- Types of heating radiators and their comparative characteristics

- Standard

- Cast iron

- Aluminum plate

- Bimetallic

- Low

- Cast iron

- Aluminum

- Bimetallic

- Cast iron

- Aluminum

- Bimetallic

- Manufacturers of bimetallic radiators

- Global

- The best manufacturers of bimetallic radiators

- The best bimetal sectional radiators with side connection

- Global STYLE PLUS 500

- Rifar Monolit 500

- Sira RS Bimetal 500

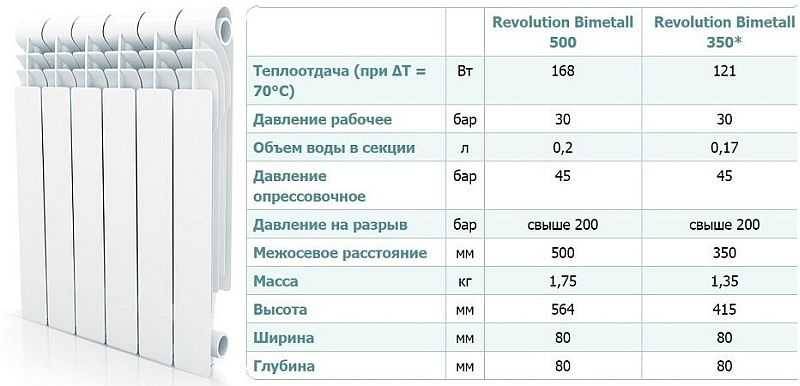

- Royal Thermo Revolution Bimetall 500

- Radena CS 500

- Bimetal or aluminum radiators

- center distance

- What to look for when choosing

- Types of radiators: which is better and more reliable?

- Bimetallic

- semi-bimetallic

- Device and types of bimetallic batteries

- Aluminum and steel radiators

- Copper-aluminum batteries

- Types of bimetallic radiators

- Sectional radiators

- Monolithic radiators

- Bimetallic heating radiators of which company to buy

- Sira Group

- Royal Thermo

- What is a bimetal radiator?

- Comparative analysis: bimetal and competitors

- Additional selection criteria

- Conclusions and useful video on the topic

Types of heating radiators and their comparative characteristics

The size of the heating device is a significant characteristic that is paid attention to when choosing, as it determines the power and space occupied in the room.

Standard

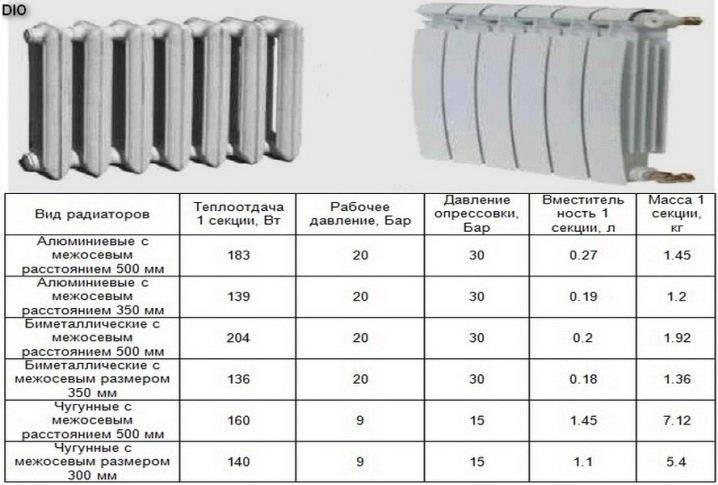

In addition to the size, heating radiators also differ in the material of manufacture.

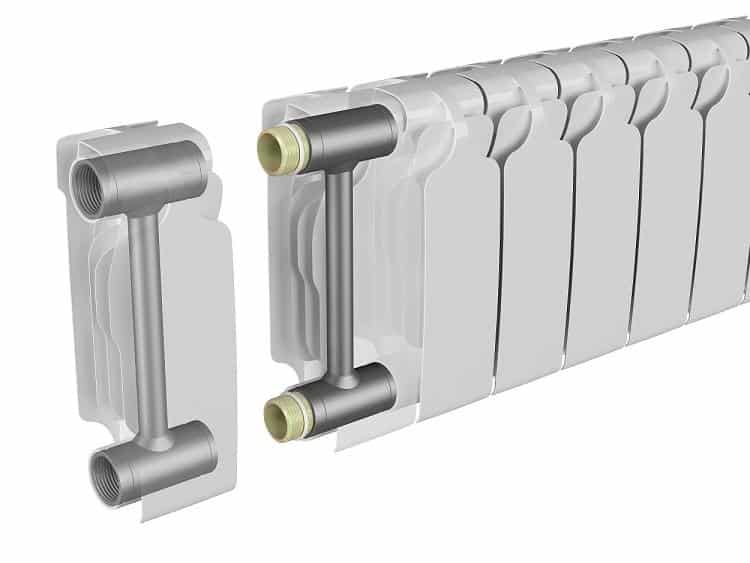

Photo 1. Bimetallic radiators of standard size. Such devices are usually installed in apartments.

Cast iron

Heating systems common in Soviet times, which remain in communal apartments in the 21st century, are cast-iron batteries. Characteristics of standard cast iron products:

- average height - 50-60 cm;

- length of one section - 7-8 cm;

- power limit - 0.15-0.17 kW;

- working pressure - 9-10 atmospheres.

Aluminum plate

The material of such heaters quickly transfers heat from the liquid into the room.

In addition, these devices are much lighter than cast iron heating systems, and the flat plates of the body look much more modern. But their dimensions are similar, the differences are revealed in the technical characteristics:

- average height - 60-70 cm;

- long one component - 7-8 cm;

- thermal ceiling - 0.17-0.19 kW;

- working pressure - 16 atmospheres.

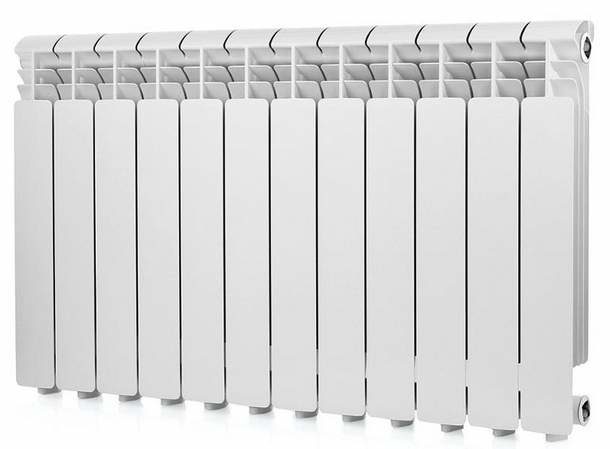

Bimetallic

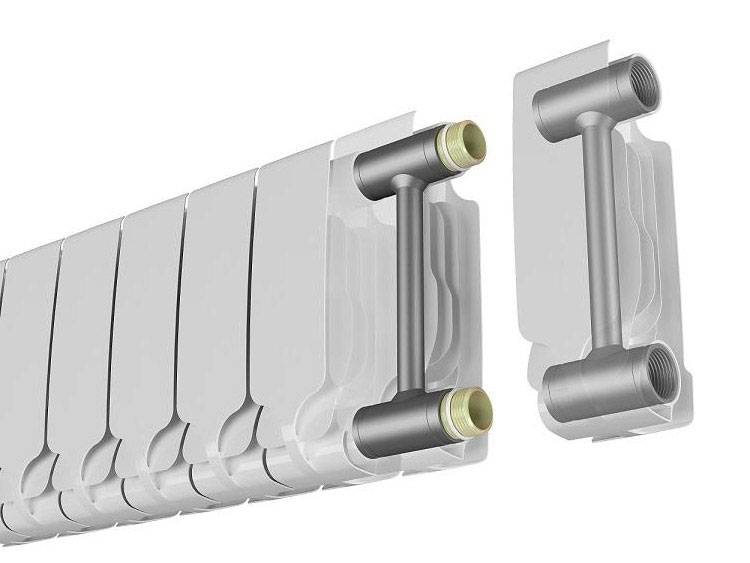

These radiators outwardly do not differ from aluminum ones, since the body is made of the same material, but steel tubes are placed inside them, which protect the structure from water hammer, high pressure and improve thermal conductivity.

Characteristics of standard models:

- the height of the section and, accordingly, the whole product - 40-50 cm;

- component length - 8 cm;

- maximum power - 0.19-0.21 kW;

- withstand pressure during operation - 20-35 atmospheres.

Photo 2. Design of a bimetallic heating radiator. The arrows indicate the component parts of the device.

Low

Low radiators are the most compact among all types of radiator appliances.

Cast iron

Since such products were produced according to strict standards, their sizes do not differ in variety. Neat cast-iron radiators of small sizes are made to order by figured casting. Dimensions and values:

- section height - 40-50 cm;

- component length - 5-6 cm;

- thermal ceiling - 0.09-0.11 kW;

- working pressure - 9 atmospheres.

Photo 3. Low radiator made of cast iron. The device is white in color with a fairly modern design.

Aluminum

Small aluminum radiators are much more common, as production is not so long ago and technology continues to improve. The small size determines the scope of their use: such devices are installed in kindergartens, utility rooms, heated garages, attics and verandas. Characteristics:

- height - 50 cm;

- section length - 6-7 cm;

- temperature maximum - 0.11-0.13 kW;

- operating pressure - up to 16 atm.

Bimetallic

The scope of application of bimetallic heaters of small sizes is limited to the same category of room types that are presented for aluminum devices.

The list is supplemented only by office premises at a considerable height - due to the high pressure in the pipes of skyscrapers and business centers. Characteristics:

- product height - 30-40 cm;

- the length of one section is 6-7 cm;

- power ceiling - 0.12-0.14 kW;

- withstand pressure during operation - up to 28-32 atmospheres.

Cast iron

Here, the dimensions of cast iron products are not much different from other categories: all factory models are standard in size, as they were produced according to GOSTs.

High cast-iron radiators are purchased in specialized foundries (not so cheap). Characteristics of devices of this type:

- height of the body of the heating system - 80-90 cm;

- length of one section - 7-8 cm;

- temperature ceiling - 0.18-0.21 kW;

- the maximum pressure is about 9-12 atmospheres.

Aluminum

Here the choice is much wider: for cramped rooms where long radiators do not fit, it is better to purchase narrow but high aluminum models. They, as a rule, have only 4 components, but this is fully compensated by their length. Characteristics:

- The height of the product is up to two meters.

- The length of the section is about 10-12 cm.

- Maximum power - 0.40-0.45 kW.

- Pressure ~ 6 atmospheres.

Attention! It is strictly forbidden to use this type of radiators in central heating systems - the battery simply cannot withstand such pressure

Bimetallic

The steel core of bimetallic batteries does not allow them to be very high, since the circulation of water through it will be difficult.

However, even half the size, compared with a fully aluminum counterpart, is enough to heat a spacious room. And the value of the maximum pressure level is simply amazing:

- The height of the heating system is ~ 80-90 cm.

- The length of the component is 7-8 cm.

- Thermal ceiling - 0.18-0.22 kW.

- Working pressure - from 20 to 100 atmospheres.

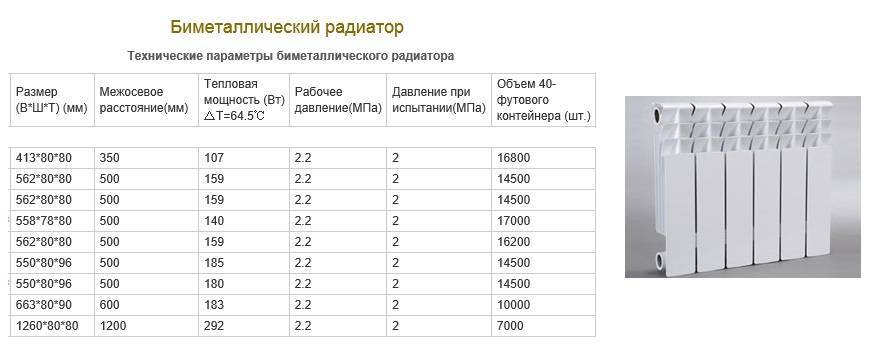

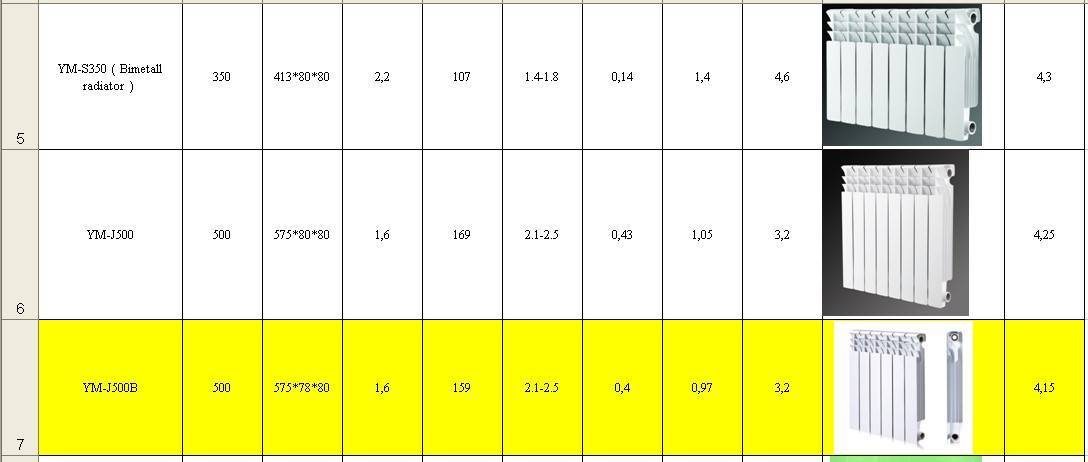

Manufacturers of bimetallic radiators

If we talk about heating devices, then experts recommend choosing products from foreign companies.

However, it is important to remember that bimetallic batteries are not in demand in Europe, which means that local manufacturers do not always produce them.

- Global Style is an Italian manufacturer that offers high quality products. Such good batteries are designed for a pressure of 35 bar. In this case, the power is at least 125 watts. One section will weigh about 1.5 kg. The element itself is designed for an amount of water of 160 g. Style Plus models are on sale. Their feature is improved properties, due to which the heat-conducting qualities are significantly increased.

- Sira is an Italian company that offers bimetal radiators with improved heat dissipation. Although such products withstand less pressure, they are not afraid of water hammer. The weight of one section starts from 600 g, and the power is 90 watts. In the company's catalog you can find standard models, as well as units with rounded shapes or original designs.

- Tenrad. The advantage of the products of this German manufacturer is a more affordable price, since the production facilities are located in China. However, in the manufacturing process, German technology is used, the development of which took into account modern standards. The power of the equipment is at least 120 watts.

Some people are not ready to overpay for good foreign equipment. They choose domestic heating appliances. In order not to encounter a low-quality unit, you should give preference to Rifar products. It is designed for low pressure, but at the same time it has improved heat dissipation. The manufacturer offers several series of equipment.

- Base is the standard 136W model rated for 180g water up to 135˚C.

- Alp - such a device has an attractive design. During its development, the requirements of SNiP were taken into account.

- Flex - such batteries can be installed under a bend, for this reason the model is ideal for installation in bay windows, as well as semicircular areas.

- Forza - this equipment is often used to heat large areas;

- Monolit - as the name suggests, this design is monolithic, which means that corrosion will not occur even at the joints.

Among other domestic manufacturers, it is worth noting Santekhprom and Regulus. The first company offers products according to European standards, taking into account the peculiarities of operating conditions. We are talking about the quality of water, as well as the level of pressure. The advantage of good batteries from Regulus is the presence of a copper core. Thanks to this element, the use of various liquids as a coolant is allowed. In addition, even when the radiator fluid freezes, it will not burst. The models have a bottom connection, which means that it will be possible to hide the pipeline under the floor.

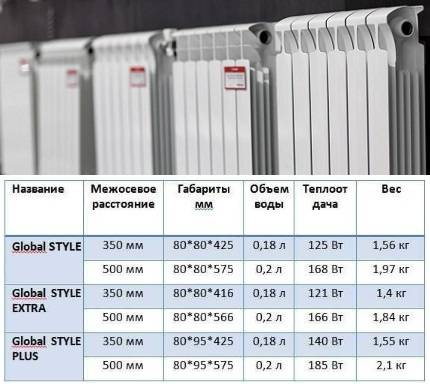

Global

Models of radiators of the Italian manufacturer have earned a good reputation in the CIS. The insides of the batteries are made of alloy steel, the outer part is aluminum alloy. They have all the advantages of high-quality bimetal. The disadvantages include a slight drop in heat transfer with a decrease in the degree of coolant.

The maximum operating temperature is 110 °C, pressure is 35 atm. The range is represented by the following models with a center distance of 350 and 500 mm:

- Global STYLE 350/500. Heat transfer of 1 section - 120 and 168 W, respectively.

- Global STYLE PLUS 350/500. Section power - 140/185 W.

- Global STYLE EXTRA 350/500. The heat output of one section is 120/171 W.

The best manufacturers of bimetallic radiators

The best and most conscientious firms are easy to calculate

You need to read the numerous customer reviews regarding the model you are interested in. So which company is better to buy equipment so that it is both high-quality and inexpensive? Consideration should also be given to expert opinion. According to the public, the best brands are:

| Brand Name | Producing country |

|---|---|

| Rommer | Germany |

| Royal Thermo | Italy |

| Sira | Italy |

| Tenard | Germany |

| Bilux | Russia (Britain) |

| global style | Italy |

| Rifar | Russia |

| Konner | Russia |

| Halsen | China |

| tropical | Russia |

| Oasis | China |

The best bimetal sectional radiators with side connection

| Global STYLE PLUS 500 8 091 Global Style Plus 500 is intended primarily for central heating systems with high pressure and low quality heating medium. Made from steel and aluminium. Silicone gaskets between the sections provide reliable protection against leaks. The high-pressure crimping of steel tubes during the casting process can withstand the bursting pressure of water and compensate for the difference in thermal deformation of steel and aluminum to keep heat transfer constant. We also note the excellent quality of painting and a larger diameter of the intercollector tube than most analogues. Working pressure - up to 35 atmospheres. Main advantages:

Minuses: High price | 9.9 Rating Reviews The difference with other radiators is visible to the naked eye. Thicker than metal walls. Very well made. |

| Read more |

| Rifar Monolit 500 6 305 The model of the Russian manufacturer is a single steel block coated with aluminum. This design almost completely eliminates the possibility of leaks. The radiator is resistant to low quality coolant, as well as to its temperature fluctuations. Along with water, antifreeze can also be used. The maximum working pressure is 100 atmospheres, the radiator is excellent for central heating systems. Main advantages: Maximum leakage protection

Minuses: Only an even number of sections | 9.8 Rating Reviews Outwardly, they are very pleasant. No sharp corners. I was warned that due to the fact that the inside is a monolithic piece of steel, they heat a little weaker than the same Rifar Base. But for me it doesn't matter. |

| Read more |

| Sira RS Bimetal 500 8 518 Almost silent radiators, they can be safely placed in bedrooms or meeting rooms. Depending on the area of the room, up to 12 sections can be placed in one block. The steel inner shell is resistant to corrosion and can be used with poor quality coolant. Paint is not the strongest point of this radiator, but if not mechanically damaged, it can last a long time. Heat transfer is at a high level, the maximum working pressure is an impressive 40 atmospheres, the radiator is not afraid of water hammer and other troubles of the central heating system. Main advantages:

Insensitive to sudden changes in system pressure Minuses: Pretty high price | 9.8 Rating Reviews Excellent radiators, they heat very well, in winter almost all the time in the kitchen there is a window for ventilation. |

| Read more |

| Royal Thermo Revolution Bimetall 500 4 105 Radiator of domestic production with a high-alloy steel collector for use in central heating systems. He is not afraid of water hammer and a low-quality coolant (along with water, antifreeze can also be used). Thanks to the use of PowerShift technology (additional fins on the collector), it has an increased heat transfer by 5%. The paint is applied in seven stages. The maximum number of sections in one block is 14. Working pressure is up to 30 bar. Main advantages:

Minuses: At low coolant temperatures, heat transfer is markedly reduced. | 9.6 Rating Reviews I recommend this radiator to those who are doing well with the coolant temperature - then you will be in chocolate. |

| Read more |

| Radena CS 500 5 980 Radiators of a well-known Italian brand (some of the products are made in Italy, some in China) are designed specifically for use in central heating systems (although they will also come to the yard in individual residential buildings). Unlike many competitors, they perform well at low coolant temperatures. Steel tubes withstand high pressure, water hammer, and are protected from corrosion. The maximum working pressure is 25 bar. In one block, the manufacturer mounts up to 14 sections. Main advantages:

Minuses: Not all products are of the same quality. | 9.6 Rating Reviews Immediately with the onset of cold weather, I felt a significant difference, heat transfer compared to cast-iron batteries differs many times for the better. |

| Read more |

Bimetal or aluminum radiators

A little about which radiators are better, aluminum or bimetal. In relation to the coolant, the advantage is clearly on the side of the latter. Aluminum does not withstand prolonged contact with water with a large amount of impurities.

Also, bimetallic radiators are more resistant to high pressure than aluminum ones. After all, the core is made of alloy steel, which has increased fracture and tensile strength.

However, in some moments, bimetallic heaters lose to aluminum ones. They are more bulky and heavy, cost much more, and the steel core reduces energy efficiency and reduces heat exchange with the room.

Externally, aluminum and bimetallic radiators are very similar.

Definitely bimetallic heaters require increased heating costs. But they are more durable and more adapted to urban heating networks. At the same time, aluminum radiators are ideal for private homes, where owners can control the pressure and change the water in the system.

center distance

The center distance is the distance between the location of the lower and upper collectors. As a rule, the parameter is indicated in millimeters. Standard sizes are available from 200 to 800 mm. These options are usually enough to match the radiators to the wiring installed in the room.

More often on the market there are products with a distance between the cores of 500 and 350 mm. These dimensions are standard for most modern new buildings. Difficulties arise when finding narrow 200mm batteries that are well suited for a small kitchen or toilet, and wide 800mm products are usually only available on an individual order.

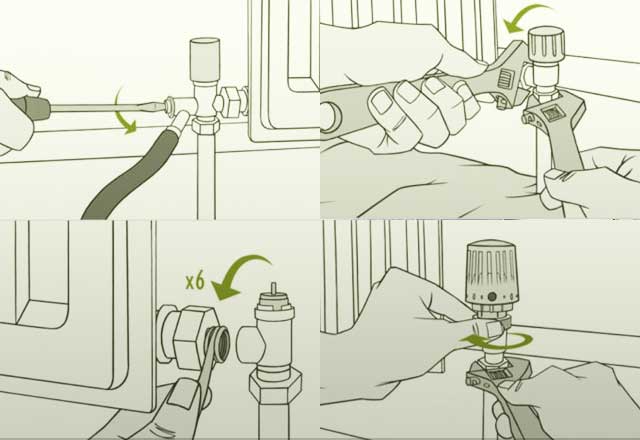

What to look for when choosing

What parameter do buyers pay attention to most often? That's right, for the cost. But this approach is completely wrong.

Choosing a device such as a radiator is very careful. In this situation, you certainly should not save on quality. In addition, we advise you to pay attention to the following points:

Heat transfer power level. Only a specialist can calculate the optimal power level for your apartment. It is he who will correctly calculate the quadrature of the room, the number of windows, the height of the ceilings. Only after that the required number of sections in the battery is determined.

Pressure. If you are the owner of an apartment connected to central heating, we strongly recommend that you purchase a more durable radiator, the pressure in which reaches 40 atmospheres. In a private house, you can use more democratic models.

Design. In total there are 2 types of heating systems - monolithic and sectional. The first option will be the best choice if the system has unstable pressure and powerful water hammer.

The second, sectional view is used more often, as it has one important advantage - you can always add or remove a couple of sections.

Types of radiators: which is better and more reliable?

Bimetallic and semi-bimetallic radiators are absolutely identical in appearance, but, despite this, they have certain inconsistencies with each other.

To understand this, you need to analyze each type in detail.

Bimetallic

In such sources of space heating, a steel core with a high strength index is placed under the body. The outer casing of the equipment and pipes, which are in special forms, are made of aluminum.

The differences between such radiators from aluminum and cast iron batteries are as follows:

- Heat transfer index. According to this parameter, bimetal is ahead of cast iron, since it has greater energy efficiency. The first range varies from 160 to 180 watts, the second from 110 to 160 watts. The aluminum radiator section has a capacity of about 200 watts.

- Price. The most expensive is bimetal. It is almost twice as expensive as cast iron, and only one third ahead of aluminum radiators.

- Reaction to the quality of the coolant. Aluminum is very sensitive to any impurities. Connecting such batteries to the central heating system leads to thinning of their walls, and, as a result, to leaks.

Thanks to the steel core, bimetallic heating radiators do not undergo any chemical reactions, but when the system is drained and air gets into them, corrosion begins. The most stable in this indicator is cast iron.

Photo 1. Bimetallic radiator in the interior of the apartment, has high heat transfer rates, is not subject to chemical reactions.

- Lifetime. Aluminum is considered the most short-lived, it serves only 10 years, bimetal - 15, and cast iron over 50 years.

- limiting water temperature.The value of this parameter for bimetallic radiators is 130 ° C, and for the other two types of batteries - 110 ° C.

- Response to high pressure. Water hammer is the weak side of cast iron. It is able to withstand only 12 atmospheres, aluminum - 16. While the bimetal, due to its structure, endures pressure surges up to 50 atmospheres.

semi-bimetallic

According to the internal structure, the difference of this type from a full-fledged bimetal is that in a semi-bimetallic structure, the vertical internal channels are made of steel, and the horizontal ones are made of aluminum.

Such batteries are not suitable for connection to a central heating system.

Photo 2. A semi-metal battery with a built-in thermostat that cannot be connected to a central heating system.

The differences from other types of heating devices are as follows:

- the cost is 20% less than that of bimetal;

- the heat transfer rate of radiators is slightly lower than that of cast iron and higher than the other two types of heaters;

- semi-bimetallic batteries are very sensitive to the presence of impurities and the low quality of the coolant, this indicator absolutely equalizes them with aluminum radiators;

- The service life of such space heating sources is 7-10 years.

Important! Under the influence of water hammer or high temperature in semi-bimetallic structures, aluminum elements can be displaced. This inevitably leads to the formation of leaks and an emergency.

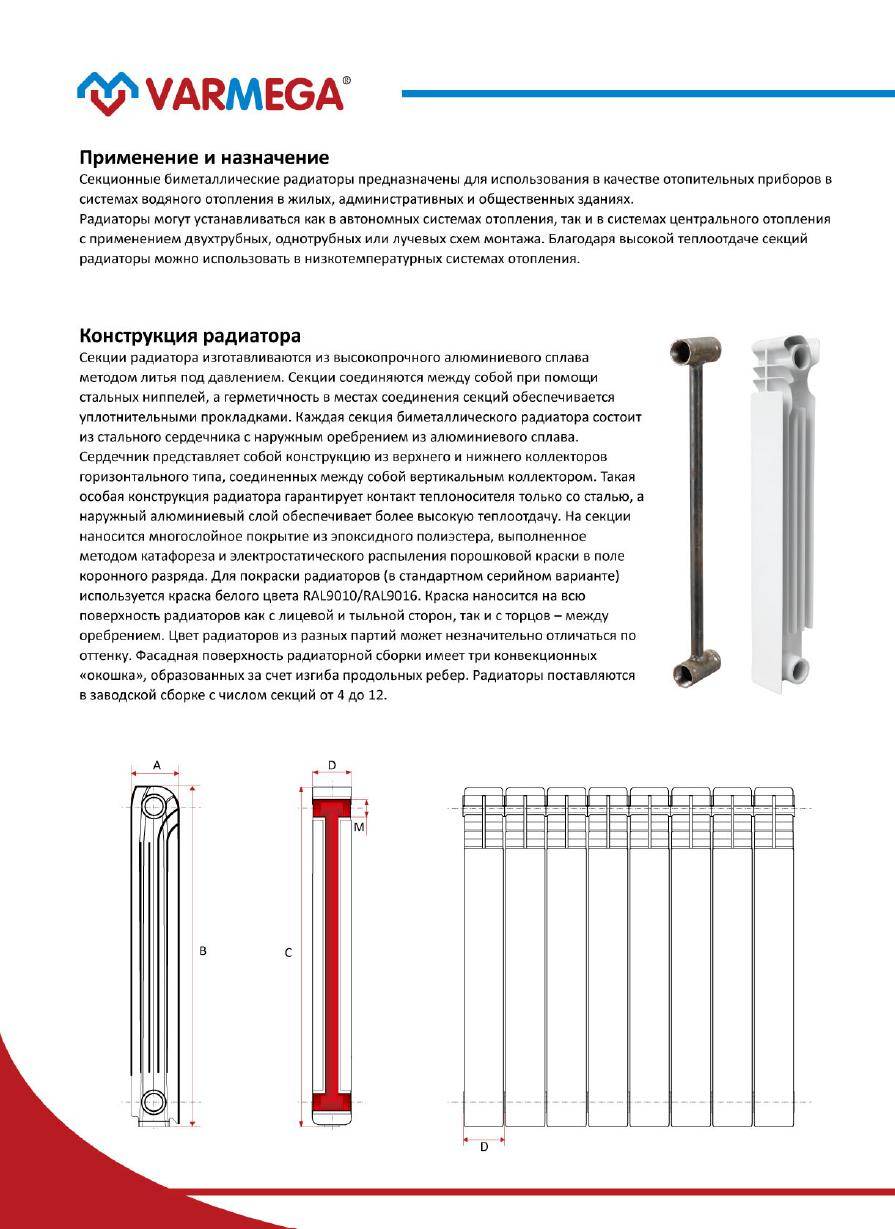

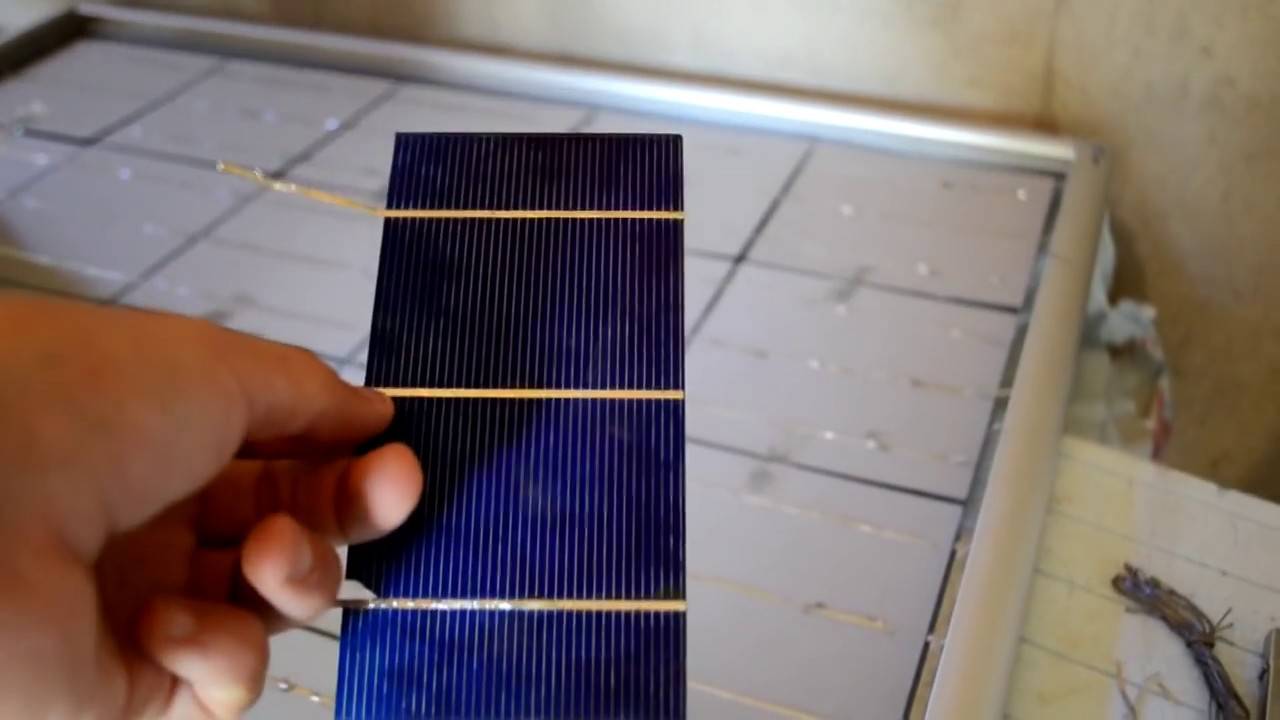

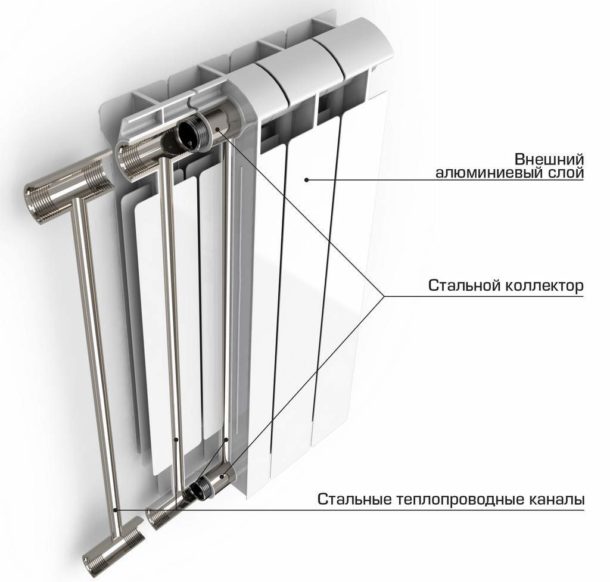

Device and types of bimetallic batteries

The joint use of aluminum with another metal for the design of heating devices made it possible to obtain more advanced devices than monometal batteries.There are 2 types of bimetallic products on the market.

Aluminum and steel radiators

Aluminum-steel radiator

This type of battery is more common in the Russian market. They consist of a steel core and an aluminum body. The coolant is in contact only with the steel medium, and the aluminum shell has a special configuration that determines the heating and air flow.

Most often, aluminum-steel batteries consist of separate sections, which are connected to each other during the assembly stage. If necessary, any locksmith can disassemble such a sectional structure, remove the desired element.

A less common model is monolithic. They are already given, constant length. The absence of joints allows to increase the strength of the product in relation to high pressure.

Copper-aluminum batteries

Inside the panel batteries there is a copper pipe-coil that can withstand high pressure, and outside there is an aluminum casing. There are also sectional models.

The combination of steel or copper with aluminum made it possible to lighten the design and get a lot of other advantages.

Types of bimetallic radiators

There are two main types - sectional and monolithic. Below we will tell you more about them and help you figure out which one is best for you.

Sectional radiators

They are assembled from several sections. Often performed in the form of a "layer cake" of heating plates. This discovery allows to significantly increase the area of heat exchange with the environment. But there is a big drawback: any coolant destroys the joints of the components. The result is a relatively short service life.

Sectional heaters consist of several parts

Monolithic radiators

They also have a large heat exchange area, so they are in no way inferior to sectional heaters. Gives out one section of about 100-200 watts. Monolithic radiators are manufactured according to a fundamentally new technology: the body is cast as a whole, and then processed by pressure. A layer of aluminum is applied over the steel frame under pressure.

Monolithic heaters are one piece

The advantage of monolithic radiators is obvious. The service life is twice as high and is not 25 years, like sectional ones, but 50. But at the same time, they cost about a fifth more. Their disadvantage is that they do not make it possible to add additional sections and thereby adjust the power.

If you think about the question of which heating battery is better for apartments in high-rise buildings, then the answer is unequivocal - monolithic. The point is a large pressure drop due to altitude.

Bimetallic heating radiators of which company to buy

Sira Group

A brand from sunny Italy, which many experts in this industry attribute to the founder of bimetallic equipment. Having started its victorious march around the planet at the beginning of the second half of the last century, the company by this moment has many production sites, a significant part of which are located outside the country. The brand has earned such success with consumers by offering high-tech equipment with elegant external forms and efficient heat dissipation. Orientation to the needs of people is not the only advantage of the company. Today, the brand's efforts are focused on the production of resource-saving equipment, coupled with a claim to protect and restore the environment.

Another Italian brand founded by the Fardelli brothers in 1971. At the first stages of its development, the company produced exclusively aluminum radiators. This fact is easily explained - at that time in Italy, energy resources were very expensive, and with equal consumption, aluminum radiators give 4 times more heat than cast-iron or steel batteries. However, having entered the Russian market in 1994, the company had to master the production of bimetallic radiators. The fact is that the domestic heating system is somewhat different from the Italian one. For example, the pressure of the working medium in our pipes is much higher than in European countries. The equipment of this company complies with domestic state standards. In addition, the company gives an unprecedented warranty period of operation - 25 years!

Royal Thermo

A brand that owes its origin to the merger of the English corporation "Industrial Investment Fund Ltd" with several construction companies from Italy. After a couple of successful transactions in the northern regions of Italy, the British believed in the rapid development of the real estate market and began to invest in the production of radiators for water heating. Until 1998, all brand products were aimed at meeting the needs of the domestic market. However, at the turn of the millennium, it became necessary to develop the markets of Eastern Europe and in particular Russia. Today, heating equipment adapted for difficult natural conditions is successfully implemented in the post-Soviet space.Evaluating the brand's products, experts say that the company confidently occupies a leading position in this industry in terms of price and quality ratio.

Also an Italian brand founded by Silvestro Niboli in 1970 in the province of Brescia. Naturally, the history of the brand is directly linked to its founder, who almost 50 years ago left the small production of chandelier elements, with the firm intention of developing and manufacturing die-cast radiators under his own brand. Today it is a dynamically developing company whose products are well known to many consumers around the world. High-quality equipment and constant production of new products, coupled with a realistic assessment of the market and its development course, make the company competitive.

Domestic brand, which began its activity in 2002. The design development of bimetallic radiators of this company was carried out together with specialists from Italy. Production equipment - machining lines, high pressure casting and so on also come from Italy. A distinctive feature of the radiators of this brand is a high heat transfer, which allows them to be installed even in large areas. In general, the company's products are an ideal combination of European quality with the vast experience of Russians in using heating equipment in climatic conditions close to extreme!

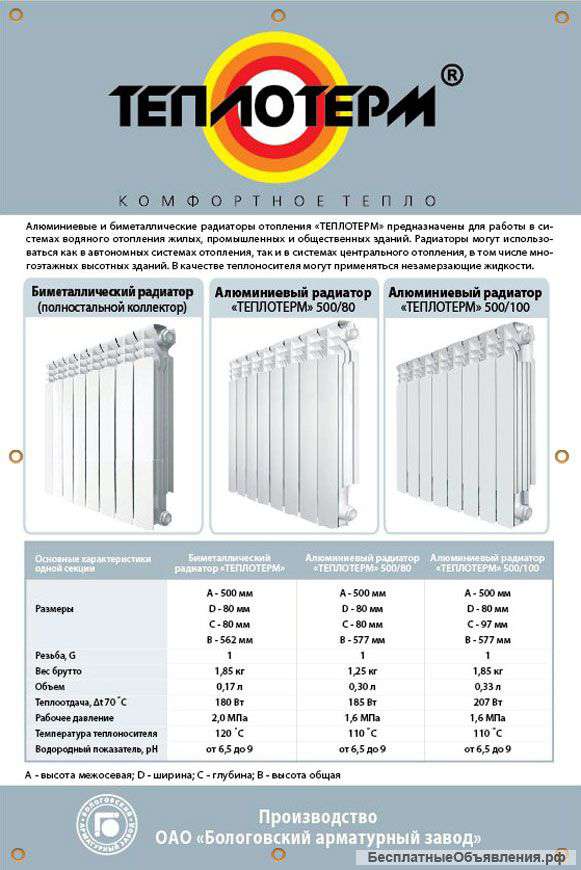

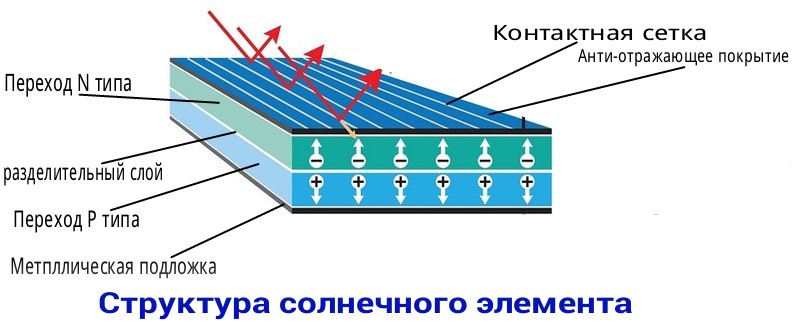

What is a bimetal radiator?

As can be seen from the name of the heating device, it is made from two metals that differ in properties. The body is made of aluminum, which is characterized by good heat dissipation and low weight.To enhance the heating properties of the outer part of the battery, they give a special shape for the free circulation of air flows.

A steel or copper core is placed inside the radiator, through which hot water or other liquid circulates. The pipe material is very durable, therefore it is able to withstand coolant pressure up to 100 atmospheres (some models), and heating up to 135 ° C.

Bimetal product combines the strength of steel and the excellent thermal conductivity of aluminum.

Comparative analysis: bimetal and competitors

Before choosing a bimetallic or other radiator, it is advisable to compare its capabilities with its closest competitors. For composite convectors, these are aluminum, cast iron, steel batteries.

The assessment should be carried out according to the main criteria:

- heat transfer;

- endurance to pressure drops;

- wear resistance;

- ease of installation;

- appearance;

- durability;

- price.

Heat dissipation. In terms of heating efficiency, aluminum units are leaders, bimetal takes an honorable second place. Steel and cast iron radiators noticeably lose.

Aluminum is characterized by minimal thermal inertia - after starting the system, the air in the room warms up within 10 minutes

Water hammer resistance. The most durable are bimetallic units that can withstand up to 40 atmospheres (sectional models). The maximum working pressure on an aluminum heating network is 6 bar, steel - 10-12 bar, and cast iron - 6-9 bar.

It is bimetal that is able to withstand numerous water hammers of a centralized heating system. This property is a key argument in favor of composite radiators for apartment buildings.

chemical inertness.According to this criterion, the positions were distributed as follows:

- Cast iron. The material is indifferent to the adverse environment. Cast iron radiators can be used for decades, transporting an "alkaline", "acidic" environment.

- Steel and bimetal. By itself, the steel core endures the impact of aggressive components. The weak point of the steel pipeline is the interaction with oxygen, contact with which leads to the formation of rust.

- Aluminum. The metal reacts with various impurities in water.

Aluminum walls are especially susceptible to acidic environments - the pH of the coolant must be within 8. Otherwise, corrosion is actively developing.

Ease of installation. In terms of installation, aluminum and bimetallic products are easier. Cast iron radiators are more difficult to mount due to their impressive weight.

In terms of durability, the leaders are composite and cast iron batteries. Aluminum and steel products, subject to operational requirements, must be replaced after 10-15 years. Among the indicated batteries, bimetallic ones are the most expensive

It can be concluded. The purchase of a bimetallic radiator is clearly justified for assembling a heating network in a multi-storey building, where there are risks of pressure surges and contamination of the coolant. In a private house, with stable operation of the boiler and filtration of incoming water, available aluminum batteries can be used in the heating device.

Additional selection criteria

Today on the market you can find bimetallic radiators that differ from each other in the way (technology) of production. In the first case, a metal steel frame is made. Basically, it is a pipe collector on which an aluminum shell is installed.The second way is to pour an aluminum case into which a steel manifold is inserted. The latter can be collapsible or solid. The one-piece version is stronger, more reliable, but more expensive.

The prefabricated collector is the most vulnerable point through which the coolant can leak. Therefore, manufacturers are trying to use the latest developments and materials in this place. It is the collapsible part of the collector that is responsible for the strength characteristics of the radiator. When the temperature of the coolant changes, the nodes can shift in it, so many companies today are trying to use a one-piece version of the collectors.

Conclusions and useful video on the topic

The video review clearly demonstrates the design features of composite radiators and the basic requirements that a high-quality device must meet:

Full-fledged bimetallic radiators combine the positive characteristics of both materials. Batteries are distinguished by high thermal power, resistance to water hammer and excellent decorative properties. Their acquisition is a justified investment, subject to the purchase of a certified product.

Tell us about how you chose a bimetallic heating device for your own apartment or country house. Share which argument was decisive in your choice? Please leave comments in the block below, ask questions, post thematic photos.