- Biofuel installations in households

- Advantages and disadvantages of the system

- What is biofuel?

- Varieties of biofuels and their features

- Do-it-yourself step-by-step instructions for a biofireplace

- Varieties and benefits

- liquid biofuel

- Solid

- gaseous fuel

- Advantages

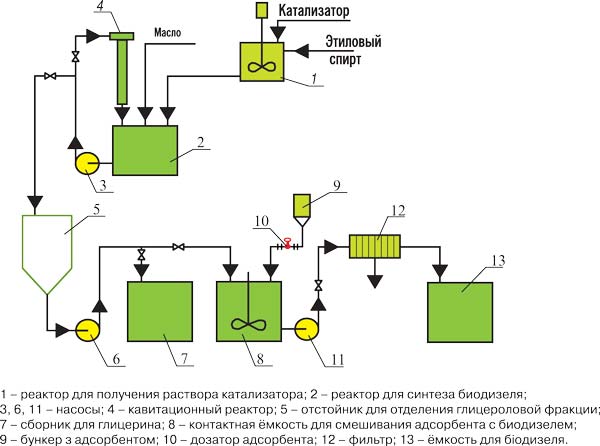

- Biodiesel at home

- Bioreactor

- What materials can be made

- Reactor sizing

- Overview of popular brands

- How to choose

- Instructions for self-construction

- Stage 1 - preparation of a pit for a bioreactor

- Stage 2 - arrangement of gas drainage

- Stage 3 - installation of the dome and pipes

- Bioreactor heating methods

- Conclusions and useful video on the topic

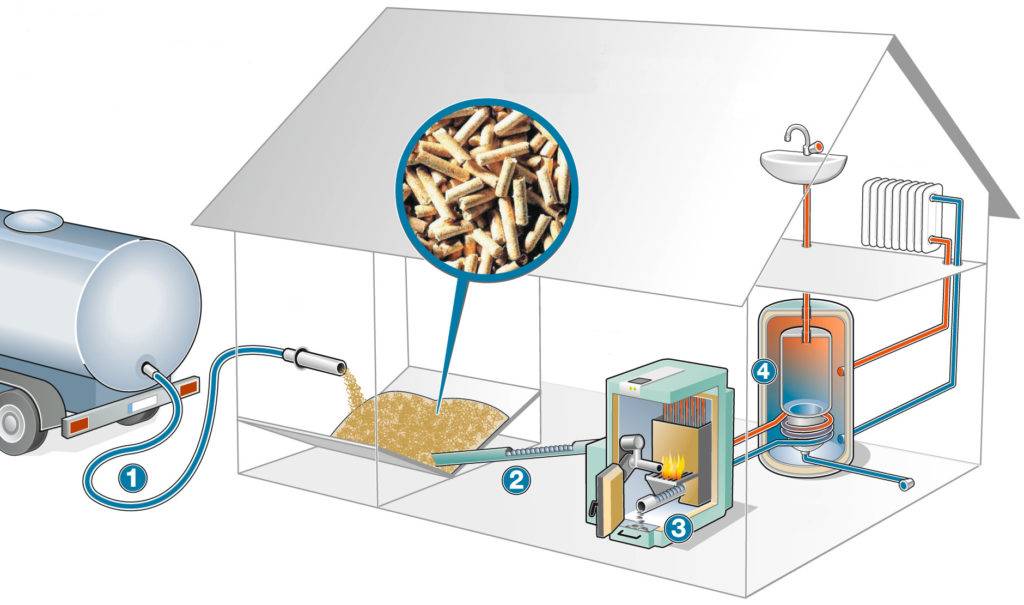

Biofuel installations in households

Farms and livestock complexes successfully produce biofuels from manure. The technology is based on the process of fermentation of manure under the influence of heat in special hermetic bunkers, separation of liquid fertilizers, evaporation of excess liquid and drying of the solid product.

During fermentation, biogas is released, which is used for space heating and cooking, as biofuel for greenhouses or for stoves.

Production of solid fuel from manure

Sufficient volumes of own raw materials make such a waste-free livestock complex efficient.A biofuel boiler house serving all areas of its own economy, heating, gas, electricity obtained from its own raw materials, significantly reduce the cost of the total cost of production.

If there is a sufficient raw material resource, it is easy to produce biofuel with your own hands. Economically, a project for the production of biofuel at home makes sense when its quantity is capable of performing any independent energy task.

It is enough to make a calculation of the daily rate of raw materials to obtain energy consumed daily on the farm for the basic needs listed below:

- a biofuel generator to support the production process;

- energy consumption for space heating;

- energy consumption for cooking;

- energy consumption for agricultural production processes.

Straw is the main raw material for fuel briquettes

The next step will be the study of the process itself, its length in time and the necessary equipment. It is necessary to have or learn the basics of process physics in order to build correctly.

The main technological structures and components are easy to find in the photo on the Internet. Manufacturing instructions are often posted by craftsmen on forums, and they themselves willingly share secrets and questions on how to make this or that element most efficiently.

Home biofuel plants can produce this resource of different types and conditions, using 100% raw materials and by-products of each of the stages of its processing.

For example, while receiving biofuel for a greenhouse, biogas is simultaneously produced for heating and cooking. Thus, from the available waste we get second generation biofuels.

In a household environment, it is possible to recreate many technologies for the production of biofuels, as they were originally peeped from nature.

They are based on obtaining energy as a result of natural processes:

- heating in a natural way or with a slight addition of catalysts;

- drying;

- pressing into briquettes;

- gas collection from manure fermentation;

- modern process control devices.

The final step in the chain is transportation to the place of consumption, which in most cases is the boiler.

Advantages and disadvantages of the system

Biogas plants have many advantages, but there are also enough disadvantages, so before starting design and construction, you should weigh everything:

- Recycling. Thanks to a biogas plant, you can get the most out of the garbage that you would have to get rid of anyway. This disposal is less hazardous to the environment than landfill.

- Renewability of raw materials. Biomass is not coal or natural gas, the extraction of which depletes resources. In agriculture, raw materials appear constantly.

- Relative small amount of CO2. When gas is produced, the environment is not polluted, but when it is used, a small amount of carbon dioxide is released into the atmosphere. It is not dangerous and is not capable of critically changing the environment, because. it is absorbed by plants during growth.

- Moderate sulfur emission. When biogas is burned, a small amount of sulfur is released into the atmosphere. This is a negative phenomenon, but its scale is known in comparison: when natural gas is burned, environmental pollution with sulfur oxides is much greater.

- Stable work.Biogas production is more stable than solar panels or windmills. If solar and wind power cannot be controlled, then biogas plants depend on human activity.

- You can use multiple settings. Gas is always a risk. To reduce potential damage in the event of an accident, several biogas plants can be dispersed around the site. If correctly designed and assembled, a system of several fermenters will work more stable than one large bioreactor.

- Benefits for agriculture. Some types of plants are planted to obtain biomass. You can choose those that improve the condition of the soil. For example, sorghum reduces soil erosion and improves its quality.

Biogas also has disadvantages. Although it is a relatively clean fuel, it still pollutes the atmosphere. There may also be problems with the supply of plant biomass.

Irresponsible plant owners often harvest it in ways that deplete the land and upset the ecological balance.

What is biofuel?

Biofuel is an environmentally friendly material produced on the basis of bioethanol. It is a colorless and odorless liquid. Possesses high combustibility. In the process combustion breaks down into water and carbon dioxide, therefore safe for indoor use.

Biofuel is an environmentally friendly material produced on the basis of bioethanol. It is a colorless and odorless liquid. Possesses high combustibility. In the process combustion breaks down into water and carbon dioxide, therefore safe for indoor use.

The properties of biofuels are as follows:

- Ethanol, which is part of the liquid, decomposes into steam, carbon monoxide during combustion and is accompanied by the release of energy. It is absolutely harmless to the human body and does not smell.

- There are no solid decay products (soot, ash) during the operation of the eco-fireplace.

- The combustion efficiency reaches 95%.

- In liquids with the addition of sea salt, there is a crackling effect of natural firewood.

- When burning fuel, the flames are similar in color and shape to the fire in a classic fireplace.

Composition of ecofuel:

The basis of biological fuel is ethanol, of vegetable origin. It is obtained by fermenting the sugars of most plant crops, such as wheat, beets, potatoes, sugar cane, bananas and others. However, this type of fuel is not sold in its pure form, but is required to denature alcohol.

For additional effects, dyes or sea salt are added to the liquid.

Ecofuel has the following characteristics:

- Does not form ash during combustion.

- Does not emit harmful gases.

- Differs in ecological harmlessness.

- Has a long burning period.

- Easy to use.

Environmentally friendly fuel is produced all over the world. The leading positions in the manufacture of this fuel belong to South Africa, India, and China.

There are the following types of biofuels:

- Biogas - waste from garbage and production is pre-treated and gas is produced from it, an analogue of natural gas.

- Biodiesel - obtained from natural oils and fats of biological origin (animal, microbial, vegetable). The main raw materials for the production of this type of fuel are food industry waste or palm, coconut, rapeseed, and soybean oils. The most widespread in Europe.

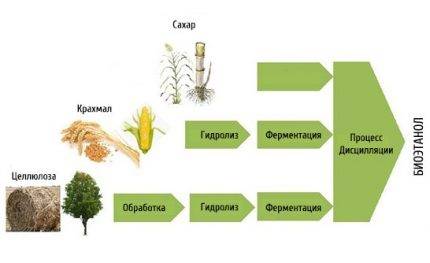

- Bioethanol is an alcohol-based fuel, a substitute for gasoline. Ethanol is produced by the fermentation of sugars. Cellulosic biomass is the raw material for production.

The advantages of environmentally friendly fuels include the following:

- In the process of burning fuel, smoke, harmful gases, soot and soot are not formed.

- The intensity of the flame and heat transfer during the combustion of biofuel can be adjusted.

- The fuel block and individual structural elements are easy to clean.

- For the operation of the structure, the installation of air outlet structures is not required.

- Fuel for a biofireplace is easy to transport and store.

- No debris during storage, unlike solid fuels.

- It does not require a separate room to store a large amount of fuel.

- Heat transfer during fuel combustion is 95%.

- During the combustion of ecofuels, the air in the room is humidified due to the release of steam.

- Flame return excluded.

- Thanks to the device of the biofireplace and the structural features of the burner with biofuel, the design is fireproof.

- Low fuel cost with low consumption.

The use of environmentally friendly fuel is simple in everyday life. Using the gel, you just need to open a jar of gel and install it in the biofireplace structure, hiding it in decorative elements or containers. When using liquid fuel, it is enough to pour it into the fuel tank and light it. However, despite all the positive qualities, this substance has several disadvantages.

Disadvantages of biofuels:

- It is forbidden to store a container with fuel near an open flame;

- It is impossible to add fuel during the operation of the biofireplace; it is required to extinguish the device and wait for it to cool completely;

- Kindling the fireplace is allowed only with a special lighter or with the help of electric ignition.

Varieties of biofuels and their features

Biofuels - environmentally friendly fuel

The existence of the prefix "bio" in the name of the fuel determines its environmental friendliness.Indeed, in the manufacture of this type of fuel, renewable natural resources are used. The main components used in the production of ecological fuel are cereals and herbaceous crops with a high content of sugar and starch. Thus, cane and corn are the most suitable raw materials for the creation of biofuels.

Biofuel for biofireplaces, produced from natural ingredients, is not inferior to less environmentally friendly counterparts in terms of its energy characteristics:

- bioethanol. consisting almost entirely of alcohol, can replace gasoline;

- biogas. which is a product of the specific processing of various garbage waste, like natural gas is used to create thermal and mechanical energy;

- Biodiesel is made from vegetable oil for fueling cars and other uses.

For kindling biofireplaces, preference is given to bioethanol - a colorless and odorless liquid.

- Environmental friendliness is due to the complete absence of the production of carbon monoxide, soot and soot.

- Ease of cleaning burners.

- The ability to adjust the intensity of combustion.

- No need to install ventilation devices.

- High fire safety and reliability of fuel use due to thermal insulation of the fireplace body.

- Convenience of transportation of the fuel itself and ease of installation of fireplaces for its use.

- It is characterized by one hundred percent heat transfer, since heat is not lost in the wilds of the chimney.

- It does not require the preparation of firewood and cleaning near the fireplace side effects: dirt, debris and ashes.

- The water vapor released when ethyl alcohol is heated contributes to the normalization of the humidity level in the room.

Do-it-yourself step-by-step instructions for a biofireplace

As you can see from the previous paragraph, if you have step-by-step instructions for a biofireplace, it is very easy to do it yourself. After collecting the burner, the process is divided into the following stages:

Pieces of glass are held together with silicone sealant in accordance with the design idea. For complete drying, they must be left for about 24 hours, a more accurate time is indicated in the instructions for the sealant.

Optionally, the base of the fireplace can be made from a rectangular metal box. Then it will hide the jar for the burner.

If the fuel was purchased in a tin, it only needs to be placed inside the burner. If it was sold in a plastic container, you should take another tin can and pour it there. The size of the jar should be such that it is convenient to get it out of the burner.

Lower the prepared wick into the fuel. Install a grid on top of the burner, pour pebbles on top of it.

To make a beautiful and simple bio-fireplace with your own hands, the step-by-step instructions above will provide all the necessary knowledge. The finished fireplace can be immediately put into operation, that is, set fire to the wick.

Varieties and benefits

Today, there are 3 types of biofuels:

- liquid;

- hard;

- gaseous;

liquid biofuel

It is the most discussed type. After all, the life of a modern person depends on oil, without it humanity will not be able to survive, and oil is a fossil resource and at some point its reserves will run out.

Liquid biofuels can replace this fossil resource.

Liquid biofuels include:

- alcohols (ethanol, methanol, butanol),

- biodiesel,

- biomasut,

- ethers;

Solid

It mainly includes wood (woodworking waste and fuel pellets, briquettes).As a rule, forests are the source for their production, where grass, shrubs and trees grow.

gaseous fuel

Biogas, hydrogen.

Also, biofuels can be classified by generation. There are biofuels of 1, 2, 3 and 4 generations:

- Generation 1 includes biofuels obtained by processing agricultural plants into biodiesel and ethanol.

- 2nd generation - biofuel obtained from food waste.

- The 3rd generation of biofuels includes biofuels obtained using introduced technologies as a result of the destruction of biomass.

- 4th generation biofuels are produced on lands unsuitable for agriculture and without biomass destruction.

Another classification of biofuels is the division of biofuels into primary and secondary. Primary biofuel refers to biofuel that has not been processed. To the secondary - processed. Recycled biofuels undergo a variety of changes before use and can be in solid, liquid and gaseous forms.

Advantages

The advantages of biofuels are as follows:

- Mobility. Biofuel has the ability to be produced in any corner of the world, regardless of climatic conditions and topography, because this type of fuel can be produced from various organic compounds.

- Renewability. Since biofuels are obtained from a variety of organic compounds of plant or animal origin, such as manure, their quantity will not run out.

- Environmental friendliness. It is a cleaner type of fuel and, when burned, emits less harmful substances into the air than fossil fuels.

- Caring for the environment. Biofuel production solves the problems associated with waste disposal.

Biodiesel at home

Biodiesel is a fuel obtained from any vegetable oil (sunflower, rapeseed, palm).

Brief description of the biodiesel production process:

- Vegetable oil is mixed with methanol and a catalyst.

- The mixture is heated for several hours (up to 50-60 degrees).

- During the esterification process, the mixture separates into glycerol, which settles down and biodiesel.

- Glycerin is drained.

- Diesel is cleaned (evaporated, settled and filtered).

The finished product is of suitable quality and is clear and pH neutral.

The yield of biodiesel from vegetable oil is approximately 95%.

The disadvantage of home-made biological diesel is the high cost of vegetable oil. It makes sense to produce biodiesel with your own hands only if you have your own fields for growing rapeseed or sunflower. Or having a constant source of cheap processed vegetable oil.

Biofuel fireplaces - This is a decorative element of the interior with live fire. The industrial production of biofireplaces offers models of various sizes and configurations. However, many people make biofireplaces with their own hands.

To make a fuel block for a biofireplace with your own hands, you need to take a metal box, put a container with bioethanol inside. Cover the box with a metal grill (you can take a simple barbecue grill). Install a wick on the grate, set it on fire and the biofireplace is ready.

In fact, this is all that is needed to make a biofireplace with your own hands. It remains to decorate it with stones or other elements to your taste.

There is very little heat from such a fireplace; it is rather just an original decoration of the house.

It is quite possible to do biofireplace fuel with your own hands. It contains ethanol and gasoline. Consider the process of producing bioethanol at home.

You will need the following ingredients:

Ethyl alcohol 96%, sold in a pharmacy

Aviation gasoline (it is also used to refuel lighters)

It is practically odorless, which is important for use in a residential area. Only about 70 g is needed per liter of alcohol.

gasoline. Mix well and pour into fuel container. A liter of biofuel will last from 2 to 8 hours of continuous burning, depending on the type of fireplace burner and the intensity of the flame

Only about 70 g of gasoline is needed per liter of alcohol. Mix well and pour into fuel container. A liter of biofuel will last from 2 to 8 hours of continuous burning, depending on the type of fireplace burner and the intensity of the flame.

DIY biofuel

Bioethanol is a safe type of fuel; when it is burned, only hydrogen in a gaseous state and carbon dioxide are released. However, an open fire burns oxygen, so you need to regularly ventilate the room. It will also help remove excess carbon dioxide. gas from air.

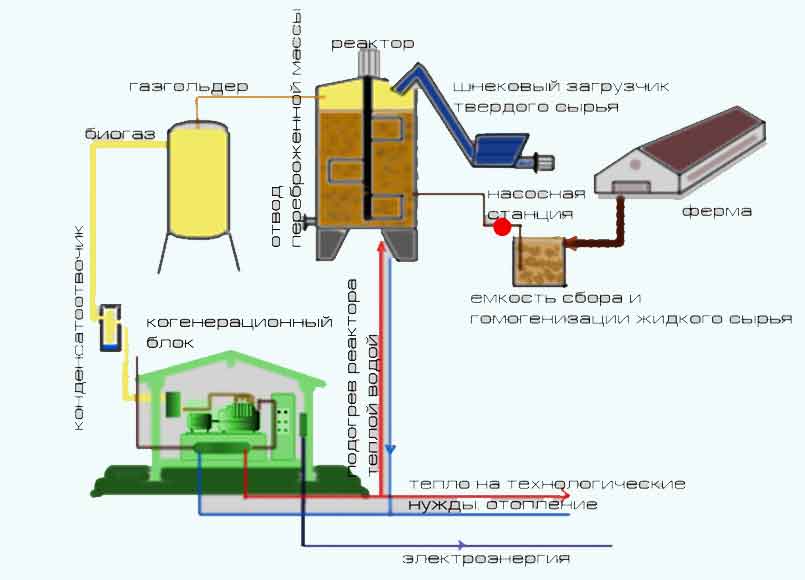

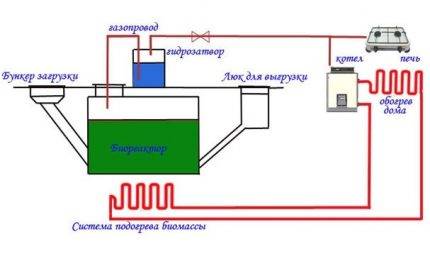

Bioreactor

To capacity for manure processing quite stringent requirements:

It must be impervious to water and gases. Water tightness must work both ways: the liquid from the bioreactor must not contaminate the soil, and groundwater must not change the state of the fermented mass.

The bioreactor must have high strength. It must withstand the mass of a semi-liquid substrate, the gas pressure inside the tank, the soil pressure acting from the outside

In general, when building a bioreactor, special attention must be paid to its strength.

Serviceability.More user-friendly cylindrical containers - horizontal or vertical

In them, mixing can be organized throughout the volume; stagnant zones do not form in them. Rectangular containers are easier to implement when building with your own hands, but cracks often form in their corners, and the substrate stagnates there. It is very problematic to mix it in the corners.

All these requirements for the construction of a biogas plant must be met, as they ensure safety and create normal conditions for the processing of manure into biogas.

What materials can be made

Resistance to aggressive environments is the main requirement for materials from which containers can be made. The substrate in the bioreactor may be acidic or alkaline. Accordingly, the material from which the container is made must be well tolerated by various media.

Not many materials answer these requests. The first thing that comes to mind is metal. It is durable, it can be used to make a container of any shape. What's good is that you can use a ready-made container - some kind of old tank. In this case, the construction of a biogas plant will take very little time. The lack of metal is that it reacts with chemically active substances and begins to break down. To neutralize this minus, the metal is covered with a protective coating.

An excellent option is the capacity of a polymer bioreactor. Plastic is chemically neutral, does not rot, does not rust. Only it is necessary to choose from such materials that endure freezing and heating to sufficiently high temperatures. The walls of the reactor should be thick, preferably reinforced with fiberglass. Such containers are not cheap, but they last a long time.

It is also possible to build a bioreactor for biogas production from bricks, but it must be well plastered using additives that provide water and gas impermeability.

A cheaper option is a biogas plant with a tank made of bricks, concrete blocks, stone. In order for the masonry to withstand high loads, it is necessary to reinforce the masonry (in each 3-5 row, depending on the wall thickness and material). After completion of the wall construction process for to ensure water and gas impermeability, subsequent multi-layer treatment of the walls is necessary both from the inside and outside. The walls are plastered with a cement-sand composition with additives (additives) that provide the required properties.

Reactor sizing

The volume of the reactor depends on the selected temperature for processing manure into biogas. Most often, mesophilic is chosen - it is easier to maintain and it implies the possibility of daily additional loading of the reactor. Biogas production after reaching the normal mode (about 2 days) is stable, without bursts and dips (when normal conditions are created). In this case, it makes sense to calculate the volume of the biogas plant depending on the amount of manure generated on the farm per day. Everything is easily calculated based on the average data.

| animal breed | Excrement volume per day | Initial humidity |

|---|---|---|

| cattle | 55 kg | 86% |

| Pig | 4.5 kg | 86% |

| chickens | 0.17 kg | 75% |

Decomposition of manure at mesophilic temperatures takes from 10 to 20 days. Accordingly, the volume is calculated by multiplying by 10 or 20. When calculating, it is necessary to take into account the amount of water that is necessary to bring the substrate to an ideal state - its humidity should be 85-90%.The found volume is increased by 50%, since the maximum load should not exceed 2/3 of the volume of the tank - gas should accumulate under the ceiling.

For example, the farm has 5 cows, 10 pigs and 40 chickens. As a matter of fact, 5 * 55 kg + 10 * 4.5 kg + 40 * 0.17 kg = 275 kg + 45 kg + 6.8 kg = 326.8 kg are formed. To bring chicken manure to a moisture content of 85%, you need to add a little more than 5 liters of water (that's another 5 kg). The total mass is 331.8 kg. For processing in 20 days it is necessary: 331.8 kg * 20 \u003d 6636 kg - about 7 cubes only for the substrate. We multiply the found figure by 1.5 (increase by 50%), we get 10.5 cubic meters. This will be the calculated value of the volume of the biogas plant reactor.

Overview of popular brands

Biodiesel fuel for cars is mainly produced in America (USA, Canada and Brazil), as well as India, China and Europe. Often this is presented as concern for the environment and the expansion of the use of alternative energy sources.

The output is rather ambiguous. It is one thing when waste is processed for the manufacture of such fuel, and quite another is the processing of plants specially grown for this purpose.

The main ingredient of all brands of biofuel for fireplaces is alcohol, it does not have any special differences in quality and composition from different manufacturers (+)

With ethanol biofuels, the situation is somewhat different. It is produced on a much smaller scale. This is mainly done in Europe, but Russia also has its own factories. For the production of this biofuel, raw materials of plant origin are also needed, but not in such huge volumes as in the case of the automotive counterpart.

In domestic stores, fireplace biofuel can be selected from the following brands:

- Kratki BioDECO (Poland).

- InterFlame (Russia).

- BioKer (Russia).

- Planika Fanola (Germany).

- Vegeflame (France).

- Bionlov (Switzerland).

- Bioteplo Slimfire (Italy).

The choice is quite extensive. The price per liter ranges from 260-600 rubles. The cost often depends on the presence / absence and combination of additional additives. Some essential oils are quite expensive. Although they are present in the composition of biofuels in the smallest proportions, they still affect the price.

How to choose

When choosing fuel for biofireplaces, it is necessary to pay attention to a number of factors:

- availability of certificates of conformity;

- indicator of productivity and energy capacity;

- absence of decomposition products in the fuel tank after combustion;

- lack of sharp and unpleasant odors from the liquid;

- best before date;

- the authenticity of the packaging;

Instructions for self-construction

If there is no experience in assembling complex systems, it makes sense to pick up on the net or develop the simplest drawing of a biogas plant for a private house.

The simpler the design, the more reliable and durable it is. Later, when building and system handling skills become available, it will be possible to modify the equipment or mount an additional installation.

Expensive structures of industrial production include biomass mixing systems, automatic heating, gas purification, etc. Household equipment is not so difficult. It is better to assemble a simple installation, and then add elements that need to arise.

Expensive structures of industrial production include biomass mixing systems, automatic heating, gas purification, etc. Household equipment is not so difficult. It is better to assemble a simple installation, and then add elements that need to arise.

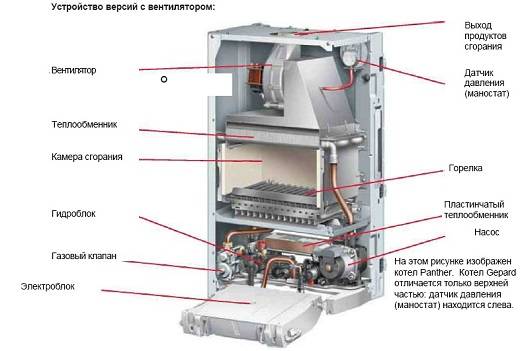

When calculating the volume of the fermenter, it is worth focusing on 5 cubic meters.Such an installation allows you to get the amount of gas needed to heat a private house with an area of 50 sq.m., if in as a heat source use a gas boiler or stove.

This is an average indicator, because the calorific value of biogas is usually not higher than 6000 kcal/m3.

In order for the fermentation process to proceed more or less stably, it is necessary to achieve the correct temperature regime. To do this, the bioreactor is installed in an earthen pit or reliable thermal insulation is thought out in advance. Constant heating of the substrate can be ensured by placing a water heating pipe under the base of the fermenter

The construction of a biogas plant can be divided into several stages.

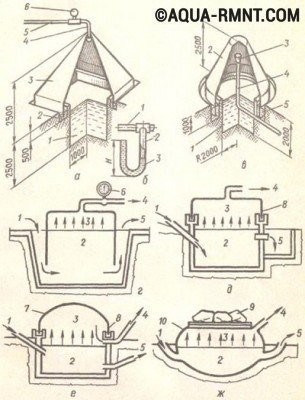

Stage 1 - preparation of a pit for a bioreactor

Almost the entire biogas plant is located underground, so a lot depends on how the pit was dug and finished. There are several options for strengthening the walls and sealing the pit - plastic, concrete, polymer rings.

The best solution is to buy ready-made polymer rings with a blank bottom. They will cost more than improvised materials, but additional sealing is not required. Polymers are sensitive to mechanical stress, but they are not afraid of moisture and chemically aggressive substances. They are not repairable, but if necessary, they can be easily replaced.

The intensity of the fermentation of the substrate and the gas output depend on the preparation of the walls and the bottom of the bioreactor, so the pit is carefully strengthened, insulated and sealed. This is the most difficult and time-consuming stage of work.

Stage 2 - arrangement of gas drainage

Buying and installing special agitators for biogas plants is expensive. The system can be reduced in cost by equipping gas drainage.It is a vertically installed polymer sewer pipes, in which many holes have been made.

When calculating the length of the drainage pipes, one should be guided by the planned filling depth of the bioreactor. Pipe tops must be above this level.

For gas drainage, you can choose metal or polymer pipes. The former are stronger, while the latter are more resistant to chemical attack. It is better to give preference to polymers, because. metal will quickly rust and rot

The substrate can be immediately loaded into the finished bioreactor. It is covered with a film so that the gas released during the fermentation process is under slight pressure. When the dome is ready, it will ensure the normal supply of biomethane through the outlet pipe.

Stage 3 - installation of the dome and pipes

The final stage of assembling the simplest biogas plant is the installation of the dome top. At the highest point of the dome, a gas outlet pipe is installed and pulled to the gas tank, which is indispensable.

The capacity of the bioreactor is closed with a tight lid. To prevent mixing of biomethane with air, a water seal is equipped. It also serves to purify gas. It is necessary to provide a release valve that will work if the pressure in the fermenter is too high.

Read more about how to make biogas from manure in this material.

The free space of the bioreactor to some extent performs the functions of a gas storage, but this is not enough for the safe operation of the plant. Gas must be consumed constantly, otherwise an explosion from overpressure under the dome is possible

Bioreactor heating methods

Microorganisms that process the substrate are constantly present in the biomass, however, for their intensive reproduction, a temperature of 38 degrees and above is required.

For heating during the cold period, you can use a coil connected to the home heating system, or electric heaters. The first method is more cost-effective, so it is more often used.

A biogas plant does not have to be buried in the ground; there are other arrangement options. An example of the operation of a system assembled from barrels is shown in the video below.

The easiest way to equip heating from below, laying a pipe from the heating system, but the efficiency of such a heat exchanger is relatively low. It is better to equip external heating, ideally with steam, so that the biomass does not overheat

Conclusions and useful video on the topic

How to make the simplest installation from an ordinary barrel, you will learn if you watch the video:

How the construction of an underground reactor is going on, you can see in the video:

How manure is loaded into an underground installation is shown in the following video:

An installation for biogas production from manure will significantly save on payment for heat and electricity, and use organic material, which is available in abundance in every farm, for a good cause. Before starting construction, everything must be carefully calculated and prepared.

The simplest reactor can be made in a few days with your own hands, using available tools. If the farm is large, then it is best to buy a ready-made installation or contact specialists.

If, while reading the information provided, you have any questions, or have suggestions that you want to share with site visitors, please leave comments in the block below.