- Instructions for self-construction

- Stage 1 - preparation of a pit for a bioreactor

- Stage 2 - arrangement of gas drainage

- Stage 3 - installation of the dome and pipes

- General principles

- Conditions for gas production

- The principle of operation of the bioreactor

- Additional requirements for raw materials

- Manufacturers and models

- BioMash-20

- Series "BIO"

- Series "SBG"

- Series "BUG"

- Series "BGR"

- Ways to equip the installation with heating

- How to build a bioreactor (installation) with your own hands

- How to ensure biomass activity

- What's this?

- Benefits of using biotechnology

- Pros and cons of the biological method

- What conditions should the bioinstallation create?

- What is biogas and how can it be used?

- Recommended bioreactor volume

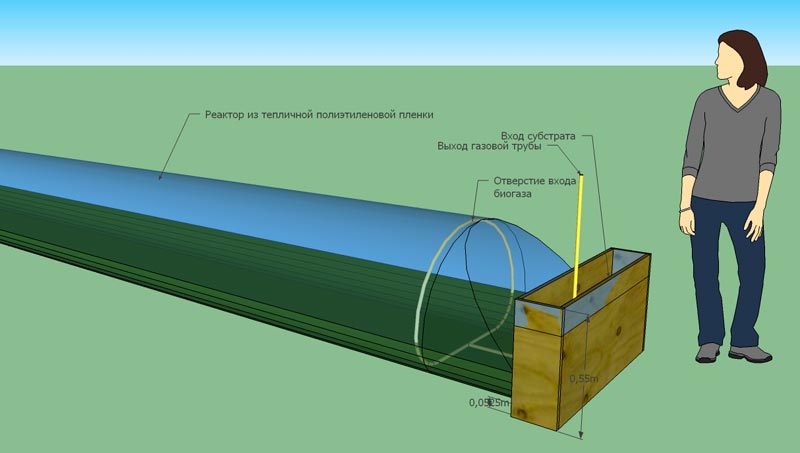

Instructions for self-construction

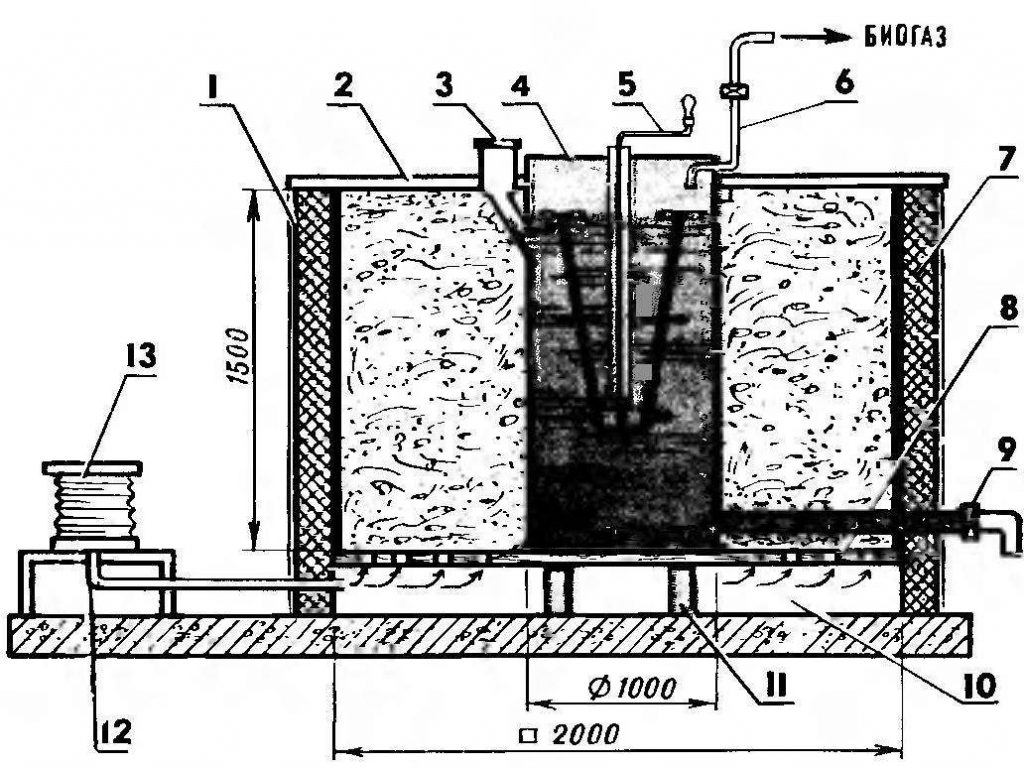

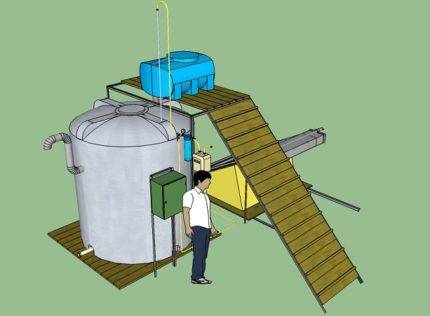

If there is no experience in assembling complex systems, it makes sense to pick up on the net or develop the simplest drawing of a biogas plant for a private house.

The simpler the design, the more reliable and durable it is. Later, when building and system handling skills become available, it will be possible to modify the equipment or mount an additional installation.

Expensive structures of industrial production include biomass mixing systems, automatic heating, gas purification, etc. Household equipment is not so difficult.It is better to assemble a simple installation, and then add elements that need to arise.

When calculating the volume of the fermenter, it is worth focusing on 5 cubic meters. Such an installation allows you to get the amount of gas needed to heat a private house with an area of 50 square meters, if a gas boiler or stove is used as a heat source.

This is an average indicator, because the calorific value of biogas is usually not higher than 6000 kcal/m3.

In order for the fermentation process to proceed more or less stably, it is necessary to achieve the correct temperature regime. To do this, the bioreactor is installed in an earthen pit or reliable thermal insulation is thought out in advance. Constant heating of the substrate can be ensured by placing a water heating pipe under the base of the fermenter

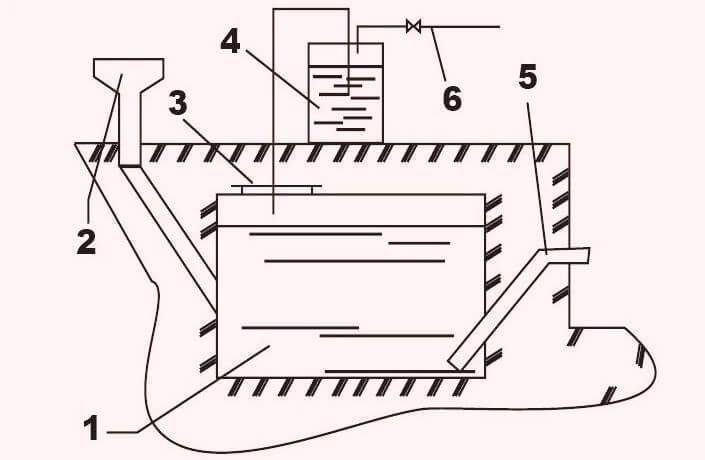

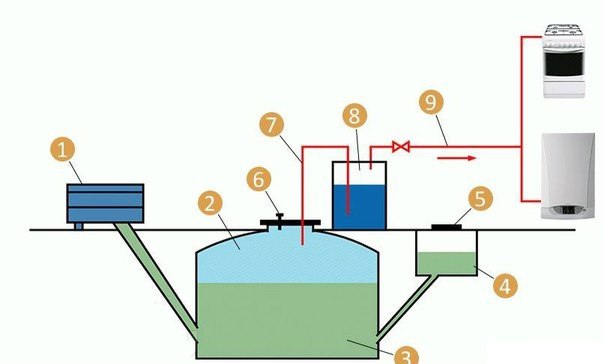

Construction of a biogas plant can be divided into several stages.

Stage 1 - preparation of a pit for a bioreactor

Almost the entire biogas plant is located underground, so a lot depends on how the pit was dug and finished. There are several options for strengthening the walls and sealing the pit - plastic, concrete, polymer rings.

The best solution is to buy ready-made polymer rings with a blank bottom. They will cost more than improvised materials, but additional sealing is not required. Polymers are sensitive to mechanical stress, but they are not afraid of moisture and chemically aggressive substances. They are not repairable, but if necessary, they can be easily replaced.

The intensity of the fermentation of the substrate and the gas output depend on the preparation of the walls and the bottom of the bioreactor, so the pit is carefully strengthened, insulated and sealed. This is the most difficult and time-consuming stage of work.

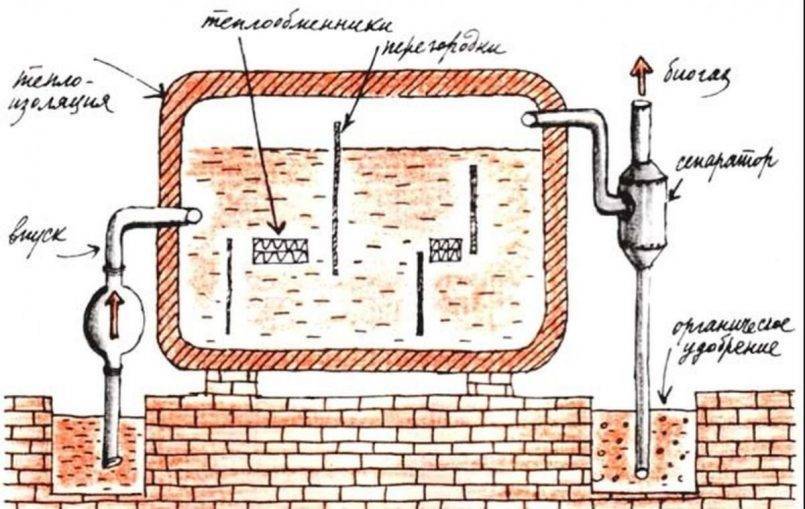

Stage 2 - arrangement of gas drainage

Buying and installing special agitators for biogas plants is expensive. The system can be reduced in cost by equipping gas drainage. It is a vertically installed polymer sewer pipes, in which many holes have been made.

When calculating the length of the drainage pipes, one should be guided by the planned filling depth of the bioreactor. The tops of the pipes must be above this level.

For gas drainage, you can choose metal or polymer pipes. The former are stronger, while the latter are more resistant to chemical attack. It is better to give preference to polymers, because. metal will quickly rust and rot

The substrate can be immediately loaded into the finished bioreactor. It is covered with a film so that the gas released during the fermentation process is under slight pressure. When the dome is ready, it will ensure the normal supply of biomethane through the outlet pipe.

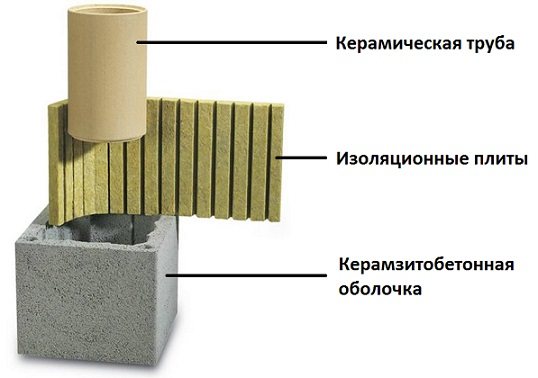

Stage 3 - installation of the dome and pipes

The final stage of assembling the simplest biogas plant is the installation of the dome top. At the highest point of the dome, a gas outlet pipe is installed and pulled to the gas tank, which is indispensable.

The capacity of the bioreactor is closed with a tight lid. To prevent mixing of biomethane with air, a water seal is equipped. It also serves to purify gas. It is necessary to provide a release valve that will work if the pressure in the fermenter is too high.

Read more about how to make biogas from manure in this material.

The free space of the bioreactor to some extent performs the functions of a gas storage, but this is not enough for the safe operation of the plant. Gas must be consumed constantly, otherwise an explosion from overpressure under the dome is possible

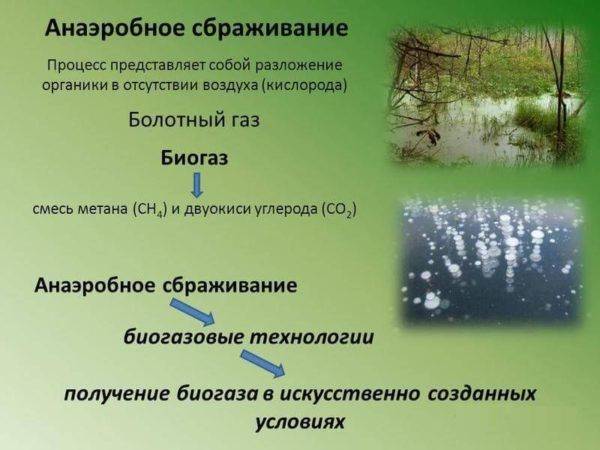

General principles

Biogas is a product that is obtained from the decomposition of organic matter. In the process of decay / fermentation, gases are released, by collecting which you can meet the needs of your own household. The equipment in which this process takes place is called a “biogas plant”.

In some cases, the gas output is excessive, then it is stored in gas tanks - for use during the period of its insufficient quantity. With proper organization of the gas process, there may be too much gas, then its surplus can be sold. Another source of income is fermented leftovers. This is a highly effective and safe fertilizer - in the process of fermentation, most microorganisms die, plant seeds lose their germination capacity, parasite eggs become unviable. The export of such fertilizers to the fields has a positive effect on productivity.

Conditions for gas production

The process of biogas formation occurs due to the vital activity of various kinds of bacteria that are contained in the waste itself. But in order for them to actively “work”, they need to create certain conditions: humidity and temperature. To create them, a biogas plant is being built. This is a complex of devices, the basis of which is a bioreactor, in which the decomposition of waste occurs, which is accompanied by gas formation.

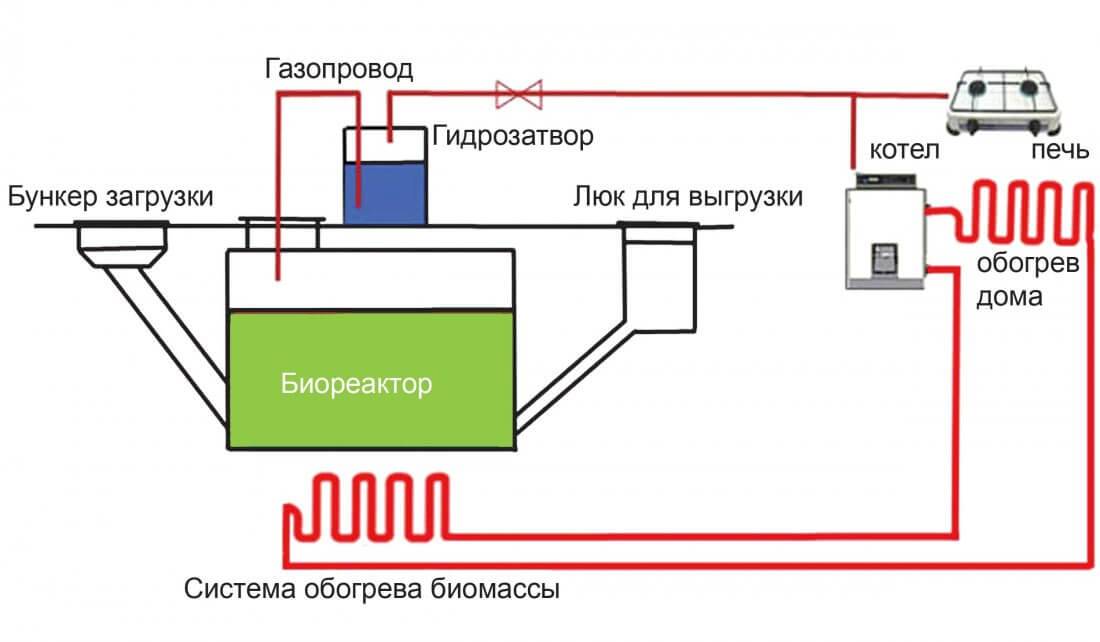

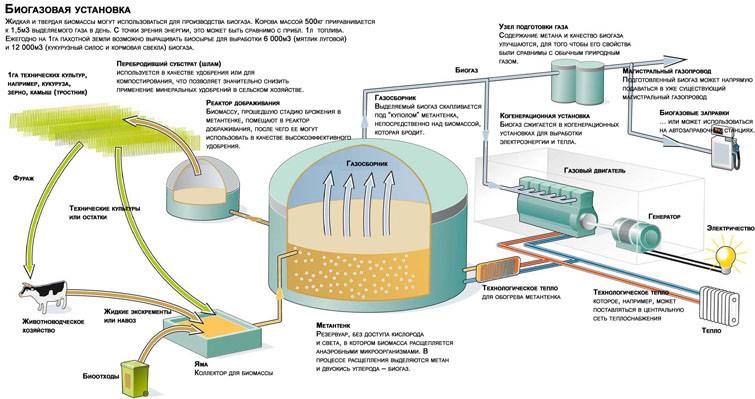

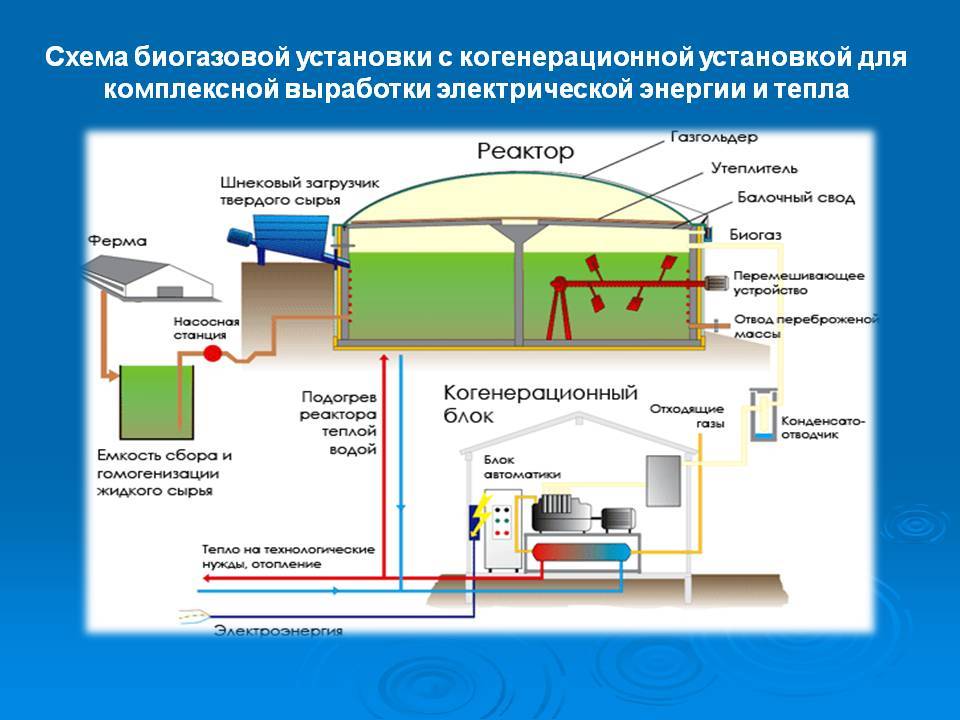

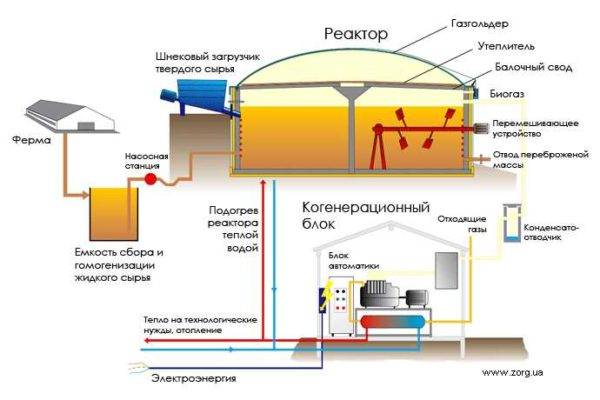

Organization of the cycle of processing manure and plant waste into biogas

There are three modes of processing manure into biogas:

- Psychophilic mode. The temperature in the biogas plant is from +5°C to +20°C. Under such conditions, the decomposition process is slow, a lot of gas is formed, its quality is low.

- Mesophilic. The unit enters this mode at temperatures from +30°C to +40°C. In this case, mesophilic bacteria actively multiply.In this case, more gas is formed, the processing process takes less time - from 10 to 20 days.

- Thermophilic. These bacteria multiply at temperatures above +50°C. The process is the fastest (3-5 days), the gas yield is the largest (under ideal conditions, up to 4.5 liters of gas can be obtained from 1 kg of delivery). Most reference tables for gas yield from processing are given specifically for this mode, so when using other modes, it is worth making an adjustment down.

The most difficult thing in biogas plants is the thermophilic regime. This requires high-quality thermal insulation of a biogas plant, heating and a temperature control system. But at the output we get the maximum amount of biogas. Another feature of thermophilic processing is the impossibility of reloading. The remaining two modes - psychophilic and mesophilic - allow you to add a fresh portion of prepared raw materials daily. But, in the thermophilic mode, a short processing time makes it possible to divide the bioreactor into zones in which its share of raw materials with different loading times will be processed.

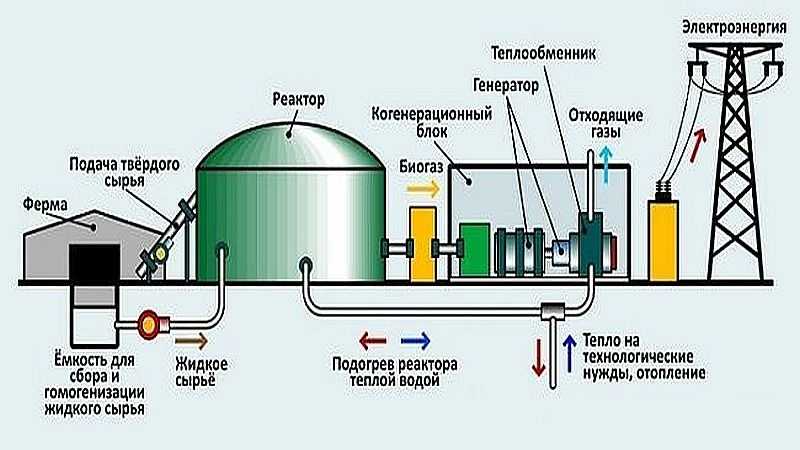

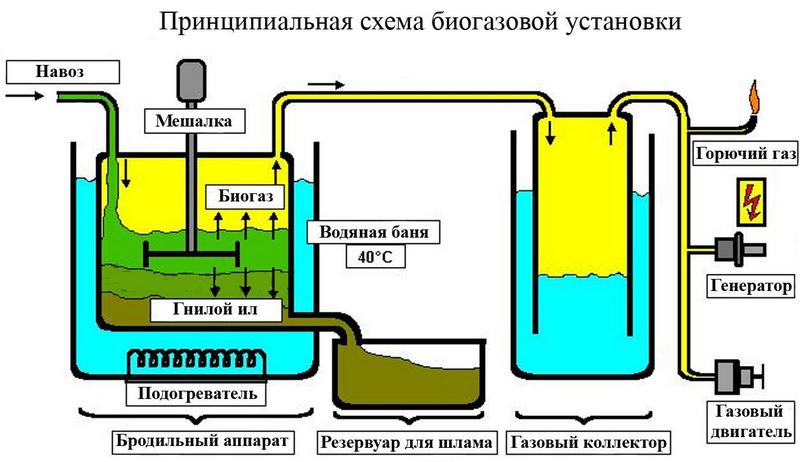

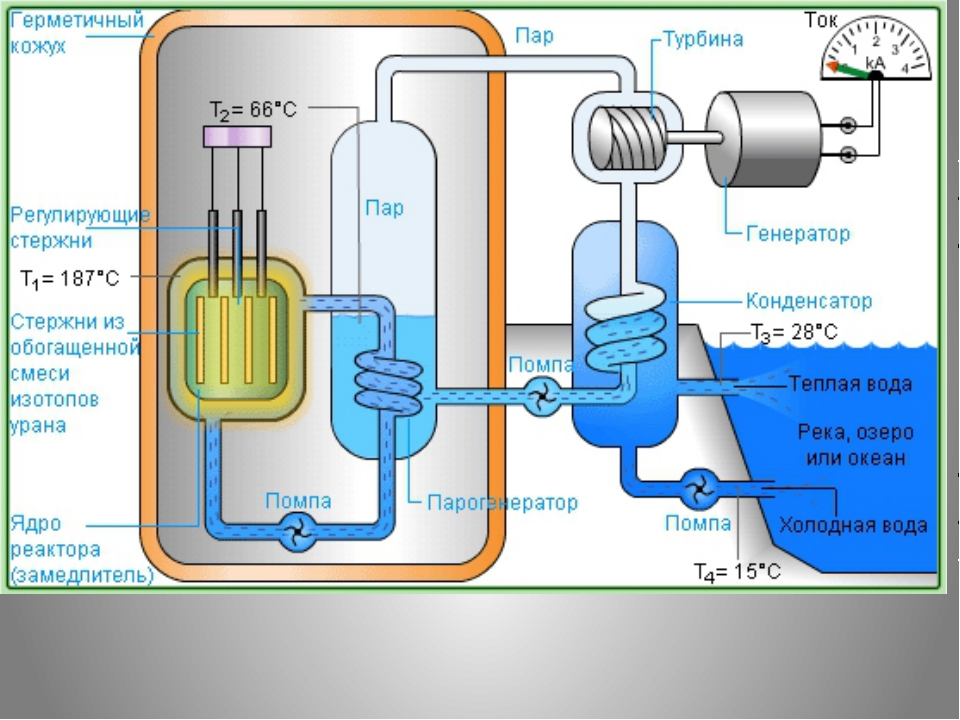

The principle of operation of the bioreactor

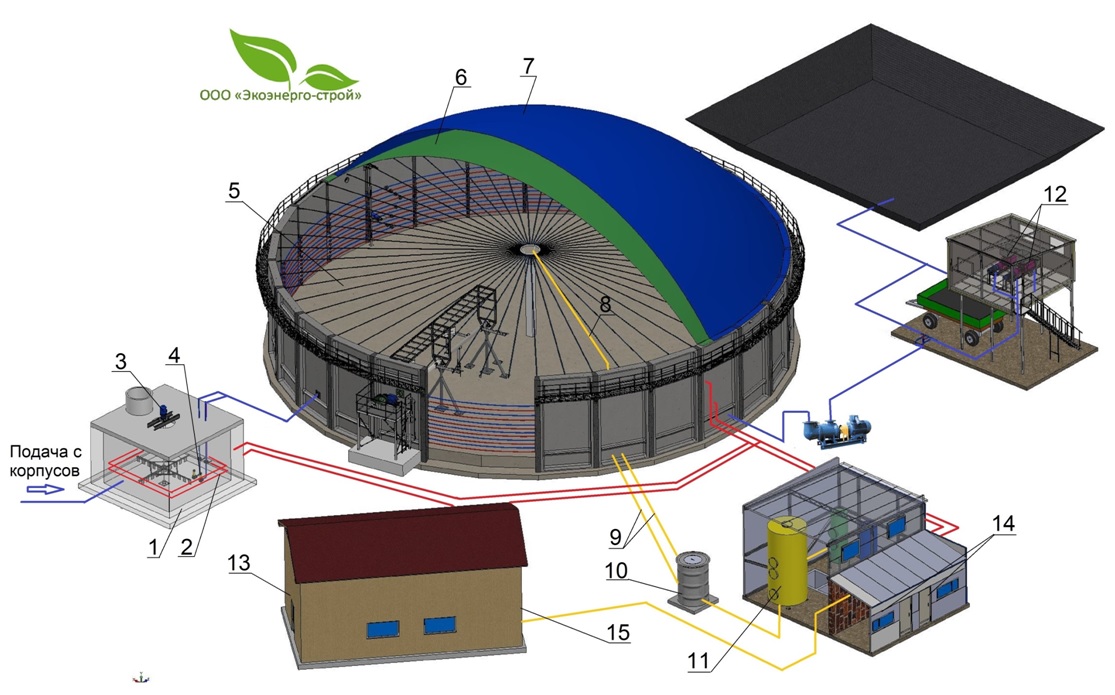

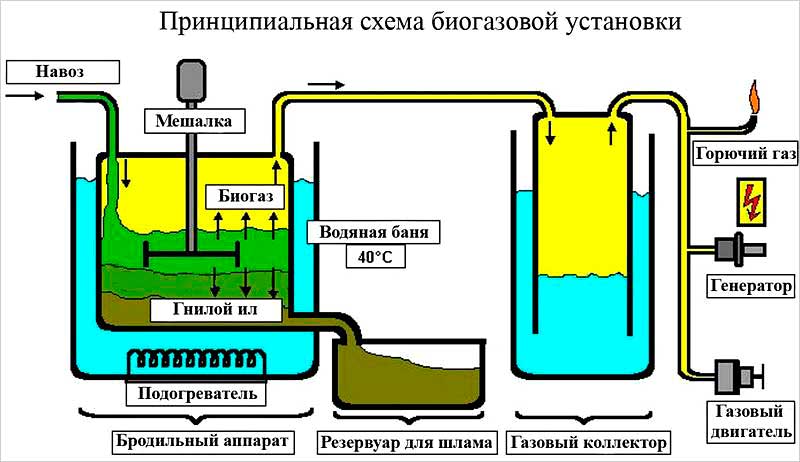

Schematic diagram of a biogas plant The bioreactor works on organic waste, therefore, for its continuous operation, the constant presence of manure and other agricultural waste is necessary. The biogas produced by the plant is a biologically clean fuel, and in terms of its performance it is similar to natural gas.

The work of the bioreactor is to process organic waste into gas and fertilizer. To do this, they are loaded into a bioreactor tank, where anaerobic bacteria process the biomass.To obtain proper fermentation, air must not enter the tank. The processing time depends on the amount of waste loaded. The emitted gas consists of methane 60%, and carbon dioxide - 35%. Other impurities make up 5%. The resulting gas is purified and then ready for use in household appliances.

Additional requirements for raw materials

A serious problem faced by farms that have installed modern equipment for biogas production is that the raw material should not contain solid inclusions, a stone, nut, piece of wire or board that accidentally gets into the mass will clog the pipeline, disable an expensive fecal pump or mixer.

It must be said that the given data on the maximum gas yield from the feed correspond to ideal laboratory conditions. In order to approach these figures in real production, it is necessary to observe a number of conditions: maintain the required temperature, periodically mix finely ground raw materials, add additives that activate fermentation, etc. On a makeshift installation, assembled according to the recommendations of articles on “getting biogas with your own hands”, you can barely reach 20% of the maximum level, high-tech installations can achieve values of 60-95%.

Sufficiently objective data on the maximum yield of biogas for various types of raw materials

Manufacturers and models

We have prepared a brief overview of the most popular models of Russian manufacturers, because they are no different from their foreign counterparts.

In addition, some manufacturers offer a complete list of components required to create a fully autonomous biogas plant, while others only produce a bioreactor and some related devices.

BioMash-20

The biogas plant from the Klimov Design Bureau is suitable for processing manure/dung with a moisture content of ≤90% with a total weight of 300–700 kg per day with the addition of bedding material (maximum 20% by weight).

The biogas plant from the Klimov Design Bureau is suitable for processing manure/dung with a moisture content of ≤90% with a total weight of 300–700 kg per day with the addition of bedding material (maximum 20% by weight).

The bioreactor is made of polyethylene, therefore it does not require maintenance and repair.

Together with the reactor, the main gas holder and a pump for its pumping (maximum pressure 2.8 MPa) are supplied. Thanks to such a high pressure, gas can be pumped into ordinary gas cylinders.

Also included in the kit:

- gas heat generator generating 100 kW per day;

- methane electric generator with a capacity of 11 kW;

- a complete set of equipment for heating the digester;

- complete set of pipelines.

Series "BIO"

These units manufactured by Agrobiogas are designed to process manure/dung weighing 10-350 tons per day (depending on the model).

The advantage of this series is a relatively low price, however, only a minimal set of equipment is included in the package, so gas tanks and much more will have to be purchased separately.

Series "SBG"

This series of biogas complexes is produced by the Kirov company SelkhozBioGaz.

This series of biogas complexes is produced by the Kirov company SelkhozBioGaz.

Thanks to an individual approach to each client, the company offers not only ready-made kits, but also the manufacture of such products for specific conditions.

The model range includes installations capable of processing from 100 kilograms to 1000 tons of excrement per day.

The delivery set includes all the necessary equipment for the deployment of a full-fledged line for the processing of manure into gas and purification of the product.

Series "BUG"

A series of biogas plants "BUG" is produced by the association of enterprises "BMP". This series includes bioreactors of small volume (0.5–12 m3) equipped with gas holders with a capacity of 1–2 m3.

Therefore, the main buyers of this series of biogas plants for the production of manure and manure are small farms or households with a large number of birds / livestock.

Series "BGR"

A series of biogas plants "BGR" is produced by the enterprise "BioGasRussia" located in Yaransk. The smallest unit of this series (BGR-12) is capable of processing 500-900 kg of excrement per day, and the volume of its bioreactor is 12 m3.

The volume of the reactor and the mass of the daily manure intake for larger plants of this series are negotiated individually, thanks to which the customer receives an apparatus or even a plant that best suits his needs.

The volume of the reactor and the mass of the daily manure intake for larger plants of this series are negotiated individually, thanks to which the customer receives an apparatus or even a plant that best suits his needs.

As part of large-volume plants, both vertical and horizontal digesters can be included, this is discussed when placing an order.

In addition, BioGasRussia offers a full range of necessary equipment, thanks to which the biogas plant can operate in a completely autonomous mode - without being connected to electrical or gas networks.

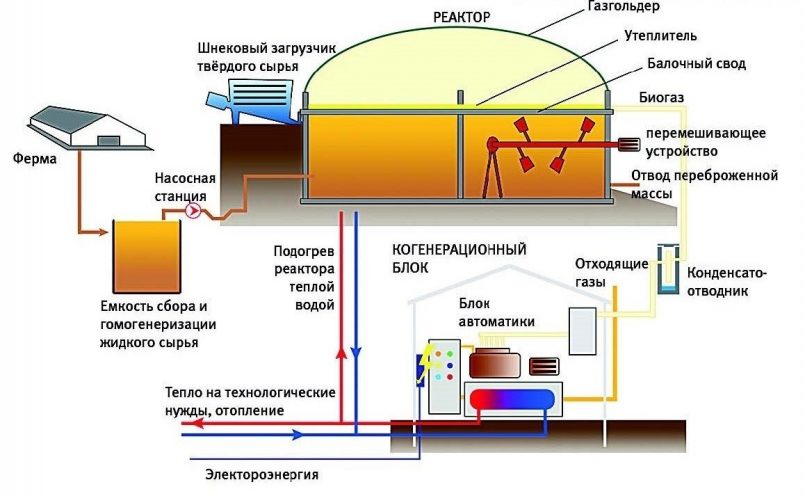

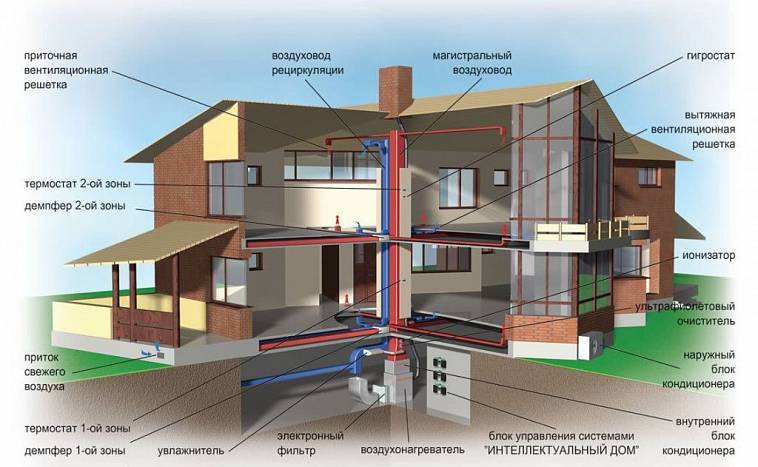

Ways to equip the installation with heating

There are several ways to install heating in a bioreactor.

- One of them involves connecting the station to the heating system. This is done in the form of a coil. Its installation should be carried out under the reactor.

- Another method involves installing an electrical heating element in the base of the tank.

- Another method of organizing heating involves the use of electric heating systems to heat the tank.

If you use automated systems to organize heating, then the device will be turned on without your help when cold biomass enters the reactor. When the raw material warms up to the set temperature, the heating system will turn off.

In order to make a high-quality biogas plant with your own hands, it is necessary to prepare drawings before starting work, which you need to focus on when carrying out work. Heating elements can be mounted in hot water boilers, so you need to take care of purchasing the necessary gas equipment.

In order to increase the amount of biogas produced, in addition to heating, you can also equip your plant with a device for mixing biomass. To do this, you will have to spend some time and create a device that will work in the same way as a regular household mixer. With the help of a shaft, it will be set in motion. The latter must be brought out through the holes in the lid.

How to build a bioreactor (installation) with your own hands

Biogas plants that extract gas from manure can be easily assembled with your own hands on your own site. Before assembling a bioreactor for manure processing, it is worth drawing drawings and carefully studying all the nuances, because.A container containing a large amount of explosive gas can be a source of great danger if it is used incorrectly or if there are errors in the design of the installation.

Biogas scheme

The capacity of the bioreactor is calculated based on the amount of raw material that is used to produce methane. In order for the operating conditions to be optimal, the reactor vessel is filled with waste at least two-thirds. For these purposes, a deep hole is used. In order for the tightness to be high, the walls of the pit are reinforced with concrete or reinforced with plastic, sometimes concrete rings are installed in the pit. The surface of the walls is treated with moisture insulating solutions. Tightness is a necessary condition for the efficient operation of the installation. The better the container is insulated, the higher the quality and quantity of the gas produced. In addition, the decay products of the waste are toxic and, if leaked, can be harmful to health.

A stirrer is installed in the waste container. It is responsible for mixing the waste during fermentation, preventing the uneven distribution of raw materials and the formation of a crust. Following the agitator, a drainage structure is mounted in the manure gasifier, which facilitates the removal of gas into the storage tank and prevents leakage. It is necessary to remove the gas for safety reasons, as well as to improve the quality of the fertilizers remaining in the reactor after processing is completed. A hole is made in the lower part of the reactor for the exit of spent raw materials. The hole is equipped with a tight cover so that the equipment remains airtight.

How to ensure biomass activity

For proper biomass fermentation, it is best to heat the mixture. In the southern regions, the air temperature contributes to the start of fermentation. If a you live on north or in the middle lane, you can connect additional heating elements.

To start the process, a temperature of 38 degrees is needed. There are several ways to provide it:

- Coil under the reactor, connected to the heating system;

- Heating elements inside the tank;

- Direct heating of the tank with electric heaters.

The biological mass already contains bacteria that are needed to produce biogas. They wake up and begin activity when the air temperature rises.

It is best to heat them with automatic heating systems. They turn on when cold mass enters the reactor and turn off automatically when the temperature reaches the desired value. Such systems are installed in water-heating boilers, they can be bought at gas equipment stores.

If you provide heating to 30-40 degrees, then it will take 12-30 days to process. It depends on the composition and volume of the mass. When heated to 50 degrees, bacterial activity increases, and processing takes 3-7 days. The disadvantage of such installations is the high cost of maintaining a high temperature. They are comparable to the amount of fuel received, so the system becomes inefficient.

Another way to activate anaerobic bacteria is biomass mixing. You can independently install the shafts in the boiler and bring the handle out to stir the mass if necessary. But it is much more convenient to design an automatic system that will mix the mass without your participation.

What's this?

Biogas, which is an environmentally friendly fuel, is obtained in biogas plants, units, which are a complex of technical structures and apparatuses combined into a single technological cycle.

The complete set of a biogas plant can be different, depending on its capacity, type of raw material and the final product obtained in the form of thermal or electric energy, both types of energy or only biogas used in domestic gas stoves and as a fuel for cars.

Standard installation consists of the following components and assemblies:

- Storage tank, in which raw materials used for biogas production are accumulated;

- Mixers and mills of various designs, dividing large fractions of raw materials into smaller ones;

- Gas holder, a hermetically sealed container that serves as a storage tank for the resulting gas;

- Reactor, container or tank in which the process of biofuel formation takes place;

- Systems for supplying raw materials to the plant's reactor;

- The system for transferring the resulting fuel from the reactor and gas holder, further to the stages of processing and conversion into other types of energy;

- Automation, protection and control systems for the production of gas and products of its processing.

The above diagram conventionally shows the technological cycle of biogas production using liquid and solid raw materials, with its further processing and production of thermal and electrical energy.

Benefits of using biotechnology

The technology for obtaining biofuels from various natural sources is not new. Research in this area began at the end of the 18th century and successfully developed in the 19th century. In the Soviet Union, the first bioenergy plant was created in the forties of the last century.

Biotechnologies have long been used in many countries, but today they are of particular importance.Due to the deteriorating environmental situation on the planet and the high cost of energy, many are turning their eyes towards alternative sources of energy and heat.

The technology of manure processing into biogas makes it possible to reduce the amount of harmful methane emissions into the atmosphere and obtain an additional source of thermal energy

Of course, manure is a very valuable fertilizer, and if there are two cows on the farm, then there are no problems with its use. Another thing is when it comes to farms with large and medium livestock, where tons of fetid and rotting biological material are formed per year.

In order for manure to turn into high-quality fertilizer, areas with a certain temperature regime are needed, and these are extra costs. Therefore, many farmers store it where necessary, and then take it to the fields.

Depending on the volume of raw materials generated per day, it is necessary to select the dimensions of the installation and the degree of its automation.

If storage conditions are not observed, up to 40% of nitrogen and the main part of phosphorus evaporate from manure, which significantly worsens its quality indicators. In addition, methane gas is released into the atmosphere, which has a negative impact on the ecological situation of the planet.

Modern biotechnologies make it possible not only to neutralize the harmful effects of methane on the environment, but also to make it serve for the benefit of man, while extracting considerable economic benefits.As a result of manure processing, biogas is formed, from which thousands of kW of energy can then be obtained, and production waste is a very valuable anaerobic fertilizer.

Pros and cons of the biological method

The design of biogas plants is a responsible stage, therefore, before making a final decision, it is better to weigh the pros and cons of this method.

The advantages of such production include:

- Rational utilization of organic waste. Thanks to the installation, it is possible to put into action what would otherwise be just garbage that pollutes the environment.

- Inexhaustibility of raw materials. Natural gas and coal will run out sooner or later, but for those who have their own economy, the necessary waste will constantly appear.

- Small amount of carbon dioxide. It is released into the atmosphere when using biogas, but carbon dioxide cannot adversely affect the ecological situation.

- Uninterrupted and efficient operation of biogas plants. Unlike solar collectors or windmills, biogas production does not depend on external conditions.

- Reduced risk through the use of multiple installations. Large bioreactors are always a big threat, but they can be eliminated by making a system of several fermenters.

- Obtaining high quality fertilizer.

- Small energy savings.

Another plus is the possible benefit to the condition of the soil. Some plants are planted on the site specifically for biomass. In this case, you can choose those that can improve the quality of the soil. An example is sorghum, which reduces its erosion.

Each type of alternative sources has its drawbacks. Biogas plants are no exception.The downside is:

- increased risk of equipment;

- energy costs required for the processing of raw materials;

- negligible biogas output due to the small volume of domestic systems.

The most difficult thing is to make a biogas plant designed for the most efficient, thermophilic regime. The costs in this case promise to be serious. Such design of biogas plants is best left to a professional.

What conditions should the bioinstallation create?

The most important conditions that provide the most comfortable conditions for the activity of methanogens are:

- lack of oxygen supply (tightness);

- constant temperature corresponding to the type of processes occurring in the reactor;

- adjustable inflow of fresh material;

- adjustable removal of gas and waste separately for liquid and solid fractions;

- regular mixing of the contents, preventing separation into solid and liquid fractions.

Tightness should be combined with the possibility of maintenance and repair of the internal space, because the contents of the bioreactor are very aggressive substances.

To create a sufficient temperature, which in most cases greatly exceeds the outdoor temperature, digesters are insulated and equipped with heating elements.

In order for the production of methane to be at a high level, it is necessary to remove the waste of this process in a timely manner, that is, process water and sludge (sapropel). This is done using pipes and water seals or other locking devices that prevent the exit of the generated gas.

Stirring is carried out mechanically, bringing the entire contents of the digester into a circular and vertical movement, due to which the separated layers of different densities mix and form a single layer with the same moisture content in any area.

What is biogas and how can it be used?

Owners of household plots know that by putting together any vegetable raw materials, bird droppings and manure, after a while you can get valuable organic fertilizer. But few of them know that biomass does not decompose by itself, but under the influence of various bacteria.

Processing the biological substrate, these tiny microorganisms release waste products, including a gas mixture. Most of it (about 70%) is methane - the same gas that burns in the burners of household stoves and heating boilers.

The idea of using such eco-fuels for various household needs is not new. Devices for its extraction were used in ancient China. The possibility of using biogas was also explored by Soviet innovators in the 60s of the last century. But the technology experienced a real revival in the early 2000s. At the moment, biogas plants are actively used in Europe and the USA for heating houses and other needs.

Recommended bioreactor volume

To determine the required volume of the reactor for processing biomass, it is necessary to calculate the amount of manure produced during the day. It is mandatory to take into account the type of raw materials used, the temperature regime that will be maintained in the installation. The tank used should be filled to 85-90% of its volume. The remaining 10% is necessary for the accumulation of the obtained biological gas.

The duration of the processing cycle is necessarily taken into account. When maintaining the temperature at +35°C, it is 12 days. We must not forget that the raw materials used are diluted with water before being sent to the reactor. Therefore, its quantity is taken into account before calculating the volume of the tank.