models are simply placed in a convenient place. If the floor is wooden, it is recommended to make a concrete foundation for the apparatus. The process of how to properly mount the boiler, and additional recommendations for installing a specific model are written in the instruction manual.

Description of the model range

All types of tanks are made and assembled in the Czech Republic, which confirms the high quality. There are combined devices for heating from electricity and heating systems that operate from only one source, boilers with two spiral exchangers. To purchase a suitable option, you need to consider the features of several series:

1. Drazice OKCV, combined type OKC (80-200L).

These are hinged structures with a steel tank covered with enamel. Equipped with a water outlet tube, temperature indicator, safety thermostat. Thermal insulation made of 40 mm thick polyurethane does not contain freon, the inner surface is covered with high-quality nickel-free enamel. The service hatch allows you to carry out preventive maintenance to remove scale and sediment.

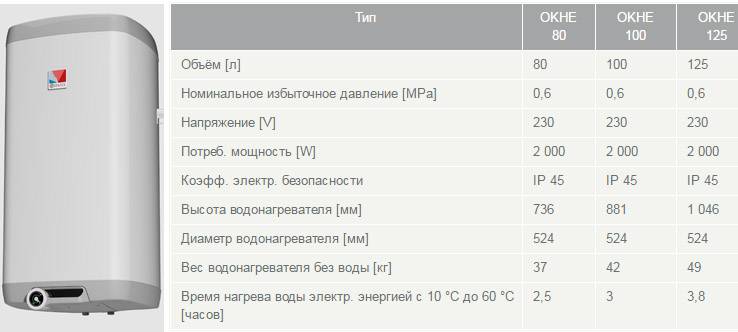

This series of Drazice combined boilers includes OKCV 125, 160, 180, 200 NTR brands.Tank volume 75-147 l, working pressure - 0.6-1 MPa. Power consumption - 2 kW. The maximum temperature is 80 °C, the heating time is 2.5-5 hours. Models Drazice OKC 80, 100, 125, 160, NTR / Z are designed for vertical mounting, according to reviews they are very productive, almost all types have a dry ceramic thermocouple and circulation. Volume - 175-195 l, power consumption - 2.5-9 kW. Heating time - 5 hours, with a heat exchanger - 25-40 minutes.

2. OKCE NTR/BP, S dragice with indirect heating.

Boilers manufactured by Drazice for 160-200 liters of storage type. Suitable for technical and household needs with a given volume. They operate from boilers with solid and liquid fuels, gas equipment and alternative energy sources. The model can be purchased complete with auxiliary thermocouples built into the flange. The body is finished with white powder-based paint, thermal insulation is optional and needs to be installed by yourself.

Boilers OKCE 100-300 S/3 are designed for a power of 2.506 kW. The volume of the tank is 160-300 liters, the maximum pressure is 0.6 MPa, and the temperature is 80 °C. The heating time takes from 3 to 8.5 hours. Drazice OKCE 100-250 NTR/BP have integral or side flange. They can work with a volume of water from 95 to 125 liters at a pressure of 0.6-1 MPa. The power of the lower and upper exchanger is 24-32 kW. The maximum water temperature is 110 °C. Network security factor IP44.

3. Electrical types.

Dražice water heaters are accumulative, designed for wall mounting. Due to the fact that the distance between the fasteners has not changed throughout the history of the company, it will not be difficult to replace the old equipment with a more advanced one.The activity is carried out with the help of a ceramic element, which is controlled by a thermostat. A fuse is installed for safety. Parts can be replaced without breaking the tightness, thanks to the service hatch.

Drazice OKHE 80-160 are equipped with a dry heating element, an adjusting screw, reinforced thermal insulation 55 mm thick, which protects against resource loss. Tank volume - 80-152 l, nominal overpressure - 0.6 MPa. Power consumption - 2 kW, the time of heating water from electricity is 2-5 hours.

4. Boilers powered by a heating system.

This series includes Drazice OKC 200 NTR, OKCV NTR. Suitable for the preparation of hot water from the carrier or with the help of solar systems. This hinged vertical or horizontal floor equipment of a round form. The tank is closed with a steel casing treated with white lacquer. Heat loss is reduced by a 40 mm thick polyurethane layer. Equipped with magnesium anodes, tubular exchanger, thermometer, service hatch. In the configuration of the OKS, the insulation is supplied separately, it is mounted independently. All models have their own circulation. The volume of tanks is from 150 to 245 liters in the first version and 300-1000 liters in Drazice OKCV. The water heating temperature is 80-100 °C, the power of the elements is 32-48 kW. Working pressure - 1-1.6 MPa.

5. Boilers with two spiral heat exchangers.

Boilers from Drazice Solar, Solar Set, OKC NTRR are used for solar collectors. The system is controlled by a special controller that activates or deactivates the pump, depending on temperature fluctuations between the solar system and the hot water tank. Additional heating is carried out using an electric thermoelement or a top-type heat exchanger.

The best models with a heat exchanger

You can use such boilers only in winter, as the water will be heated only from the boiler. But you will not spend a penny of extra money, because there will be no additional costs for electricity.

Baxi Premier Plus–150

This model is one of the recognized leaders among water heating equipment. Quality and reliability are guaranteed by a well-known Italian manufacturer. Despite the rather high price, the device confidently occupies a leading position. After all, the quality of components and assembly is not satisfactory.

The internal tank of the unit is made of stainless steel and has a volume of 150 liters. Coil-in-coil technology is provided to ensure fast and smooth heating. An additional heat-insulating layer of foamed polyurethane will minimize heat loss.

Main advantages:

- possibility of floor or wall installation;

- fast heating to the desired temperature;

- if necessary, it is possible to equip with a heating element;

- it is possible to connect to the circuit of the recirculation system;

- high mounting characteristics, compatibility with many types of boilers.

Bad moments:

- rather high cost;

- The temperature sensor is not compatible with all boilers.

Drazice OKC 125 NTR

A proven and unpretentious representative from a Czech manufacturer. Superbly proved itself in Russian realities. The water heater can be connected to a gas or solid fuel boiler. Thanks to a specially designed circulation system, water is heated in a very short time.

Pros:

- not too demanding on the parameters of the coolant;

- high quality performance;

- affordable cost.

Minuses:

- designed for use under pressure not higher than 6 atmospheres, therefore it is not very suitable for installation in apartments (from central heating);

- enameled tank has insufficient corrosion resistance.

Gorenje GV 120

Excellent budget model. Equipped with a 120-liter tank made of enamelled steel. Heating is pretty fast.

Advantages:

- very attractive price;

- possibility of floor or wall installation;

- the possibility of combining with a boiler of any type;

- full compatibility with central heating.

Flaws:

- tank with enamel coating;

- the presence of only the upper wiring, and this is not always acceptable.

Protherm FE 200/6 BM

A high-quality indirect heating boiler from a Slovak manufacturer. Perfectly compatible with many types of boilers. The tank is 184 liters, which is quite enough for a family of several people. In order to reduce the formation of corrosive spots and scale, the design uses a titanium anode. Rapid heating of water is due to the lower location of the tubular heat exchanger.

To eliminate the consequences of water overheating, the water heater is equipped with an additional protection system. Provided additional thermal insulation by means of a polyurethane "fur coat".

Pros:

- tank with antibacterial coating;

- the ability to quickly drain through a special fitting;

- a temperature sensor that allows you to adjust the temperature of water heating;

- quality assembly;

- the price tag is unbelievable.

Minuses:

- there is no possibility of additional installation of heating elements;

- quite a lot of weight.

Bosch WSTB 160-C

Excellent German quality at the best price. The model has a tank with a volume of 156 liters and can be mounted on the floor under a wall-mounted boiler.The steel tank has a high-quality enamel coating for rust protection. Installed water heating sensors and frost protection. Can heat water up to 95 C.

Advantages:

- light weight and small size;

- magnesium anode to prevent corrosion;

- maximum heating time 37 minutes;

- affordable price.

Flaws:

no negative reviews found.

Selection Options

Before talking about which indirect heating boiler is better to buy, let's look at some points that you should pay attention to.

Volume of the tank

First of all, this parameter depends on which heating boiler will be connected to the common circuit.

In addition, it is worth paying attention to the daily needs for hot water. An incorrectly calculated parameter can lead to the fact that it will simply be impossible to use hot water at several water points at the same time

In order not to lack hot water, each family member should have about 70-80 liters of tank volume. This will allow not only to wash dishes, but also to take a bath without thinking that the water temperature may be uncomfortable. Of course, the power of the boiler must also correspond to the calculated parameters.

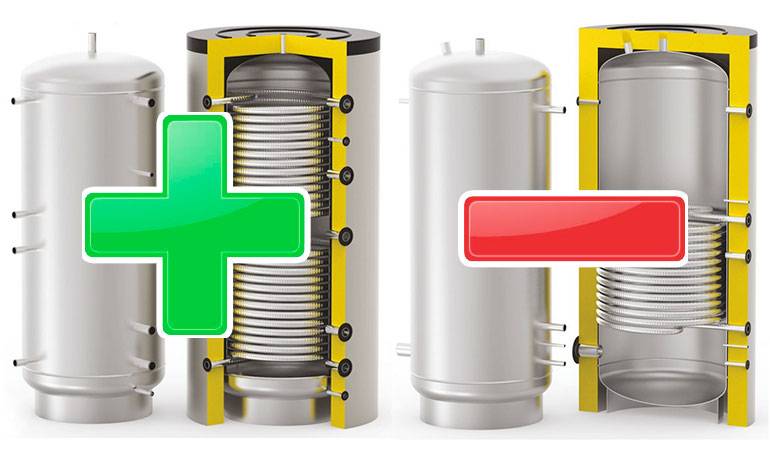

Heat exchanger device

There are two versions:

Two tanks placed one inside the other. The inside is filled with water. And a coolant circulates through the outer contour space, providing heating.

Coil system. The standard version uses one coil. However, there are models where two similar elements are present. Thus, the boiler can be connected to an alternative source of thermal energy.

The presence of heating elements

This is worth paying attention to if you want to use hot water not only during the heating season, but all year round. If an alternative coolant supply is not available, the device can operate as a conventional electric boiler, from the mains

tank material

There are three modifications on the market: enameled or stainless steel and titanium coating. The latter is much rarer and more expensive.

When choosing a tank, you should pay attention to its anti-corrosion qualities, as well as the presence of an additional magnesium anode.

Operating pressure

This indicator is especially important for units installed in apartments. Centralized heating, unfortunately, cannot boast of the absence of regular jumps in the system. So it is better to choose models with a margin of safety.

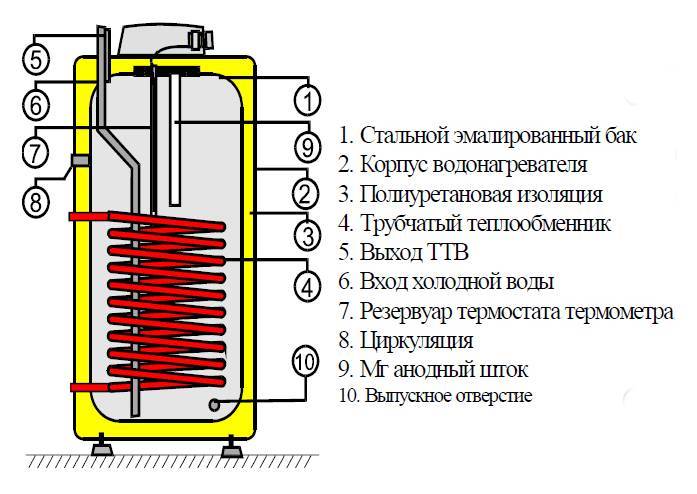

Technical description of the water heater Drazice OKC 200 NTR

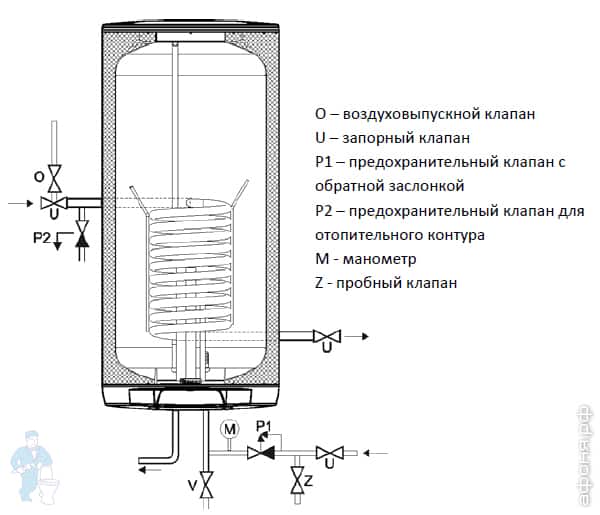

The water heater tank is made of steel sheet and tested with overpressure of 0.9 MPa. The inner surface of the tank is enamelled. A flange is welded to the bottom of the tank, to which the flange cover is screwed. An O-ring is inserted between the flange cover and the flange. There are sleeves in the flange cover

to accommodate the sensors of the control thermostat and thermometer.

An anode rod is installed on the M8 nut. The water tank is insulated with rigid polyurethane foam. The electrical wiring is located under a plastic removable cover. The water temperature can be set with a thermostat. To pressure tank

welded heat exchanger.

The shut-off valves of the heat exchanger must be open, thereby ensuring the flow of heating water from the hot water heating system.Together with a shut-off valve on the inlet to the heat exchanger, it is recommended to install an air vent valve, with the help of which, as necessary, especially at the beginning of the heating season, the air is vented from the heat exchanger.

The heating time of the Drazice OKC 200 NTR boiler by means of a heat exchanger depends on the temperature and water flow in the hot water heating system.