- Specificity of biogas production

- Biofuel efficiency

- How does a biogas plant work?

- Which raw material is suitable for bioreactor?

- What cannot be used in a biogas plant?

- How to ensure biomass activity

- Features of the use of biogas for household needs

- Advantages of biodiesel over petroleum diesel

- How to heat the bioreactor?

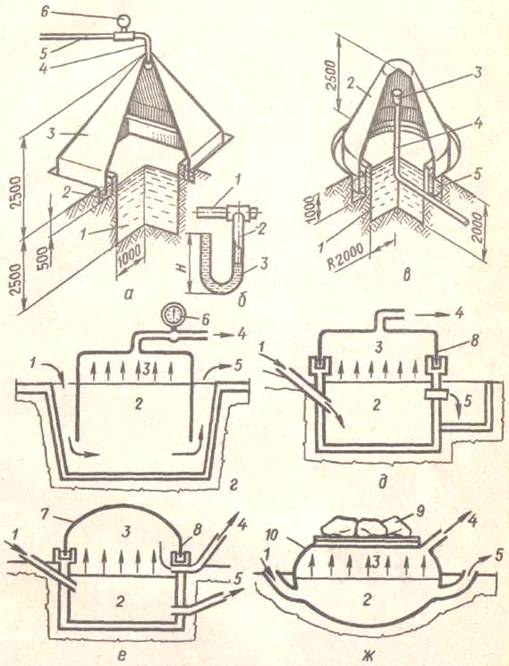

- The simplest installation principle

- Uniqueness

- Operation and safety rules

- Instructions for self-construction

- Stage 1 - preparation of a pit for a bioreactor

- Stage 2 - arrangement of gas drainage

- Stage 3 - installation of the dome and pipes

- Is it profitable to make a reactor and use biogas

- What is biogas? Beginner's Guide

- Biogas - a complete fuel from waste

- What factors affect production?

- Bioinstallation by Yuri Davydov

- Recommended composition of raw materials for processing

Specificity of biogas production

Biogas is formed as a result of the fermentation of a biological substrate. It is decomposed by hydrolytic, acid- and methane-forming bacteria. The mixture of gases produced by bacteria turns out to be combustible, because. contains a large percentage of methane.

By its properties, it practically does not differ from natural gas, which is used for industrial and domestic needs.

If desired, each owner of the house can purchase an industrial biogas plant, but it is expensive, and the investment pays off within 7-10 years. Therefore, it makes sense to make an effort and make a bioreactor with your own hands.

Biogas is an environmentally friendly fuel, and the technology for its production does not have a particular impact on the environment. Moreover, as a raw material for biogas, waste products are used that need to be disposed of.

They are placed in a bioreactor where processing takes place:

- for some time, the biomass is exposed to bacteria. The fermentation period depends on the volume of raw materials;

- as a result of the activity of anaerobic bacteria, a combustible mixture of gases is released, which includes methane (60%), carbon dioxide (35%) and some other gases (5%). Also, during fermentation, potentially dangerous hydrogen sulfide is released in small quantities. It is poisonous, so it is highly undesirable for people to be exposed to it;

- the mixture of gases from the bioreactor is cleaned and enters the gas holder, where it is stored until it is used for its intended purpose;

- gas from a gas tank can be used in the same way as natural gas. It goes to household appliances - gas stoves, heating boilers, etc.;

- decomposed biomass must be regularly removed from the fermenter. This is an additional effort, but the effort pays off. After fermentation, the raw material turns into high-quality fertilizer, which is used in fields and gardens.

A biogas plant is beneficial for the owner of a private house only if he has constant access to waste from livestock farms. On average, out of 1 cubic meter. substrate can be obtained 70-80 cubic meters.biogas, but gas production is uneven and depends on many factors, incl. biomass temperature. This complicates the calculations.

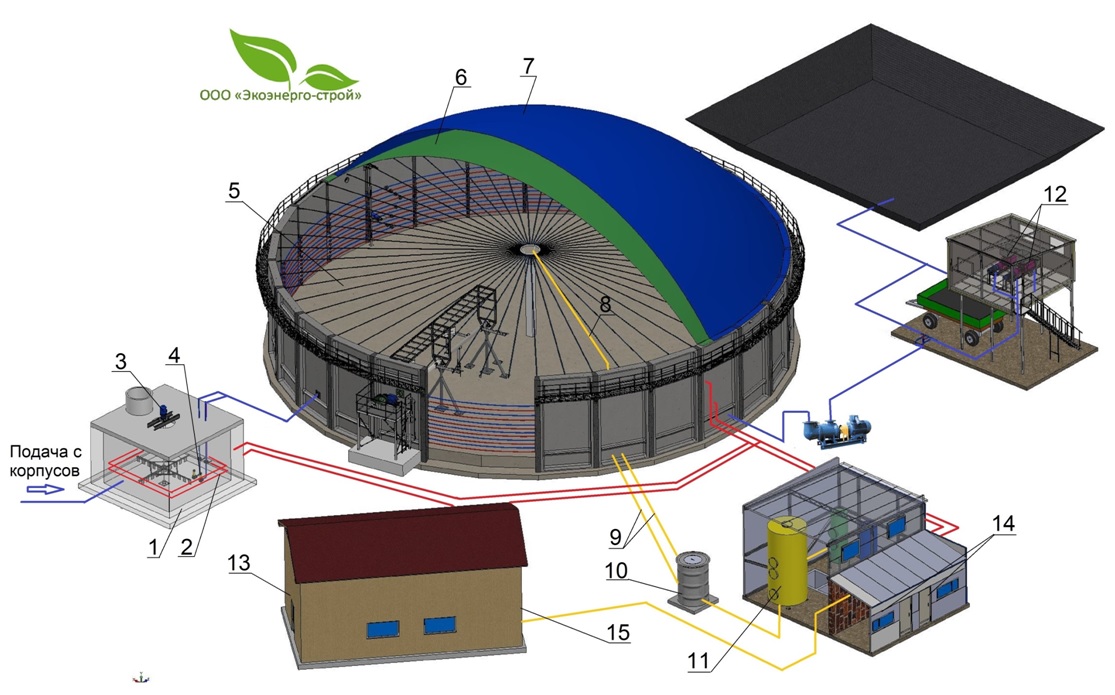

Biogas plants are ideal for farms. Animal waste can provide enough gas to fully heat residential premises and outbuildings.

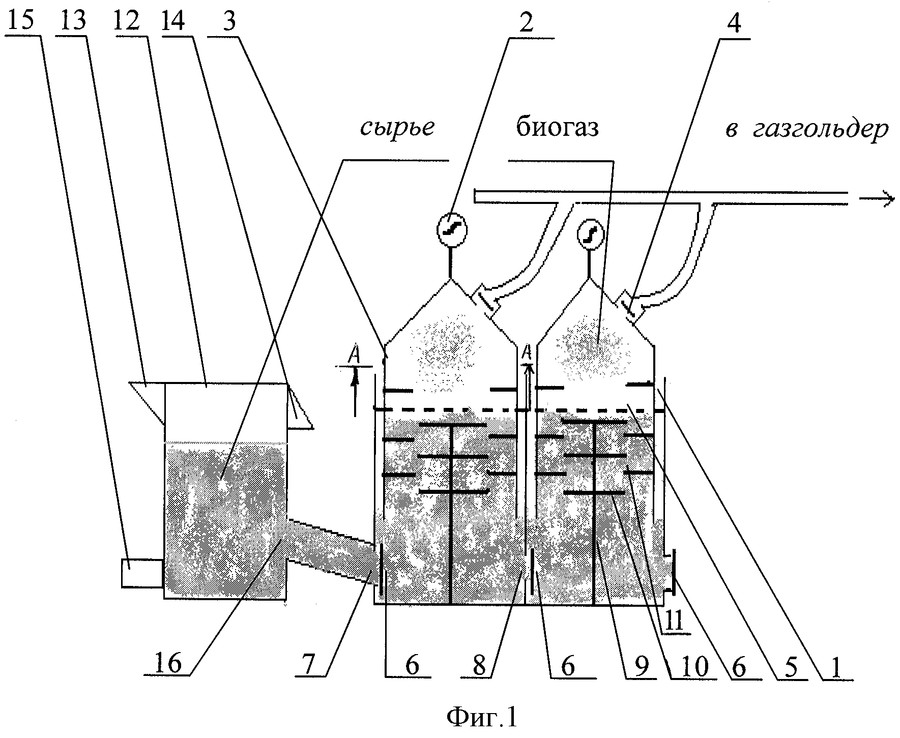

In order for the gas production process to be stable and continuous, it is best to build several biogas plants, and put the substrate into the fermenters with a time difference. Such installations operate in parallel, and the raw materials are loaded into them sequentially.

This guarantees a constant production of gas, so that it can be continuously supplied to household appliances.

Ideally, the bioreactor should be heated. Every 10 degrees of heat doubles the production of gas. Although the arrangement of heating requires investment, it pays off with greater design efficiency.

Homemade biogas equipment, assembled from improvised materials, is much cheaper than industrial production plants. Its efficiency is lower, but it fully corresponds to the invested funds. If you have access to manure and the desire to make your own efforts to assemble and maintain the structure, this is very beneficial.

Biofuel efficiency

Biogas from litter and manure is colorless and odorless. It gives as much heat as natural gas. One cubic meter of biogas provides as much energy as 1.5 kg of coal.

Most often, farms do not dispose of waste from livestock, but store it in one area. As a result, methane is released into the atmosphere, manure loses its properties as a fertilizer. Timely processed waste will bring much more benefits to the farm.

Calculating the efficiency of manure disposal in this way is easy. The average cow gives 30-40 kg of manure per day. From this mass, 1.5 cubic meters of gas is obtained. From this amount, electricity is generated 3 kW / h.

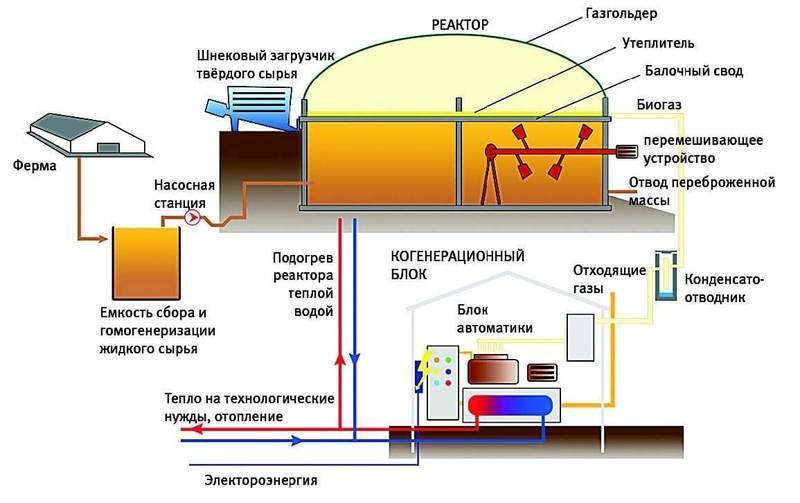

How does a biogas plant work?

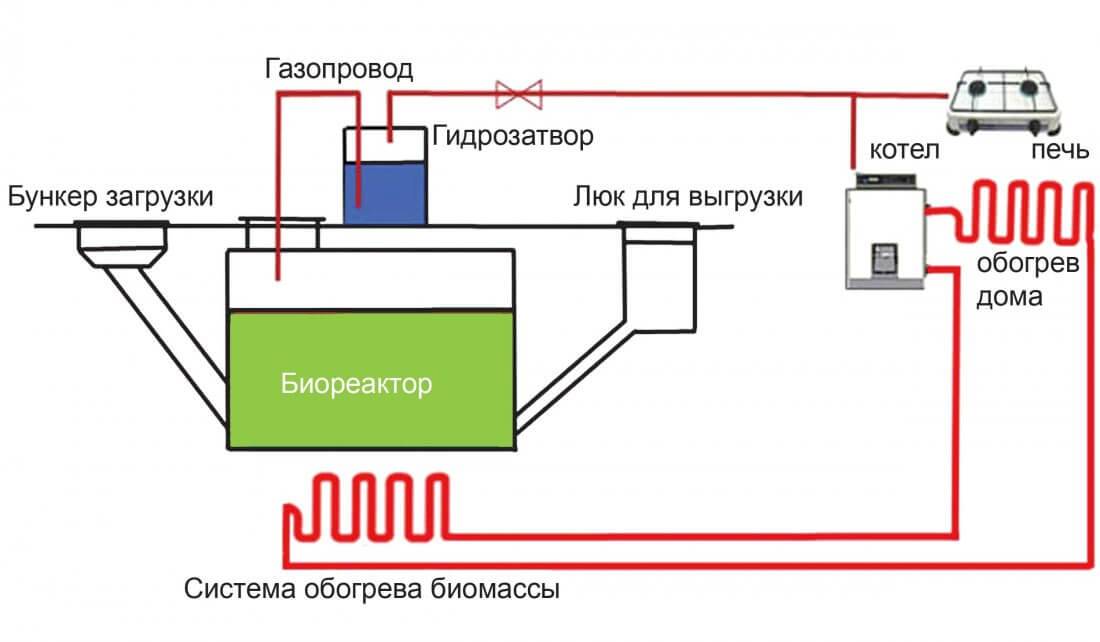

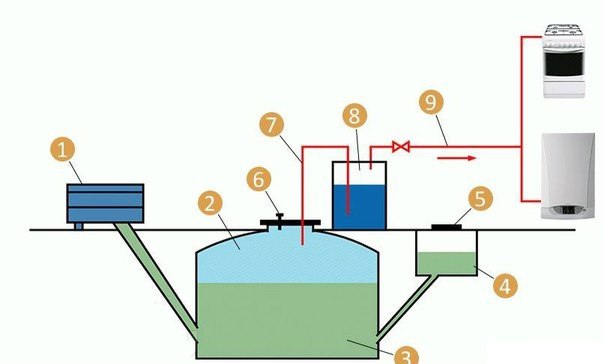

The principle of operation of the device for the production of biogas is quite simple:

- biomass diluted with water is loaded into a sealed container, where it begins to “ferment” and release gases;

- the contents of the tank are regularly updated - the raw materials processed by bacteria are drained and fresh ones are added (on average, about 5-10% daily);

- the gas accumulated in the upper part of the tank is supplied through a special tube to the gas collector, and then to household appliances.

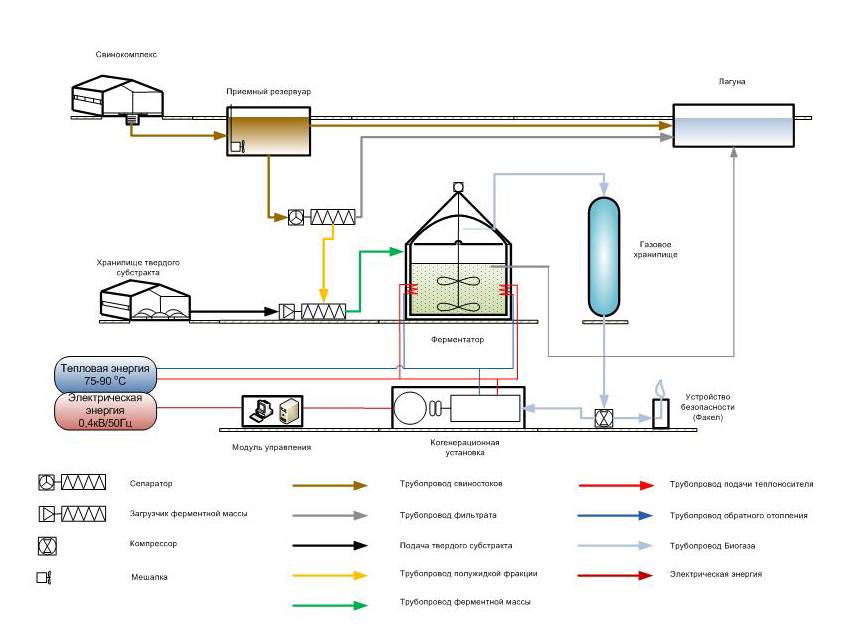

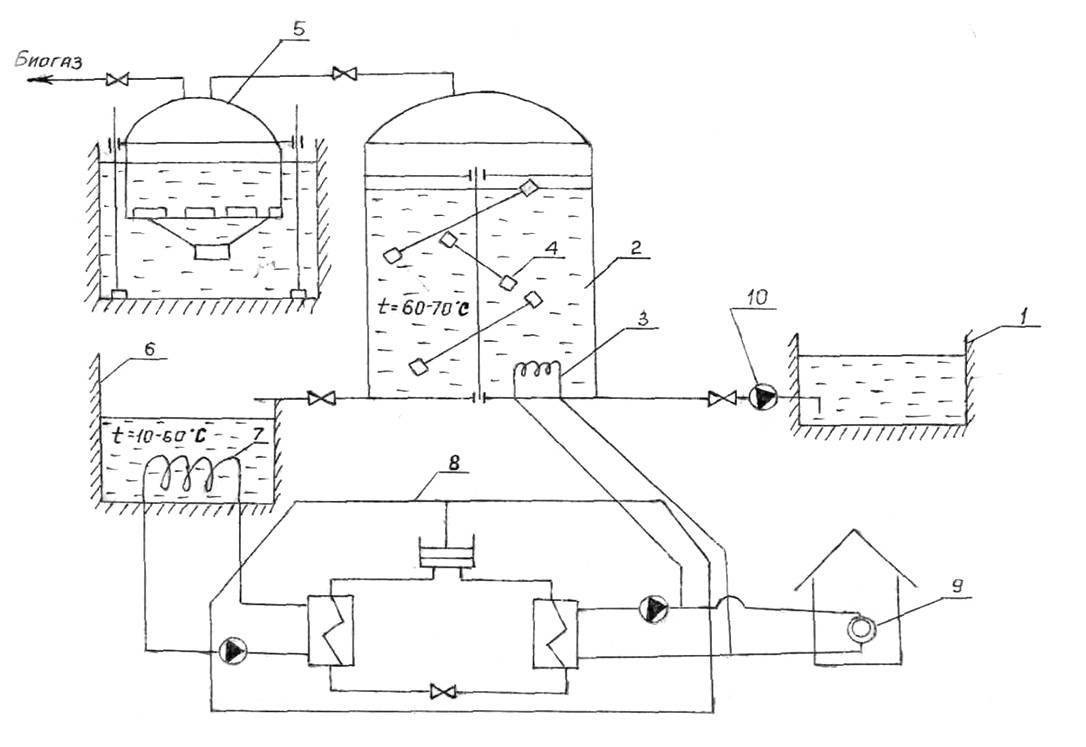

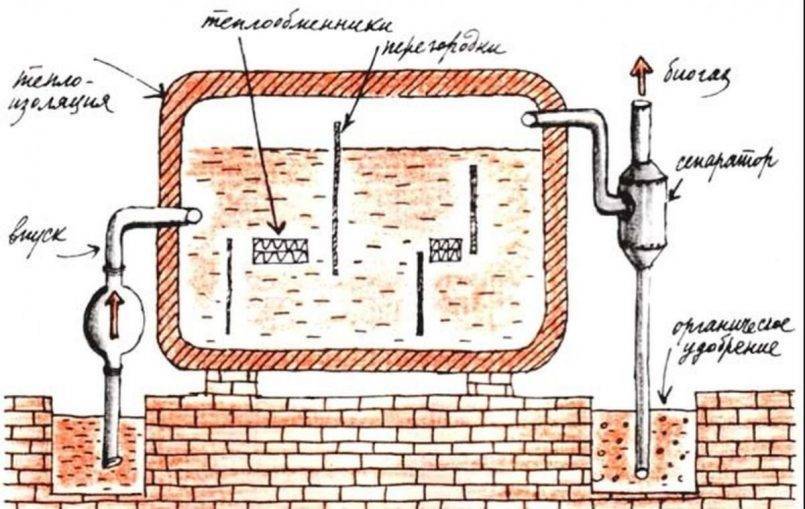

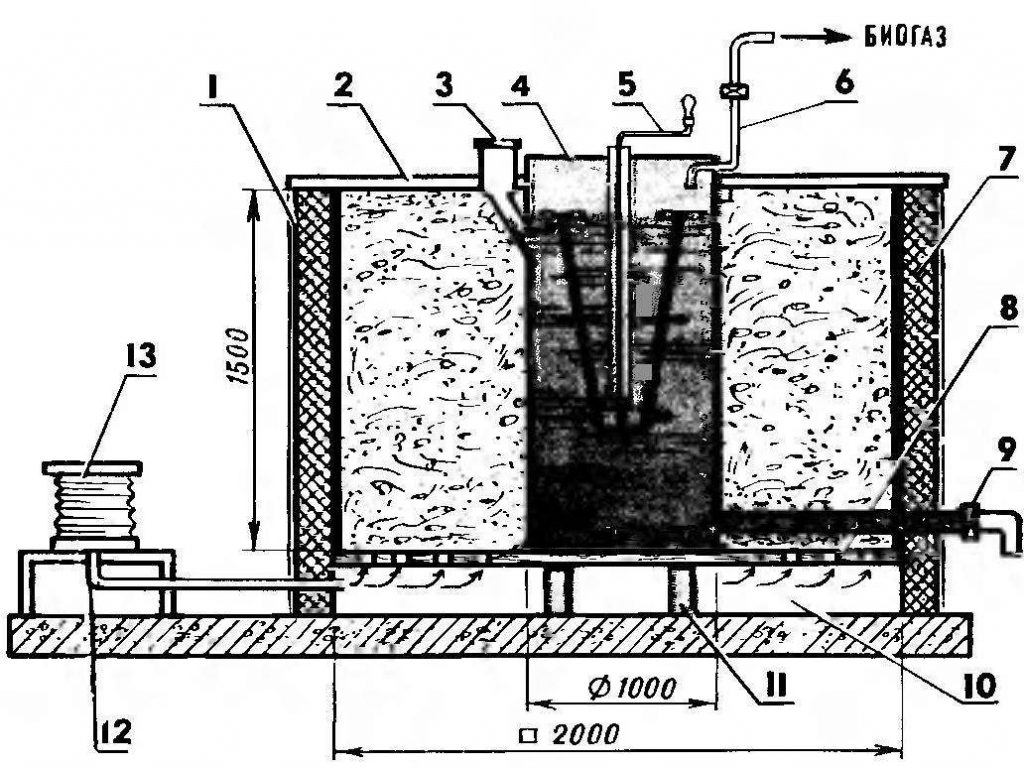

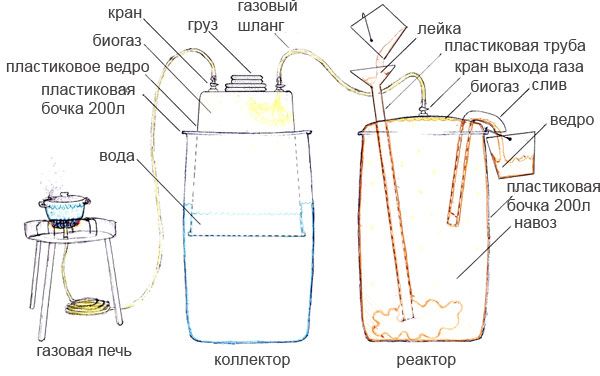

Diagram of a biogas plant.

Which raw material is suitable for bioreactor?

Biogas plants are profitable only where there is a daily replenishment of fresh organic matter - manure or droppings from livestock and poultry. Also, crushed grass, tops, leaves and household waste (in particular, vegetable peelings) can be mixed into the bioreactor.

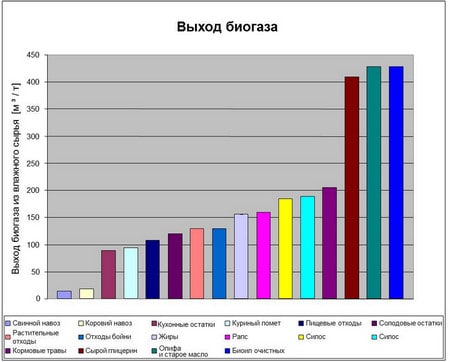

The efficiency of the installation largely depends on the type of feedstock. It has been proven that with the same mass, the largest biogas yield is obtained from pig manure and turkey manure. In turn, cow dung and silage produce less gas for the same load.

The use of bio-raw materials for home heating.

What cannot be used in a biogas plant?

There are factors that can significantly reduce the activity of anaerobic bacteria, or even completely stop the process of biogas production. Do not allow raw materials containing:

- antibiotics;

- mold;

- synthetic detergents, solvents and other "chemistry";

- resins (including sawdust of coniferous trees).

It is inefficient to use already rotting manure - only fresh or pre-dried waste is to be loaded. Also, waterlogging of raw materials should not be allowed - an indicator of 95% is already considered critical. However, it is still necessary to add a small amount of pure water to the biomass - in order to facilitate its loading and speed up the fermentation process. Dilute manure and waste to the consistency of thin semolina.

How to ensure biomass activity

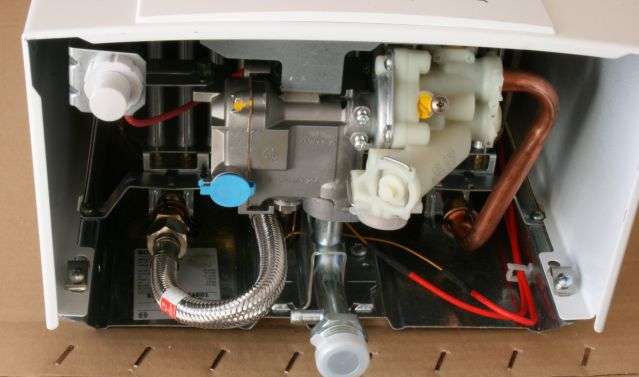

For proper biomass fermentation, it is best to heat the mixture. In the southern regions, the air temperature contributes to the start of fermentation. If you live in the north or in the middle lane, you can connect additional heating elements.

To start the process, a temperature of 38 degrees is needed. There are several ways to provide it:

- Coil under the reactor, connected to the heating system;

- Heating elements inside the tank;

- Direct heating of the tank with electric heaters.

The biological mass already contains bacteria that are needed to produce biogas. They wake up and begin activity when the air temperature rises.

It is best to heat them with automatic heating systems. They turn on when cold mass enters the reactor and turn off automatically when the temperature reaches the desired value. Such systems are installed in water-heating boilers, they can be bought at gas equipment stores.

If you provide heating to 30-40 degrees, then it will take 12-30 days to process. It depends on the composition and volume of the mass.When heated to 50 degrees, bacterial activity increases, and processing takes 3-7 days. The disadvantage of such installations is the high cost of maintaining a high temperature. They are comparable to the amount of fuel received, so the system becomes inefficient.

Another way to activate anaerobic bacteria is biomass mixing. You can independently install the shafts in the boiler and bring the handle out to stir the mass if necessary. But it is much more convenient to design an automatic system that will mix the mass without your participation.

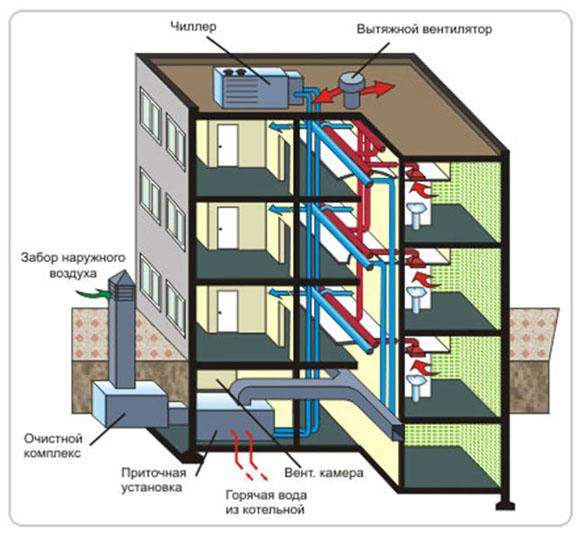

Features of the use of biogas for household needs

The scope of this type of energy resource is quite extensive. Thanks to the use of biogas as a fuel, electricity is produced, hot water or steam is obtained. There are numerous examples from practice where road transport is fueled with biofuels.

But in order to avoid problems on the farm when using such fuel, it is extremely important to equip the storage for the resulting biogas, allocating the right place for the gas tank on the site. Biogas plants of this type are equipment that opens up the possibility of creating waste-free industries.

In this regard, individual countries of Western Europe are a good example.

Biogas plants of this type are equipment that opens up the possibility of creating waste-free industries. In this regard, individual countries of Western Europe demonstrate a good example.

For example, in Denmark, the production of this type of fuel has reached the level of almost 20% of the country's total energy resources. In large regions of the world - India and China - biogas plants account for hundreds of thousands.

Powerful industrial installations for the production of biofuels. Such structures are able to fully provide large agricultural structures with biofuel. A huge number of such systems are used around the world. And the quantitative growth continues actively

It is not for nothing that there is a significant increase in interest around the world in biogas production processes.

This is one of those energy options that are classified as alternative sources and which they see as the future, so farmers and housing and communal services managers, owners of private households and small businesses are closely monitoring the development of technology.

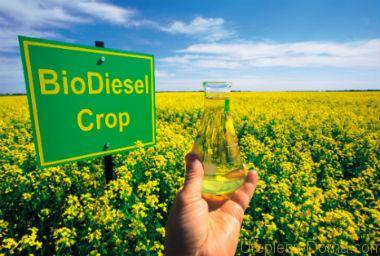

Advantages of biodiesel over petroleum diesel

Biodiesel does not pollute the planet.

If we are talking about buying ready-made fuel, then from an economic point of view, ordinary diesel fuel, which is made from oil, will be more profitable, since it is cheaper. If do biodiesel at home from purchased oil, it is also expensive. The only option when it is profitable to produce biofuels is to have your own oil. If this is not the case, buy ordinary diesel fuel and heat it with it.

The strengths of using biofuels to heat your home:

- it is much safer to store an energy carrier supply - the ignition temperature is 100 degrees, while ordinary diesel fuel ignites at 60 degrees;

- biodiesel does not litter nature, minimal sulfur content;

- biodiesel emits little carbon dioxide.

That it is safer to store biofuels is good, but not everything is perfect here either. After three months, biodiesel begins to break down into its constituent parts, and this imposes some restrictions.

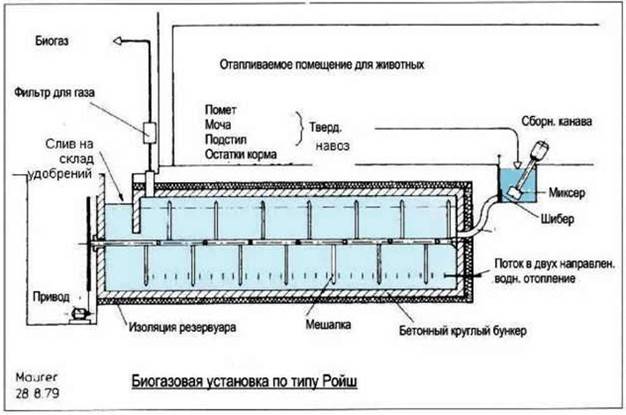

How to heat the bioreactor?

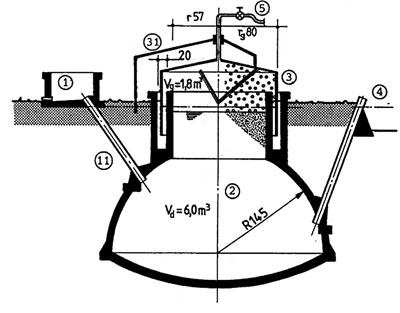

The device of the biogas plant assumes its underground location.It is necessary to prepare a hole of the required volume. Its walls can be hermetically reinforced and finished with plastic, polymer rings or concrete.

The intensity of processing of raw materials depends on the tightness. Ideally, you should purchase factory-made polymer rings with a dry bottom. This is a more expensive solution, but additional sealing can be avoided.

Polymeric materials are resistant to moisture and aggressive environments. They do not need to be repaired, and if damaged, they can be quickly replaced.

Therefore, the bioreactor must be heated, especially in winter. You can install a coil connected to a domestic heating system.

Another way is to install electric heating elements. But, a more cost-effective solution is to connect to the heating system.

A biogas plant may or may not be done underground. There are alternative methods. For example, it can be performed in a barrel, which will be located in a separate room.

You can also use, for example, a tank. This option will simplify heating, but requires sufficient space.

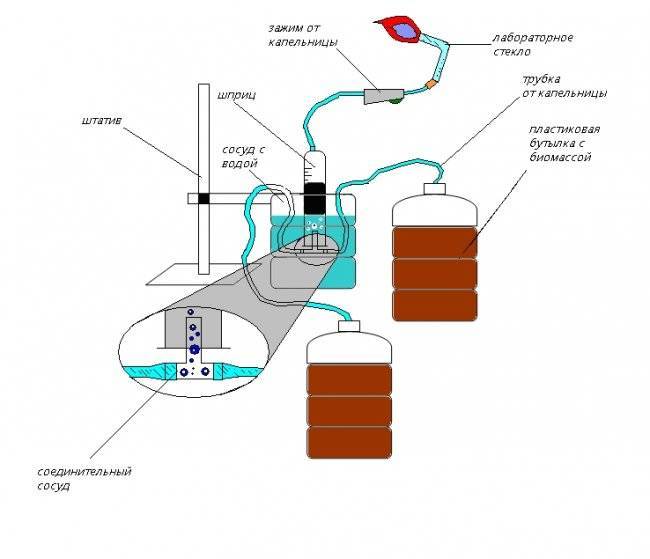

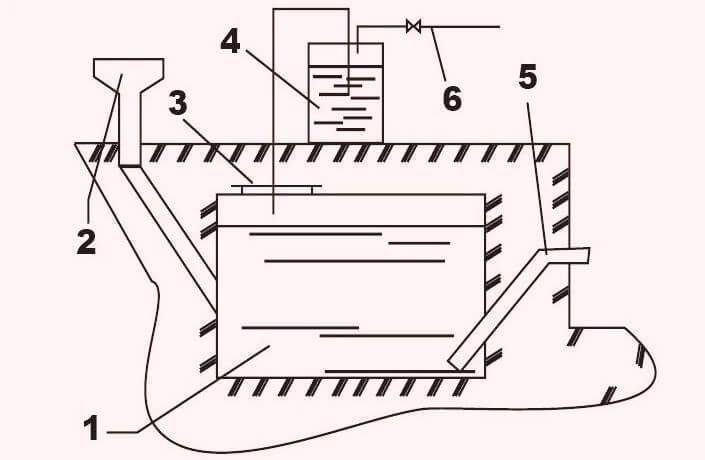

The simplest installation principle

For a simple biogas production system, a barrel can be used as a reactor. However, it must be clean. Do not use containers that contain poisonous particles, such as dyes or toxins. This can reduce the vital activity of microorganisms to zero.

For a simple biogas production system, a barrel can be used as a reactor. However, it must be clean. Do not use containers that contain poisonous particles, such as dyes or toxins. This can reduce the vital activity of microorganisms to zero.

The barrel should be hermetically sealed, but it needs openings for loading biomass, pumping gas and removing waste material. To simplify the task, you can make a universal conclusion that will allow you to carry out all the manipulations. First, biomass diluted to kefir density is poured through this hole.Later, it can be tightened with a cork with a tube brought out for gas.

The gas outlet from the barrel must pass through a filter, because the biological mass emits up to 10% hydrogen sulfide, which is harmful, and 35% carbon, which worsens the combustible properties of methane. A flask with metal shavings can be used to filter hydrogen sulfide, and a slaked lime slurry is suitable to remove carbon.

After passing through the filters, the gas must enter the storage tank. For this purpose, a container of large volumes is suitable, in which a collector must be placed, it is also a container for saving blue fuel. As a collector, dense sealed polyethylene or an old car camera is suitable.

Uniqueness

In our production, an innovative approach to obtaining biofuel is used: first, raw materials (algal biomass) are synthesized for its production, then oil is pressed, from which biodiesel fuel is produced using a proven technology. Such a fundamentally new approach to obtaining biofuels from non-food raw materials has a number of advantages compared to the production of bioenergy from vegetable oils. The main advantage of such production is independence from the yield of oilseeds and their cost (rapeseed and other oils used as the main raw material for the production of biodiesel), the price of which increases with the increase in biofuel production.

Consumer

We plan to work on a B2B scheme and, ideally, we will implement the full volume of biodiesel production of one interested company.Such companies may include companies engaged in:

rail and road transport

oil sales

agro-industrial companies

Organization

The commercial organization CJSC "BioEnergoRoss" is aimed at the production of biodiesel fuel. The management team is also the founders of the organization. The investor will be given a part of the company's shares corresponding to the invested funds.

Marketing

Products

BioEnergoRoss CJSC produces the main product - biodiesel, and two by-products - glycerin and a food additive for cattle and pigs (algae cake).

Operation and safety rules

Constant loading of regular batches and unloading of finished fertilizers, control of fermentation conditions, will ensure the correct operation of the biogas plant.

Specialized firms sell batches of organic-fermenting bacteria to produce biogas.

There are mesophilic, thermophilic and psychrophilic bacteria. Complete fermentation of organics with the participation of thermophilic bacteria will occur in 12 days. Mesophilic bacteria work more slowly, they will process raw materials in 20 days.

The biomass in the reactor must be stirred at least twice a day, otherwise a crust will form on the surface, preventing the free exit of biogas. In the cold season, the reactor should be heated, maintaining the optimum temperature for the highest product yield.

The organic mixture loaded into the reactor should not contain antiseptics, detergents, chemicals that are harmful to the life of bacteria and slow down the production of biogas.

For the correct operation of the bioreactor, it is necessary to follow the same rules as for any gas installations.If the equipment is airtight, biogas is discharged to the gas tank in a timely manner, then there will be no problems.

If the gas pressure exceeds the norm or will poison if the tightness is broken, there is a risk of an explosion, therefore it is recommended to install temperature and pressure sensors in the reactor. Inhaling biogas is also hazardous to human health.

Instructions for self-construction

If there is no experience in assembling complex systems, it makes sense to pick up on the net or develop the simplest drawing of a biogas plant for a private house.

The simpler the design, the more reliable and durable it is. Later, when building and system handling skills become available, it will be possible to modify the equipment or mount an additional installation.

Expensive structures of industrial production include biomass mixing systems, automatic heating, gas purification, etc. Household equipment is not so difficult. It is better to assemble a simple installation, and then add elements that need to arise.

When calculating the volume of the fermenter, it is worth focusing on 5 cubic meters. Such an installation allows you to get the amount of gas needed to heat a private house with an area of 50 square meters, if a gas boiler or stove is used as a heat source.

This is an average indicator, because the calorific value of biogas is usually not higher than 6000 kcal/m3.

In order for the fermentation process to proceed more or less stably, it is necessary to achieve the correct temperature regime. To do this, the bioreactor is installed in an earthen pit or reliable thermal insulation is thought out in advance. Constant heating of the substrate can be ensured by placing a water heating pipe under the base of the fermenter

The construction of a biogas plant can be divided into several stages.

Stage 1 - preparation of a pit for a bioreactor

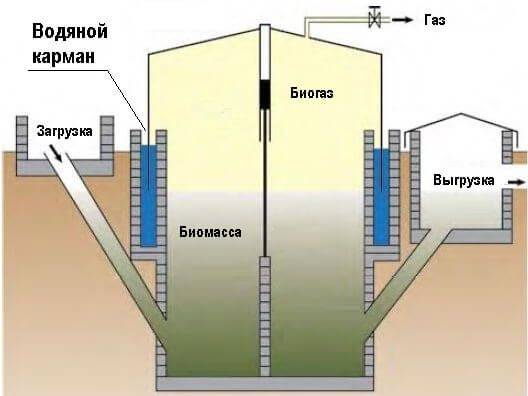

Almost the entire biogas plant is located underground, so a lot depends on how the pit was dug and finished. There are several options for strengthening the walls and sealing the pit - plastic, concrete, polymer rings.

The best solution is to buy ready-made polymer rings with a blank bottom. They will cost more than improvised materials, but additional sealing is not required. Polymers are sensitive to mechanical stress, but they are not afraid of moisture and chemically aggressive substances. They are not repairable, but if necessary, they can be easily replaced.

The intensity of the fermentation of the substrate and the gas output depend on the preparation of the walls and the bottom of the bioreactor, so the pit is carefully strengthened, insulated and sealed. This is the most difficult and time-consuming stage of work.

Stage 2 - arrangement of gas drainage

Buying and installing special agitators for biogas plants is expensive. The system can be reduced in cost by equipping gas drainage. It is a vertically installed polymer sewer pipes, in which many holes have been made.

When calculating the length of the drainage pipes, one should be guided by the planned filling depth of the bioreactor. The tops of the pipes must be above this level.

For gas drainage, you can choose metal or polymer pipes. The former are stronger, while the latter are more resistant to chemical attack. It is better to give preference to polymers, because. metal will quickly rust and rot

The substrate can be immediately loaded into the finished bioreactor. It is covered with a film so that the gas released during the fermentation process is under slight pressure.When the dome is ready, it will ensure the normal supply of biomethane through the outlet pipe.

Stage 3 - installation of the dome and pipes

The final stage of assembling the simplest biogas plant is the installation of the dome top. At the highest point of the dome, a gas outlet pipe is installed and pulled to the gas tank, which is indispensable.

The capacity of the bioreactor is closed with a tight lid. To prevent mixing of biomethane with air, a water seal is equipped. It also serves to purify gas. It is necessary to provide a release valve that will work if the pressure in the fermenter is too high.

Read more about how to make biogas from manure in this material.

The free space of the bioreactor to some extent performs the functions of a gas storage, but this is not enough for the safe operation of the plant. Gas must be consumed constantly, otherwise an explosion from overpressure under the dome is possible

Is it profitable to make a reactor and use biogas

The construction of a biogas plant has the following objectives:

- production of cheap energy;

- production of easily digestible fertilizers;

- savings on connection to expensive sewerage;

- processing of household waste;

- possible profit from the sale of gas;

- reducing the intensity of unpleasant odors and improving the environmental situation in the territory.

Graph of the profitability of the production and use of biogas

To assess the benefits of building a bioreactor, a prudent owner should consider the following aspects:

- the cost of the bio-installation is a long-term investment;

- home-made biogas equipment and installation of a reactor without the involvement of third-party specialists will cost much less, but its efficiency is also lower than that of an expensive factory one;

- to maintain stable gas pressure, the farmer must have access to animal waste in sufficient quantities and for a long time. In the case of high prices for electricity and natural gas or the lack of the possibility of gasification, the use of the installation becomes not only profitable, but also necessary;

- for large farms with their own raw material base, a profitable solution would be to include a bioreactor in the system of greenhouses and cattle farms;

- for small farms, efficiency can be increased by installing several small reactors and loading raw materials at different intervals. This will help avoid interruptions in gas supply due to a lack of feedstock.

What is biogas? Beginner's Guide

Biogas is a type of biofuel that is naturally produced from the decomposition of organic waste. When organic matter, such as food and animal waste, is broken down in an anaerobic environment (an environment where oxygen is absent), they release a mixture of gases, mainly methane and carbon dioxide. Because this decomposition takes place in an anaerobic environment, the biogas production process is also known as anaerobic digestion. Anaerobic digestion is a natural form of waste-to-energy that uses the fermentation process to break down organic matter. Animal manure, food waste, and sewage are all examples of organic matter that can produce biogas through anaerobic digestion.Due to the high methane content of biogas (typically 50-75%), biogas is flammable and therefore produces a deep blue flame and can be used as an energy source.

Biogas - a complete fuel from waste

Everyone knows that the new is the well-forgotten old. So, biogas is not a discovery of our time, but a gaseous biofuel, which they knew how to extract in ancient China. So what is biogas and how can you get it on your own?

Biogas is a mixture of gases obtained by overheating organic matter without air. Manure, tops of cultivated plants, grass or any waste can be used as starting material. As a rule, manure is used as a fertilizer, and few people know that it can be useful for obtaining biofuels, with which it is quite possible to heat living quarters, greenhouses, and also cook food.

The approximate composition of biogas: methane CH4, carbon dioxide CO2, impurities of other gases, for example, hydrogen sulfide H2S, and the specific gravity of methane can reach up to 70%. About 0.5 kg of biogas can be obtained from 1 kg of organic matter.

What factors affect production?

First, it is the environment. The warmer, the more active the reaction of decomposition of organic substances and the release of gas. No wonder the first production plants biofuels such as biogas have been used in regions with a warm climate. Despite this, with sufficient insulation of biogas plants and the use of heated water, it is quite possible to build them in more severe climatic conditions, which is being successfully carried out at the present time.

Secondly, raw materials.It should decompose easily and contain a large amount of water in its composition, without inclusions of detergents, antibiotics and other substances that can slow down the fermentation process.

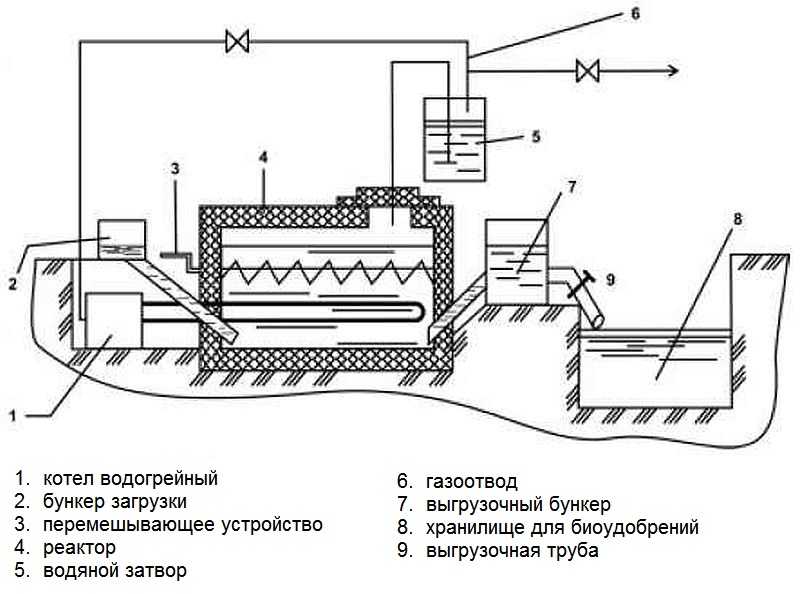

Bioinstallation by Yuri Davydov

An inventor from the Lipetsk region built with his skillful hands a device that allows you to extract "blue biofuels" at home. There was no shortage of raw materials, since he himself and his neighbors had plenty of livestock, and, of course, manure.

What did he come up with? He dug a huge hole with his own hands, laid concrete rings in it and covered it with an iron structure in the form of a dome and weighing about one ton. He brought pipes out of this container, and then filled the pit with organic matter. A few days later, he was able to cook food for cattle and heat the bathhouse on the biogas he received. Later they brought gas to the house for household needs.

Recommended composition of raw materials for processing

For this purpose, 1.5 - 2 tons of manure and 3 - 4 tons of plant waste are poured with water until 60-70% moisture content of the mixture is reached. The resulting mixture is placed in a tank and heated with a coil to 35 degrees Celsius. Under such conditions, the mixture begins to ferment without access to air and heats up to a higher temperature, which contributes to the gas evolution reaction. Gas is removed from the pit through special tubes and used for its intended purpose. The design of the installation, made by the hands of the master, is clearly visible in the diagram.

SUBSCRIBE to OUR youtube channel Econet.ru, which allows you to watch online, download from YouTube for free a video about healing, rejuvenation of a person. Love for others and for yourself, as a feeling of high vibrations, is an important factor in healing.

Homemade biogas plant:

Put LIKE, share with FRIENDS!