- The purpose of the rotation unit of an air conditioner of any capacity

- Selection factors and additional functionality

- How to set up

- Rotation, with data transmission via IR and radio channel

- Connection of the rotation module for industrial air conditioners

- 1 What is the purpose of the rotation unit of air conditioners

- Purpose and device of the rotation block

- Temperature indicators in the server room

- Reservation schemes for air conditioners

- Features of installation on the example of BURR-1

- The principle of operation of the rotation unit

- Specifications of rotation module for air conditioner

- Purpose and functional features

- Rotation with data transmission via IR and radio channel

- Conclusions and useful video on the topic

The purpose of the rotation unit of an air conditioner of any capacity

Maintaining the temperature in a room with one or more servers is the initial task. Continuous operation of equipment is provided by air conditioners with a backup system, the role of which is performed by a rotation unit. The principle of operation of a simple additional device is quite simple. The module sets the time intervals when the air conditioner should cool the entire room. Built-in sensors record minimal changes and, if necessary, correct the temperature regime. The use of a rotation block eliminates human intervention.The system works offline, and only checks (diagnostics) of the module are performed using the wizard.

The air conditioner rotation system regulates the voltage level supplied to the cooler. The sensors that are directly involved in the operation of the cooling (special room) equipment are located according to a strategic principle. One part sensitive to temperature changes is installed directly in the room, the other two sensors are mounted inside the module.

Advantages of the air conditioner rotary unit:

- the user has the right to change the temperature regimes and set their frequency;

- if the main air conditioner breaks down, the system automatically switches to the backup device;

- installation of additional sensors (thoroughly regulate the temperature, adjust to the change of environmental factors);

- emergency shutdown of equipment in emergency situations.

For synchronous operation of several climatic devices, it is not necessary to use rotation modules, but simple devices simplify the maintenance of auxiliary equipment and allow you to extend its service life. Communication of the entire installation with a security point or emergency services ensures safety not only for people working near the server, but also for expensive equipment.

If the main air conditioner breaks down, the unit will switch the system to a backup

Selection factors and additional functionality

There are different models and modifications of air conditioner rotation and redundancy units on the market, which differ from each other:

- by characteristics;

- according to the set of functions;

- according to the method of installation;

- by type of management.

The control signal can be transmitted not only via the infrared channel, as with BURR-1, but also via wires.The complete set differs in the number of temperature sensors. themselves sensors can work with one or another error, on which, to a certain extent, the speed of operation of the rotation unit depends

Also pay attention to the error of the timer. These and other data must be indicated in the accompanying documentation.

When choosing a matcher, the requirements for the air conditioning system, its composition and configuration are taken into account. So, for air conditioners without photodetectors, you can choose devices with a wired type of control. An important criterion is the functionality of the device.

Today you can buy rotation blocks with a wide range of functions. In addition to performing their basic tasks, these devices automatically restart air conditioners that have been stopped due to a power outage. They do not allow turning off air conditioners if a person accidentally gives such a command from the remote control.

One of the simplest redundancy blocks for two air conditioners, buttons for registration and settings on the left, buttons for switching to operating and service modes on the right

When alarm loops are connected, alarm messages are transmitted. For example, a fire report is sent if the temperature in the server room rises above a certain value (usually at 69º C). The signal can be sent to the fire department, it is also possible to alert personnel via SMS.

Events and data from temperature sensors are recorded in non-volatile logs. The possibility of remote control via RS485 interface and Ethernet is provided. The industrial communication protocol Modbus is supported.

Having familiarized yourself with the description and technical characteristics of the device, you should make sure of the significance of its functionality in order to make an informed economically viable choice.

It should be borne in mind that the uninterrupted cooling depends not only on the backup unit, but also on the air conditioners themselves. In server rooms, precision, channel and wall-mounted inverter split systems are used. The latter option is most in demand, since such devices are much cheaper and take up less space.

Wall-mounted air conditioners provide adequate cooling for server rooms and, unlike precision models, can be used in small areas

When choosing a wall-mounted air conditioner, attention is paid to the cooling capacity, which must correspond to the excess heat to be neutralized. The air conditioning system must function in the server room, regardless of the time of year

If the lower limit of the operating temperature of air conditioners is limited to -10 C, low-temperature kits are additionally purchased

The air conditioning system must function in the server room, regardless of the time of year. If the lower limit of the operating temperature of air conditioners is limited to -10 C, low-temperature kits are additionally purchased.

How to set up

Based on the settings of the rotation control module set by the user, the air conditioners are turned on and off. In this case, a certain sequence and specified time intervals are observed.

To enter the settings menu of the control unit, press "Enter". If the settings are changed during operation, at the moment this button is pressed, the unit can transmit commands using a previously set protocol.In this case, you will have to wait a little while continuing to press "Enter".

The settings menu items are combined into several groups, including registration of execution units, time and temperature parameters. Information about the operation of the system is displayed on the display of the control unit. It is presented in the form of clearly formulated phrases and symbols. On the display you can see the type of transmitted command and its current status, which facilitates the configuration and subsequent operation of the BURR-1.

Using the control panel, each air conditioner is assigned a number, its purpose is determined. Air conditioners are grouped depending on their purpose: reserve, rotation participants, etc.

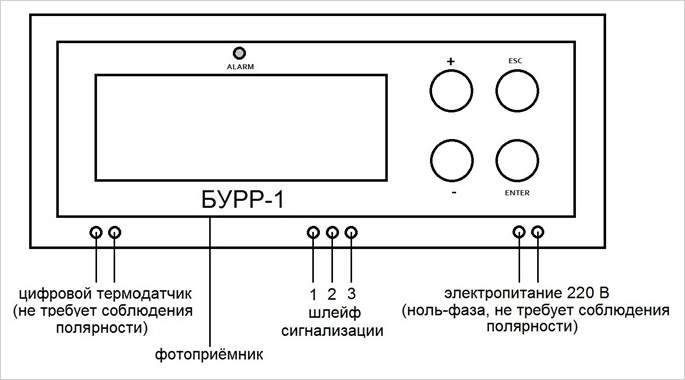

Front panel BURR-1 with LCD display and control buttons, due to its compact size takes up little space in the switchboard cabinet, thanks to thoughtful ergonomics it is convenient for setting the settings

Using the data entry panel, set temperature limits in the server room, connection temperature, disconnection temperature, alarm operation, as well as time parameters regarding collaboration and rotation.

The operating mode of the executing unit is determined by the change in color and blinking frequency of the diode located at the bottom of the housing. For example, when the execution unit is in normal mode and waiting for a command from the control unit, its LED slowly flashes green.

When such a command is received, a yellow light lights up for 1-2 seconds. Execution of the power-on command is accompanied by a rapid flashing of the green color. If a shutdown occurs, the LED lights up red and also flashes quickly.

After setting the settings and wanting to exit the menu, press the "ESC" button.If you do not press the buttons for 4 minutes, that is, completely inactive, the exit will be performed automatically.

If no buttons are pressed because a command is being recorded and an IR signal is expected, there will be no auto-logout

Please note that when performing some operations, pressing "ESC" will exit the menu, in which the changes made to the settings will not be saved.

Regardless of the model, the setup process is intuitive, as can be seen from the photo of the SRK-M3 air conditioner coordinator, indicating the control buttons, sensors, service and information LEDs

When the unit is in the setting mode, the rotation control is suspended, although all the timers are running, counting down the operation time of each group of air conditioners and the rotation time.

The process of setting up the rotation control module is described in detail in the instructions attached to it.

Rotation, with data transmission via IR and radio channel

Many business leaders use household air conditioners to maintain the required temperature in laboratories and server rooms. This is due to the rather high cost of specialized equipment designed to cool the air in such rooms. To save energy, increase the fault tolerance of household climate control equipment, and also to ensure uninterrupted operation of cooling, redundancy and alternating switching of air conditioners based on BURR and BIS rotation modules are often used.

The base works in a set with BIS executive modules installed one for each device, which can be 15. The BURR base is equipped with its own temperature sensor, based on which the climate equipment is diagnosed. The principle of its operation is to switch the power supply to a certain group of cooling devices.

Commands that allow or prohibit the supply of electricity are transmitted from the base module to the executive ones, via a radio channel. The range between the executive modules can be 50 m, and they transmit commands to the air conditioner via an IR channel. Programming the actions of IR emitters to turn on or off certain climatic devices is carried out on the base module. Before the first start-up of the “base”, using the data entry panel, the temperature limits in the room are set.

Commands that allow or prohibit the supply of electricity are transmitted from the base module to the executive ones, via a radio channel. The range between the executive modules can be 50 m, and they transmit commands to the air conditioner via an IR channel. Programming the actions of IR emitters to turn on or off certain climatic devices is carried out on the base module. Before the first start-up of the “base”, using the data entry panel, the temperature limits in the room are set.

Such a system makes it possible to implement various options for the alternate use of climate technology, which can consist of two or three groups. The air conditioner rotation device, made on the basis of the BURR and BIS modules, makes it possible to:

- Instant commissioning of backup climate control equipment. In the event of a failure of the main group or a violation of its normal operation, a sharp increase in the temperature in the room occurs. This is exactly what the base module reacts to, giving the command to connect the reserve.

- Connecting an additional group of climate equipment, with a lack of performance of the main one.

- Efficient switching of several groups of air conditioners to produce the same resource. The frequency of switching between groups is user-defined.

The use of BURR and BIS devices allows you to automatically turn off the voltage supply to the air conditioners, and transmit the “Accident” or “Fire” commands to the general network. The main advantage of using BURR and BIS is:

The use of BURR and BIS devices allows you to automatically turn off the voltage supply to the air conditioners, and transmit the “Accident” or “Fire” commands to the general network. The main advantage of using BURR and BIS is:

- Ease of installation, configuration, which functions without laying communication lines to each device.

- Possibility of using for cooling climatic equipment, different power, performance and brand.

- Possibility of mounting the base module BURR in an adjacent room.

The use of rotation units for switching operating air cooling devices with backup climate technology makes it possible to significantly extend their service life due to uniform commissioning and control over temperature indicators.

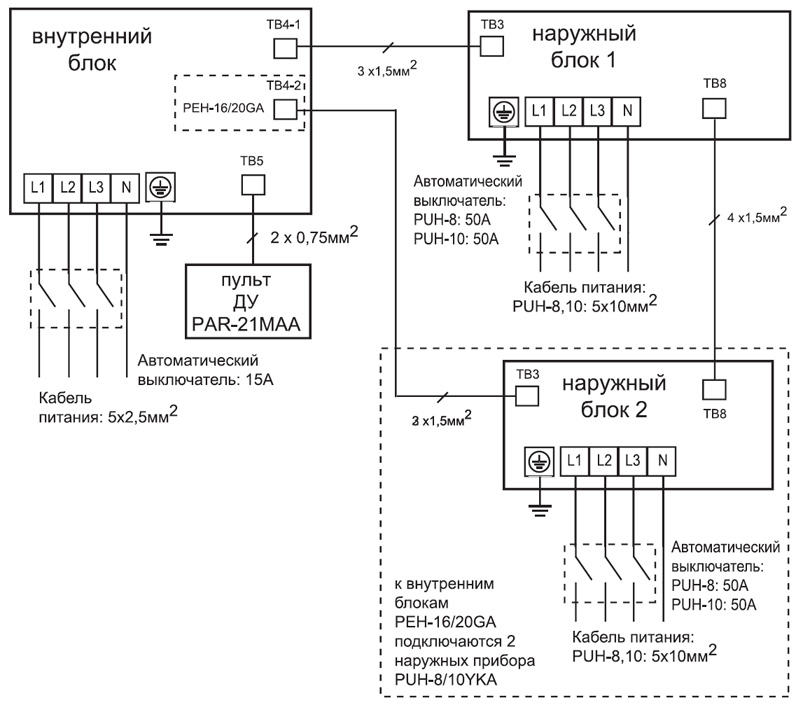

Connection of the rotation module for industrial air conditioners

The device for rotating air conditioners is equipped with blocks for sensors in advance. Small-sized parts, fix the temperature in the room (at different points in the server room). With an increase in the set indicators (humidity, temperature), all air conditioners turn on and stop working only after the indoor climate returns to the specified norm. Under familiar conditions, a single but powerful air conditioner is needed to cool a small room, and the joint operation of the main and backup devices reduces the temperature in the server room in a matter of minutes. Such measures are spontaneous in nature, because the constant operation of two air conditioners at once, although effective, is costly in terms of the amount of electricity consumed.

Quite often, owners of offices or industrial premises save on expensive equipment and instead of special coolers, air conditioning falls entirely on a simple home device. Household units can hardly cope with excessive load, so dangerous heating of the external and internal unit is inevitable. It is possible to delay the inevitable breakdown if the owner of the premises uses rotation modules configured for frequent switching on of air conditioners.

The standard factory rotation module is capable of controlling fifteen medium power devices at once. Inside the unit, one external temperature change sensor is mandatory installed. The tiny element is responsible for switching the load to a suitable air conditioner, regardless of the settings of the owner of the room.

Standard module manages 15 devices

1 What is the purpose of the rotation unit of air conditioners

As already noted in the server room it is necessary to install air conditioners to maintain ideal conditions. But, at the same time, one unit of such cooling devices will not be able to create a constant suitable temperature in this room. There should always be a back-up of equipment in case of an emergency.

Several split-systems will work in turn, controlled by the rotation device of air conditioners. This device will ensure the sequence of their work with turning on and off the air conditioners in the desired mode.

The coordinator of air conditioners eliminates the need for human presence at the control stage. Such a device will be able to turn on and off air conditioners as needed at regular intervals.The mechanism itself is provided by changing the parameters for applying voltage. This principle of operation prevents premature wear of the equipment and distributes the load evenly.

Let's consider what the climate equipment rotation system is intended for.

- 1. The voltage is switched from the failed device to the unit in reserve.

- 2. Alternate connection of both cooling modules will maintain and maintain the desired temperature in the server room.

- 3. If there is a power outage in the area, when it resumes, all groups of air conditioners will be restarted.

- 4. Unplanned shutdown of this equipment using the remote control or changing the operating modes of the air conditioner becomes impossible.

- 5. Monitored when two or more systems are turned on in very hot weather.

- 6. If, in case of abnormal outside temperature, the standard in the room rises, the additional power should be connected in series. This becomes possible due to sensors examining the temperature regime.

Thanks to the last point, in case of an abnormal situation, it is possible to drastically reduce the increased heat in the server room.

What is the structure of the matcher for air conditioners? The main elements of such a system will be a built-in programmable microprocessor and various sensors designed to collect information.

Photo 1. Location of the coordinator for the operation of air conditioners in the server room.

The main sensor is associated with a change in the temperature environment and operates within the range from fifty degrees of frost to one hundred and twenty degrees of heat. The process of connecting air conditioners is carried out through special adapters.The mode is regulated by a timer. The frequency of connections is possible in the range from one hour to ten days.

The test mode of operation involves the use of all connected systems at the same time.

The differences that manufacturers lay down are insignificant and mainly relate to the methods of connecting climate equipment.

Purpose and device of the rotation block

The organization of the cooling system by installing not only the main, but also spare, backup, air conditioners in itself does not save the situation.

It is necessary to coordinate the operation of all devices in such a way that under any conditions the temperature in the room remains stable. For this purpose, specialized complexes are used, which are often called simply matchers.

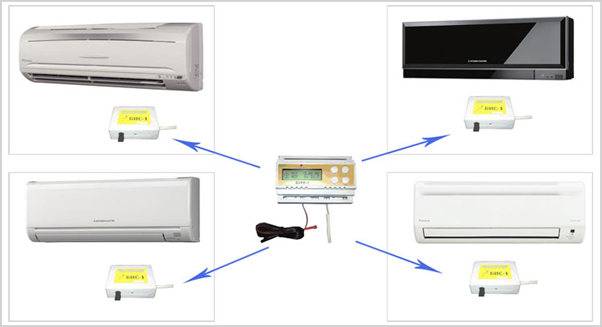

Organization of the air conditioning system, including the main and backup air conditioners, one control unit, two executing units and three temperature sensors with a bus connection for fire and emergency notification

The standard complex includes a control unit and execution units. Together they perform the following basic functions:

- control over the operation of the system;

- switching air conditioners in case of breakdowns;

- ensuring sequential functioning;

- even distribution of working hours.

A reliable air conditioning system for a server room consists of at least two air conditioners: a main one and a backup one. Each of them, according to its technical characteristics, must be able to maintain the necessary temperature conditions in the server room.

In the event of a breakdown of one air conditioner, the rotation unit promptly turns on the second, serviceable, unit. When performing this function, thermal sensors are activated that measure the temperature and react to its slightest increase. The backup function helps not only in emergency situations, but also, for example, during scheduled maintenance and repair of air conditioners.

One of the options for organizing a cooling system in a server room with a backup unit and air conditioners powered from a separate machine

The implementation of such a solution allows you to change filters, refill air conditioners with refrigerant, perform more complex operations at any convenient time, while continuing to maintain an optimal microclimate in the server room.

The rotation block also ensures the alternate operation of air conditioners and split systems, and as a result, the total time of their operation is approximately the same. As a result, the overhaul period and the operational life of the cooling equipment are extended.

Temperature indicators in the server room

Rotation units are implemented in the air conditioning systems of many laboratories, data centers, production shops in high technology industries. This is an essential element of equipping server rooms, which are available in almost every serious organization.

In the age of information technology, even new, developing companies tend to use their own server equipment for processing, storing and exchanging data with partners and customers.

Strict requirements are imposed on the temperature regime in the server room, the fulfillment of which is possible only if there are two or more air conditioners

A separate technological room, the so-called server room, is allocated for server equipment, where it is necessary to maintain the operating conditions specified in the technical documentation by the manufacturer. In particular, one of the most important parameters is the air temperature.

The American Society of Heating, Refrigeration and Air Conditioning Engineers (ASHRAE) recommends that server rooms be kept between 18°C and 27°C. Most specialized companies, for example, providing hosting services, do not allow the air temperature to rise above 24 ° C.

An increase in temperature, even for a short time, can cause a failure in the operation of server equipment, and to eliminate the accident, it will be necessary to replace expensive components

Such strict temperature limits are due to the operational features of server computers. Local overheating of certain devices that are part of the server leads to their breakdown

As a result, it all comes down to the loss of important information, disruptions in production, commercial, logistics processes and, as a result, to the loss of reputation and profit

A modern server is equipped with an internal heat dissipation system. All internal components that generate heat during their operation are cooled. But it is impossible to completely avoid heat transfer due to leaks in the housing. Despite heat sinks and even liquid cooling, the temperature inside the case will be close to the ambient temperature.

The following components are most sensitive to climatic operating conditions:

- CPU;

- HDD;

- RAM.

As the temperature rises, the materials that make up hard drive components expand. This leads to failure of magnetic disks, heads, positioning systems

Hard drive problems are fraught with the loss of important information

For local cooling of server processors and RAM, metal radiators are used, but with a significant increase in ambient temperature, they are not able to provide protection against overheating

Modern servers are equipped with random access memory devices equipped with their own passive cooling system (radiators). But the situation does not change from this. Heatsinks can save RAM only with a very short and slight increase in temperature. But with a stronger heating of the air, they are ineffective.

The processor protection system automatically triggers on overheating, which leads to the shutdown of the server and the impossibility of its normal, uninterrupted operation. Do not tolerate high temperatures and many microchips, in particular on the south and north bridges.

You should not expect that if the outdoor (street) temperature is in an acceptable range, you can refuse to cool the air in the server room. It is necessary to take into account all indicators of heat release and heat inflows. Thus, the thermal power of servers is 80-90% of the consumed electrical power and often exceeds 1 kW.

So, the use of expensive and important equipment for solving business problems, which is sensitive to temperature rise and fluctuations, requires properly organized air conditioning, in which each split system must work smoothly.

Reservation schemes for air conditioners

It is possible to implement various redundancy schemes, which are conventionally designated as N + 1 and 2N, where N is the number of air conditioners performing a similar function in the system (from the English "Need" - "Necessity").

The simplest scheme, which involves the use of only one backup air conditioner, is N + 1. If the rotation system is not configured, the backup air conditioner is switched on only in emergency cases and takes over the entire load.

There can be several main working air conditioners in the system and each of them has a backup air conditioner, which is denoted as 2N and means 100% redundant. It is clear that the more backup air conditioners, the higher the fault tolerance of the system.

Features of installation on the example of BURR-1

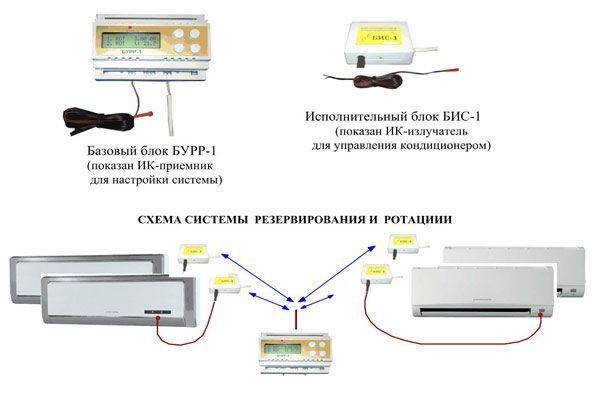

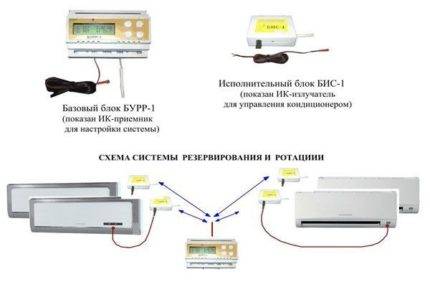

We will show how the installation is performed with a specific example. In Russia, rotation and redundancy control units BURR-1 are widely used, working in conjunction with specialized executive units BIS-1. The number of execution units may vary depending on the total number of air conditioners in the system.

BURR-1 and BIS-1 connection diagram with infrared signal transmission, with the possibility of coordinating the operation of 15 air conditioners

BURR-1 and BIS-1 connection diagram with infrared signal transmission, with the possibility of coordinating the operation of 15 air conditioners

In addition to the device itself, the BURR-1 package includes a temperature sensor. Executing units are purchased for each air conditioner. Equipped with an IR probe and a double-sided self-adhesive gasket for its fixation. The thermostat is sold separately.

Note that the complete set of matchers depends on the manufacturer and often includes the entire set of temperature sensors and auxiliary accessories.

Before starting installation work, the equipment is de-energized, other safety requirements are observed.

BURR-1 has a plastic case, convenient for installation on a special metal profile - a DIN rail, which is placed on the electrical panel, next to the circuit breakers. A 3.5 cm DIN rail is suitable for this purpose.

BIS-1 is installed above the air conditioner or directly on the air conditioner body with fixation on a self-adhesive double-sided gasket. A temperature sensor is fixed in the entry area of the guide blinds. It is here that he will be able to catch the flow of cold air and determine that the air conditioner is in working condition.

The system also requires one common remote temperature sensor, which is installed in a holder on the wall in the server room at an equal distance from the air conditioners. This sensor should not be subjected to external thermal effects, for example, coming from heating radiators.

If it is possible to organize electrical wiring, the BURR-1 control unit can be installed outside the control room, for example, on a wall or even in an adjacent room.

A passport and detailed instructions are attached to BURR-1, where installation recommendations are given and diagrams are given, one of the advantages of the model is the connection of a temperature sensor and power supply without observing polarity

The emitter probe is installed in such a way that it “looks” into the photodetector of the air conditioner from a distance of no more than 10 cm at an acceptable deviation angle of 45-60 degrees.

The transmission range of a stable radio signal is 50 meters. That is, this is the maximum distance between the main and executive units. It is desirable to reduce it in order to reduce the level of interference coming from third-party equipment.

The following installation features should be highlighted:

- lack of cable lines;

- the possibility of expanding the system;

- implementation of different redundancy schemes.

When connecting an air conditioner rotation unit, you do not have to run a cable to transmit control signals, which, among other things, saves space in the server room. The composition of the air conditioning system is variable.

It can include a different number of air conditioners that differ in their power. Developing and increasing the equipment of the server room, the company, as necessary, can include new air conditioners in the system (up to 15 devices in total).

The principle of operation of the rotation unit

In the process of working with BURR-1, commands are transmitted via radio signals at a frequency of 433 MHz to the executive units, which turn the air conditioners on and off using infrared emitters, in accordance with the settings. Air conditioners must be equipped with photodetectors. This requirement is met by most modern models, including household ones.

Thermal sensors are continuously monitored. By comparing the received data, the status of each air conditioner is determined. If the air conditioner is turned on, and the sensor installed on its blinds indicates that the change in temperature at the outlet is less than 2 C, the reserve power is turned on and an alarm is given.

Specifications of rotation module for air conditioner

Using a radio signal from the base module, a signal is sent to the device (rotation unit) to stop working. Such commands act contrary to the initial settings of the entire system.The signal range reaches fifty meters, which is convenient for remote control of the server cooling system. The main advantage of the rotation module is its multitasking, because several large, difficult-to-use air conditioners are connected to one simple unit at once. The launch of backup devices, if such a need arose, occurs instantly, without hitches and delays (they can cost the owner of the premises of precious equipment).

The rotation module is a universal device that can hide the shortcomings of climate technology. In conditions of improper operation of the air conditioner, using the unit, the mode switching is regulated.

For air conditioners installed in rooms where the flow of incoming data needs to create a separate server room, load distribution is the initial task. What is the rotation module for? A device with simple settings and a certain principle of operation guarantees the correct operation of the coolers at any temperature changes. In hot or cold seasons, the modules will balance the climate inside the technical room - the server room.

Source

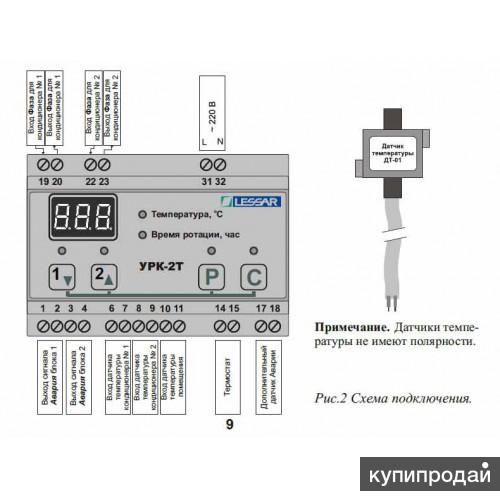

Purpose and functional features

The main function of the rotation module is to alternate the operation of air conditioners in a given time interval by regulating the voltage supply to all cooling devices. To do this, the alternation module uses three temperature sensors, one of which diagnoses the room temperature, and the rest are installed near the standard sensors of the indoor units. The rotation module allows you to:

- Alternate switching of climate technology, the frequency of which is set by the user.

- Switching from a faulty air conditioner to a backup. In this case, a fault code is transmitted to the local notification network of the enterprise.

- The ability to control the temperature in the server room, due to its own sensor, and in case of its increase, the connection of additional climatic equipment.

- Shutdown of all cooling equipment in case of an unforeseen or emergency situation, with the issuance of an “Emergency” signal to the external network.

It should be taken into account that URK-2 and URK-2T rotation blocks are the simplest devices for alternating two groups of household climate equipment, semi-industrial air conditioners or evaporative blocks of multisystems. The use of such modules allows the cooling system to be integrated with a burglar or fire alarm system, which makes it possible to quickly respond to a break-in and fire in a room with expensive equipment.

It should be taken into account that URK-2 and URK-2T rotation blocks are the simplest devices for alternating two groups of household climate equipment, semi-industrial air conditioners or evaporative blocks of multisystems. The use of such modules allows the cooling system to be integrated with a burglar or fire alarm system, which makes it possible to quickly respond to a break-in and fire in a room with expensive equipment.

Rotation with data transmission via IR and radio channel

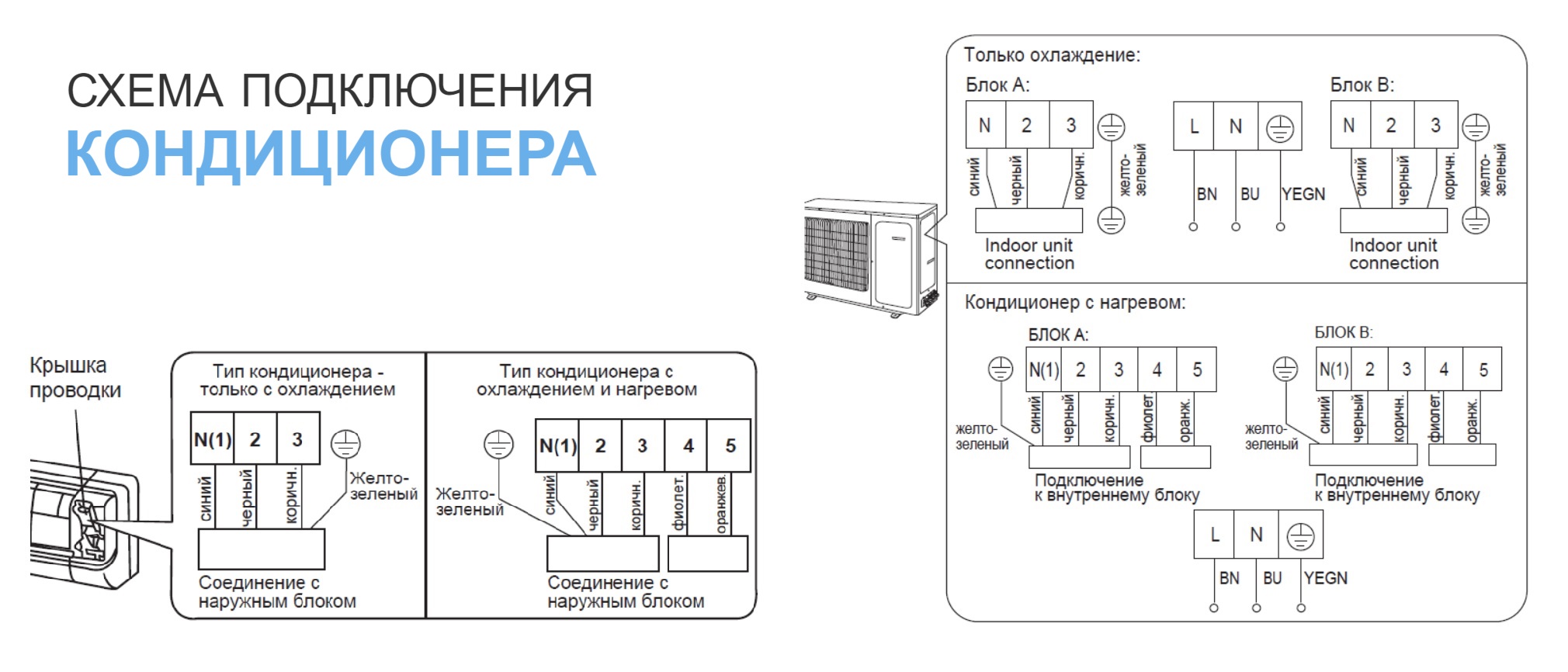

The system of rotation and redundancy, using the infrared channel for data transmission, consists of several parts:

The system of rotation and redundancy, using the infrared channel for data transmission, consists of several parts:

- BURR rotation control unit;

- BIS rotation executive unit.

The infrared channel for data transmission does not need a wired connection. Commands from the base module are transmitted via radio to the execution units, which are installed one by one on the air conditioner. The complex can combine up to 15 split systems, divided into 2 or 3 groups. It is possible to combine different rotation options. The workgroup is set up via the base module.

Distinctive characteristics of rotation through IR:

- Wide choice of cooling parameters thanks to the use of 15 split systems. Air conditioners of various brands and capacities are connected to the complex.It is not required to equip the equipment with the “Restart” function.

- The wireless device allows you to save time and money for laying communications.

- High reliability of the system, which does not have switching devices in the design. Contact burnout is excluded.

- Easy setup, the ability to place the base in an adjacent room.

Conclusions and useful video on the topic

The experience of installing the indoor unit "cassette" in these two videos:

Second part of the guide:

How to connect pipelines and power to a cassette air conditioner, you will learn from this video material:

Installation of cassette air conditioners, as a rule, is performed by masters from the service department. This is due to both the complexity of fastening, the organization of air communications, and the need for adjustment work. The latter require some experience, since there are many nodes in the equipment design, incl. electronics and automation.

Tell us about how you installed a cassette air conditioner in your office or country house. It is possible that your recommendations will be very useful to site visitors. Write comments, please, in the block form below, ask questions and publish photos on the topic of the article.