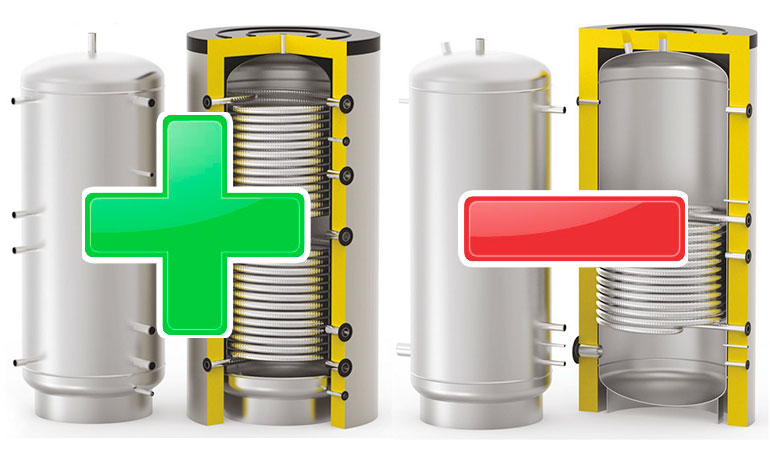

- Advantages and disadvantages

- Heat accumulator for heating boilers: features of the device and connection

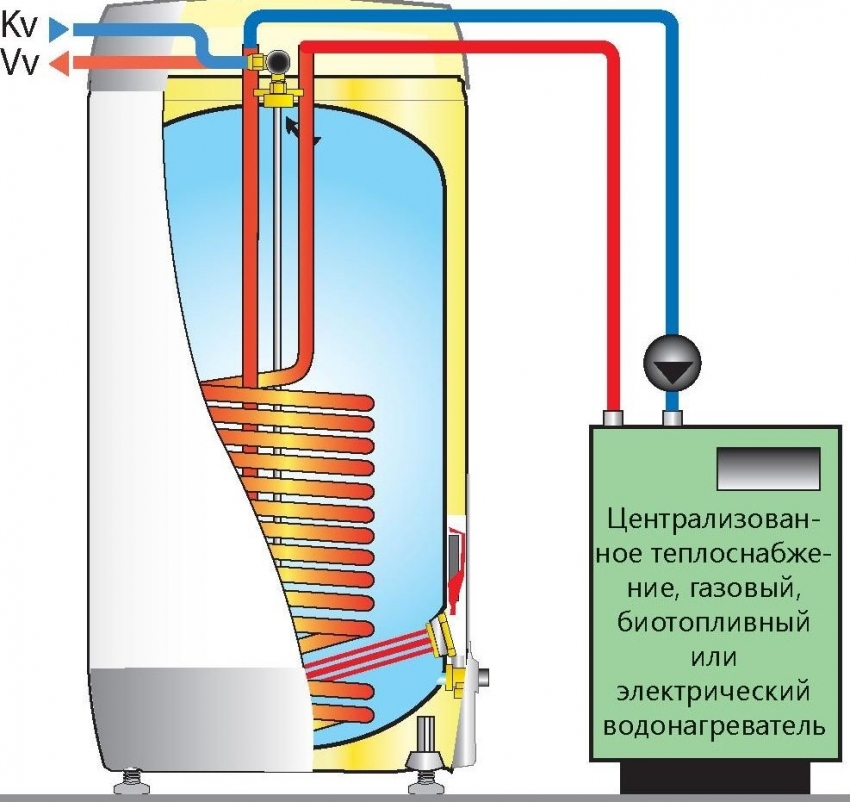

- Heat accumulator device and rational connection of external devices

- What is an indirect heating boiler and what are they

- Kinds

- Which boilers can be connected to

- Tank shapes and installation methods

- Tying the "indirect" with the boiler

- Indirect heating boiler

- Quantities

- Water heater design

- Electric storage

- Electric flow

- Gas water heaters

- The principle of operation of an electric storage water heater

- How to calculate the volume of an indirect heating boiler

- What is an indirect water heater?

- The device and principle of operation of an indirect heating boiler

- Features of installation and connection of the water heater

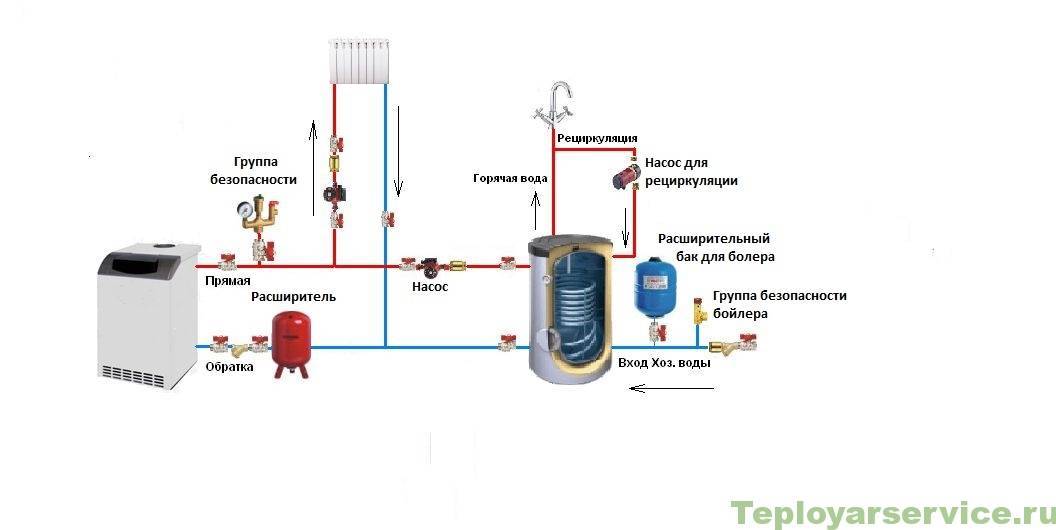

- Connecting an indirect heating boiler with two circulation pumps

- Indirect heating boiler: principle of operation

Advantages and disadvantages

The strong qualities of indirect water heaters can be safely considered:

- Significant volumes of hot water and uninterrupted supply of hot, not warm water.

- Simultaneous provision of several sources of hot water consumption of the required temperature.

- During the heated period of the year, the cost of heated water is the lowest in terms of costs.Since heating occurs due to the heat already received from another carrier (heating system).

- Water heating, unlike flow heaters, occurs without an inert delay. Opened the faucet and hot water came out.

- Depending on the availability of heat sources, several energy options can be applied, including solar energy.

Weaknesses include:

- Additional financial investments are required. The water boiler works in conjunction with other equipment.

- It will take a long time for the boiler to heat up initially. During this heating period, the heating temperature of the house may decrease.

- The boiler must be installed in the same room as the heating system. The volume of the room must provide a complete installation of both the heating system and the boiler.

Heat accumulator for heating boilers: features of the device and connection

The purpose of using this unit is to collect and store the coolant heated to a certain temperature for its further transfer to the system when the need arises. Being connected to the water circuit of the room, this type of battery provides support for the temperature regime, even if the heat source is turned off.

Useful advice! If the water heating of the house is produced from electricity, registration of a night tariff with a reduced cost of 1 kW / h. will save you money on bills. The heating system will be sufficiently heated at night, and during the daytime the heat accumulator will work.

The heat accumulator is used to maintain water heated to a certain temperature.

This device also performs other functions. The main ones include:

- reduces fuel consumption by almost a third.At the same time, the efficiency of the fuel plant increases;

- protects heating devices from overheating, collecting excess heat;

- heats water for the domestic hot water system. That is, in fact, this is one of the varieties of an indirect heating boiler. The price of this unit varies over a very wide range: from 13 to more than 300 thousand rubles;

- the heat accumulator tank can connect several heat sources operating on different types of energy or fuel;

- the design of the device allows the selection of coolant of different temperatures.

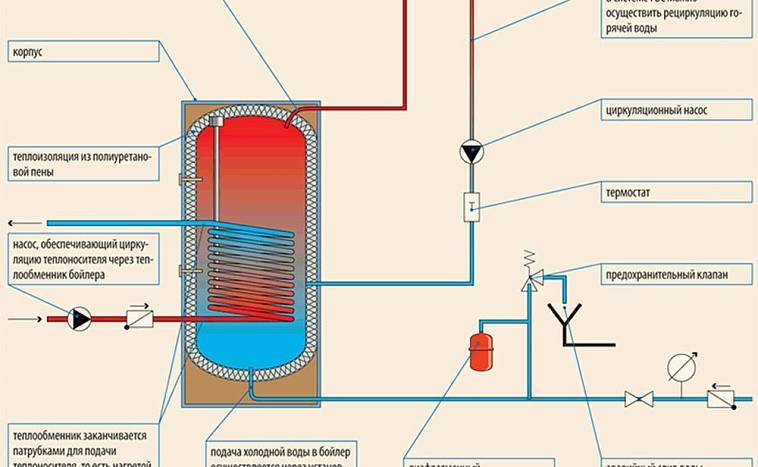

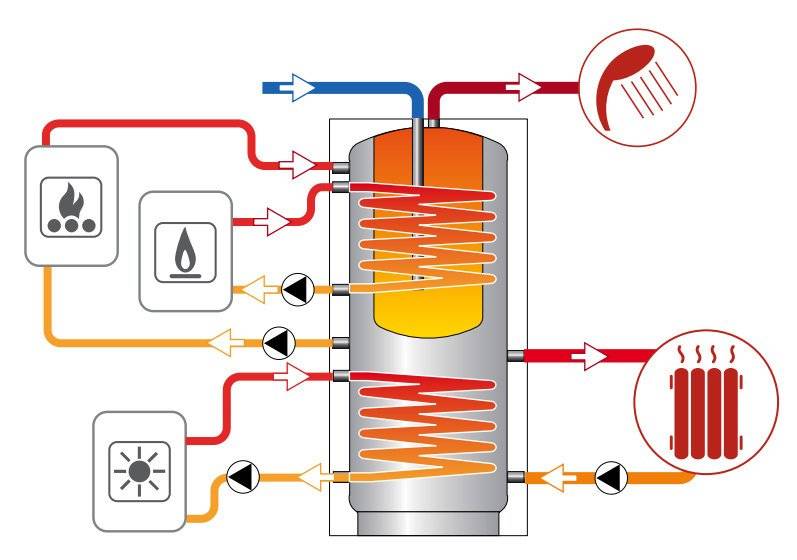

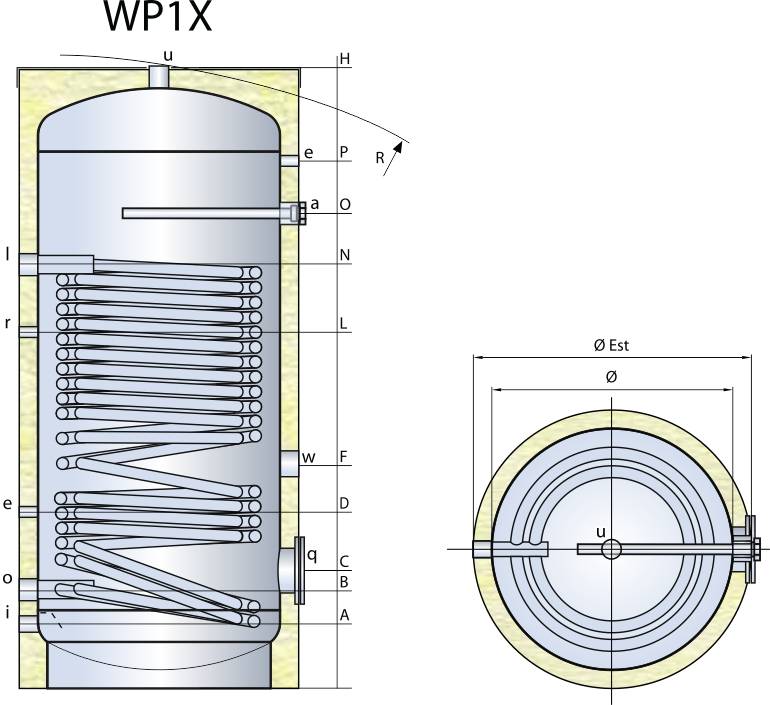

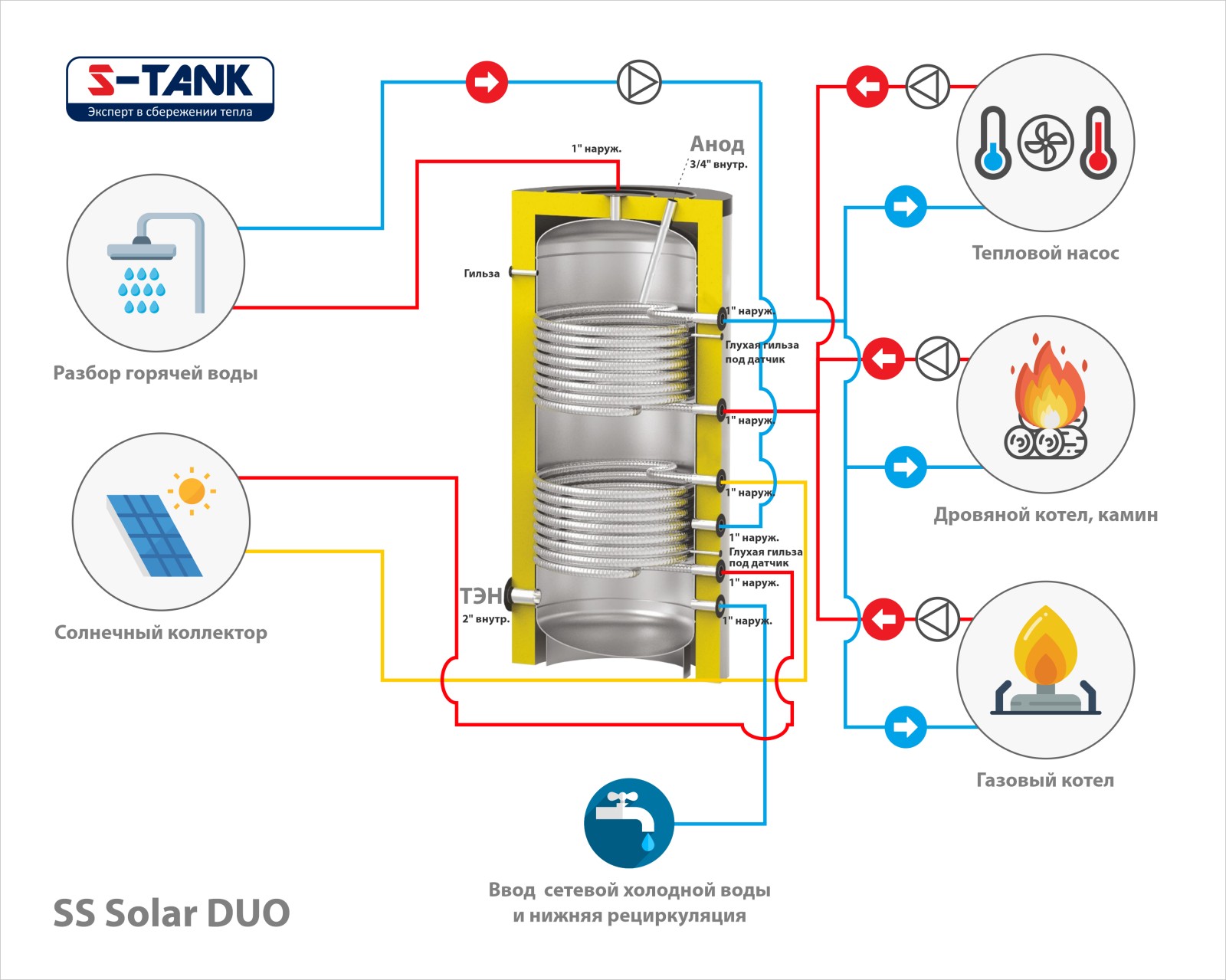

Heat accumulator device and rational connection of external devices

The main part of this unit is a cylindrical stainless tank filled with a liquid characterized by a high heat transfer coefficient. Its strapping is carried out with a heat-insulating material. In combination with the installation of the upper jacket, such a constructive solution increases the cooling time of the heat accumulator. Inside the cylindrical tank are placed from 1 to 3 heat exchangers. The number of coils is determined by the capabilities and needs of homeowners.

Heated water from solid fuel or gas boilers enters the cavity of the accumulator tank from above, and the cooled liquid settles closer to the bottom and is pumped back into the boiler for heating.

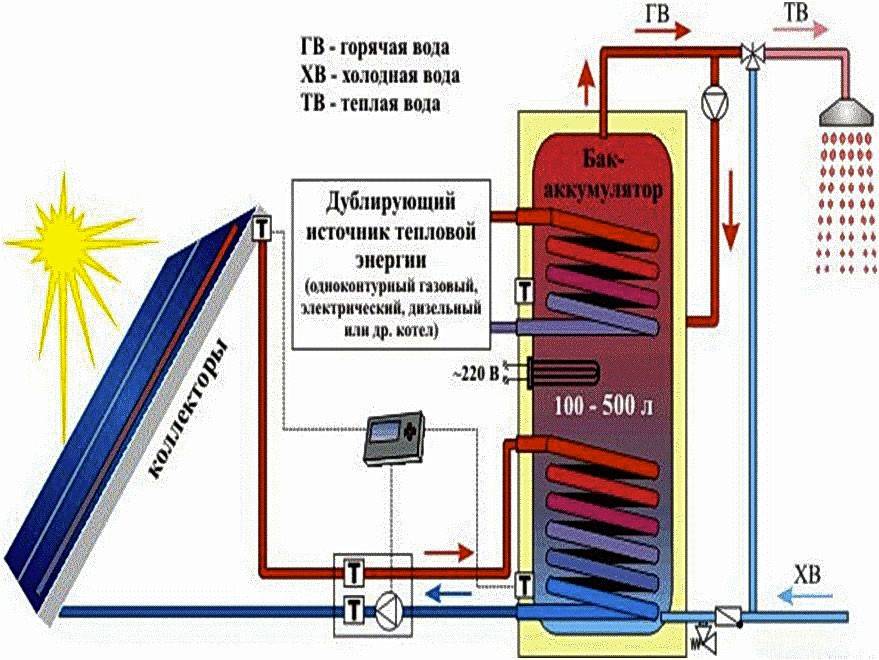

Scheme of the heat accumulator device with the ability to connect to alternative energy sources

The lower compartment usually has a temperature of the order of 35-40°C. Therefore, it is advisable to connect it to the underfloor heating system. The temperature of the middle part is 60-65°C. Therefore, heating devices should be connected to it. The upper part of the tank is connected to the hot water supply. The water temperature there reaches 80-85°C.

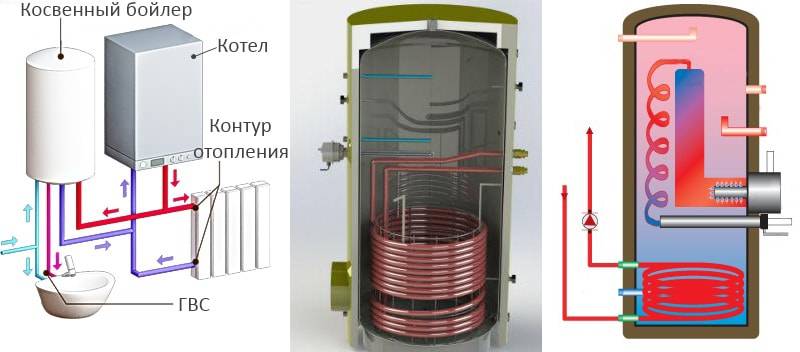

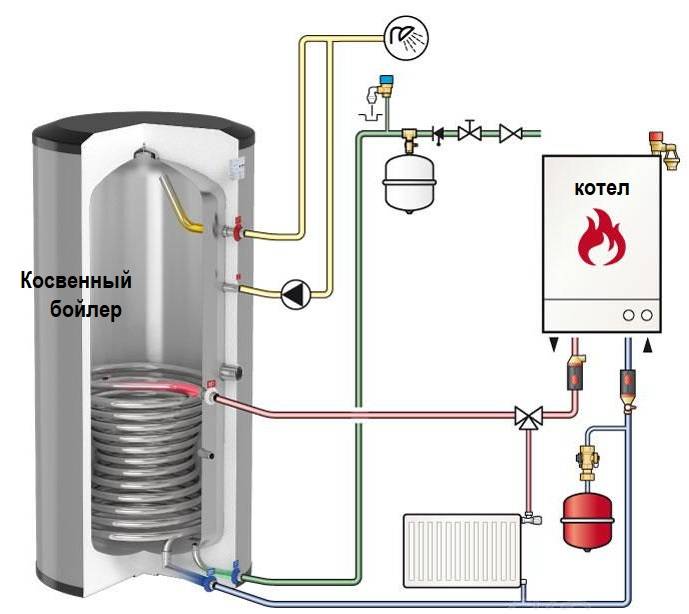

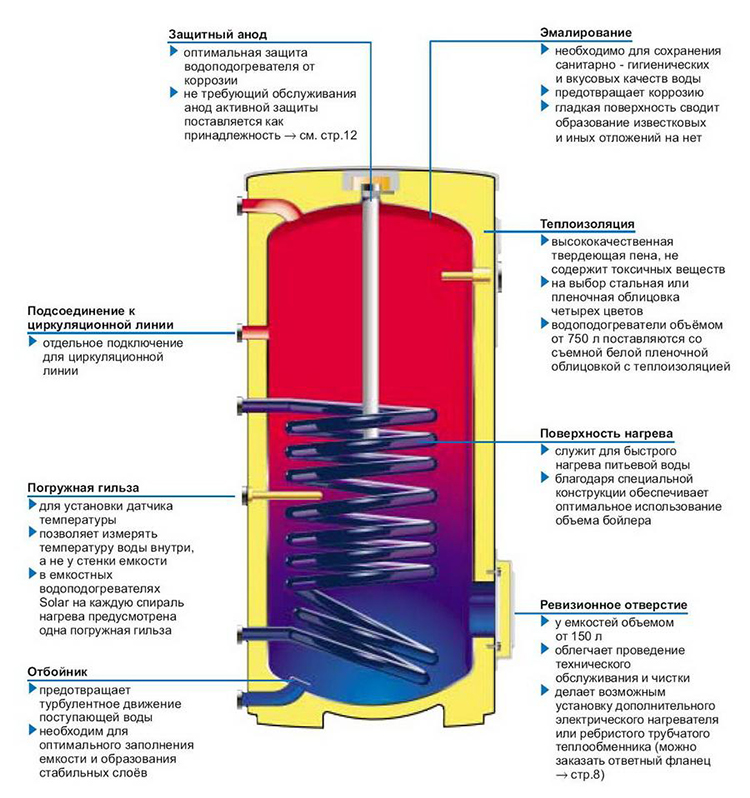

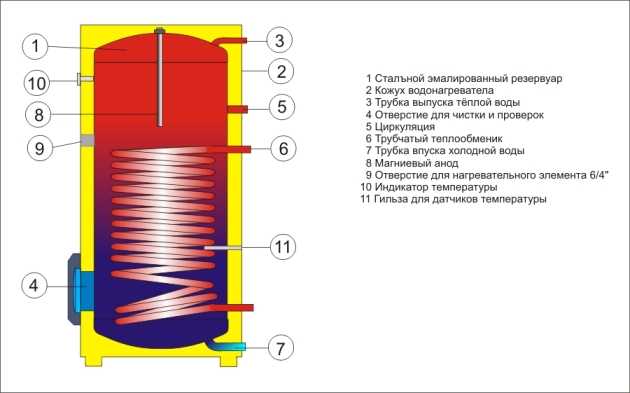

What is an indirect heating boiler and what are they

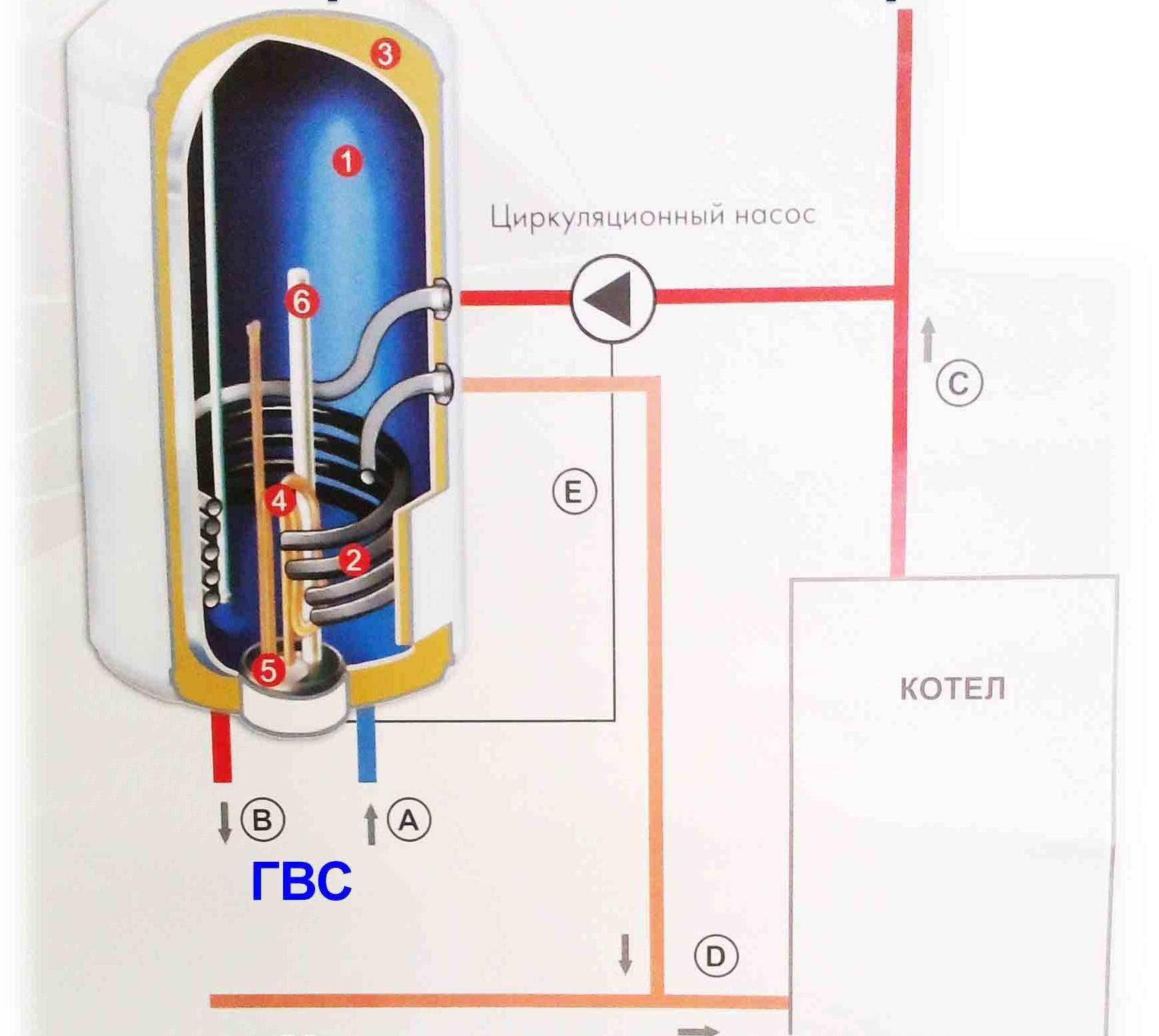

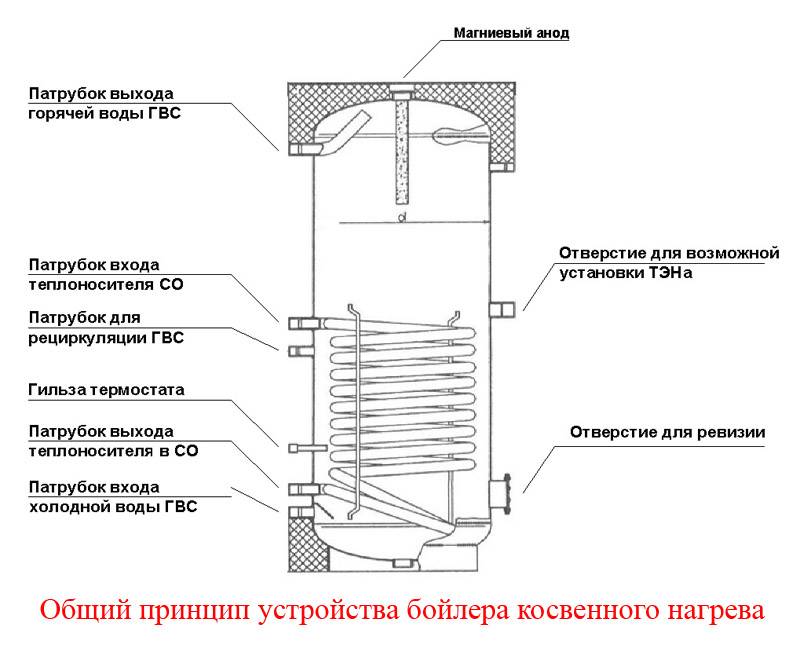

A water heater or an indirect exchange boiler is a tank with water in which a heat exchanger is located (a coil or, according to the type of water jacket, a cylinder in a cylinder). The heat exchanger is connected to a heating boiler or to any other system in which hot water or other coolant circulates.

Heating is simple: hot water from the boiler passes through the heat exchanger, it heats the walls of the heat exchanger, and they, in turn, transfer heat to the water in the tank. Since the heating does not occur directly, then such a water heater is called "indirect heating". The heated water is used for household needs as needed.

Device indirect heating boiler

One of the important details in this design is the magnesium anode. It reduces the intensity of corrosion processes - the tank lasts longer.

Kinds

There are two types of indirect heating boilers: with built-in control and without. Indirect heating boilers with built-in control are connected to a heating system powered by boilers without control. They have a built-in temperature sensor, their own control that turns on / off the supply of hot water to the coil. When connecting this type of equipment, all that is needed is to connect the heating supply and return to the corresponding inputs, connect the cold water supply and connect the hot water distribution comb to the upper outlet. That's all, you can fill the tank and start heating it.

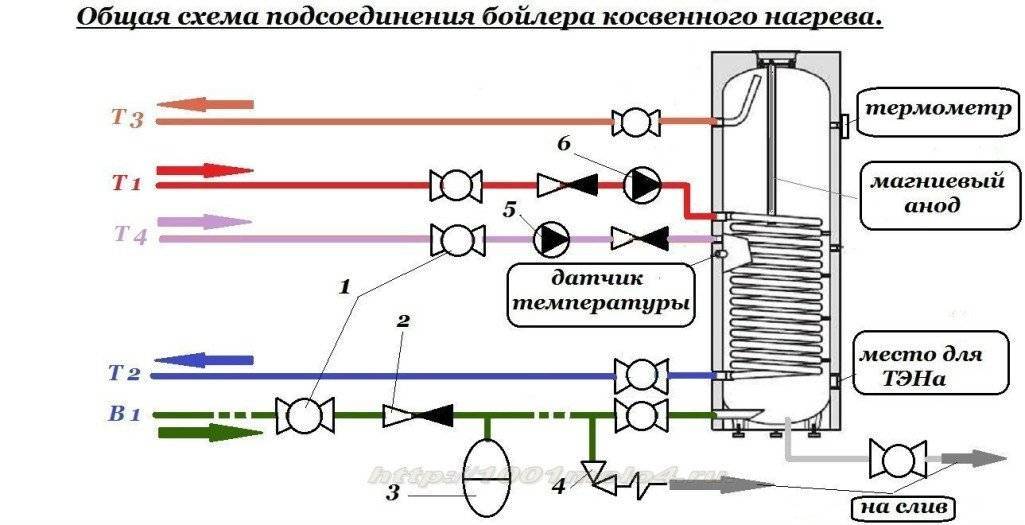

Conventional indirect heating boilers work mainly with automated boilers. During installation, it is necessary to install a temperature sensor in a certain place (there is a hole in the body) and connect it to a certain boiler inlet.Next, they make the piping of the indirect heating boiler in accordance with one of the schemes. You can also connect them to non-volatile boilers, but this requires special schemes (see below).

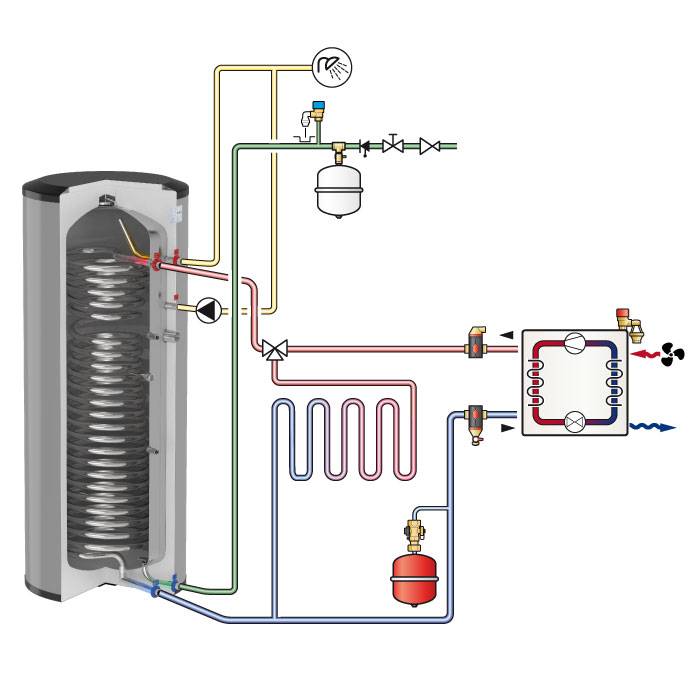

What you need to remember is that the water in the indirect heating boiler can be heated just below the temperature of the coolant circulating in the coil. So if your boiler works in low-temperature mode and produces, say, + 40 ° C, then the maximum temperature of the water in the tank will be just that. You can't heat it up anymore. To get around this limitation, there are combined water heaters. They have a coil and a built-in heating element. The main heating in this case is due to the coil (indirect heating), and the heating element only brings the temperature to the set one. Also, such systems are good in tandem with solid fuel boilers - the water will be warm even when the fuel has burned out.

What else can be said about the design features? Several heat exchangers are installed in large-volume indirect systems - this reduces the time for heating water. To reduce the time of heating water and for slower cooling of the tank, it is better to choose models with thermal insulation.

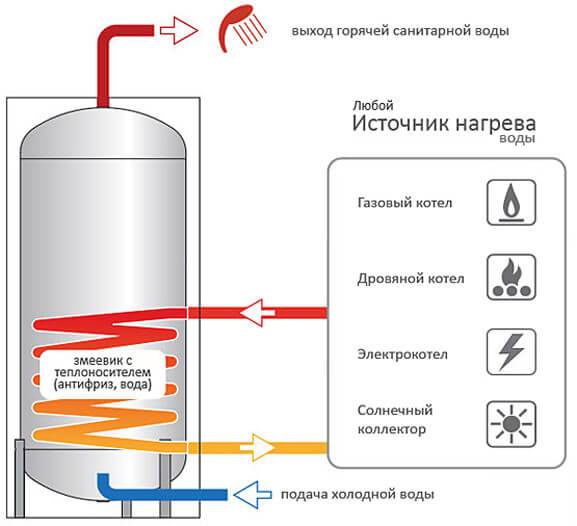

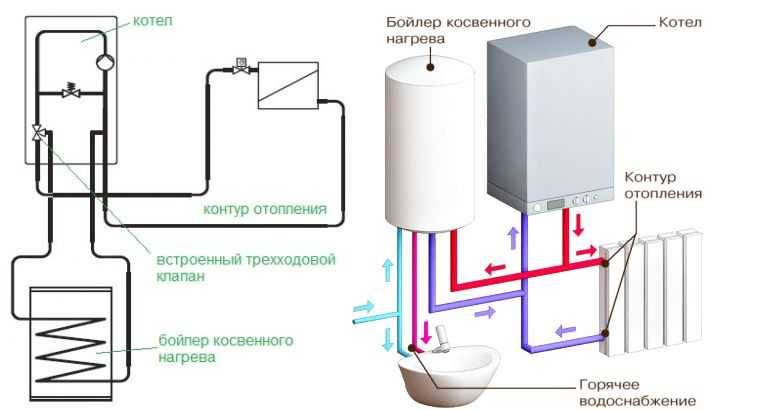

Which boilers can be connected to

Boilers of indirect heating can work with any source of hot water. Any hot water boiler is suitable - solid fuel - on wood, coal, briquettes, pellets. It can be connected to any type of gas boiler, electric or oil-fired.

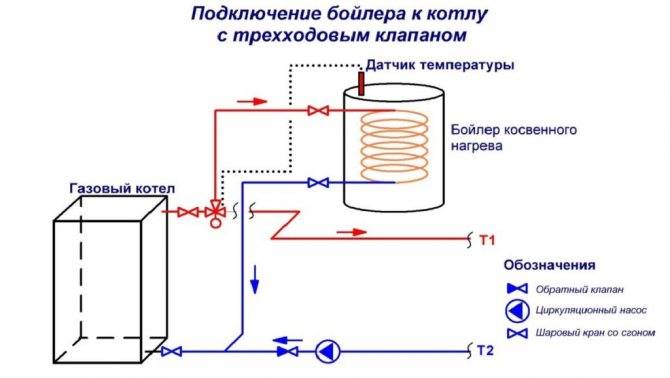

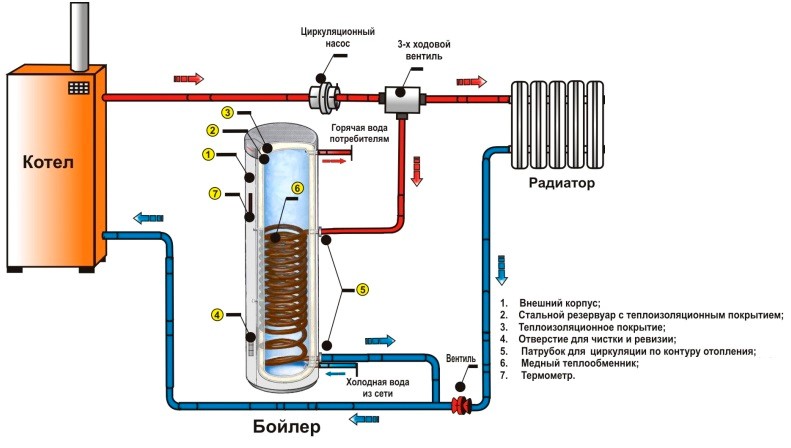

Scheme of connection to a gas boiler with a special outlet for an indirect heating boiler

It’s just that, as already mentioned above, there are models with their own control, and then installing and tying them is a simpler task.If the model is simple, it is necessary to think over a system for controlling the temperature and switching the boiler from heating radiators to heating hot water.

Tank shapes and installation methods

The indirect heating boiler can be installed on the floor, it can be hung on the wall. Wall-mounted options have a capacity of no more than 200 liters, and floor options can hold up to 1500 liters. In both cases, there are horizontal and vertical models. When installing the wall-mounted version, the mount is standard - brackets that are mounted on dowels of the appropriate type.

If we talk about the shape, then most often these devices are made in the form of a cylinder. In almost all models, all working outputs (pipes for connection) are brought out at the back. It is easier to connect, and the appearance is better. On the front of the panel there are places for installing a temperature sensor or a thermal relay, in some models it is possible to install a heating element - for additional heating of water in case of a lack of heating power.

By type of installation, they are wall-mounted and floor-mounted, capacity - from 50 liters to 1500 liters

When installing the system, it is worth remembering that the system will work effectively only if the boiler capacity is sufficient.

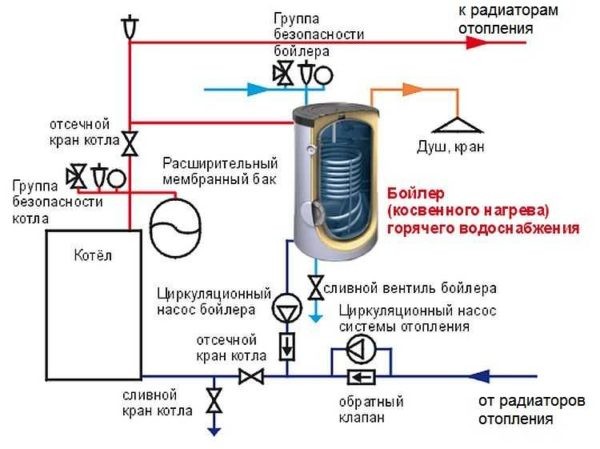

Tying the "indirect" with the boiler

First of all, the unit must be installed on the floor or securely attached to a main wall made of brick or concrete. If the partition is built of porous materials (foam block, aerated concrete), it is better to refrain from wall mounting. When installing on the floor, keep a distance of 50 cm from the nearest structure - clearance is necessary for servicing the boiler.

Recommended technological indents from the floor boiler to the nearest walls

Connecting the boiler to a solid fuel or gas boiler that is not equipped with an electronic control unit is carried out according to the diagram below.

We list the main elements of the boiler circuit and indicate their functions:

- an automatic air vent is placed at the top of the supply line and discharges air bubbles that accumulate in the pipeline;

- the circulation pump provides the coolant flow through the loading circuit and the coil;

- a thermostat with an immersion sensor stops the pump when the set temperature inside the tank is reached;

- check valve eliminates the occurrence of parasitic flow from the main line to the boiler heat exchanger;

- the diagram conventionally does not show shut-off valves with American women, designed to turn off and service the apparatus.

When starting the boiler “cold”, it is better to stop the circulation pump of the boiler until the heat generator warms up

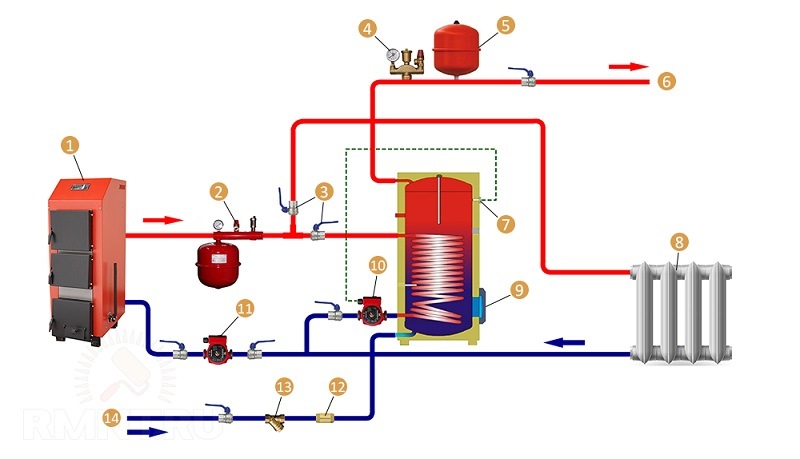

Similarly, the heater is connected to more complex systems with several boilers and heating circuits. The only condition: the boiler must receive the hottest coolant, therefore it crashes into the main line first, and it is connected directly to the hydraulic arrow distribution manifold, without a three-way valve. An example is shown in the primary/secondary ring tying diagram.

The general diagram conventionally does not show the non-return valve and boiler thermostat

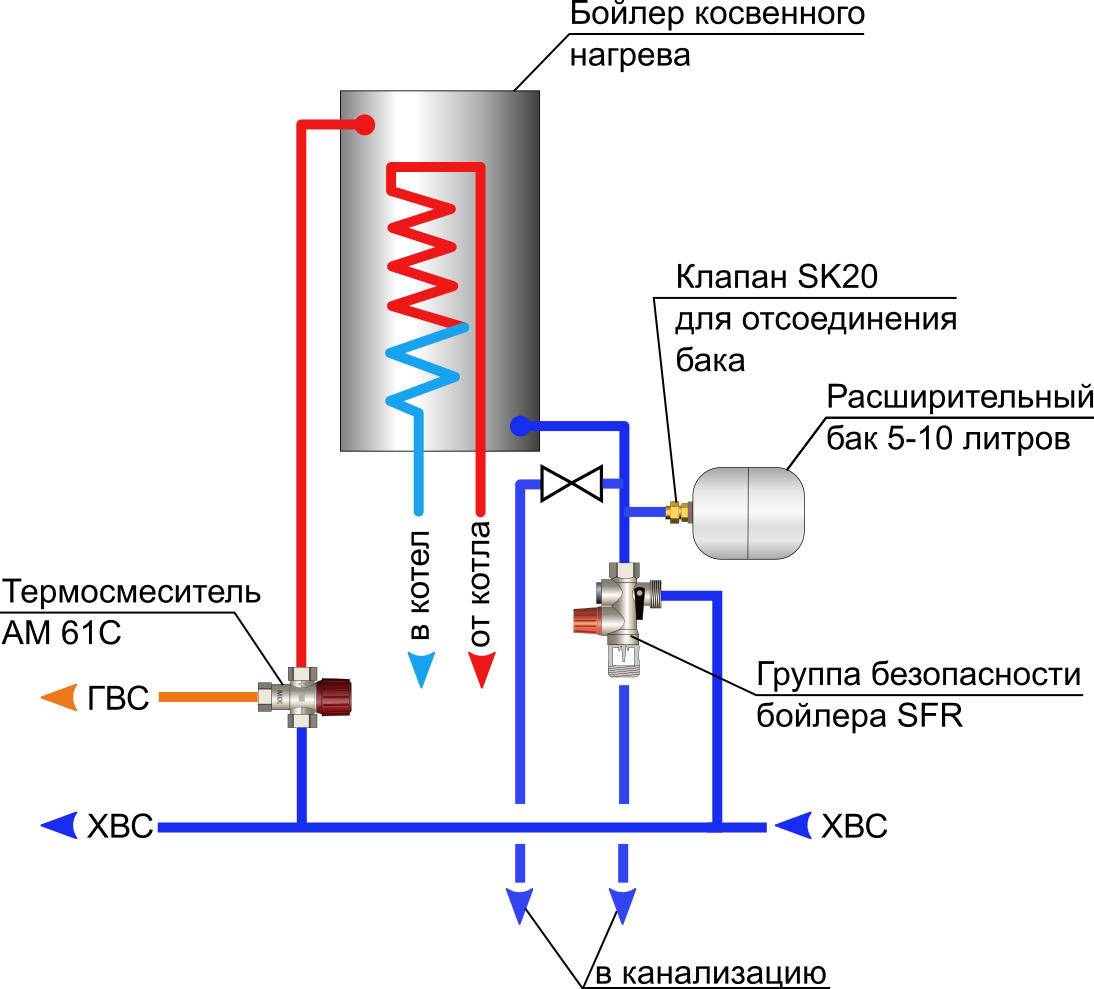

When it is required to connect a tank-in-tank boiler, the manufacturer recommends using an expansion tank and a safety group connected to the coolant outlet. Rationale: when the internal DHW tank expands, the volume of the water jacket decreases, there is nowhere for the liquid to go.Applied equipment and fittings are shown in the figure.

When connecting tank-in-tank water heaters, the manufacturer recommends installing an expansion tank on the side of the heating system

The easiest way is to connect an indirect heating boiler to wall-mounted boilers, which have a special fitting. The remaining heat generators, equipped with electronics, are connected to the water heater via a motorized three-way diverter valve controlled by the boiler controller. The algorithm is this:

- When the temperature in the tank drops, the thermostat signals the boiler control unit.

- The controller gives a command to the three-way valve, which transfers the entire coolant to the loading of the DHW tank. The circulation through the coil is provided by the built-in boiler pump.

- Upon reaching the set temperature, the electronics receives a signal from the boiler temperature sensor and switches the three-way valve to its original position. The coolant goes back to the heating network.

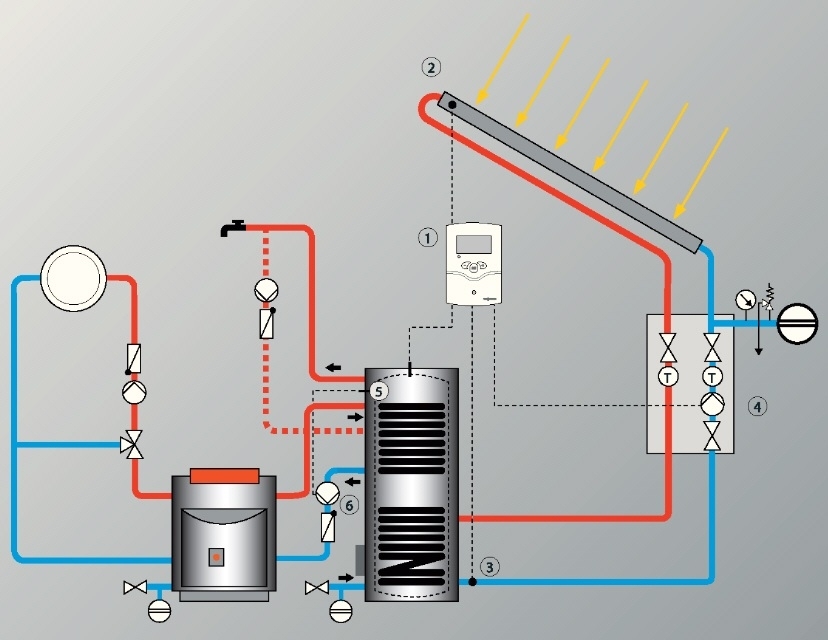

The connection of the solar collector to the second boiler coil is shown in the following diagram. The solar system is a full-fledged closed circuit with its own expansion tank, pump and safety group. Here you can not do without a separate unit that controls the operation of the collector according to the signals of two temperature sensors.

Heating water from the solar collector must be controlled by a separate electronic unit

Indirect heating boiler

Many owners of private houses are wondering how to supply the house not only with heat, but also with hot water through the heating system.Why does such a question even arise, because the market is simply teeming with offers of electric and gas storage and instantaneous water heaters? Everything is very banal - electricity is not cheap, and gas water heaters are not able to provide a constant temperature that is comfortable for use. Therefore, indirect heaters are an excellent option for a home with heating from a gas boiler, moreover, economical.

Quantities

We consume water in liters, and its temperature is measured in degrees. Water, in order to heat up, uses thermal energy in Joules based on its mass in kilograms. The water heater generates power in watts, and the efficiency is calculated as a percentage. Let's translate these units of measurement into one, understandable, plane.

- According to the laws of physics, in order to raise the temperature of 1 kg of water, which is equal to 1 liter, 4.187 kJ of thermal energy is required by 1 ° C, which is 0.001 kW / h of the power of the heating device. Type, manufacturer and losses are not taken into account. Whoever produces the heater and in whatever conditions this mechanism is located, the water always needs just that much energy.

- The water entering the boiler in winter (the boiler does not work in summer) has a temperature of about 10o. Insulated supply pipes will reduce the temperature difference at the inlet and outlet of the boiler and help save fuel.

- The number 60o is set on the control panel of the device. This means that the liquid in the unit will be heated to this temperature. Therefore, 60-10=50o. It is not necessary to set a high heating value. Such a load will entail increased wear on the equipment.

- The temperature must be raised by this amount.We multiply the found difference in degrees by the energy needed to obtain each of them - 50 * 0.001 \u003d 0.05 kW / h of power the boiler will need for such work.

So, to heat 1 liter of water to 60 °, 0.05 kW / h of boiler power will be needed, and to increase by 1 ° - 0.001 kW / h of its efforts.

The hot water that we take from the tap to wash our face or wash dishes has a temperature of about 40o. Above it will be hot, below it will be cool. In order for the calculation of the operation of a boiler, not only indirect heating, but also any other type of heater, to be correct, it must be taken into account that we mix two waters, each of which has its own temperature.

- Hot water is thermal energy. We calculated that 10 = 0.001 kWh.

- The water we want should be 40o, which means 40 * 0.001 \u003d 0.04 kW.

- Cold water has 10o, so 0.01 kW / h is already there. This is 25% of the required amount of heat.

- So you need to add another 75% of the temperature, which will be 0.05 * 75% \u003d 0.0375 kW / h.

Thus, 1 liter of the desired mixture (hereinafter referred to as warm water) will contain 0.75 liters of fully heated water from our unit and 0.0375 kW / h of its power.

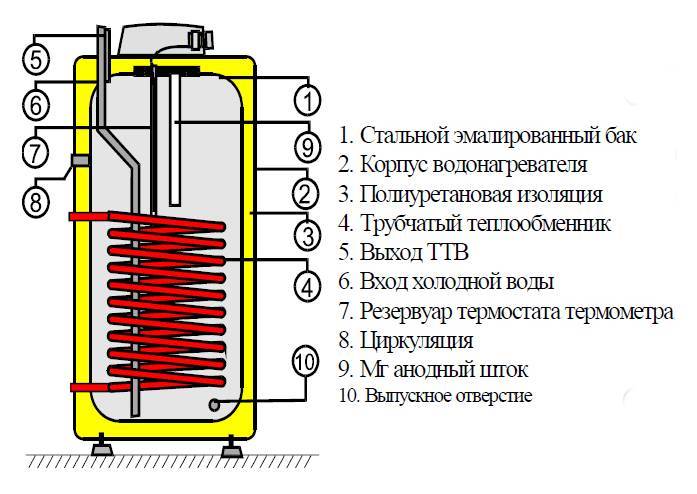

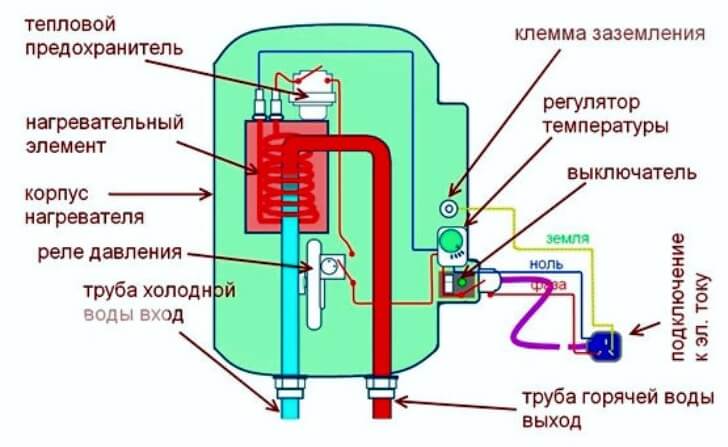

Water heater design

Products of various shapes, volumes and technical characteristics are presented on the market. Regardless of this, water heaters of each individual type are similar in design.

Electric storage

By design, this type of product is a container of a round or oval shape. The tank is used to store and heat water.

It is in a case made of metal or plastic. To avoid rapid cooling of the liquid, manufacturers equip the container with a heat-insulating layer.

The tank is made from materials that are the least susceptible to corrosion.There are products on the market, the capacity of which is made of enameled or stainless steel. To protect internal parts from scale formation, water heaters are equipped with a magnesium anode.

Electric storage heater operation

In the lower part there is an electric electric heater. It is equipped with a thermostat that allows you to maintain a certain temperature of the liquid. Some models have two heaters.

After warming up the liquid, one of them is turned off, and a certain temperature indicator is maintained by the other. This allows you to save energy.

The boiler device includes two nozzles. They are used to supply water and drain it from the tank. The cold water connection is installed at the bottom of the tank, and the hot liquid withdrawal pipe is at the top.

Electric flow

The flow boiler device for heating water does not include a storage tank. The liquid warms up as it passes through the device. Heating is carried out by an electric heater high power.

The design features of the flow-type product allow you to quickly warm up a small amount of water. The design of the product of the flow type includes:

- High power electric water heater.

- Operation indicator.

- Shirt for passing water.

- Sensors and relays.

Flow boiler. Source

Flow boiler. Source

Due to the lack of storage capacity, flow-through boilers are small in size. This makes it possible to install the device in rooms with limited free space.

Gas water heaters

Devices that use gas as a heat source can be either flow-through or storage type.Instantaneous water heaters - geysers can quickly warm up a small amount of liquid passing through them.

With the help of storage you can get a large amount of hot water, but after that it will take time to warm up a new portion.

Storage devices consist of a metal tank through which the flue passes. It is necessary for the removal of combustion products of gas. Instead of a heating element, a gas burner is used in the water heater. The degree of heating is controlled by a specialized unit.

The principle of operation of an electric storage water heater

Equipment of this type operates according to a special principle. Water is mixed inside the storage heater. According to the laws of physics, a more heated liquid rushes up the reservoir. Cold or less heated water accumulates below, this is the heating zone where the heating element works. Passive fluid shear provides periodic activation of the equipment, that is, heating until ready.

Note! The device is permanently connected to the network. The load on the heating equipment is controlled through thermostatic contacts. Their task is to open the circuit when the water reaches the required degree of heating.

To block the inversion (recirculation), a check valve operates in the equipment system. It is he who does not allow the heated water to move in the other direction. Water distribution fittings work on the outlet line (to the consumer). After dispensing with a nozzle, the pressure inside the boiler system decreases. The reaction to this is to open the filling valve to fill the tank with cold water from the water supply.

Note! Decisive for the efficiency of the electric water heater provides a divider. It controls the water mixing process by limiting the speed

How to calculate the volume of an indirect heating boiler

The description of the schemes presented above requires a correct calculation. A heater is needed to maintain the water temperature at the same level.

In order to carry out the calculation, it is necessary to consider an example of such an action. A family of 4 people will be taken as a basis, where a large amount of warm water is consumed daily.

Washing dishes in 1 minute takes up to about 3 liters of hot water. If you add rinsing here, then it will take about 8 minutes. Washing after two meals a day will require approximately 48 liters (3*8*2). It turns out that in a week the water consumption for washing dishes will be 48 * 7 = 336 liters.

All family members take a bath 3 times a week. On average, about 80 liters of water are consumed per 1 person. For a week, a family of 4 spends 4 * 3 = 12 * 80 = 960 liters on water procedures

On the other 4 days of the week, each member of the family takes a shower. The average procedure time is 10 minutes. Water consumption per minute is 8 liters. One family member consumes 4*10*8= 320 liters per week. It turns out that a family spends 320 * 4 = 1280 liters per week on a shower.

All family members collectively use up to 40 liters of water per day for small household activities. This figure will leave 280 liters per week.

As a result, a family of 4 spends about 336+960+1280+280=2856 liters of water per week.Taking into account errors and unforeseen expenses, it is better to round the figure up to 2900 liters. The flow in the boiler is calculated by the hour. Therefore, everything must be converted in units. To do this, we divide the resulting volume by the number of days and by 24 hours - 2900/7/24 = 17 liters per hour the family spends.

To calculate the ratio of temperature and power, we obtain the following indicator 17 * 0.0375 = 0.637 kW per hour.

What is an indirect water heater?

A feature of the design of indirect type boilers is the absence of their own heating element. Such a device works by obtaining heat from the outside, as a rule, from a central heating system or solar panels. It is possible to use a cascade system, that is, the heating process in an indirect type unit occurs after the activation of the main boiler.

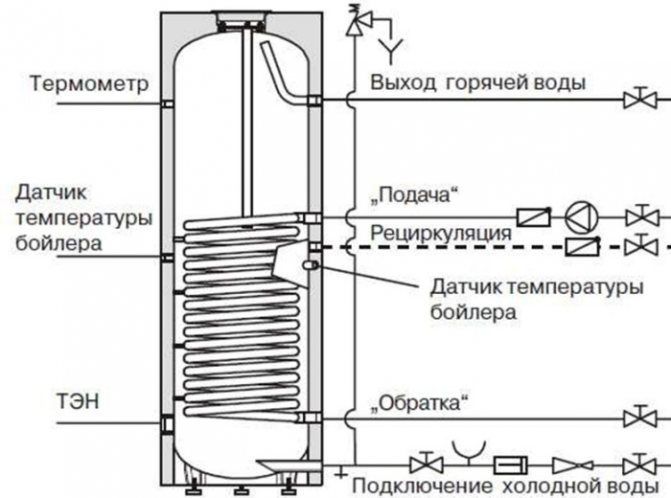

The device and principle of operation of an indirect heating boiler

The water heater of the so-called indirect heating is a cylindrical tank. The device consists of the following elements:

- corps;

- thermal insulation;

- internal stainless tank;

- temperature meter;

- heat exchange systems;

- magnesium anode.

The installed insulation between the tank and the body provides the least heat loss. There is a heat exchanger inside the tank. It is made of a steel or brass tube, which is laid at the bottom with special bends, thus ensuring uniform heating of the water. The installed thermometer monitors the temperature. To protect against corrosion, a magnesium anode is installed.

The water heater can be installed:

- On the wall, when there is not enough space in the room or you want to save it.But it must be taken into account that the fastenings are carried out with brackets that have weight restrictions, so the mass of the boiler should not exceed 100 kg.

- On the floor, used for devices from 100 kg, on special stands.

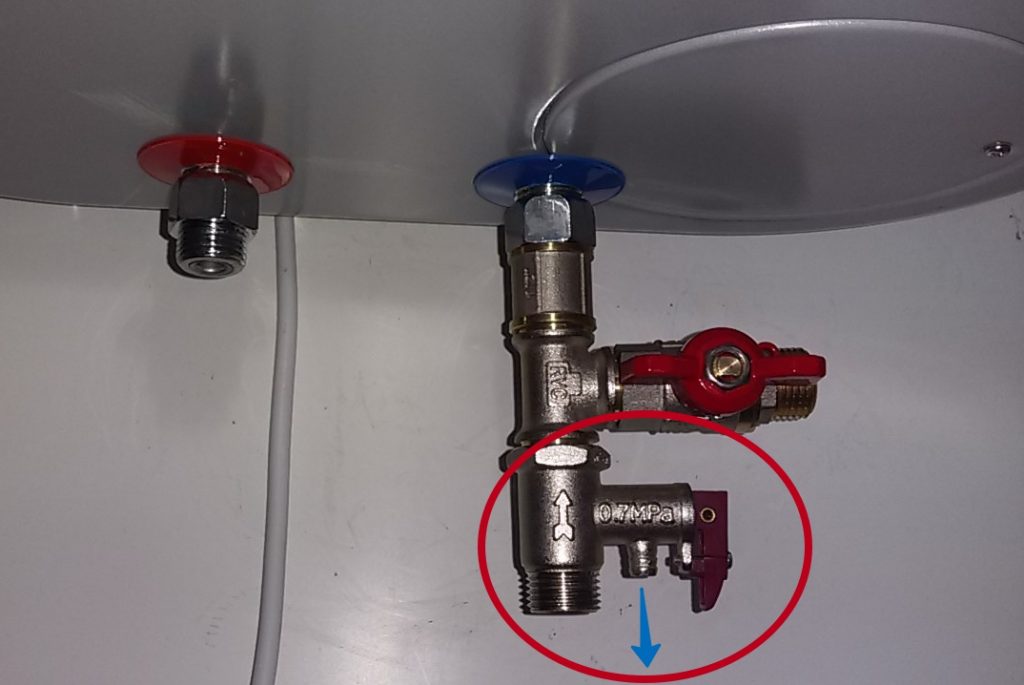

Features of installation and connection of the water heater

Before turning on, you must properly mount the device. It is necessary to take into account the following nuances:

First you need to select the installation location

As a rule, this is a bathroom or toilet.

When installing, it is important to consider: ease of dismantling, the ability to get to the connections. This will be needed during maintenance and repair work.

You can not interfere with the passage and block other engineering systems.

If in the room where the water heater is installed, the walls are not solid, but plasterboard, then it cannot be fixed. In this case, the floor version is used or the installation is carried out on a metal rack.

Connection to the water supply and electricity system is carried out by qualified specialists

Particular attention should be paid to the fact that before being connected to the electrical network, the metal case must be grounded.

After installation, it is connected to the electrical network, according to the instructions specified in the product passport. The correct operation of the device is checked.

After supplying hot water to the heat exchanger of the water heater, the coolant must constantly circulate to maintain the temperature - for this, a pump is installed

After heating to the desired temperature, the pump turns off. Water can remain hot for a long time due to the heat-insulating insulation.

Connecting an indirect heating boiler with two circulation pumps

If you decide to install an indirect system in the circulation pump system, but at some distance from it, a scheme with two circulation pumps will be relevant for you, in accordance with it, the best location of the pump is in the circuit to the water heater.

In this scheme, the pump can be installed both on the supply pipe and on the return pipe. The presence of a three-way valve is not required here, the circuit is connected here using conventional tees. It is possible to switch the coolant flow by turning on or off the circulation pumps, which are controlled by a thermostat that has two pairs of contacts.

If the water cools down, the pump located in the boiler circuit starts working, and the pump responsible for transferring the coolant to the heating system is turned off. When the water reaches the desired temperature, the reverse reaction occurs: the 1st pump turns off, and the 2nd turns on and transfers the coolant back to the heating system.

Indirect heating boiler: principle of operation

Circulating in the "Boiler-heat exchanger-pipeline-boiler" system, the heat carrier gives off part of the energy to the cold water in the tank, gradually heating it to the desired temperature. The process is identical to what is happening in the heating device: only here the heat exchanger acts as a radiator, and water is heated instead of air.

The speed and degree of heating depend on the power of the boiler and the surface area of the heat exchanger.

In order not to waste time waiting for hot water to reach the tap from the heater, a recirculation system is used, using a special pump, creating a continuous circulation of water in a closed circuit.