- The mechanism of gas formation from organic raw materials

- Benefits of using biotechnology

- 2 Bioreactor for processing organic waste

- 2.1 Processes occurring in the bioreactor

- Pros and cons of the biological method

- Collection and disposal of biogas

- Purification of impurities

- Gas tank and compressor

- What is biogas

- General information about biogas

- Video about obtaining biogas from manure

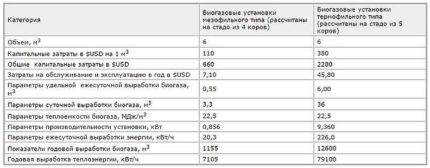

- Options for Biofuel Plants

- Construction of a typical biogas plant

- Reactor

- Biomass Feeding System

- Agitators

- Automated heating system

- Separator

- General principles

- Conditions for gas production

- What it is

The mechanism of gas formation from organic raw materials

Biogas is a colorless and odorless volatile substance that contains up to 70% methane. In terms of its quality indicators, it approaches the traditional type of fuel - natural gas. It has a good calorific value, 1 m3 of biogas emits as much heat as is obtained from the combustion of one and a half kilograms of coal.

We owe the formation of biogas to anaerobic bacteria that are actively working on the decomposition of organic raw materials, which are used as manure of farm animals, bird droppings, waste of any plants.

In self-produced biogas, bird droppings and waste products of small and large livestock can be used. The raw material can be used in pure form and in the form of a mixture with the inclusion of grass, foliage, old paper

To activate the process, it is necessary to create favorable conditions for the vital activity of bacteria. They should be similar to those in which microorganisms develop in a natural reservoir - in the stomach of animals, where it is warm and there is no oxygen.

Actually, these are the two main conditions that contribute to the miraculous transformation of rotting manure mass into environmentally friendly fuel and valuable fertilizers.

To obtain biogas, you need a sealed reactor without air access, where the process of manure fermentation and its decomposition into components will take place:

- methane (up to 70%);

- carbon dioxide (about 30%);

- other gaseous substances (1-2%).

The resulting gases rise to the top of the tank, from where they are then pumped out, and the residual product settles down - a high-quality organic fertilizer, which, as a result of processing, has retained all the valuable substances in the manure - nitrogen and phosphorus, and has lost a significant part of pathogenic microorganisms.

The biogas reactor must have a completely sealed design, in which there is no oxygen, otherwise the process of manure decomposition will be extremely slow

The second important condition for the effective decomposition of manure and the formation of biogas is compliance with the temperature regime. The bacteria involved in the process are activated at a temperature of +30 degrees

Moreover, manure contains two types of bacteria:

- mesophilic.Their vital activity occurs at a temperature of +30 - +40 degrees;

- thermophilic. For their reproduction, it is necessary to observe the temperature regime of +50 (+60) degrees.

The processing time of raw materials in plants of the first type depends on the composition of the mixture and ranges from 12 to 30 days. At the same time, 1 liter of useful area of the reactor gives 2 liters of biofuel. When using plants of the second type, the time for the production of the final product is reduced to three days, and the amount of biogas increases to 4.5 liters.

The effectiveness of thermophilic plants is visible to the naked eye, however, the cost of their maintenance is very high, so before choosing one or another method of obtaining biogas, it is necessary to carefully calculate everything

The effectiveness of thermophilic plants is visible to the naked eye, however, the cost of their maintenance is very high, so before choosing one or another method of obtaining biogas, it is necessary to carefully calculate everything

Despite the fact that the efficiency of thermophilic installations is ten times higher, they are used much less often, since maintaining high temperatures in the reactor is associated with high costs.

Mesophilic plants are cheaper to maintain and maintain, which is why most farms use them to produce biogas.

Biogas according to the criteria of energy potential is slightly inferior to the usual gas fuel. However, it contains sulfuric acid fumes, the presence of which should be taken into account when choosing materials for the construction of the installation.

Benefits of using biotechnology

The technology for obtaining biofuels from various natural sources is not new. Research in this area began at the end of the 18th century and successfully developed in the 19th century. In the Soviet Union, the first bioenergy plant was created in the forties of the last century.

Biotechnologies have long been used in many countries, but today they are of particular importance.Due to the deteriorating environmental situation on the planet and the high cost of energy, many are turning their eyes towards alternative sources of energy and heat.

Of course, manure is a very valuable fertilizer, and if there are two cows on the farm, then there are no problems with its use. Another thing is when it comes to farms with large and medium livestock, where tons of fetid and rotting biological material are formed per year.

In order for manure to turn into high-quality fertilizer, areas with a certain temperature regime are needed, and these are extra costs. Therefore, many farmers store it where necessary, and then take it to the fields.

If storage conditions are not observed, up to 40% of nitrogen and the main part of phosphorus evaporate from manure, which significantly worsens its quality indicators. In addition, methane gas is released into the atmosphere, which has a negative impact on the ecological situation of the planet.

Modern biotechnologies make it possible not only to neutralize the harmful effects of methane on the environment, but also to make it serve for the benefit of man, while extracting considerable economic benefits. As a result of manure processing, biogas is formed, from which thousands of kW of energy can then be obtained, and production waste is a very valuable anaerobic fertilizer.

Image galleryPhoto from Organizing a biogas production system is economically viable for farms. If only two cows provide raw materials, it is better to use it as fertilizer. The gas obtained by processing manure will provide heat and energy.After cleaning, it can be supplied to the stove and the boiler, pumped into the cylinder, used by the electric generator. Structurally, the simplest processing plant is easy to build with your own hands. Its main organ is a bioreactor, which must be well insulated with hydro and thermal insulation. For those who wish to reduce the time for constructing the system, a prefabricated plastic container is suitable. When using it, similar principles of construction and isolation apply. Farms are the main suppliers of raw materials for biogas production. Obtaining and using gaseous biofuels. Building a processing plant with your own hands. A finished plastic container in a bioreactor device.

2 Bioreactor for processing organic waste

A bioreactor is used to dispose of biological waste to obtain organic fertilizers and, at the same time, biogas. The BUG installation, which has several modifications, has become widespread. They differ in their performance.

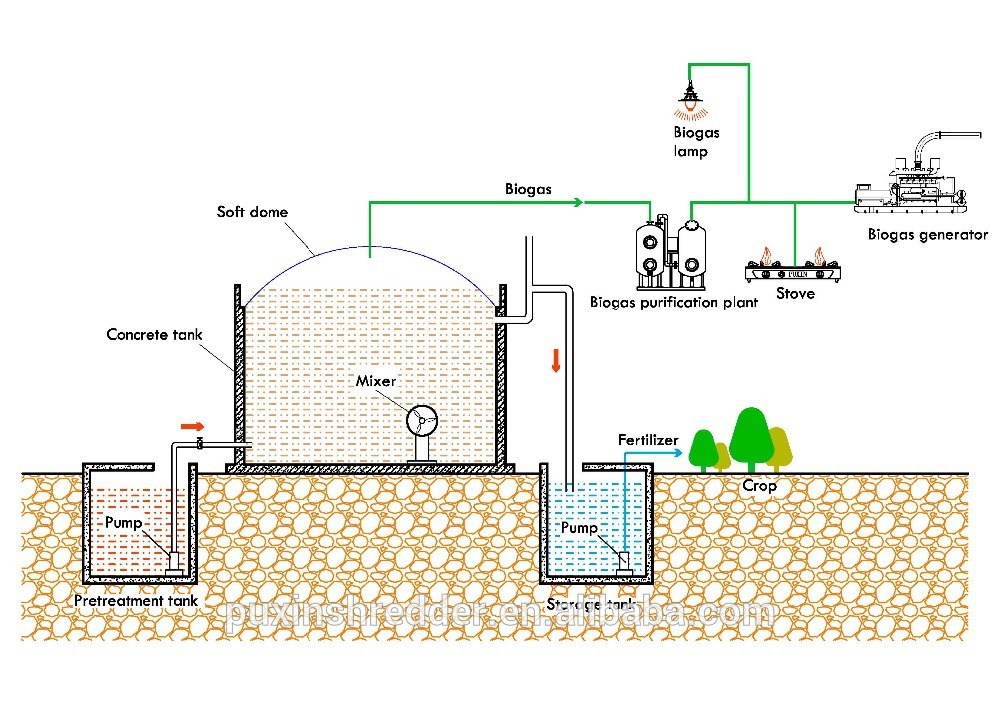

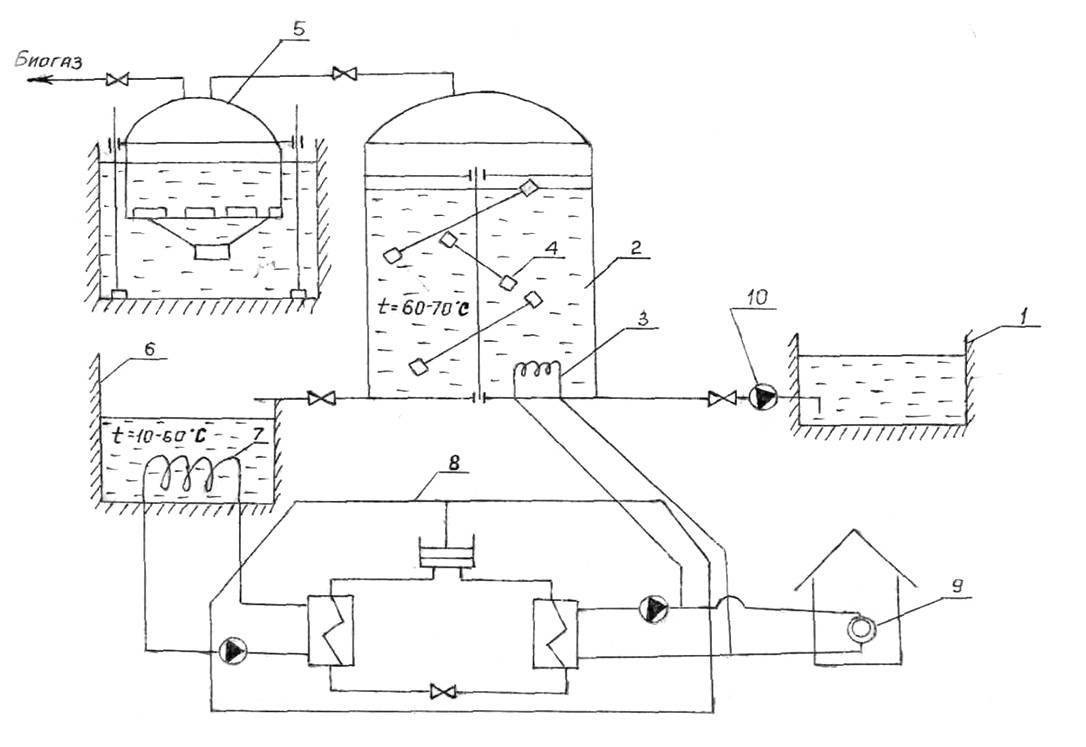

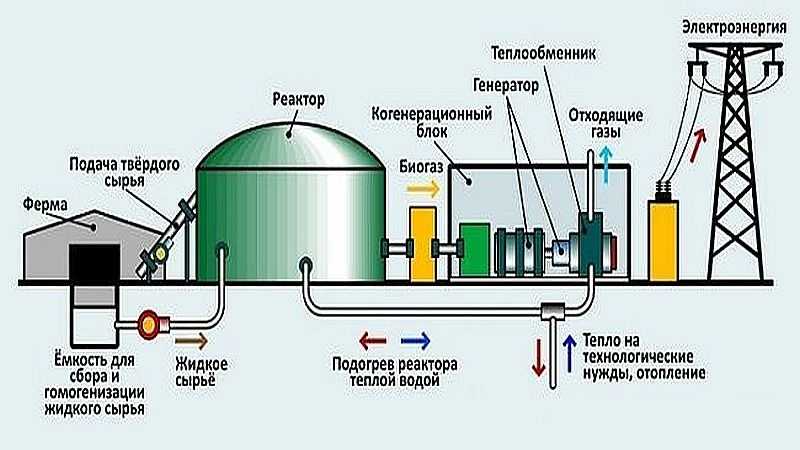

A standard biogas plant includes the following equipment for processing manure and other organic waste:

- container for homogenization;

- loaders of liquid and solid raw materials;

- security system;

- instrumentation and automation with visualization;

- bioreactor with gas holder;

- mixers and separators;

- pumping station;

- heating and water mixing systems;

- gas system.

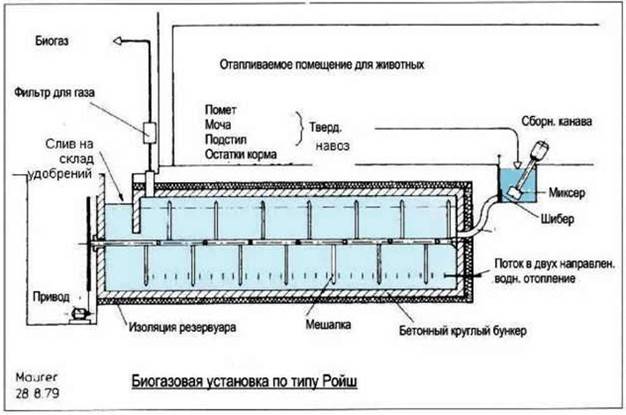

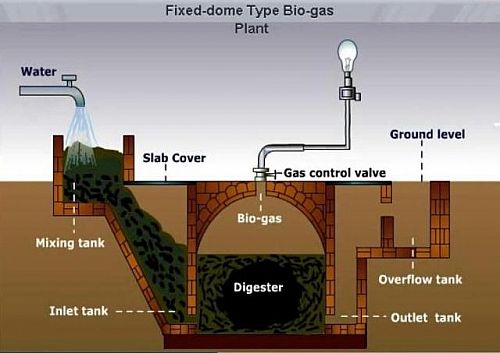

2.1 Processes occurring in the bioreactor

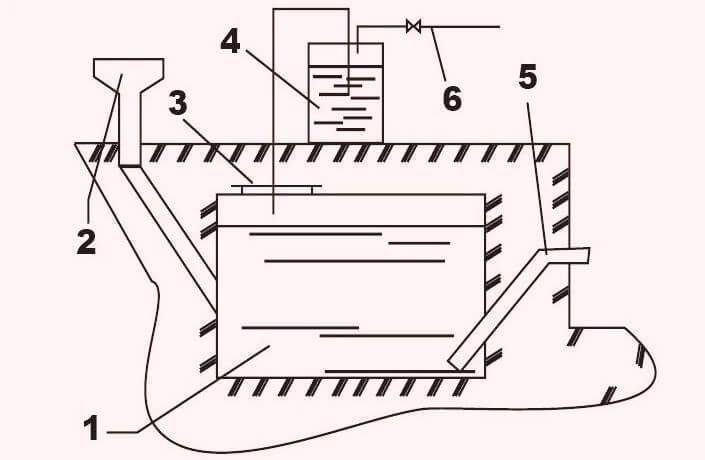

The bioreactor consists of three divided sections:

Biogas plants

- boot;

- working;

- unloading.

The inner surface part of the reactor is not smooth, but is made in the form of a tubular container. This contributes to the acceleration and more complete flow of the processing process. From the receiving section, the substrate processed into a homogeneous biomass and mixed with water through the technological hatch enters the bioreactor.

The upper middle part of the working section is also equipped with a sealed hatch, on which there are devices for monitoring the biomass level, biogas sampling and its pressure. When the pressure inside the reactor increases, the compressor automatically turns on, which prevents the tank from bursting. The compressor pumps the biogas from the reactor to the gas tank. A heating element is installed in the bioreactor, which maintains the temperature necessary for the fermentation of the biomass.

In the working section of the reactor, the temperature is always higher than in the other two sections. This ensures the completeness of the cycle of the chemical process and increases productivity. In this part of the reactor, the biomass is continuously mixed, which prevents the formation of a floating crust that prevents the biogas from escaping.

Completely processed substrate enters the unloading section of the bioreactor. Here the final separation of gas residues and liquid fertilizers takes place.

Installations processing manure, bird droppings and other organic waste of any kind of action are widely in demand and used in agriculture. Biogas plants are used in urban utilities for the disposal of organic waste and the production of biogas for thermal power.

Pros and cons of the biological method

The design of biogas plants is a responsible stage, therefore, before making a final decision, it is better to weigh the pros and cons of this method.

The advantages of such production include:

- Rational utilization of organic waste. Thanks to the installation, it is possible to put into action what would otherwise be just garbage that pollutes the environment.

- Inexhaustibility of raw materials. Natural gas and coal will run out sooner or later, but for those who have their own economy, the necessary waste will constantly appear.

- Small amount of carbon dioxide. It is released into the atmosphere when using biogas, but carbon dioxide cannot adversely affect the ecological situation.

- Uninterrupted and efficient operation of biogas plants. Unlike solar collectors or windmills, biogas production does not depend on external conditions.

- Reduced risk through the use of multiple installations. Large bioreactors are always a big threat, but they can be eliminated by making a system of several fermenters.

- Obtaining high quality fertilizer.

- Small energy savings.

Another plus is the possible benefit to the condition of the soil. Some plants are planted on the site specifically for biomass. In this case, you can choose those that can improve the quality of the soil. An example is sorghum, which reduces its erosion.

Each type of alternative sources has its drawbacks. Biogas plants are no exception. The downside is:

- increased risk of equipment;

- energy costs required for the processing of raw materials;

- negligible biogas output due to the small volume of domestic systems.

The most difficult thing is to make a biogas plant designed for the most efficient, thermophilic regime. The costs in this case promise to be serious.Such design of biogas plants is best left to a professional.

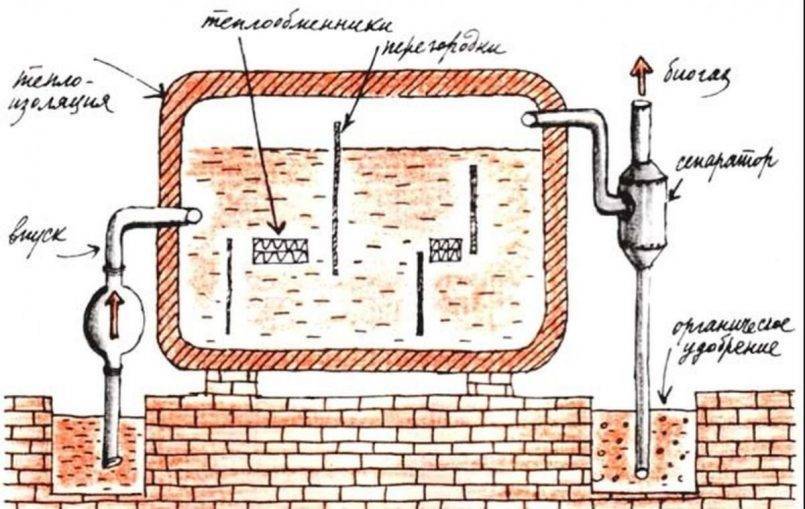

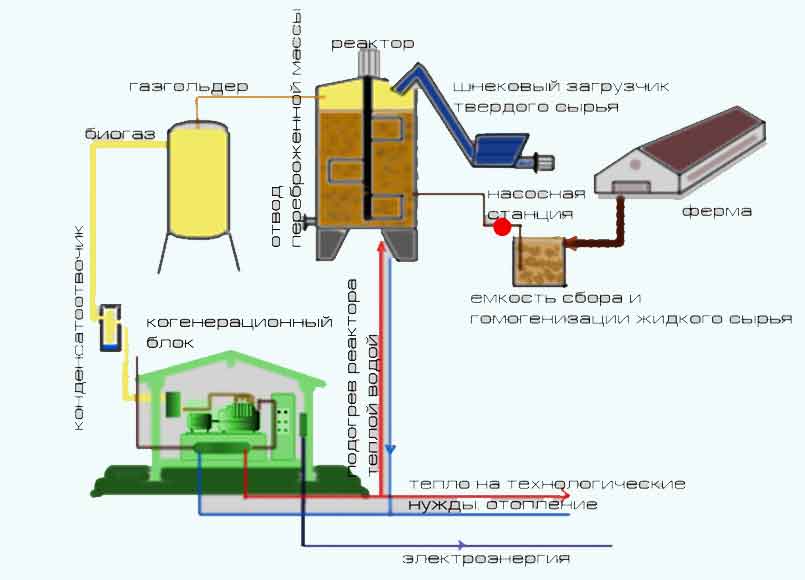

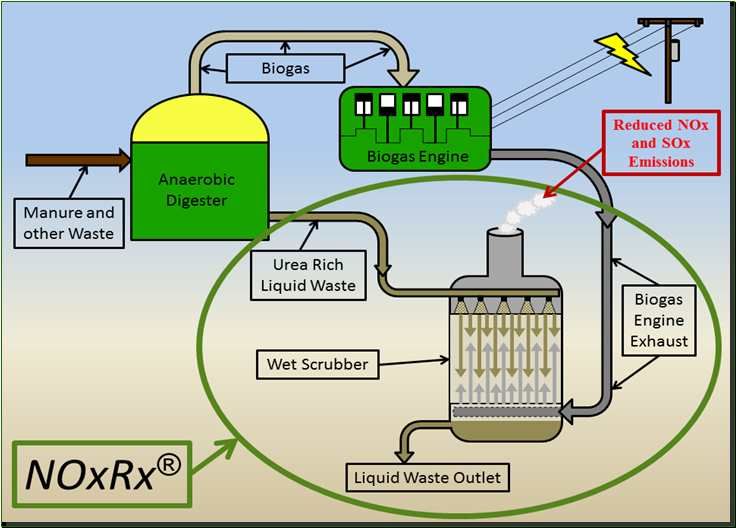

Collection and disposal of biogas

The removal of biogas from the reactor occurs through a pipe, one end of which is under the roof, the other is usually lowered into a water seal. This is a container with water into which the resulting biogas is discharged. There is a second pipe in the water seal - it is located above the liquid level. More pure biogas comes out into it. A shut-off gas valve is installed at the outlet of their bioreactor. The best option is ball.

What materials can be used for the gas transmission system? Galvanized metal pipes and gas pipes made of HDPE or PPR. They must ensure tightness, seams and joints are checked with soap suds. The entire pipeline is assembled from pipes and fittings of the same diameter. No contractions or expansions.

Purification of impurities

The approximate composition of the resulting biogas is as follows:

Approximate composition of biogas

- methane - up to 60%;

- carbon dioxide - 35%;

- other gaseous substances (including hydrogen sulfide, which gives the gas an unpleasant odor) - 5%.

In order for biogas to have no smell and burn well, it is necessary to remove carbon dioxide, hydrogen sulfide, and water vapor from it. Carbon dioxide is removed in a water seal if slaked lime is added to the bottom of the installation. Such a bookmark will have to be changed periodically (as the gas starts to burn worse, it's time to change it).

Gas dehydration can be done in two ways - by making hydraulic seals in the gas pipeline - by inserting curved sections under the hydraulic seals into the pipe, in which condensate will accumulate. The disadvantage of this method is the need for regular emptying of the water seal - with a large amount of collected water, it can block the passage of gas.

The second way is to put a filter with silica gel. The principle is the same as in the water seal - the gas is fed into the silica gel, dried out from under the cover. With this method of drying biogas, silica gel has to be dried periodically. To do this, it needs to be warmed up for some time in the microwave. It heats up, the moisture evaporates. You can fall asleep and use again.

Filter for cleaning biogas from hydrogen sulfide

To remove hydrogen sulfide, a filter loaded with metal shavings is used. You can load old metal washcloths into the container. Purification occurs in exactly the same way: gas is supplied to the lower part of the container filled with metal. Passing, it is cleaned of hydrogen sulfide, collects in the upper free part of the filter, from where it is discharged through another pipe / hose.

Gas tank and compressor

The purified biogas enters the storage tank - gas tank. It can be a sealed plastic bag, a plastic container. The main condition is gas tightness, the shape and material do not matter. Biogas is stored in the gas tank. From it, with the help of a compressor, gas under a certain pressure (set by the compressor) is already supplied to the consumer - to a gas stove or boiler. This gas can also be used to generate electricity using a generator.

One of the options for gas tanks

To create a stable pressure in the system after the compressor, it is desirable to install a receiver - a small device for leveling pressure surges.

What is biogas

Biogas is a colorless and odorless volatile substance that contains up to 70% methane. In terms of its quality indicators, it approaches the traditional type of fuel - natural gas. It has a good calorific value, 1 m3 of biogas emits as much heat as is obtained from the combustion of one and a half kilograms of coal.

We owe the formation of biogas to anaerobic bacteria that are actively working on the decomposition of organic raw materials, which are used as manure of farm animals, bird droppings, waste of any plants.

In self-produced biogas, bird droppings and waste products of small and large livestock can be used. The raw material can be used in pure form and in the form of a mixture with the inclusion of grass, foliage, old paper

To activate the process, it is necessary to create favorable conditions for the vital activity of bacteria. They should be similar to those in which microorganisms develop in a natural reservoir - in the stomach of animals, where it is warm and there is no oxygen. Actually, these are the two main conditions that contribute to the miraculous transformation of rotting manure mass into environmentally friendly fuel and valuable fertilizers.

General information about biogas

Derived from various manure and bird droppings, domestic biogas mostly consists of methane. There it is from 50 to 80%, depending on whose waste products were used for production. The same methane that burns in our stoves and boilers, and for which we sometimes pay a lot of money according to the meter readings.

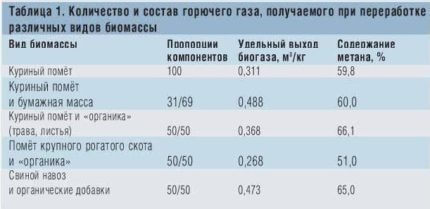

To give an idea of the amount of fuel that can theoretically be obtained by keeping animals at home or in the country, we present a table with data on the yield of biogas and the content of pure methane in it:

The rest of the substances (25-45%) that make up home biogas are carbon dioxide (up to 43%) and hydrogen sulfide (1%). Also in the composition of the fuel there is nitrogen, ammonia and oxygen, but in small quantities. By the way, it is thanks to the release of hydrogen sulfide and ammonia that the dunghill emits such a familiar “pleasant” smell. As for the energy content, 1 m3 of methane can theoretically release up to 25 MJ (6.95 kW) of thermal energy during combustion. The specific heat of combustion of biogas depends on the proportion of methane in its composition.

By nature, it is arranged in such a way that biogas from manure is formed spontaneously and regardless of whether we want to receive it or not. The manure heap rots within a year - one and a half, just being in the open air and even at a negative temperature. All this time, it emits biogas, but only in small quantities, since the process is extended in time. The reason is hundreds of species of microorganisms found in animal excrement. That is, nothing is needed to start gassing, it will occur on its own. But to optimize the process and speed it up, special equipment will be required, which will be discussed later.

Video about obtaining biogas from manure

How the construction of an underground reactor is going on, you can see in the video:

An installation for biogas production from manure will significantly save on payment for heat and electricity, and use organic material, which is available in abundance in every farm, for a good cause. Before starting construction, everything must be carefully calculated and prepared.

The simplest reactor can be made in a few days with your own hands, using available tools. If the farm is large, then it is best to buy a ready-made installation or contact specialists.

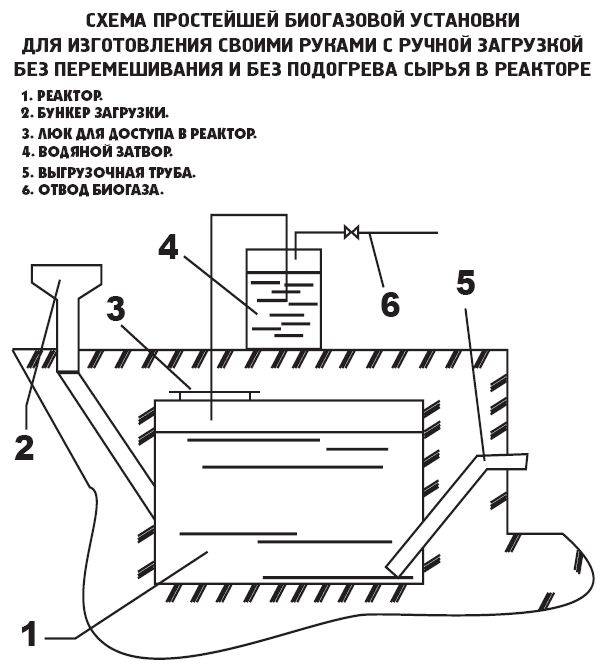

Options for Biofuel Plants

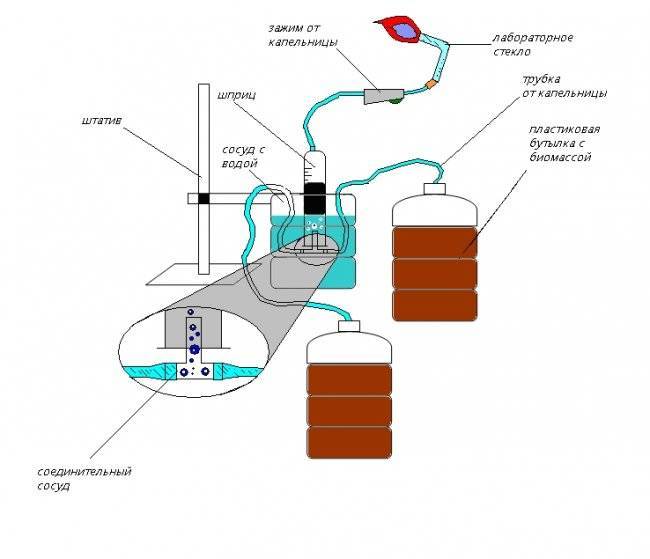

After carrying out the calculations, it is necessary to decide how to make an installation in order to obtain biogas in accordance with the needs of your farm. If the livestock is small, then the simplest option is suitable, which is easy to make from improvised means with your own hands.

For large farms that have a constant source of a large amount of raw materials, it is advisable to build an industrial automated biogas system. In this case, it is unlikely that it will be possible to do without the involvement of specialists who will develop the project and mount the installation at a professional level.

Today, there are dozens of companies that can offer a variety of options: from ready-made solutions to the development of an individual project. To reduce the cost of construction, you can cooperate with neighboring farms (if there are any nearby) and build one plant for all biogas production.

It should be noted that for the construction of even a small installation, it is necessary to draw up the relevant documents, make a technological scheme, a plan for the placement of equipment and ventilation (if the equipment is installed indoors), go through the procedures for coordination with the SES, fire and gas inspection.

A mini-plant for the production of gas to cover the needs of a small private household can be made with your own hands, focusing on the design and specifics of the installation of installations produced on an industrial scale.

Independent craftsmen who decide to start building their own installation need to stock up on a water tank, water or sewer plastic pipes, corner bends, seals and a cylinder for storing the gas obtained in the installation.

Image galleryPhoto from The main element of the future installation is a plastic tank with a tightly ground lid. In the photo there is a capacity of 700 l, it must be prepared for work: mark and draw holes for the entry of pipes. PVC pipes will be required to enter into the tank, an adapter as a funnel, plastic corners, a hose for supplying water to the tank, glue, a fitting for attaching it to it is more convenient to outline the hole outline using a pipe that will be inserted into it. The hole should be cut with the utmost care. Pipes are carefully inserted into the cut holes. They must not be damaged by burrs resulting from the cutting process. The junction is filled with glue and sealant. The pipe intended for loading raw materials for processing is installed so that 2–5 cm remain between the bottom of the container and its lower edge. The adapter is used as a funnel for loading raw materials, because.the unit being built is designed to process food leftovers. Larger funnel and pipes are needed to load manure. Similarly, a hole is formed and a horizontal outlet pipe is installed. The edge of the pipe inserted into the tank is equipped with a corner. A hole is cut into the lid into which a hose is installed to supply the water necessary for processing. Step 1: Homemade mini biogas plant Step 2: Connecting parts for portable installation PVC pipes into the hole cut in the tank Step 5: Rules for installing the raw material loading pipe Step 6: Installing the adapter as a funnel on the pipe Step 7: Installing and fixing the outlet pipe of the unit

Construction of a typical biogas plant

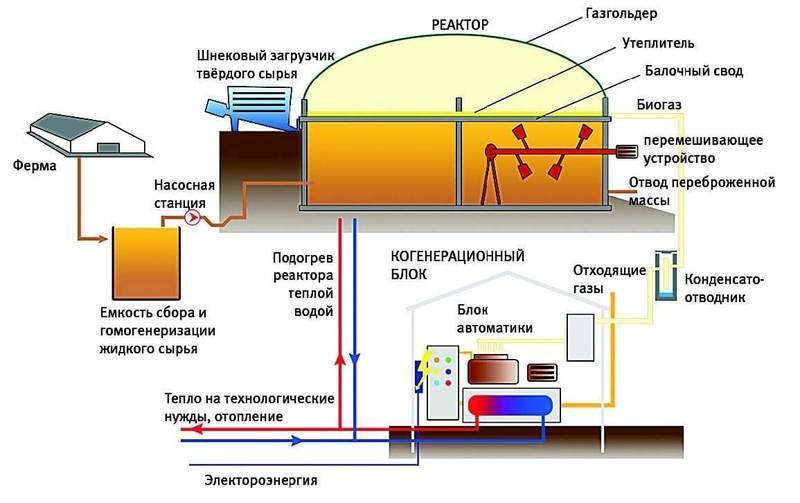

The unit consists of several technological units.

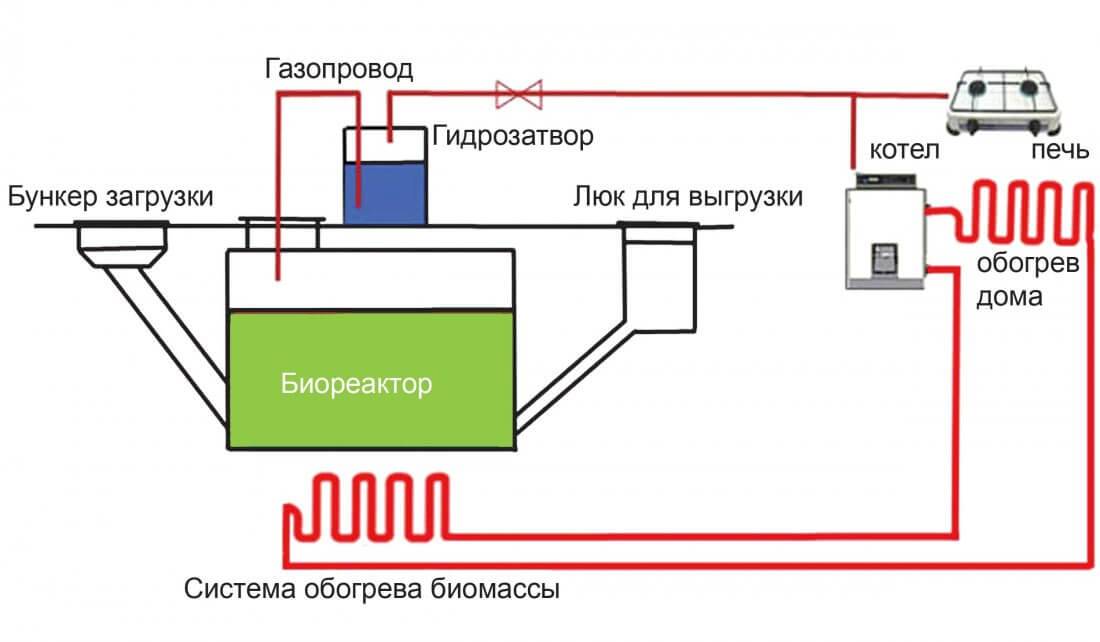

Reactor

Represents the integral reinforced concrete capacity upholstered with thermal insulation with several technological openings. The reactor must be hermetically sealed to prevent air from entering its interior.

Biomass Feeding System

To load raw materials, the plant is equipped with a bunker. Waste is fed here manually or with the help of a conveyor.

Also, a pipe with hot water is supplied to the reactor.

Agitators

The mixing blades are mounted on a vertical shaft, the shank of which goes out through a sealed hole in the reactor lid.

The mixing blades are mounted on a vertical shaft, the shank of which goes out through a sealed hole in the reactor lid.

The device is driven by an electric motor through a gear reducer.

The motor can be turned on manually or automatically.

Automated heating system

Heating is installed at the bottom of the reactor. The heat carrier can be water or electricity. The heating elements are switched on by a thermostat set to a certain temperature.

Separator

As mentioned above, biogas is a mixture of various gases. The separator allows you to separate methane from impurities for subsequent supply to the consumer.

General principles

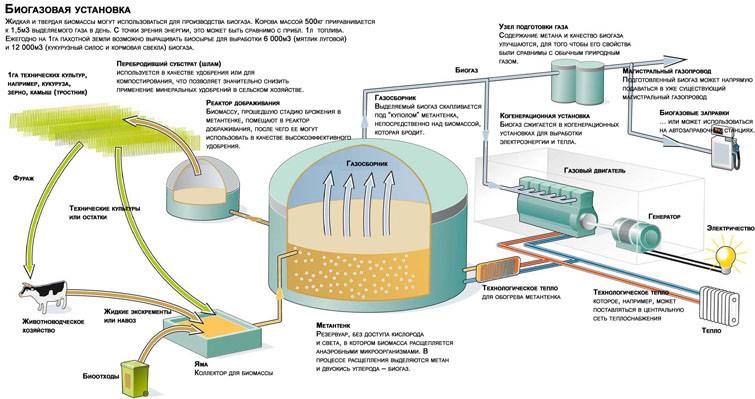

Biogas is a product that is obtained from the decomposition of organic matter. In the process of decay / fermentation, gases are released, by collecting which you can meet the needs of your own household. The equipment in which this process takes place is called a “biogas plant”.

In some cases, the gas output is excessive, then it is stored in gas tanks - for use during the period of its insufficient quantity. With proper organization of the gas process, there may be too much gas, then its surplus can be sold. Another source of income is fermented leftovers. This is a highly effective and safe fertilizer - in the process of fermentation, most microorganisms die, plant seeds lose their germination capacity, parasite eggs become unviable. The export of such fertilizers to the fields has a positive effect on productivity.

Conditions for gas production

The process of biogas formation occurs due to the vital activity of various kinds of bacteria that are contained in the waste itself. But in order for them to actively “work”, they need to create certain conditions: humidity and temperature. To create them, a biogas plant is being built. This is a complex of devices, the basis of which is a bioreactor, in which the decomposition of waste occurs, which is accompanied by gas formation.

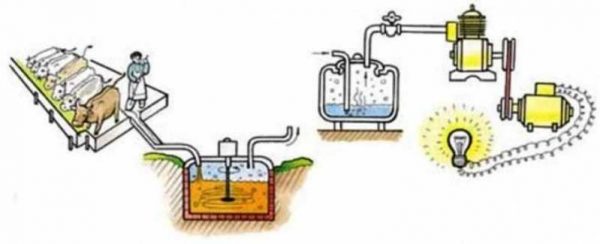

Organization of the cycle of processing manure and plant waste into biogas

There are three modes of processing manure into biogas:

- Psychophilic mode. The temperature in the biogas plant is from +5°C to +20°C. Under such conditions, the decomposition process is slow, a lot of gas is formed, its quality is low.

- Mesophilic. The unit enters this mode at temperatures from +30°C to +40°C. In this case, mesophilic bacteria actively multiply. In this case, more gas is formed, the processing process takes less time - from 10 to 20 days.

- Thermophilic. These bacteria multiply at temperatures above +50°C. The process is the fastest (3-5 days), the gas yield is the largest (under ideal conditions, up to 4.5 liters of gas can be obtained from 1 kg of delivery). Most reference tables for gas yield from processing are given specifically for this mode, so when using other modes, it is worth making an adjustment down.

The most difficult thing in biogas plants is the thermophilic regime. This requires high-quality thermal insulation of a biogas plant, heating and a temperature control system. But at the output we get the maximum amount of biogas. Another feature of thermophilic processing is the impossibility of reloading. The remaining two modes - psychophilic and mesophilic - allow you to add a fresh portion of prepared raw materials daily. But, in the thermophilic mode, a short processing time makes it possible to divide the bioreactor into zones in which its share of raw materials with different loading times will be processed.

What it is

The composition of biogas is similar to natural gas produced commercially. Stages of biogas production:

- A bioreactor is a container in which the biological mass is processed by anaerobic bacteria in a vacuum.

- After some time, a gas is released, consisting of methane, carbon dioxide, hydrogen sulfide and other gaseous substances.

- This gas is purified and removed from the reactor.

- Processed biomass is an excellent fertilizer that is removed from the reactor to enrich the fields.

Do-it-yourself biogas production at home is possible, provided that you live in a village and you have access to animal waste. It is a good fuel option for livestock farms and agricultural businesses.

The advantage of biogas is that it reduces methane emissions and provides a source of alternative energy. As a result of biomass processing, fertilizer is formed for vegetable gardens and fields, which is an additional advantage.

To make your own biogas, you need to build a bioreactor to process manure, bird droppings, and other organic waste. As raw materials are used:

- wastewater;

- straw;

- grass;

- river silt.

Use of straw for biogas production

It is important to prevent chemical impurities from entering the reactor, as they interfere with the reprocessing process.