- Rifar Monolith

- The lineup

- Design features

- The best bimetallic radiators with a center distance of 500 mm

- Royal Thermo Piano Forte 500

- Rifar Monolit 500

- Global Style Plus 500

- Sira RS Bimetal 500

- Fondital Alustal 500/100

- What should be considered when choosing a radiator?

- Opportunity assessment - thermal calculation

- Calculation by area

- Volume calculation

- How to avoid fakes: radiator inspection

- Price range

- Features of bimetallic radiators

- Feature of the material used

- How not to make a mistake in choosing such equipment

- How to choose how many radiator sections you need

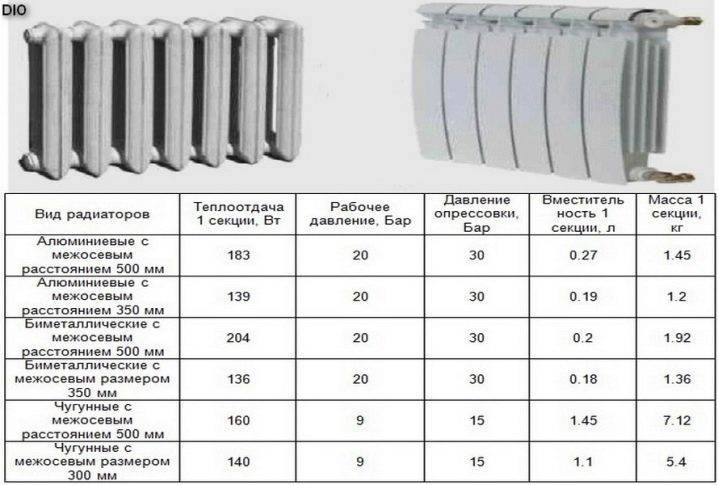

- Types of heating radiators

- Cast iron radiators

- Steel radiators

- Aluminum radiators

- Bimetal radiators

Rifar Monolit

These are products from a Russian manufacturer. The Monolit range includes about 22 bimetallic radiators. Rifar provides a 25-year product warranty. Radiators are positioned as for the most severe operating conditions.

The lineup

The model range consists of radiators including from 4 to 14 sections. Thermal power varies 536 to 2744 W. The height of the panels is 577 and 877 mm. One compartment weighs 2 kg. The radiator is able to work with various coolants (not only water) at temperatures up to 135 C.Its walls withstand operating pressure 100 bar, and pressing pressure of 150 bar.

Design features

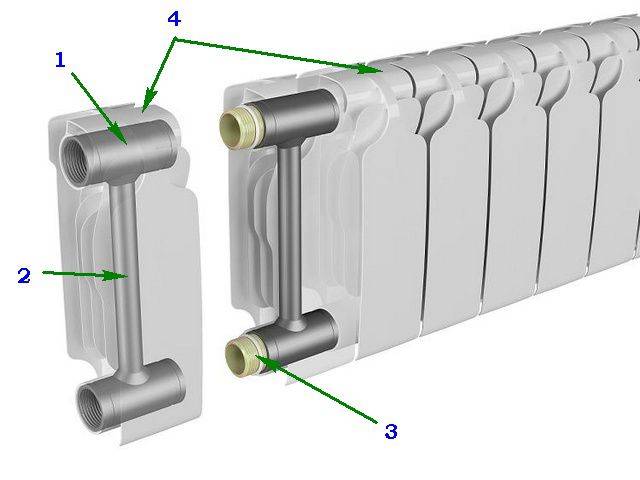

The main design feature of these bimetal radiators is the patented technology of a one-piece interior, without nipple connections - this reduces the likelihood of leaks. Each section is flat and provided with a small vertical isthmus at the top. Inside, three additional ribs of the same height are implemented.

Other design features include:

- center distance 500 mm and 800 mm;

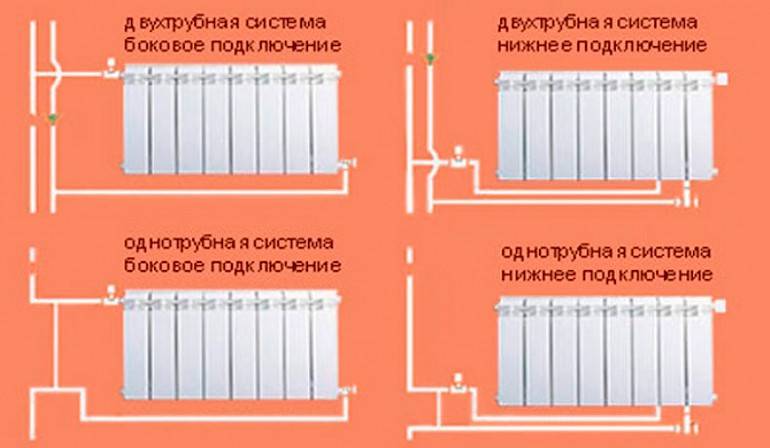

- lateral supply from any side, as well as bottom connection;

- connection diameter ¾ inch;

- internal volume of sections 210 ml;

- collector steel pipe with a cross section of 1.5 mm.

+ Advantages of bimetallic radiators Rifar Monolit

- There are no traditional joints between the sections, so they are stronger.

- High quality powder coating.

- The ¾" outlet requires no adapters.

- The outer panel is almost without gaps, so it hides the brackets well.

- They perfectly tolerate dirty water from central heating - they do not deteriorate inside and do not clog.

- Cons of bimetallic radiators Rifar Monolit

- Expensive for a Russian manufacturer.

- Some users began to leak after 5 years of operation.

- It is possible to request a free repair of a leak under warranty, but for this it is necessary to provide a copy of the act on putting the radiator into operation, which will indicate the pressure supplied for on-site testing.

- There are options only with even sections 4/6/8, and with 5/7 are absent.

- In some places, the edge from the molds, formed during the pouring of aluminum, sticks out.

- Periodically come across defective threads.

The best bimetallic radiators with a center distance of 500 mm

The choice of heating equipment with center distance 500 mm for the ranking is not accidental. The vast majority of modern residential premises have sufficiently large window openings, and the distance between the window sill and the floor is, as a rule, at least 60 cm. Therefore, bimetallic radiators of this qualification are most popular among the population.

Royal Thermo Piano Forte 500

A lot of positive user ratings for this Italian radiator on Yandex.Market, which fully confirm the reliability of the design, long service life, original design, puts it in first place in the rating.

- heat transfer from 740 W to 2590 W (depending on the number of sections);

- the number of sections varies from 4 to 14;

- Power Shift technology that increases heat transfer;

- steel collectors are designed for pressure surges in the system up to 30 atmospheres;

- resistant to the most aggressive coolants;

- wall and floor mounting possible;

- original design;

- manufacturer's warranty - 10 years.

rather high cost.

In general, as the British say, we are not rich enough to buy cheap things. Therefore, in this case, the price corresponds to the quality. Particular emphasis is placed on the presence of Power Shift technology - the presence of additional ribs on the vertical collector, which significantly increase the heat transfer of the model. In addition, in addition to the basic white and black colors, the buyer can order other tones or RAL palettes.

Rifar Monolit 500

Domestic development, deservedly taking second place in the rating in terms of the number of collected laudatory reviews in its direction.The features include the technology of the same name used in the production process - the sections are connected using contact-butt welding.

- a monolithic design that allows operation in the most severe conditions;

- heat transfer from 784 W to 2744 W;

- complete set of sections - from 4 to 14;

- high resistance to aggressive coolants (pH 7 - 9);

- there is a bottom connection;

- manufacturer's warranty - 25 years.

- expensive for a domestic product;

- there are no odd sections - for example, 5 or 7.

However, in general, the radiator of this model collects extremely positive reviews. Moreover, management companies strongly recommend it for use, due to the high resistance of the model to corrosion and a long guaranteed service life.

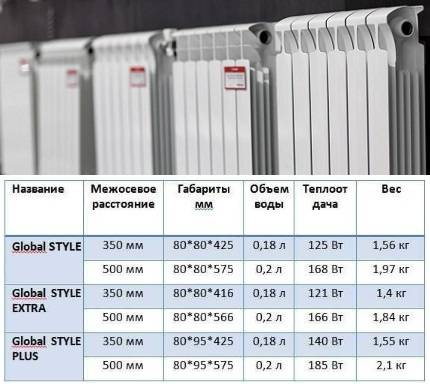

Global Style Plus 500

Once again, the Italian model, who has collected a significant number of admiring reviews addressed to her. The inside of the radiator is made of alloy steel, while the outside is coated with aluminum alloy.

- high strength;

- maximum working pressure 35 atmospheres;

- crimping pressure - 5.25 MPa;

- heat transfer in the range from 740 W to 2590 W;

- equipment - from 4 to 14 sections;

- pH value (aggressiveness of the coolant) - from 6.5 to 8.5;

- manufacturer's warranty - 10 years.

heat transfer decreases slightly with a decrease in the temperature of the coolant.

Satisfied with the purchase, the owners shower this model with extremely positive assessments - high resistance to pressure drops in the system, the presence of silicone gaskets between the sectional joints prevent leaks, adjustment works stably, and so on.

Sira RS Bimetal 500

Another Italian, appreciated by the domestic user, as the reviews speak eloquently.

- high strength - working pressure up to 40 bar;

- heat transfer from 804 W to 2412 W;

- equipment - from 4 to 12 sections;

- coolant resistance is expressed in terms of pH - from 7.5 to 8.5;

- manufacturer's warranty - 20 years.

Well, that's what premium class is for! In addition to satisfactory assessments regarding the technical characteristics of this radiator model, satisfied with the purchase, the owners note the unique design - smooth, curved shapes, the complete absence of sharp corners.

Fondital Alustal 500/100

Also, the Italian miracle of engineering, which won the approval of Russian users, which was reflected in the number of positive reviews.

- heat transfer from 191 W to 2674 W;

- equipment from 1 to 14 sections;

- high strength - working pressure up to 40 bar;

- the most aggressive coolants are not afraid (pH 7 - 10);

- manufacturer's warranty - 20 years.

In general, a minor minus, due to the fact that this model is a continuous water chamber. On the other hand, there is an internal anti-corrosion coating, as the owners of this radiator note, and a stroke pattern that prevents the system from airing.

What should be considered when choosing a radiator?

To achieve the proper thermal effect, it is necessary to calculate the total power of the battery. Bimetallic equipment is not a cheap purchase, so you should take care of its durability. Conscientious performance of the radiator is guaranteed by trusted manufacturers.

Opportunity assessment - thermal calculation

Having decided on the appropriate technical characteristics and dimensions of bimetallic radiators, it is necessary to calculate the required number of sections.

Basic formula: N=Ptot/Ppas, where Ptot. - the required battery power for the entire room, Ppass. – thermal power of the section according to the accompanying documents

The heat transfer index of the section is taken from the radiator passport, and the total power must be calculated.

Calculation by area

The normalized value of thermal power per 1 sq.m of living space for the middle climatic zone, subject to standard ceilings (250-270 cm):

- the presence of one window and a wall with access to the street - 100 W;

- a window in the room, two walls adjacent to the street - 120 W;

- several windows and "external" walls - 130 watts.

Example. The power of the section is 170 W, the total area of the heated room is 15 sq.m. Additional conditions: window - 1, external wall - 1, ceiling height - 270 cm.

N=(15*100)/170 = 8.82.

Rounding is performed upwards. This means that for heating the room it is necessary to use 9 sections of 170 watts each.

Volume calculation

SNiP separately regulates the amount of heat output per 1 cubic meter rooms in the amount of 41 W. Knowing the volume of the heated room, it is easy to calculate the heat transfer of the entire battery.

Example. Space heating with the previous parameters. For the purity of the experiment, the section power is left unchanged - 170 watts.

N=(15*2.7*41)/170= 9.76.

It is necessary to install a radiator for 10 sections. The second calculation is considered more accurate.

When calculating, attention should be paid to the sources of heat loss inside the room.

The calculated value must be increased by 10% if the apartment is located on the first / last floor, the room has large windows or the wall thickness does not exceed 250 mm

How to avoid fakes: radiator inspection

In addition to the analysis of passport data, it would be useful to conduct a visual assessment of the goods. Some manufacturers, in pursuit of customers, tend to “embellish” their products by introducing incorrect data into the documentation.

First of all, pay attention to the thickness of the core and aluminum "shirt", overall dimensions, weight and quality of components. steel core

The minimum thickness of the steel tube is 3 mm. With smaller sizes, the declared strength of the product is significantly reduced - resistance to water hammer and the development of corrosive processes

Steel core. The minimum thickness of the steel tube is 3 mm. With smaller sizes, the declared strength of the product is significantly reduced - resistance to water hammer and the development of corrosive processes.

The walls of thin metal open access for the coolant to the aluminum "shell", which, due to chemical activity, begins to quickly collapse

The result of a low-quality steel core is the formation of through holes and the creation of emergency situations on the heating network.

Radiator fins. Aluminum panels must be checked for strength - they should not bend from the efforts of the fingers of one hand. The minimum thickness of the panels is 1 mm.

It is better to choose models with profiled channels between the ribs. The formed confuser increases the air flow rate, increasing the intensity of convective heat transfer.

To reduce the risk of injury, the outer edges of the aluminum panels are rounded off.There should be no streaks, color irregularities and “gaps” on the surface

Dimensions and weight. By individual order, it is possible to manufacture radiators with a section width of less than 80 mm. However, store models with an inappropriate parameter are most likely a fake.

Some manufacturers significantly reduce the width of the internal ribs to reduce costs, "masking" them behind the front panels of a standard size. This measure worsens the heat transfer of the bimetallic radiator.

Battery accessories. It is almost impossible to check the quality of gaskets and nipples on site. You should rely on the manufacturer's name and the warranty period. Reliable companies guarantee up to 15-20 years of trouble-free operation.

Price range

The border between the lower and middle price categories for bimetallic radiators can be considered the mark of 400 rubles per section.

Cheap radiators are most often products of little-known Chinese companies; among them, there are also Russian-made batteries of not very well-known brands.

- All such radiators belong to the pseudo-bimetallic class;

- Quite often, manufacturers, in pursuit of cost reduction, reduce the thickness of metal inserts to the minimum possible value. Theoretically, this should lead to a decrease in the maximum pressure for which they are designed. It is possible, however, that some firms, especially Chinese ones, may artificially inflate this parameter. Therefore, buying cheap bimetallic radiators for city apartments is dangerous. For this reason, we will not include them in our ranking;

- Sometimes a low price is the result of not very high-quality processing, broaching or painting of the body and internal parts.It's less risky, but still not particularly pleasant.

The majority of European countries producing radiators operate in the middle and premium price segment. These are Italy, Germany, Finland and many others. There are also the best Russian firms here.

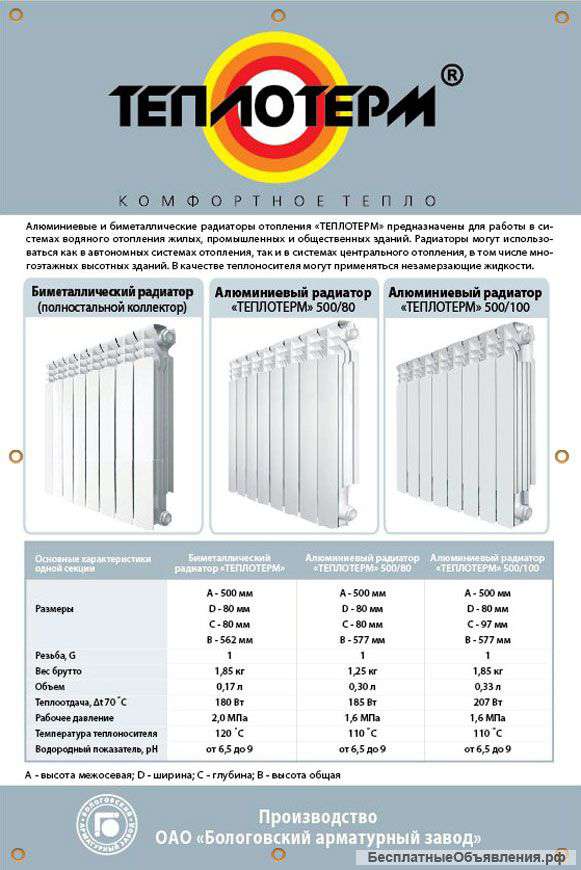

Features of bimetallic radiators

The second option that you can be offered in the store is a bimetallic radiator. The prefix "bi" in the word "bimetallic" means "two". Such a name is given to this type of batteries because they are made from two metals: steel and aluminum.

Let's immediately turn to the positive characteristics of this species:

- steel in the composition of the material from which the case is made will perfectly withstand any surges in water pressure. It is also not subject to corrosion. These properties of the metal provide high strength and many years of faithful service of the device;

- steel sheet provides serious protection of the body from external mechanical damage;

- active circulation of the coolant;

- aluminum coating will ensure rapid heating of the air in the living room;

- battery operating pressure can reach 40 atm.;

- the maximum value of the possible coolant temperature is approximately 130 degrees, while for aluminum products it is only 110;

- durable paint finish. This stability is achieved through a two-stage staining mechanism:

- First of all, the product is placed in a coloring solution and completely covered with paint;

- Then, another polymer layer based on epoxy resin is sprayed on top of the dried first staining. Radiators processed using this technology not only look very aesthetically pleasing, but also acquire clearer geometric shapes;

easy installation and transportation, especially if you resort to the help of professionals. The device of bimetallic batteries is no more complicated than that of simple aluminum ones, however, it is also better to entrust their installation to professionals. How correctly the batteries are installed, how long they will last you;

the ability to build additional sections directly at your home

However, if you admit that you still want to increase their number, when buying, pay attention to the design of the radiator housing. Some of the models on the market have a solid steel core, so they are not divided into sections.

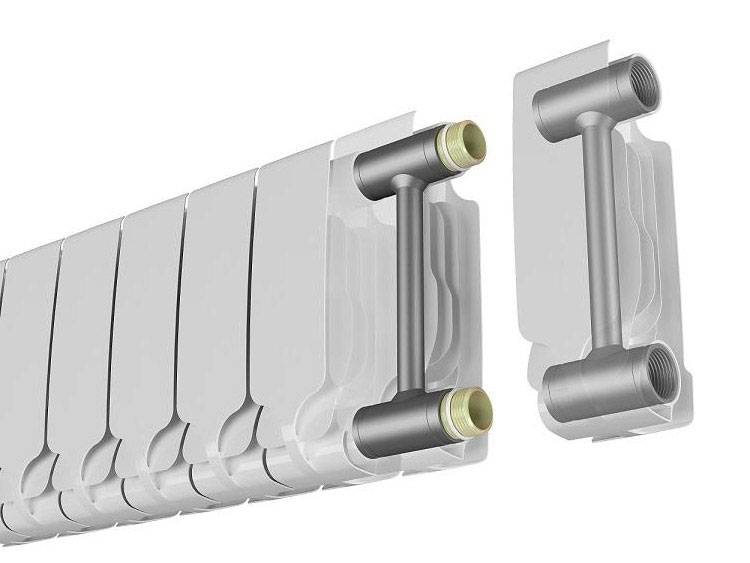

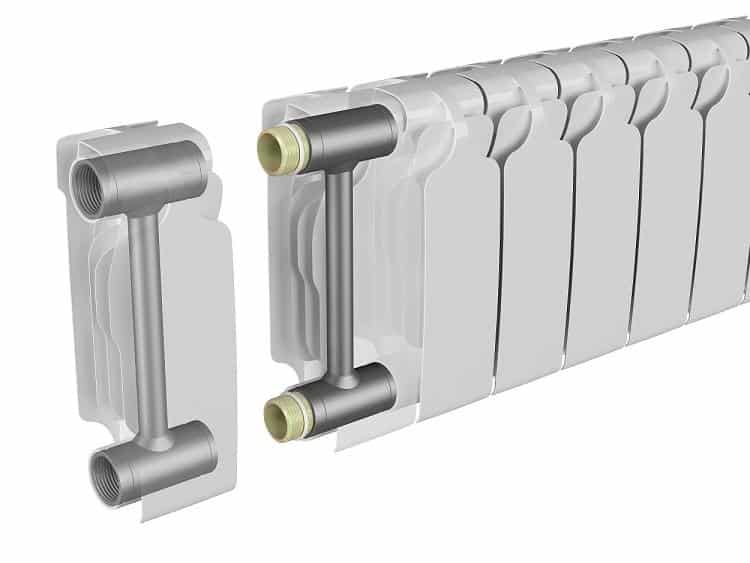

Bimetal radiator section

One of the options for the appearance of a bimetallic radiator

Let's pay attention to the disadvantages of bimetal devices:

- aluminum used in tandem with steel loses its high heat transfer properties. Due to the presence of a steel core inside the battery, you will have to wait a little longer for the air to reach the desired temperature than you are used to;

- increased price. Since the price of steel is higher than silicon, the cost of bimetallic batteries also increases by about 30% compared to aluminum;

- increased operating costs. Since bimetallic devices boast increased hydraulic resistance, the amount of energy spent on water circulation will also increase;

- improper use of radiators can lead to corrosion of its steel parts. This will definitely happen if bimetallic batteries are installed in your dacha, which is not used in winter.As soon as the heating autumn season comes to an end, it will be necessary to carry out the procedure for draining water from the system. It is because of this that corrosion processes will begin: the simultaneous contact of steel with air and water instantly starts them.

- The small bore of the tube inside the device is prone to clogging quickly. This shortens the life of the device.

Important! The coefficients of thermal expansion for steel and aluminum differ, which is why loud crackles begin to emanate from the battery after a short period of time. This sound does not mean that there is a problem inside the device.

Don't worry, your health is safe!

These modern radiators can work properly even in rooms with high humidity levels. Their surface is not subject to corrosion. Such resistance to aggressive environmental influences is given to the radiator by sheet steel, which covers the body of the device with a protective layer.

Inside the bimetallic radiators there are water channels of small cross section. Due to their modest size, they are filled as quickly as possible with hot water coming from a centralized water supply system or an autonomous boiler.

Building professionals consider the purchase of bimetallic batteries and their installation during renovations to be one of the best functional improvements to an apartment. The use of these devices over time fully pays for the money spent on them.

Feature of the material used

First of all, you need to pay attention to the fact that the radiator is reliable. An excellent solution would be a product made of stainless steel

However, such material belongs to the category of expensive, heavy and extremely difficult to process. When a battery is made from a corrosive material of this type, there will be no variety of shapes. It also implies excessive reliability, which is extremely unprofitable for the manufacturer.

The addition of aluminum will help make the machining process less costly and labor intensive. Such a material is easy to cast and is considered not only immune to corrosion, but also to electrochemical degradation. Such an alloy belongs to the category of light. In addition, it is not able to withstand regular dynamic impacts.

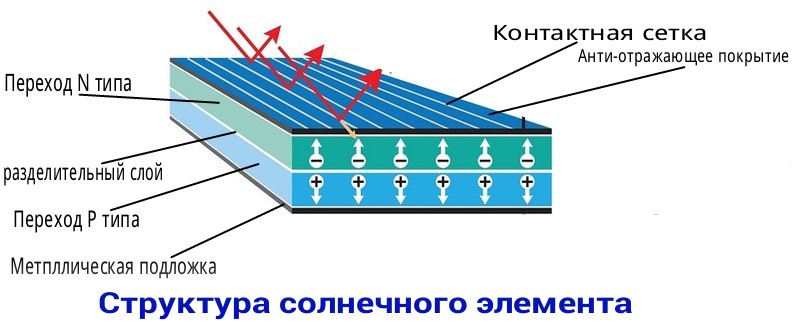

However, over time, a solution was found. It was decided to fix the steel collector inside the mold. The chosen form was simple, which allowed assembly even for a person who is not distinguished by professionalism. At the end of the aluminum alloy mold pressing, the embedded element remained inside the structure and became a second skin. Thus, heat transfer was carried out without obstacles. And the body of the bimetallic device itself was reliably protected from the effects of the coolant.

The modern buyer needs to pay attention to such factors that will help to find a high-quality bimetallic radiator. Products should answer like this parameters:

- Gaskets and nipple connections must be reliable. Even after years of operation, they must maintain tightness at times of sudden temperature fluctuations.

- Injection molding is considered the key to the formation of a quality product. It is extremely important not only the preparatory work, but also the observance of the established proportions.

- To withstand abrasion, a steel liner of normal thickness is required.

- High manufacturability, welding and molding, which are carried out exclusively on modern equipment. This reduces the risk of internal stress. For heating systems, this aspect is extremely important.

- There are a number of welding rules that apply to each of the key structural elements.

- Placing threaded bushings on the manifolds, and not just tubular inserts that were placed in the section channel. In fact, the principle of using a mortgage element has changed.

How not to make a mistake in choosing such equipment

To choose the most suitable bimetallic radiator, you must adhere to a certain algorithm of actions, the essence of which is the following steps.

number of required sections,

Such calculations are necessary to fully compensate for all the heat losses of the room due to the operation of the required amount of radiator equipment.

Different models of bimetallic radiators have different resistance to working pressure. Therefore, if you are connected to central heating, you should choose equipment with a maximum working pressure, but if you have an individual system, then this parameter is not so important and you can stop your choice on radiators with a small indicator, which will save a little the cost of their purchase .

There are a lot of manufacturers of such equipment and each of them introduces its own design features. Therefore, specify which alloys were used, whether aluminum is in contact with the coolant, and what are the dimensions of the inner steel tubes.

The appearance of all models is quite pleasant, but if unusual shapes are needed for any designer interior, the manufacture of such radiators is quite possible under an individual order.

The choice of the manufacturer's company must be carried out by studying reviews and consumer opinions. To date, the Italian companies Sira and Global are the most trusted, whose products can be purchased on average for 800 rubles (per 1 section). Of the domestic companies that have an established production of such radiators, the most famous is Rifar. Their equipment is a little cheaper, namely about 600 rubles. When calculating the budget for the purchase of bimetallic radiators, remember that really high-quality models simply cannot be cheap.

On this, our article devoted to all the nuances associated with bimetallic heating radiators has come to an end. Of course, equipment of this kind surpasses all traditional batteries and registers in all technical parameters. Therefore, the reason for refusing to purchase them can only be a relatively higher price. The most important thing to remember is that it is worth buying such heat exchangers only in specialized stores that are engaged not only in the sale, but in the professional installation of heating equipment.

How to choose how many radiator sections you need

Power can vary from 160 watts to 2.4 kilowatts. Depending on the area of the heated room, a radiator of a certain power is also chosen. Don't know how to choose how many sections bimetal heating radiators will need? You can go two ways. The first is to entrust it to competent people. They will calculate everything for you tyutelka.For any room - even in an apartment in a high-rise building, even in your own cottage with autonomous heating.

Do not want to trust anyone with the calculations - please. You can do it yourself. It turns out, of course, not so perfectly accurate, but this is not critical. But the calculation method is quite simple. For him, you need to know some standard values. This is the thermal power (in watts) that is needed to heat one square meter of the room where the radiator will be installed. Let's consider three options.

- The room has one window and one wall facing the street. Ceilings from 250 to 270 centimeters high. Power for heating one square meter requires 100 watts.

- The room has one window and two walls facing the street. Ceilings are the same. The power required to heat one square meter is 120 watts.

- The room has two windows and two walls facing the street. Ceilings are back to standard. The indicator of standard power is 130 watts.

Calculation:

1. We multiply the power indicator with the area of \u200b\u200bthe room - this will be the thermal power of the entire battery, which is necessary for a particular room. In the case of a house with high ceilings or a large window area, we multiply by an additional 1.1. This is the correction factor.

2. We take the passport of the radiator and write out the thermal power of one section from it. If the passport does not have this value, we find it off. manufacturer's website. Dividing the number obtained in the first paragraph by this parameter, we obtain the number of sections. Problem solved. Yes, and one more nuance: if the radiator is produced only with an even number of sections, and you got an odd number, then you will have to round it up, while increasing it.

Calculation example:

We want to install a Sira RS500 bimetal battery in a room with only one window. The wall facing the street is also alone. But the ceilings are high, three meters high. The floor area is 19 square meters. Let's start the calculations.

We consider the total thermal power that we need to heat this room. To do this, we multiply the area (19 square meters) by the standard (100 watts) and by a correction factor of 1.1 (we use it, since the ceiling height is higher than the standard values).

100 x 19 x 1.1 = 2090 (watts).

Looking into the passport of the radiator, we find out that one of its sections has a thermal power equal to 199 watts.

2090 / 199 = 10.5 (pieces).

This is the required number of sections. Naturally, you need to round up to a whole number. Since the ten-sectional model is closest in terms of parameters, it makes sense to put it. So, we need 10 sections. As you can see, the calculations are not particularly difficult.

Types of heating radiators

There are several main types of heating batteries used for heating of private houses and apartments in multi-apartment buildings. The choice of buyers are the following types of radiators:

- cast iron;

- Steel (panel and tubular);

- aluminum;

- Bimetallic.

There are also some other types of radiators, but they are not in great demand. Let's see how the types of heaters presented in the list differ.

Cast iron radiators

Cast iron radiators are familiar to everyone and everyone - perhaps everyone has seen these giant and heavy "accordions" made of heavy cast iron. Such radiators are still in operation in many homes, heating residential and non-residential areas.They are resistant to low pressure and can be used in low-rise buildings. Their main advantage is their high heat capacity - if the heating is turned off for some reason, the rooms will be warm for another one and a half to two hours.

Classic cast iron batteries operate at pressures up to 10 atmospheres, and their resistance to corrosion allows you to count on a long service life. Their disadvantages include lack of design, high weight and high inertia (long warm-up time). Nevertheless, cast-iron batteries still warm many houses and apartments.

Steel radiators

Steel radiators are divided into panel and tubular. Panel models cannot boast of special pressure resistance, so they are not suitable for use in apartment buildings - they often burst and do not resist water hammer at all. Tubular radiators of various designs are more stable, so they are often found in old multi-storey buildings (up to 9-16 floors). But they are gradually getting rid of such radiators, since they cannot be called modern.

It should be remembered that there are still beautiful tubular radiators with a great design on sale - they are produced as part of the design series of heating equipment. But they are characterized by a high cost, and they are very rare in stores.

Aluminum radiators

Lightweight aluminum allows you to create modern radiators, characterized by low weight and ease of installation. To date, these are the most common heating devices used to heat private houses and apartments in low-rise buildings.They withstand pressure up to 6-15 atmospheres, so they are not suitable for use in high-rise buildings. It is best to use aluminum radiators to work in autonomous heating systems where there is no high pressure.

Aluminum radiators have a high heat output, reaching up to 180-200 watts per section, and the absence of inertia allows you to count on fast heating of the premises. And for their installation, almost no effort is required. Despite many advantages, aluminum radiators also have bright disadvantages - they cannot stand the poor quality of the coolant and do not resist water hammer.

Bimetal radiators

Modern bimetallic heating batteries have absorbed the maximum of the advantages of the above heating devices. They are extremely strong and have a high heat dissipation. At the same time, their weight is quite small, especially when compared with outdated cast-iron models. It is impossible not to note such a dignity as resistance to the quality of the coolant. Such unusual characteristics were achieved through the use of such a composite of two metals - steel and aluminum.

Inside each bimetallic battery is a steel core in the form of horizontal and vertical pipes. It is through this core that the heated coolant flows. As for heat transfer, it is carried out by means of an external aluminum case. Durable steel copes well with high pressure, water hammer and high acidity of the coolant, while aluminum ensures perfect heat release.

Bimetallic radiators are a truly universal solution - due to their high endurance (maximum peak pressure is up to 50-100 atmospheres), they can be used to heat any buildings and premises, from residential to industrial.