- Calculation of an indirect heating boiler

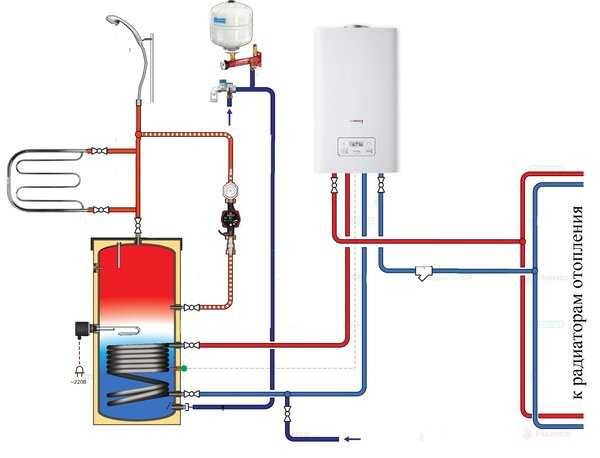

- Schemes for connecting a boiler to a single-circuit boiler

- Direct connection of the water heater to the heating system

- Temperature increase

- Using a thermostat in a water heater and automation

- Distinctive features of an indirect heating boiler

- Varieties of gas boilers

- According to the principle of placement: wall and floor

- According to the shape of the tank

- Assembling the device and connecting it

- Step 1: Preparing the Tank

- Step 2: Thermal insulation of the device

- Step 3: Installing the coil

- Step 4: Assembly and Mounting

- Step 5: Connection

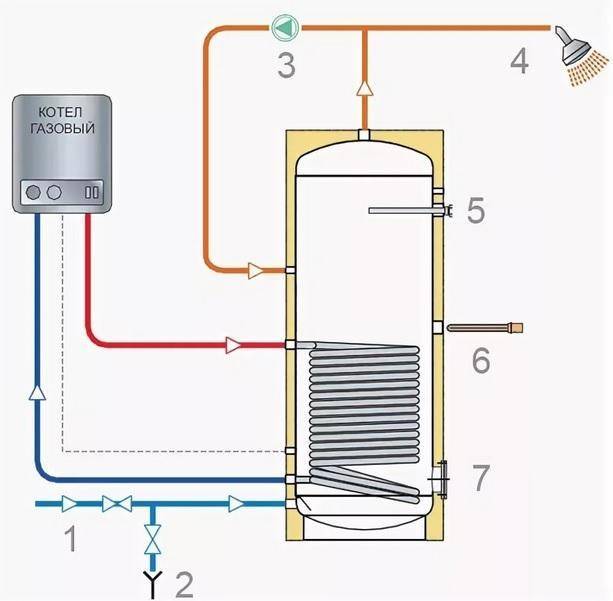

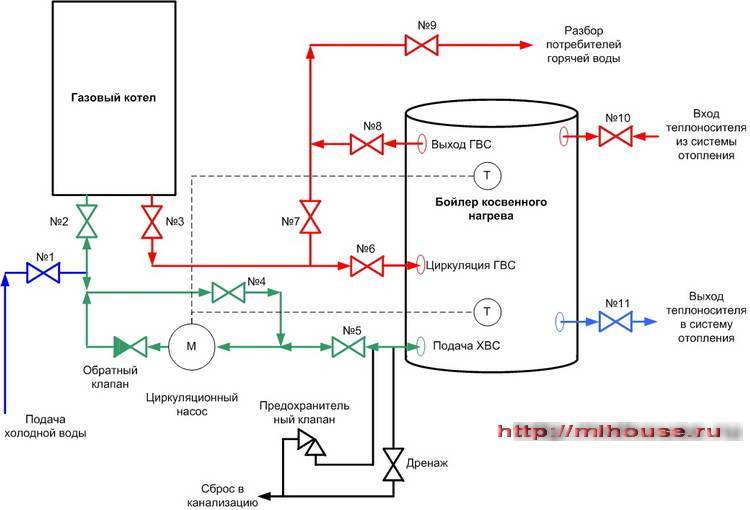

- Step 6: Possible Wiring Diagrams

- Fittings for binding BKN

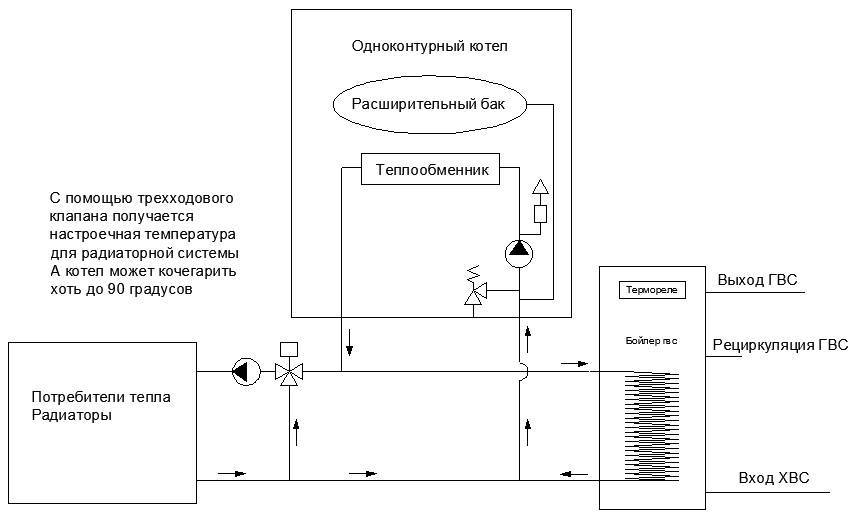

- Connection with a three-way valve

- Coolant recycling

- Manufacture of an indirect heating boiler

- Variants and stages of installation of the piping of the indirect heating boiler

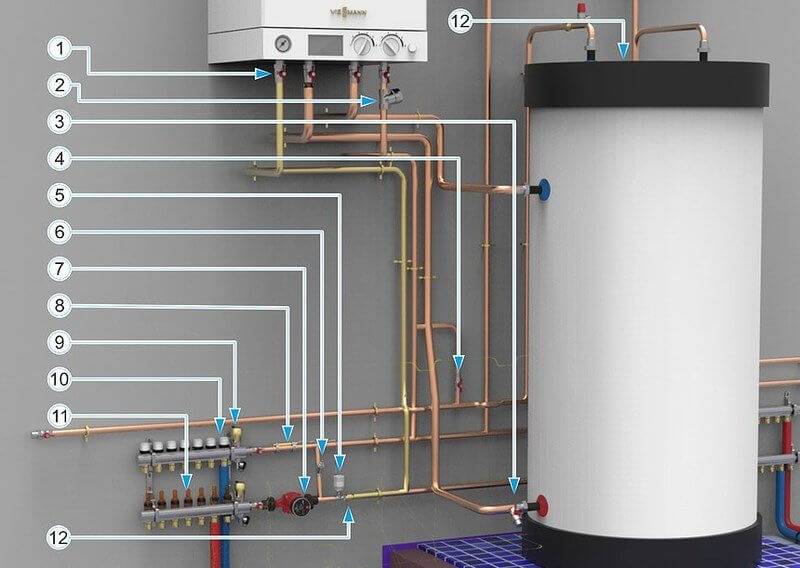

- Piping installation with two pumps

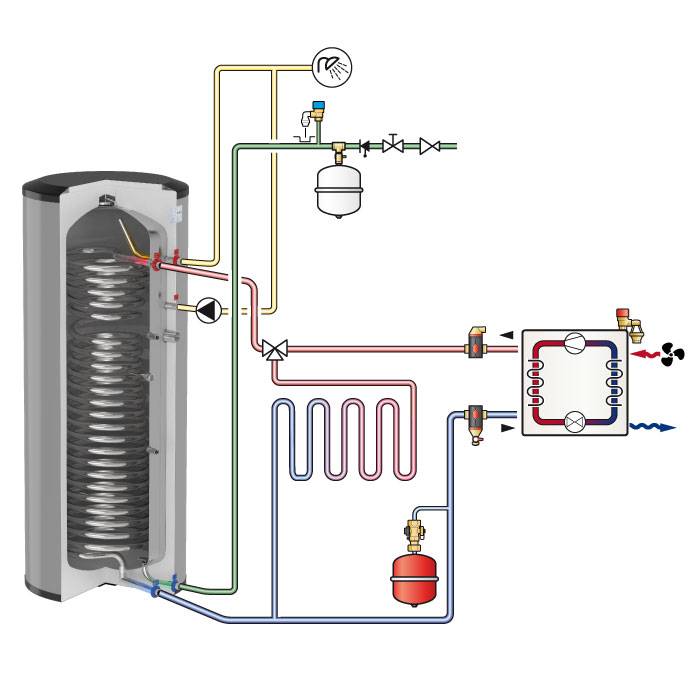

- Trim with three-way valve

- Harness with hydraulic switch

- Coolant recycling

- The difference between a double-circuit and single-circuit boiler

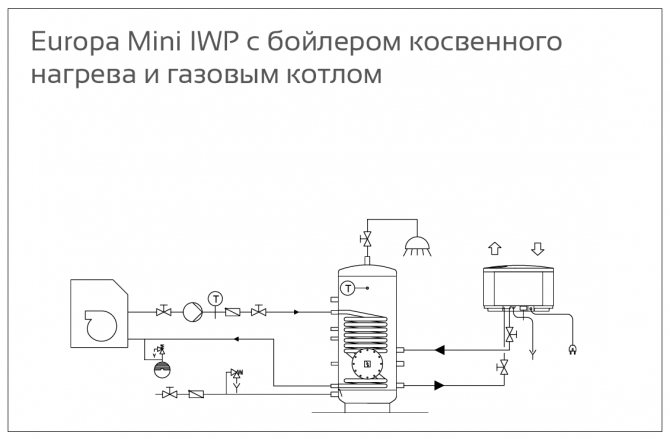

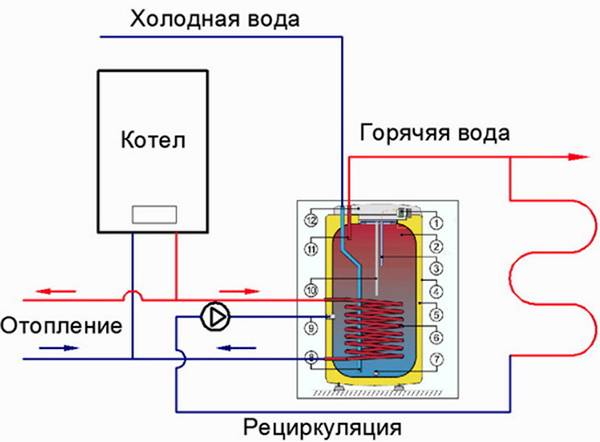

- Diagrams for connecting the boiler to the boiler

- Piping with boiler water circulation pumps

- Piping with a non-volatile boiler unit

- Piping with 3-way valve

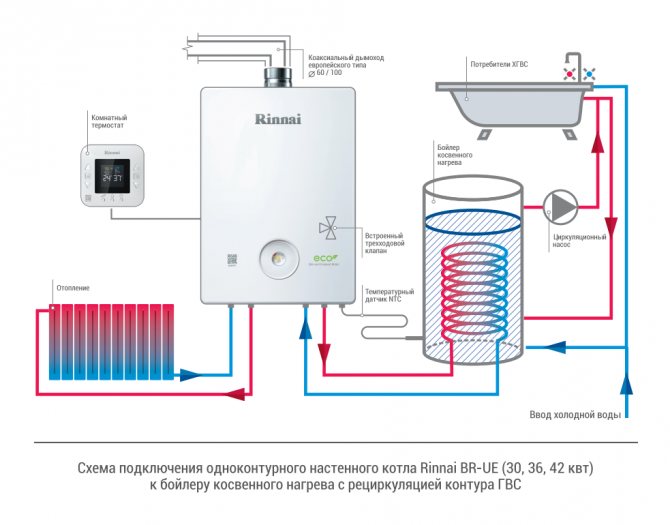

- Scheme with a recirculation line

- Is it possible to connect a boiler to a double-circuit boiler

Calculation of an indirect heating boiler

The main parameter for choosing a boiler will be the volume of its tank. The volume must be calculated from your needs for hot water consumption. To do this, the generally accepted sanitary standards necessary for one person are sufficient, multiplied by the number of your dependents.

Average hot water consumption rates:

- Washing: 5-17 l;

- For the kitchen: 15-30 l;

- Take water treatments: 65-90 l;

- Hot tub: 165-185 liters

The next point is the design of a hollow coolant tube. The best option is a removable coil made of high quality brass

This is important for maintenance. You can remove the removable coolant (coil) at any time for cleaning or replacement. The material of the tank has a significant effect on the durability of the boiler.

The best option is high quality stainless steel. It will be a little more expensive, but in the end you will only win.

The material of the tank has a significant effect on the durability of the boiler. The best option is high quality stainless steel. It will be somewhat more expensive, but in the end you will only win.

And of course, the effect of a thermos will be better from the quality of the insulation. The water will not cool quickly. Here recommendations - strictly do not save, Only high quality polyurethane.

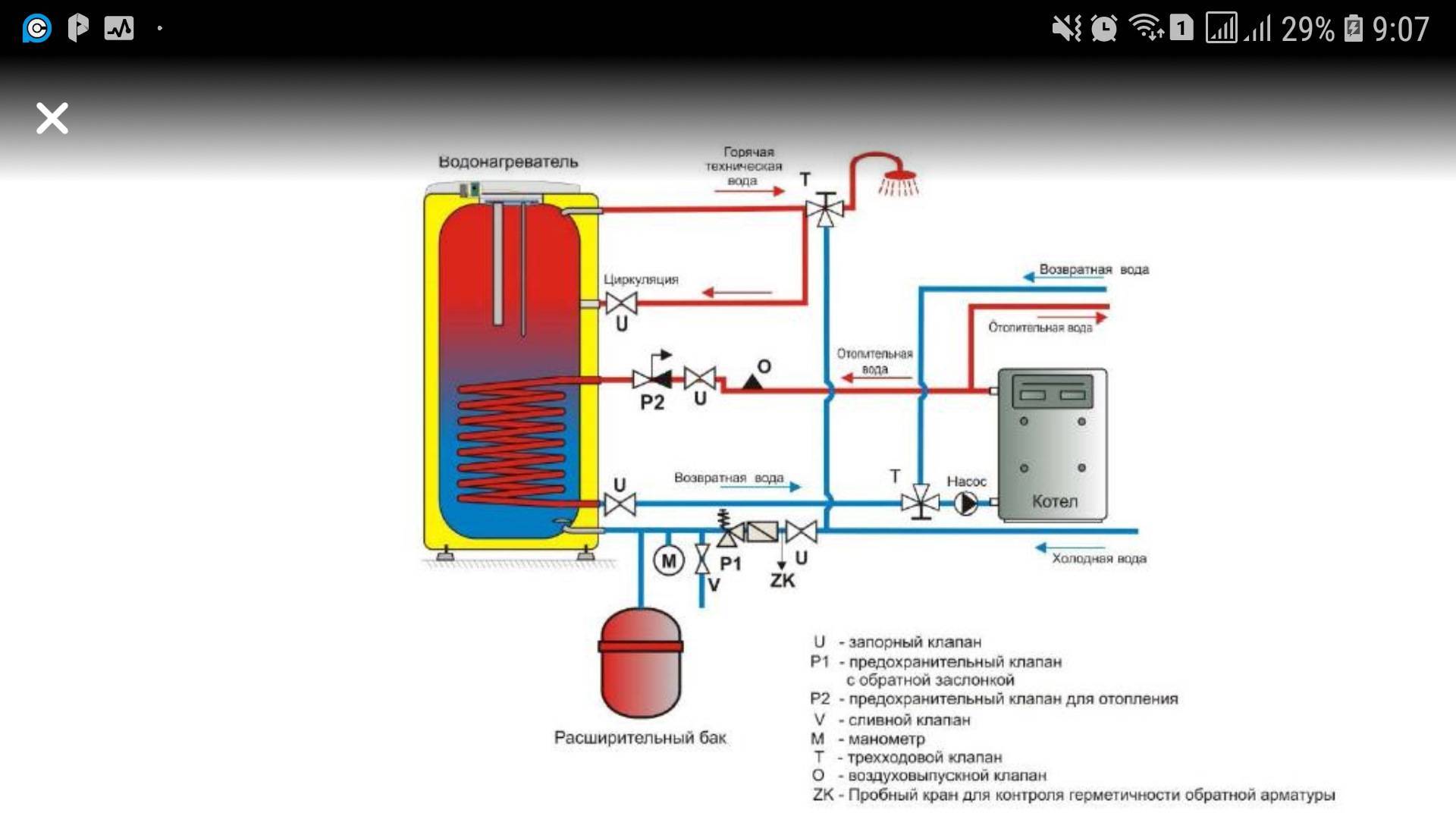

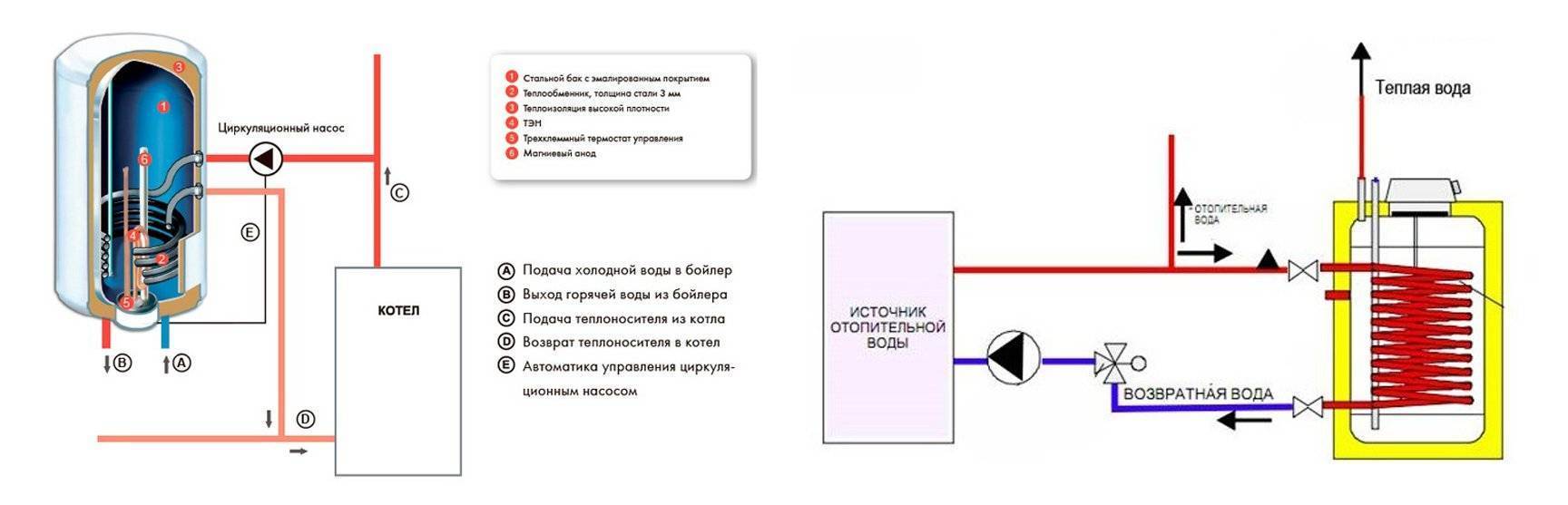

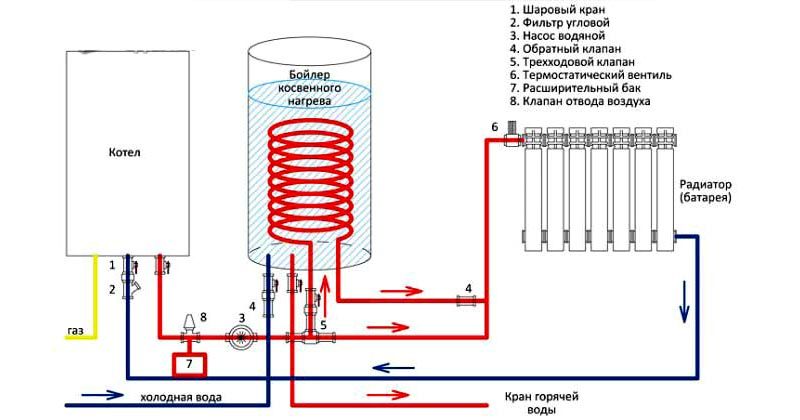

Schemes for connecting a boiler to a single-circuit boiler

There are three ways to connect the boiler to the boiler.

Direct connection of the water heater to the heating system

In this version, the BKN is included in the heating system, in series or in parallel with other radiators. The simplest and most inefficient scheme, not recommended for use and given for reference.

Scheme of direct connection of a water-heating gas single-circuit boiler to the heating system.

If the boiler temperature is set below 60 °C, this scheme becomes even less economical and the water takes a very long time to heat up.

Temperature increase

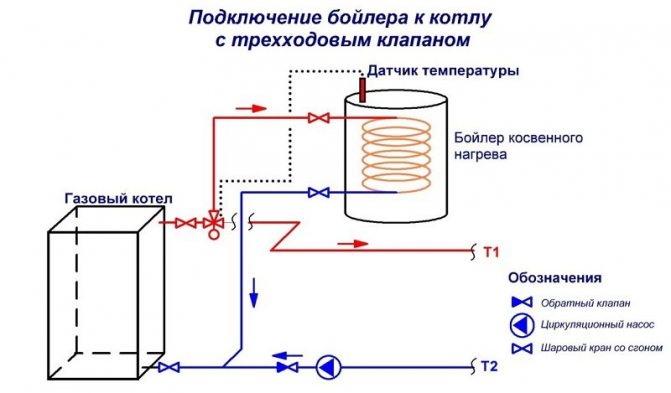

A three-way valve is added to the connection diagram - a special device that switches the movement of the coolant when the temperature in the water heater tank drops to DHW and vice versa.

Thus, if the DHW water cools down, the heating is temporarily switched off. All boiler power is redirected to DHW. The temperature on the device in this circuit is set higher (usually 80-90 ° C). And the heating temperature is regulated by a three-way valve.

Using a thermostat in a water heater and automation

If a thermal relay is installed in the BKN (a device that gives a signal when the set temperature is reached), and the boiler controller has contacts for connecting the boiler thermostat, then this scheme is the most preferable.

In this case, the boiler electronics is aware of the temperature of the water in the DHW system, and it decides where to direct its power: to heat water in the BKN or for heating.

Thermostat for the water heater in the heating system, with it you can find out data on the temperature of the water.

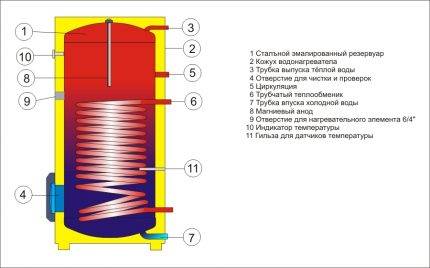

Distinctive features of an indirect heating boiler

A boiler is a large barrel, the main function of which is storage. It can be of various sizes and shapes, but its purpose does not change from this. Without a boiler, a problem may arise when using, for example, two showers at once or a shower and a kitchen faucet.

If a household 2-circuit boiler with a capacity of 24-28 kW gives out only 12-13 l / min to the flow, and 15-17 l / min is required for one shower, then when any additional tap is turned on, there will be a shortage of water supply.The boiler simply does not have enough working capacity to provide several points with hot water.

If a large storage tank is installed in the house, even with several water points turned on at the same time, everyone will be provided with hot water

All storage boilers can be divided into 2 large categories:

- direct heating, creating a supply of hot water using a heating element - for example, an electric heating element;

- indirect heating, heating the water with an already hot coolant.

There are other types of boilers - for example, conventional storage water heaters. But only volumetric storage devices can indirectly receive energy and heat water.

BKN, unlike volatile equipment operating on electric, gas or solid fuel, uses the heat generated by the boiler. Simply put, it does not require additional energy to function.

BKN design. Inside the tank there is a coil - a steel, brass or copper tubular heat exchanger that acts as a heating element. The heat inside the tank is stored according to the principle of a thermos

The storage tank easily fits into the DHW system, and does not cause problems during operation.

Users see many advantages in using BKN:

- the unit does not require electrical power and benefits from the economic side;

- hot water is always “ready”, no need to skip cold water and wait for it to heat up;

- several points of water distribution can freely operate;

- stable water temperature that does not fall during consumption.

There are also disadvantages: the high cost of the unit and additional space in the boiler room.

The volume of the storage tank is chosen, focusing on the number of people permanently residing in the house. The smallest boilers are designed for 2 consumers, so when choosing, you can start from a volume of 50 liters

But boilers are different, so we will consider both acceptable options and those where problems may arise.

Varieties of gas boilers

Gas devices with an indirect heating boiler may differ in the type of placement and the shape of the tank.

According to the principle of placement: wall and floor

Can be:

- wall;

- floor.

Units of the first category are devices of small volume - up to two hundred liters.

The floor-standing gas boiler in the package, with an indirect heating boiler, is installed in a special room.

They are installed using special brackets on a stable wall, which can withstand the weight of a water tank without loss. It's clear they're flimsy drywall partitions are not suitable for this purpose. Typically, such devices are purchased by one small family in their private home.

The second are capacious water heaters designed for a large number of people. Such devices will already require the arrangement of a special boiler room.

Usually they are purchased by enterprises and owners of large cottages and estates.

According to the shape of the tank

- Horizontal: very bulky, but they do not require pumps, they themselves maintain water in the right volume.

- Vertical: have a small capacity.

When choosing, you should take into account the number of people in the family, as well as the features of the layout and the availability of free space in the country or in the house.

Gas floor standing boiler installed in the boiler room and a small vertical expansion tank.

Assembling the device and connecting it

Having dealt with all the features of such equipment, you should move on to the practical part and dwell on the installation in more detail. But first, we will consider how you can assemble such a boiler yourself.

Self-installation of equipment

Step 1: Preparing the Tank

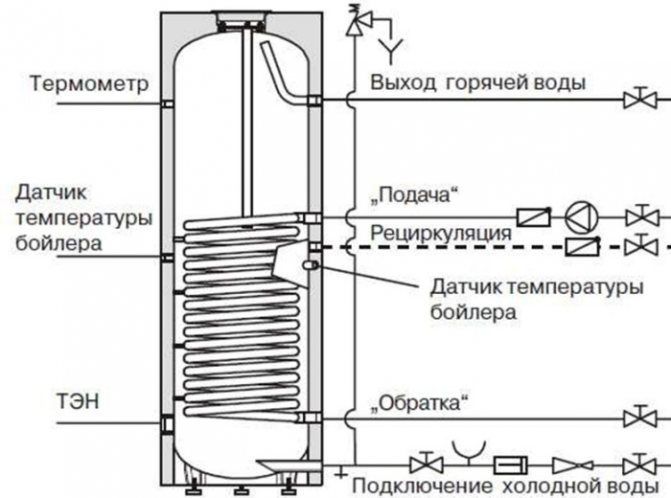

The water tank can be made of any material, as long as it is corrosion resistant. Therefore, it is better to give preference to stainless steel containers, since simple metal coated with enamel or glass ceramics can deteriorate during the first year. It is also necessary that the tank holds the right amount of liquid. Sometimes gas cylinders are used. But in this case, the container must first be cut in half, thoroughly clean the inner surface and primed. But even after such preparation, the liquid will smell like hydrogen sulfide for the first few weeks. We make three holes in our tank, which will ensure the supply of cold and the removal of hot liquid, and are also responsible for fixing the coil.

Step 2: Thermal insulation of the device

To make our boiler correctly, you should take care of its thermal insulation. We cover the entire body on the outside with a material with the desired properties. For this purpose, you can use any insulation. We fix it with glue, wire ties, or prefer any other method.

Step 3: Installing the coil

Small diameter brass tubes are best suited for the manufacture of this element. They will heat the liquid faster than steel ones, and they are easier to clean from scale.We wind the tube on the mandrel. In this case, it is necessary to correctly select the dimensions of this element. The more water will be in contact with it, the sooner the heating will occur.

Step 4: Assembly and Mounting

Now it remains to assemble all the parts of the boiler, do not forget about the thermostat. If suddenly at this stage the heat-insulating layer is damaged, then it should be immediately restored. It remains to weld metal ears to the tank so that it can be mounted on the wall. The water heater is mounted on brackets.

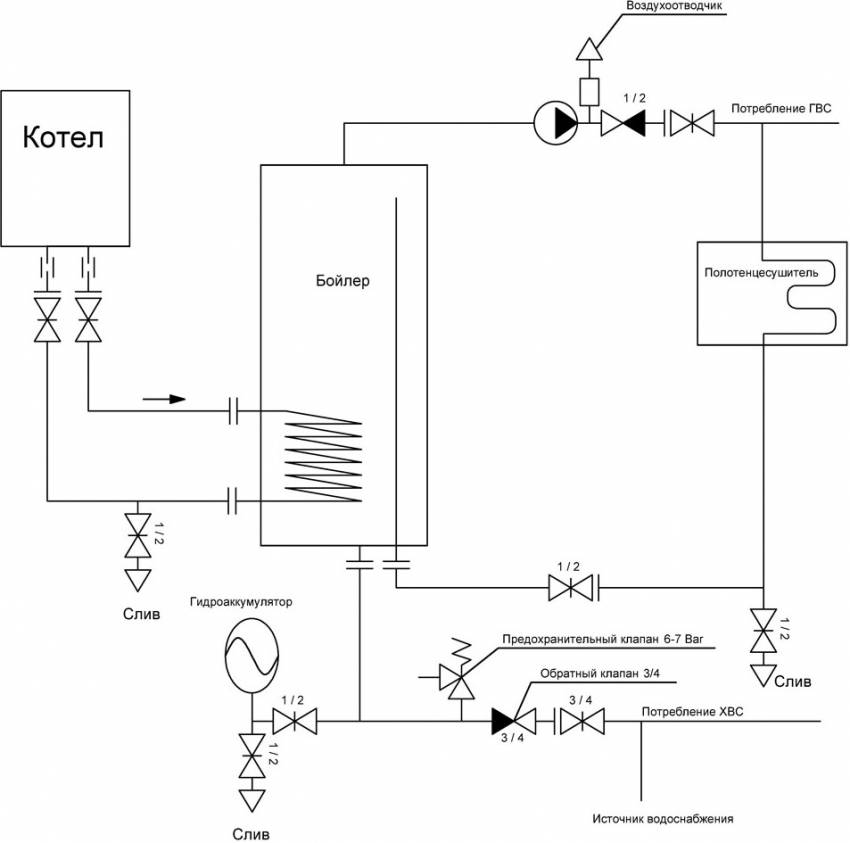

Step 5: Connection

Now about the binding. This device is connected simultaneously to the heating and water supply system. In the first, the liquid is heated by a gas boiler or other heating equipment. In this case, the movement of the coolant should be directed downward, so it is fed into the upper pipe, and when it cools, it leaves the lower one and flows back to the gas boiler. The thermostat controls the water temperature. Cold liquid from the water supply enters the lower part of the water heater. It is best to install the boiler as close to the heating equipment as possible. We connect the water heater according to any scheme indicated in the next paragraph.

Step 6: Possible Wiring Diagrams

In this paragraph, we will consider all the options for tying such a water heater. In principle, it can even be used for heating with two circuits. In this case, the distribution of the coolant occurs through a three-way valve. It is controlled by special signals coming from the water heater thermostat. Thus, as soon as the liquid has cooled too much, the thermostat switches and the valve directs the entire flow of the coolant to the accumulator heating circuit.As soon as the thermal regime is restored, the valve, again, at the command of the thermostat, will return to its original position and the coolant will again enter the heating circuit. This scheme is a worthy alternative to a double-circuit boiler.

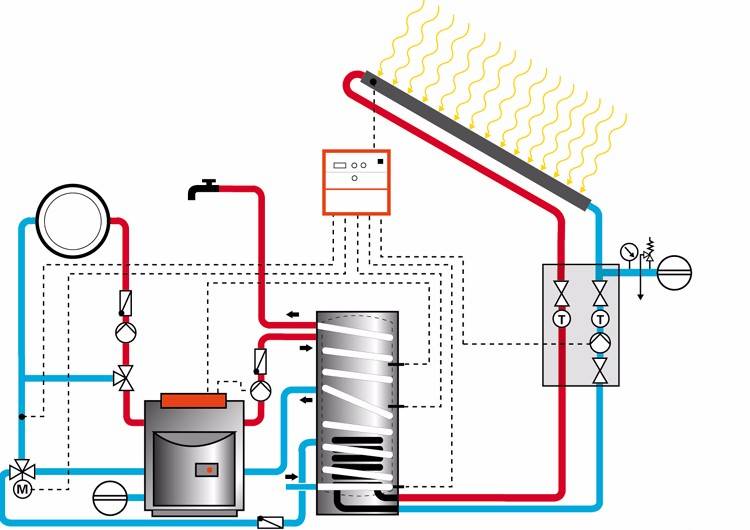

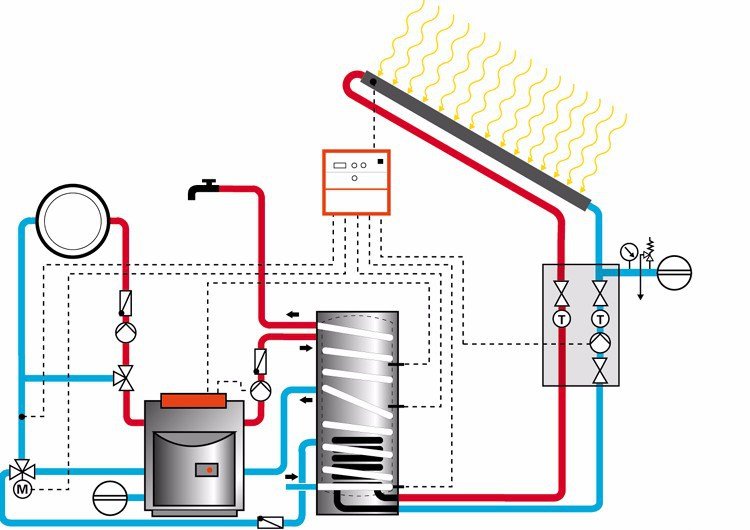

You can also control the movement of the coolant by means of circulation pumps installed in various lines. The heating and boiler heating lines are connected in parallel and have their own pressure. As in the previous case, the modes are controlled by a thermostat, and as soon as the DHW circuit is connected, the heating is turned off. You can use a more complex scheme, including two boilers. One device provides continuous operation of heating elements, and the second - hot water supply.

A circuit using a hydraulic distributor is considered quite complicated in execution; only professionals can connect it correctly. In this case, there are several home heating lines, such as underfloor heating, radiators, etc. The hydraulic module controls the pressure in all branches. You can also connect a liquid recirculation line to the water heater, then you can achieve instant hot water from the tap.

Fittings for binding BKN

This is what gives priority. If the tank is not equipped with a safety group, it is installed separately when arranging the piping.

Because in some fancy boilers there are protections against turning off the heating caused by a long warm-up of the DHW. The first is installed on the supply pipe, immediately before the BKN, the second - on the heating circuit.

Therefore, when choosing, you need to decide which boiler connection scheme is used, how many energy sources will be involved and which ones.Practice has shown that at high flow rates, water may not heat up to the required 60 degrees. To reduce the time of heating water and for slower cooling of the tank, it is better to choose models with thermal insulation.

Because there are boilers with the function of turning off the heating according to the room thermostat, and the DHW function remains working. No need to think that when the water is heated, the temperature in the house will start to drop - the water heats up quickly, your household will never have time to cool down. As noted above, solid fuel boilers that run on all available fuels are an excellent option.

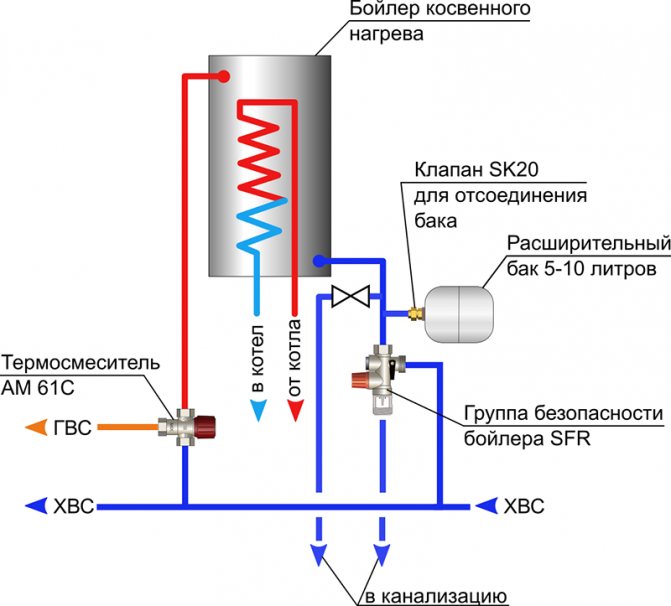

Connection with a three-way valve

Agree that such a connection is not safe, even if you dilute the water with a mixer. Conclusion The piping of a single-circuit boiler with an indirect heating boiler is carried out according to different schemes, each of which allows solving a certain number of problems.

Here the priority of the indirect heating boiler is used. If the strapping is done correctly, quick repairs will not be required, but if problems arise with the equipment, we recommend contacting specialists. When all the technical issues are settled, it remains only to choose the volume. On the other hand, high temperatures increase scale in heat exchangers and pipes, which in the future can lead to a decrease in power and failure of the boiler due to overheating. But you have to somehow put up with the lack of the ability to adjust the temperature to your liking.

If desired, you can do without a pump - for the normal supply of coolant to the water heater, the supply pipes to it must have an increased diameter compared to the pipes of the heating circuit.During normal operation, the hottest water is at the top, from where it is fed into the DHW circuit. That is, by increasing the temperature, you increase the accumulation of hot water in the boiler with the same capacity. If you have a temperature in the boiler of 90 degrees, then you can already use the shower for more than 60 minutes.

Imagine that you have hung a floor-mounted BKN per liter on a gas block wall. This scheme with the same efficiency can be used for both electric and gas or solid fuel heat generators. That is, at a low temperature, gas does not burn out. This piping method is useful for those who use the boiler in constant mode Connection with two circulation pumps If the boiler is rarely used, for example, seasonally or on weekends, or if there is a need for water whose temperature is lower than in the heating system, use a circuit with two circulation pumps. Moreover, the boiler is an auxiliary element when you need to heat up quickly, or when there is not enough solar energy.

Heating in townhouse. Inexpensive.

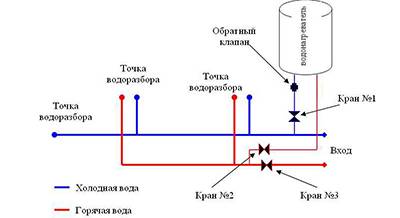

Coolant recycling

If you have a water heated towel rail available, please note that this device requires water to circulate continuously. There is no other way to work with such a device.

It is possible to connect all consumers to the loop - in this case, the hot liquid will be in constant motion with the help of a pump. This scheme has a significant advantage - you do not need to wait for hot water. You immediately get it by opening the valve on the mixer.

As for the disadvantages:

- the boiler is constantly in operation, resulting in an increased amount of energy consumed due to recycling;

- due to recirculation, the layers of water are mixed - at rest, warm layers of water are located on top, which ensures its supply to the DHW circuit. When water is mixed, its overall temperature drops.

There are two ways to connect an indirect heater with coolant recirculation. The first of them involves the purchase of an indirect heating boiler, the equipment of which provides for built-in recirculation. In this case, you simply connect to the pipes of the heated towel rail. The price of such a device is usually 2 times higher than the cost of a conventional indirect heating boiler. The second way: using a conventional boiler model, but connecting an indirect heating boiler is carried out using tees.

Manufacture of an indirect heating boiler

The process of assembling a water heater may vary depending on the type of construction, but in most cases, equipment for gas and electric boilers is manufactured in the following sequence:

- In a pre-prepared cylinder, two holes are drilled using an electric drill with a crown nozzle. One hole will be located at the bottom and used to supply cold water, the other - at the top to drain hot.

- The resulting holes are cleaned, fittings and ball valves are mounted in them. Then another hole is drilled in the lower part, into which a tap is installed to drain the stagnant water.

- For the manufacture of the coil, a copper pipe with a diameter of 10 mm is required. A spiral bend is best done with a pipe bender.If there is no such tool, then you can take any round blank - a large diameter pipe, a log, a barrel, etc.

- The coil is being manufactured according to the calculations made earlier. The ends of the heat exchanger are bent in one direction at a distance of 20–30 cm. Two holes are drilled in the lower part of the cylinder to mount the coil. Threaded fittings are installed and welded into them.

- Before installation, the coil is lowered into a bucket or large container of water and blown through. If the design is tight, then the coil is lowered into the cylinder, set relative to the inlet and outlet and brewed.

- If the cylinder was cut in the middle, then an anode is mounted in the upper part. To do this, a hole is drilled, where a threaded nozzle is screwed in, and a magnesium anode is already mounted in it. If the container is assembled from three separate parts - the bottom, the lid and the central part, then the anode can be installed at the last stage.

- Thermal insulation material is mounted on the outside of the boiler. It is best to use sprayed polyurethane. Before application, all nozzles are protected with dense polyethylene and cloth. If funds are limited, then you can use ordinary mounting foam, which, after hardening, turns into reflective insulation.

- Attachments are welded to the back of the boiler for hanging on brackets. For floor boilers, support legs from a steel angle or fittings are welded to the bottom of the equipment.

At the final stage, fittings, taps are screwed on and the top cover is mounted. If possible, the cover can not be welded, but clamping fasteners can be made of steel wire with a cross section of 3 mm.

In the manufacture of a boiler for use with solid fuel boilers, instead of a copper coil, a U-shaped steel pipe is used, which is mounted at the bottom of the device. On the side of the furnace or boiler, the pipe is connected to the outlet. From the boiler, the pipe is removed and connected directly to the chimney.

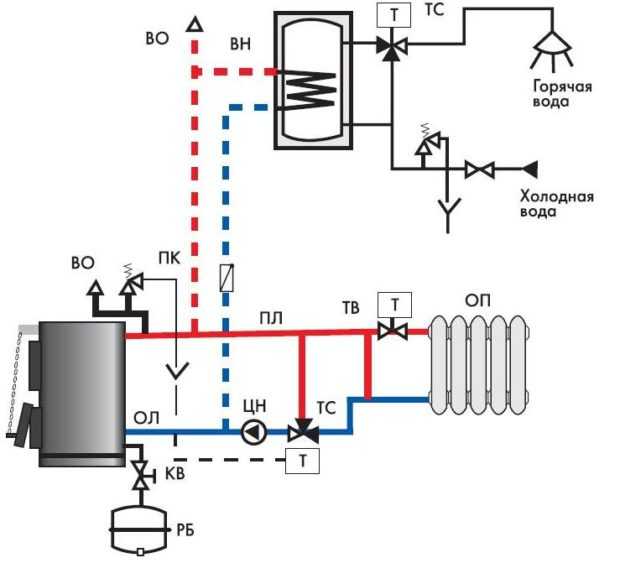

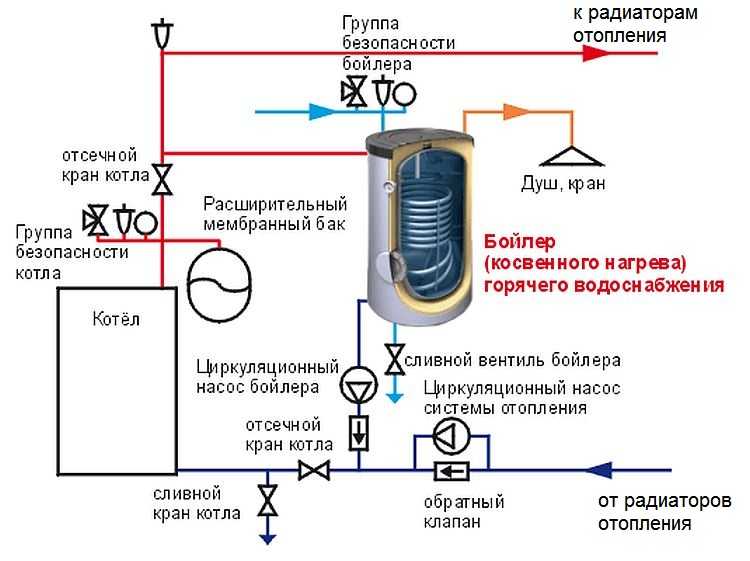

Variants and stages of installation of the piping of the indirect heating boiler

There are principles for piping BKN with and without priority for turning on hot water supply. In the first case, it is necessary to pump all the heating water through the heater element. Such heating occurs quickly, when the required T of water is reached, the temperature sensor will give a command to direct the coolant to the radiators.

In systems without priority, the coolant from the boiler is partially sent to the BKN tank, so the DHW temperature rises slowly. In connection with the fact that more users choose a system with priority, especially since it does not worsen the temperature regime in the heat supply system, since the heating lasts no more than 50 minutes and the water in the batteries cannot cool down.

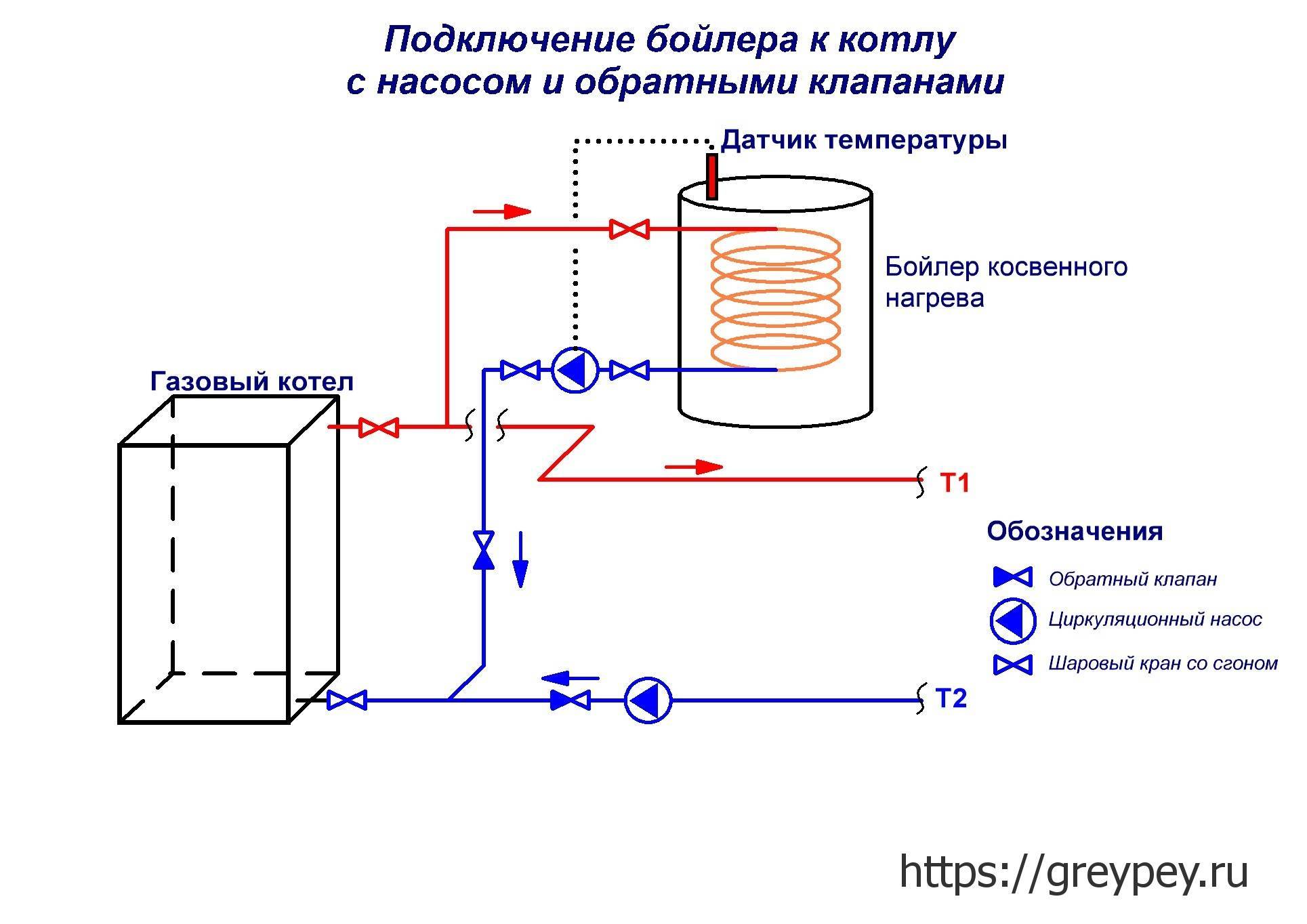

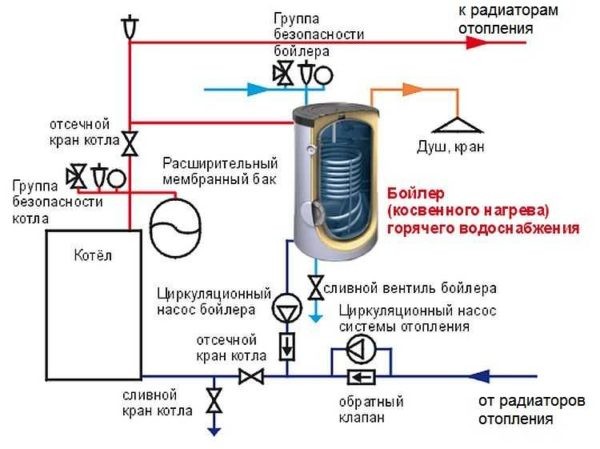

Piping installation with two pumps

A two-pump circulation system is used in a single-circuit BKN scheme. It serves to separate the direction of the heating medium and ensures the operation of the DHW circuit first. The process of turning on the pumps is regulated by the tank thermostat, to prevent the effect of mixing water flows with each other, a check valve is mounted in the system at the suction of the pumps. As a result, the operation of the pumps occurs alternately, at the time of starting the pumping in the DHW system, it is turned off in the heating system.

The BKN system with 2 pumps is often installed with 2 boilers, each of which has a separate power supply and is responsible for heating water in its own circuit - heating or hot water. Such a system has a high-speed heat transfer mode in both circuits, usually no more than an hour.

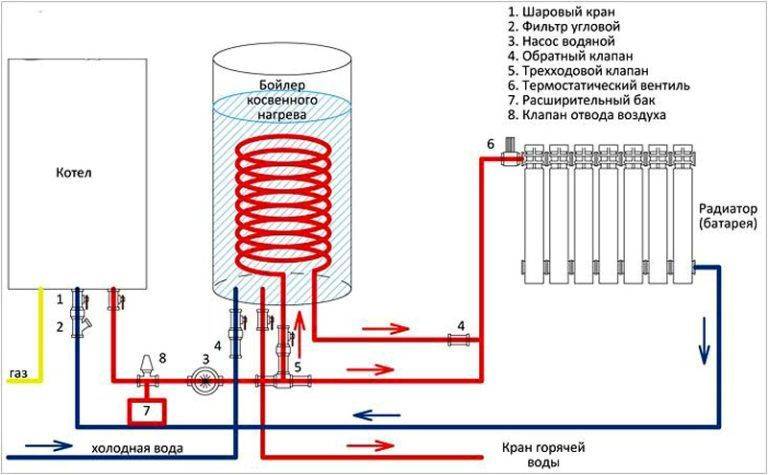

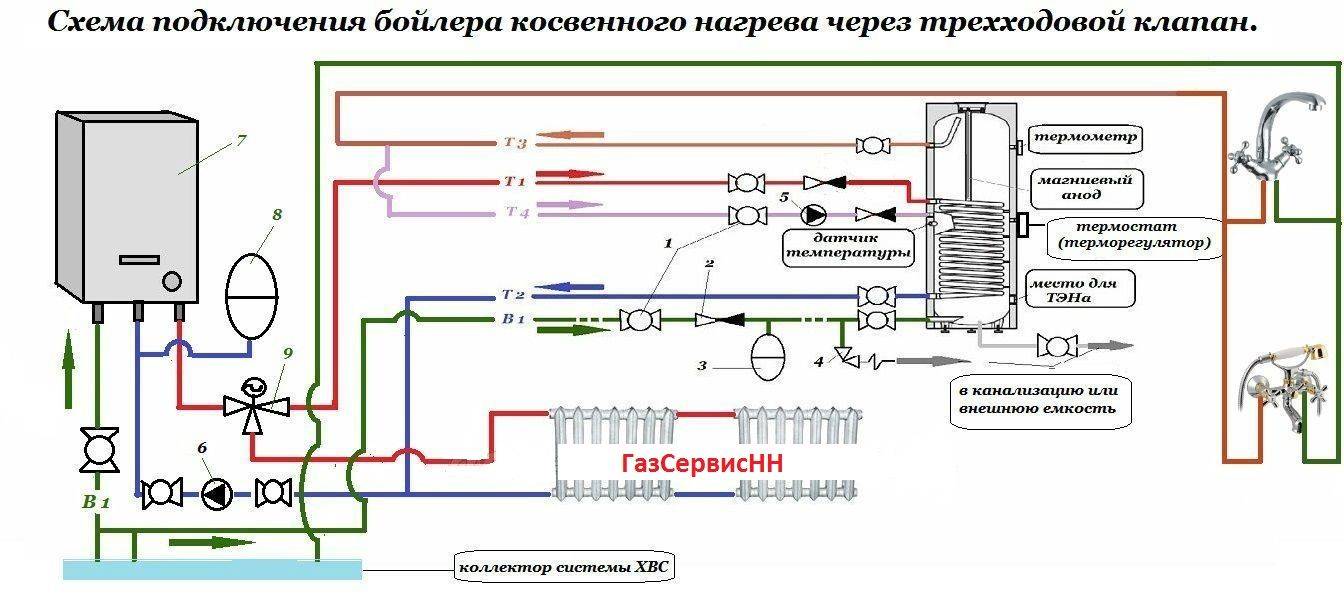

Trim with three-way valve

This option is the simplest and most common, it provides parallel connection of heating pipes and BKN equipped with shut-off and control valves. The design is installed next to the boiler, a 3-way valve is mounted at the supply for circulation behind it. This boiler piping scheme with an indirect heating boiler is also well applicable if several heating sources are operating, for example, two gas boilers.

Trim with three-way valve

Trim with three-way valve

The operation of the 3-way valve is controlled by a thermal relay. When T water falls below the operating level, the automatic system is activated and the heating coolant from the heating system passes into the DHW line. This is another priority circuit that ensures that the water in the boiler is heated quickly. As soon as T in the DHW system reaches the limit value, the 3-way valve is activated, the heating water from the gas boiler is sent to the heating network.

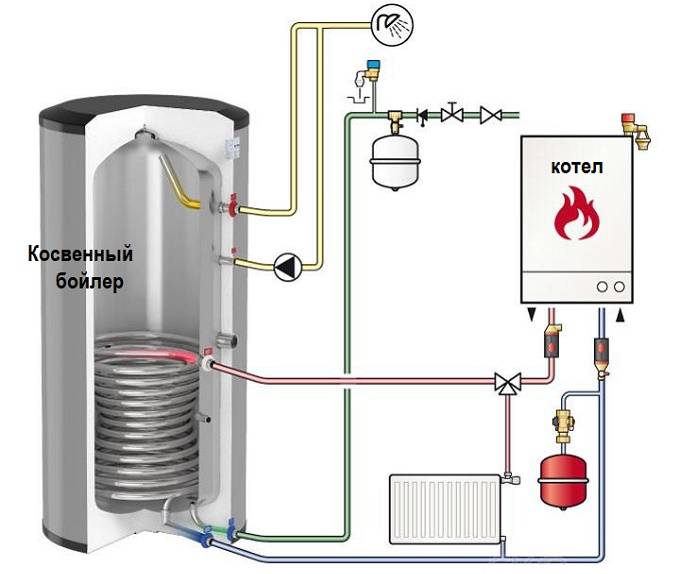

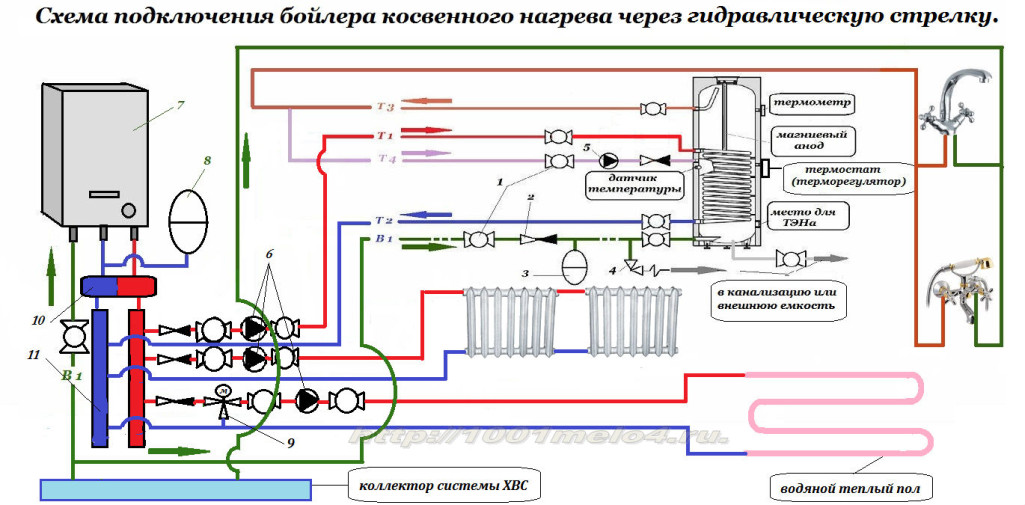

Harness with hydraulic switch

Such a piping is performed to connect large-capacity BKNs over 200.0 l and the presence of branched multi-circuit heating systems with different types of heating elements, for example, multi-level houses of individual construction, in which, in addition to the radiator network, heating is arranged according to the "warm floor" principle. The hydraulic arrow is a modern hydraulic distributor to simplify the operation of the heat supply system.Its application does not require the installation of several pumps on an independent heating line.

The equipment has structural protection and avoids thermal and hydraulic shocks in the heating network, since it creates equal medium pressures in all heating circuits. However, this is still an expensive element of a modern autonomous heating thermal scheme, it requires careful selection of equipment and precise installation. Therefore, usually such delicate work is entrusted to specialists in the field of setting up heating systems.

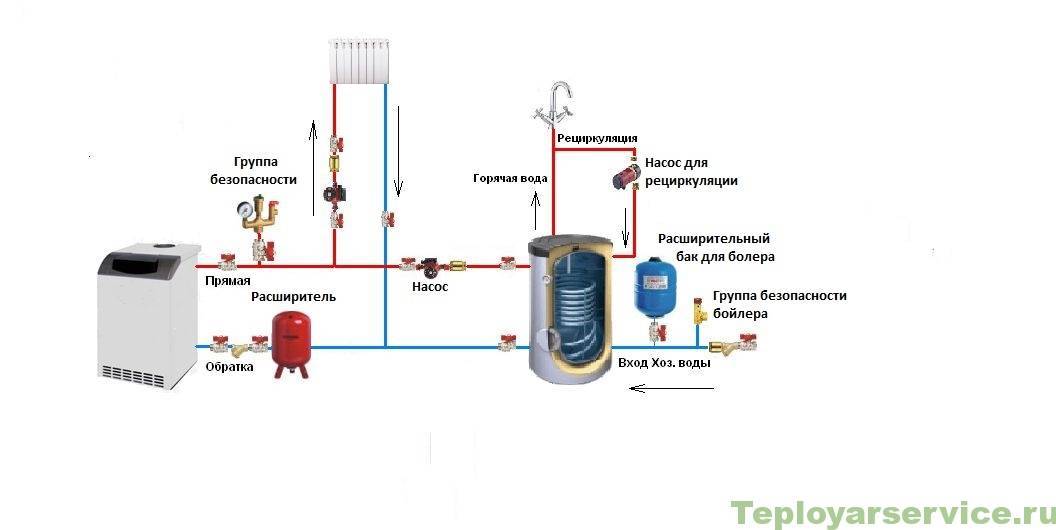

Coolant recycling

Recirculation is needed in a circuit with a constant load of heated water, for example, when using a heated towel rail. For the winter period, such a scheme works with a heating circuit in which the heating network water circulates constantly, and the dryer performs two functions, in the form of a heated towel rail and a heating heater.

This option has great advantages, it is not necessary to wait for hot water for a long time and drain it. The main disadvantage is the high fuel consumption for heating the DHW circuit. The second disadvantage is the mixing of different media flows in the tank. Since the DHW medium is at the top of the tank and the recirculation line is in the middle, when cold water is returned, the final DHW outlet temperature will drop.

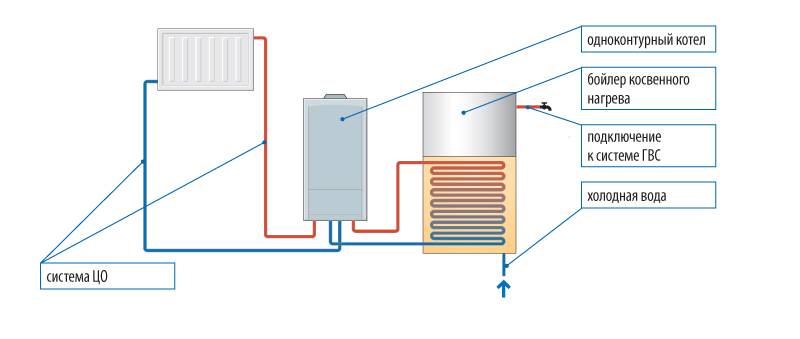

The difference between a double-circuit and single-circuit boiler

To implement heating systems in the house, single-circuit boilers are installed based on heat exchangers of various types.

But there is a method of combining the heating and water supply systems in the house through another heating boiler - a much more functional one, called a double-circuit one.

The main difference between double-circuit boilers and single-circuit boilers lies in their ability to heat not only the coolant - water (while burning gas or other energy resources for which they are intended) for the heating system, but also supply it to the consumer for his own domestic needs, providing the water supply process in the house . And usually for these purposes double-circuit boilers are made automatic. The operation of such a boiler is monitored by automation (sensors for heating water and gas consumption with microprocessors). As soon as a command arrives at the boiler to request water to the water supply system, it immediately switches its mode to this task from the heating system, since it is in its priority - at a higher level.

The maximum temperature that can be set on the hot water boiler is + 60 degrees Celsius, otherwise the automation works - burns are possible.

Wall-mounted gas boilers are the most widely used, since gas is the cheapest heating material and walls are best suited for their placement and use, although other varieties are not uncommon.

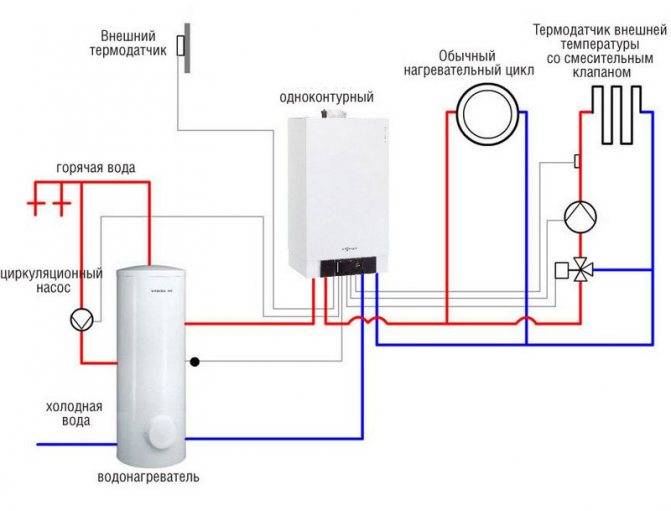

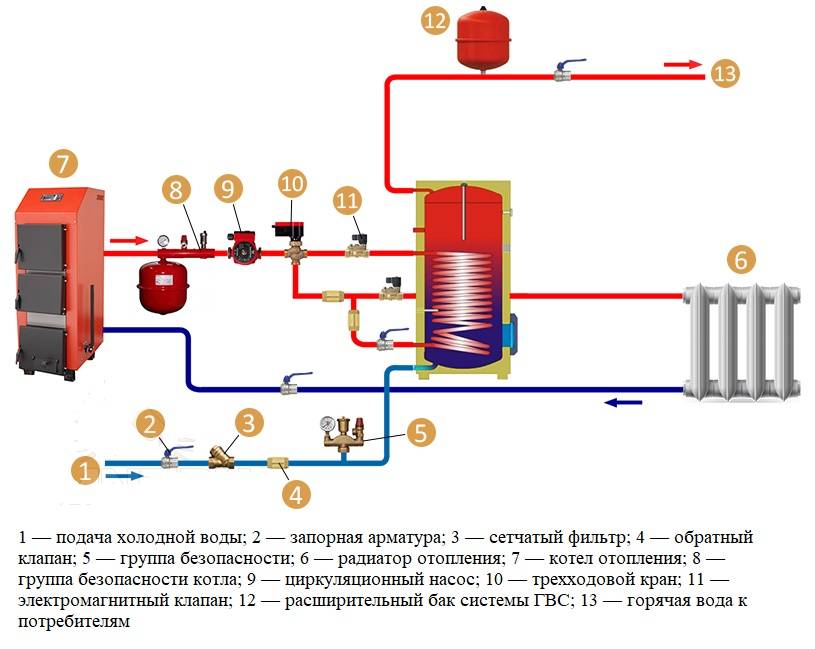

Diagrams for connecting the boiler to the boiler

Before connecting an indirect heating boiler, an executive connection diagram and installation parameters of the BKN are developed. They depend on the modification of the device, the scheme of the boiler unit and the heating system in the household.

The BKN boiler connection kit is most often used for double-circuit units and with three-way valves.

Piping with boiler water circulation pumps

The scheme with 2 circulation electric pumps is used for temporary heating of domestic hot water, for example, during seasonal operation of the BKN and when used on weekends. In addition, this option is applicable when the DHW temperature is set lower than the T of the heat carrier at the outlet of the boiler.

It is carried out with two pumping units, the first is placed on the supply pipe in front of the BKN, the second - on the heating circuit. The circulation line is controlled by an electric pump through a temperature sensor.

According to its electrical signal, the DHW pump will be switched on only when the temperature drops below the set value. There is no three-way valve in this version, the piping is carried out using conventional mounting tees.

Piping with a non-volatile boiler unit

This scheme is used for a non-volatile boiler unit operating with natural circulation of the coolant, therefore, in order to ensure the required hydraulic regime and the coolant could circulate through the boiler unit and radiators in the rooms. This scheme is for wall modifications that allow installation at a level of 1 m from the “O” mark in the furnace.

Floor models in such a scheme will have low circulation and heating rates. It may happen that the required level of heating cannot be achieved.

This scheme is used only for emergency modes, when there is no electricity. In normal energy-dependent modes, circulating electric pumps are installed in the circuit to ensure the required speed of the coolant.

Piping with 3-way valve

This is the most common piping option, as it allows the parallel operation of both heating and hot water.The scheme has a fairly simple execution.

BKN is installed next to the boiler unit, a circulation electric pump and a three-way valve are mounted on the supply line. Instead of one source, a group of boilers of the same type can be used.

The three-way valve acts as a mode switch and is controlled by a thermal relay. When the temperature in the tank drops, the temperature sensor is activated, which sends an electrical signal to the three-way valve, after which it switches the direction of movement of the heating water from heating to DHW.

In fact, this is a BKN operation scheme with priority, which provides fast heating of the DHW with the radiators completely turned off during this period. After reaching the temperature, the three-way valve switches and the boiler water enters the heating system.

Scheme with a recirculation line

Coolant recirculation is used when there is a circuit in which hot water must circulate all the time, for example, in a heated towel rail. This scheme has great advantages, because it does not allow water to stagnate in the pipes. The user of DHW services will not need to drain significant volumes of water into the sewer in order for hot water to appear in the mixer. Consequently, recycling saves the cost of water supply and hot water services.

Modern large BKN units are supplied to the market with an already built-in recirculation system, in other words, they are equipped with ready-made pipes for connecting a heated towel rail. Many for these purposes acquire an additional small tank connected to the main BKN through tees.

Is it possible to connect a boiler to a double-circuit boiler

This option is performed using an indirect heating boiler connection scheme with a hydraulic arrow for structures with a working volume exceeding 220 liters and multi-circuit heating schemes, for example, in a multi-storey building with a "warm floor" system.

A hydraulic arrow is an innovative unit of a modern in-house heat supply system that simplifies the operation and repair of a water heater, since it is not necessary to install recirculation electric pumps on each heating line.

It increases the security system, as it prevents the occurrence of water hammer, since it maintains equal pressure of the medium in the circuits of the double-circuit boiler unit.