- Marking and production process

- Technological features of factory production

- How are products labeled?

- Pouring concrete mixture into a mold

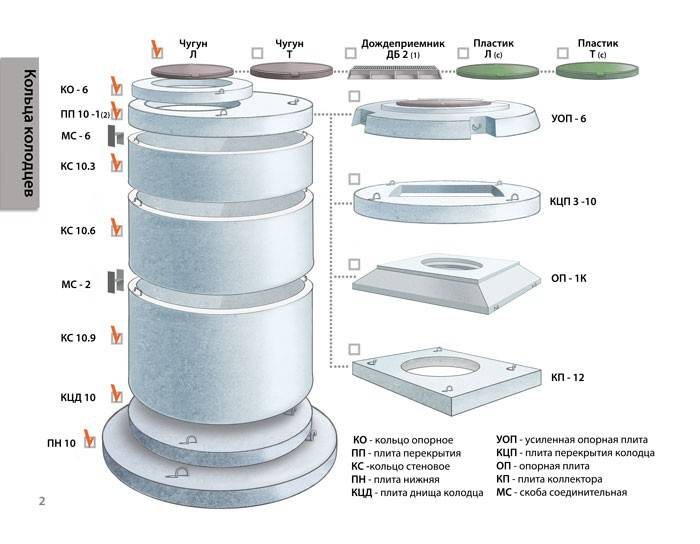

- Types of concrete well rings

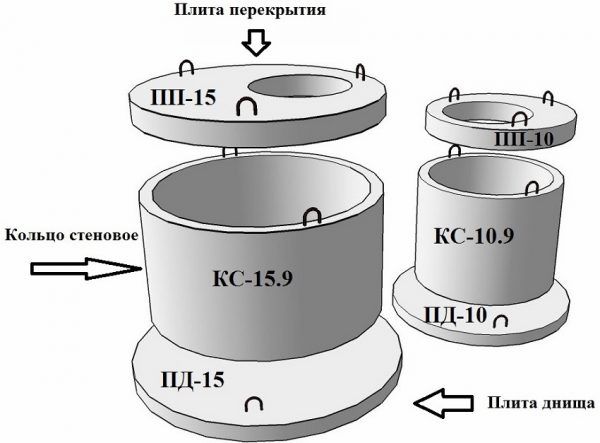

- Floor and base slabs

- How to choose the size

- What are the selection criteria

- Varieties of sewer rings and their scope

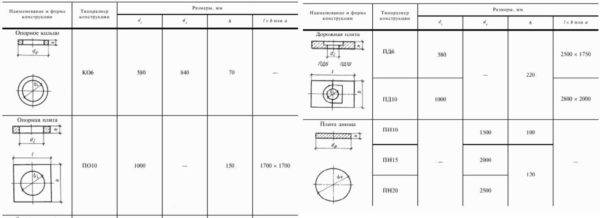

- The size of the rings for the well according to GOST

- Deciphering the marking

- What are the sizes of well rings

- Making a reinforcing frame

- Varieties of sewer rings and their scope

Marking and production process

The entire process of manufacturing rings for wells is clearly regulated by separate legislative acts and technical conditions. GOST 10180 describes in detail the quality and strength characteristics of a concrete mixture suitable for the production of modules.

Well rings made of concrete cannot be installed in areas with seismic activity of more than 8 points and in permafrost regions. For such difficult operating conditions, slightly different design and technical options and solutions are required.

Well rings made of concrete cannot be installed in areas with seismic activity of more than 8 points and in permafrost regions. For such difficult operating conditions, slightly different design and technical options and solutions are required.

Standard 10060 defines the requirements for frost resistance of the material. The required level of water resistance is reflected in document 12730.Deviations from the norms are allowed in minimal percentages and only for certain parameters.

Technological features of factory production

For the production of a well ring, a professional concrete mixer, an automatic vibroform and a crane beam designed to work with loads weighing from 1 to 2 tons are required.

A special concrete mixture is used as raw material. It includes:

- fresh cement without additives with a good rate of curing;

- coarse sand with a crushing of 2.0-2.3 Mcr (preferably without or with a minimal presence of clay lumps and dust particles);

- crushed stone with a fraction of 5-10 mm, but not more than 5-20 mm;

- technical water without impurities;

- superplasticizer.

All components in a certain proportion are placed in special equipment. It thoroughly kneads the composition, giving it a homogeneous, fluid consistency without lumps and clots.

Industrial concrete mixers are equipped with a three-phase motor, operate quickly, have high power and produce a large batch of concrete in one cycle.

Industrial concrete mixers are equipped with a three-phase motor, operate quickly, have high power and produce a large batch of concrete in one cycle.

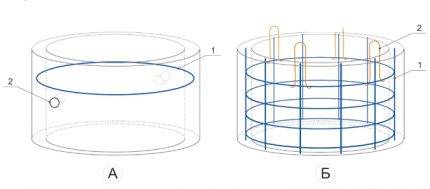

At the next stage, reinforcement elements made of steel wire with a diameter of 8-12 mm are placed in the molding container (formwork). This carcass gives the ring additional strength and provides good resistance to compression/extension during service.

Two vertical rods are placed on opposite sides of the structure. They act as lugs and facilitate the subsequent removal of the ring from the mould.

Then, the prepared cement composition is poured into the formwork and automatic vibration is activated. In the process of processing, all voids are evenly filled, and the concrete acquires the necessary integrity and density.

After a day, the product is removed from the vibroform and moved to an open area for standing. After a week, the ring acquires about 50% of its base strength, and becomes fully usable after 28 days.

How are products labeled?

All reinforced concrete products are marked with an alphanumeric abbreviation generally accepted in the state. This allows you to quickly determine the size and scope of each individual element when buying.

Letter combinations are deciphered as follows:

- KS - wall ring, available for placement in confined spaces;

- KLK - a module for creating drainage networks and local storm sewer systems;

- KO - a fundamental support that ensures the stability of the position of the well foundation;

- KFK - fragments for the arrangement of collector networks and drainage communications;

- KVG - products for the installation of water wells and the laying of a gas pipeline.

The numbers next to the letters indicate the height, thickness, specific gravity and internal diameter of the ring. Understanding these values, it will not be difficult to purchase suitable reinforced concrete products.

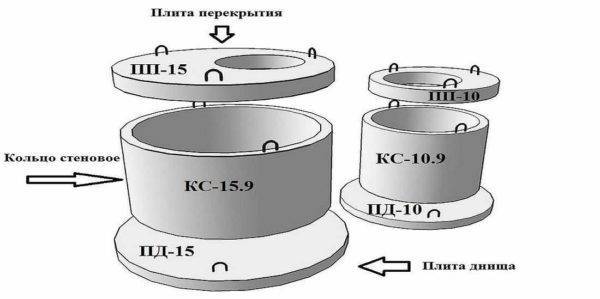

Before buying rings, you need to determine their dimensions, as well as select additional equipment for installation - support, bottom, ceiling

Pouring concrete mixture into a mold

When all the preparatory work is completed, they begin to manufacture the well ring.

Work order:

- Foundation preparation. A sheet of iron or a wooden shield is laid on a flat surface.

- Form assembly. The blanks are installed (one into the other), the parts of the formwork are carefully fixed.

- Form reinforcement.A reinforcing frame is lowered between the outer and inner walls of the formwork, fixing its position with wedges.

- Structural pouring. A thick concrete mortar (W / C = 0.5) is placed in the inter-annular space in small layers (about 100 mm) and compacted using a steel pin with a diameter of 20 mm. A creamy solution (W / C = 0.7) is immediately poured into the mold to the brim, and then the mixture is compacted with a pin.

- Ring alignment. After filling out the entire form, they begin to level the end of the concrete ring, reporting with a trowel the mortar where it is lacking. The product is covered with polyethylene or a dense cloth.

- Removing formwork. Demoulding is started after 3-4 days (if the concrete was thick), after 5-7 days (if the solution was liquid), leaving the ring on a metal sheet or wooden shield.

- Ripening of concrete. The reinforced concrete ring is wrapped with a packaging film so that the composition ripens evenly for 2-3 weeks, gaining final strength.

It is recommended to wet the product with water every 4-5 days during the curing of the concrete.

Using the same technology, rings for a cesspool are made. Detailed information on the classification and methods of manufacturing concrete rings for sewers can be found in this article.

Types of concrete well rings

Concrete rings are used in the construction of wells for various purposes. Drinking, sewer, waste columns and sedimentation tanks, tanks are collected from them. They also build sewer sedimentation tanks, septic tanks. GOST 8020-90 defines all types of products for the manufacture of networks and wells in particular. Not all of them are used in everyday life. The most commonly used types of rings are:

- KS - wall or through ring. It is a concrete cylinder.Installed one on top of the other, they form a well column. There are different diameters - from 70 cm to 200 cm, with a wall thickness of 5 to 10 cm. There may be:

- ordinary with a smooth edge, standard wall thickness;

-

with a formed protrusion - for the lock joint;

- reinforced - with a large wall thickness for cases of deep laying;

- reinforced - with introduced reinforcement.

- KCD - concrete rings with a bottom. They are like a glass with a cast bottom. They are installed during the assembly of sewer wells and sedimentation tanks, septic tanks. Guarantee tightness and speed up installation - no need to pour the bottom plate.

- KCO - support ring. Mounted on the assembled column under the neck. Allows you to bring the well cover to the desired height.

- KO - support ring. It is installed as the foundation of a well. It has a small height, but thick walls.

According to the standard, the walls of the rings can have a technological slope of no more than 1.5%. But at the same time, the wall thickness and the inner diameter in the middle of the height must match the normative ones. In general, even walls, the absence of cavities and cracks are a sign of normal quality.

Floor and base slabs

Even when constructing wells, plates may be needed. Some of them are placed on the bottom, others are closed on top. When constructing drinking wells, concrete slabs are rarely laid - more often they make a house for a well. When assembling septic tanks from well rings, the base plate is often poured, and not laid ready. So you can do without these products, but their use reduces the time of work. In general, in GOST there are such types of plates for wells:

- PN - bottom plate. This is a flat round pancake, which is placed at the bottom of a dug pit.

-

PO - base plate. It is a rectangular slab with a round hole in the center. A well is covered with it if a rectangular rather than a round platform is required from above.

- PD - road slab. It looks like a software, only it has rectangular dimensions and a large thickness. They put it on the upper ring of the well if it goes out onto the roadway.

- PP - floor slab. This is a round pancake with a round hole for the manhole cover. The hole is offset to one of the edges for easier access.

Standard dimensions for slabs

The standard allows the presence of a bevel on the side faces of plates made in one-piece forms. But the quality of concrete, the absence of cracks, cavities and other serious flaws - all these are signs of normal quality.

How to choose the size

When you have decided on the design of the well, you know what kind of bottom you want, how and with what you will cover the well, the most important thing is to decide on the size of the CC. All other elements are of the same size. They are designed to fit one another. And the number of links is determined based on the required volume or approximately calculated based on the depth of the aquifer. For sedimentation tanks, septic tanks, storm wells, they are considered based on the required storage volume.

The dimensions of the well rings of all types must match

If we talk about drinking wells, they are assembled from CS with a diameter of 100 mm (KS-10) to 150 mm (KS-15). A ring with a bottom or a bottom plate is not installed - open access to the aquifer is required. When assembling a well for drains, a sump or a septic tank, it is better to take the lower link immediately with the bottom - and installation is easier and tightness is ensured. Another option is a bottom plate and a KS or KO ring installed on it. KO is set if there is a need to weight the lower part.

What are the selection criteria

There are several recommendations for choosing reinforced concrete rings for wells:

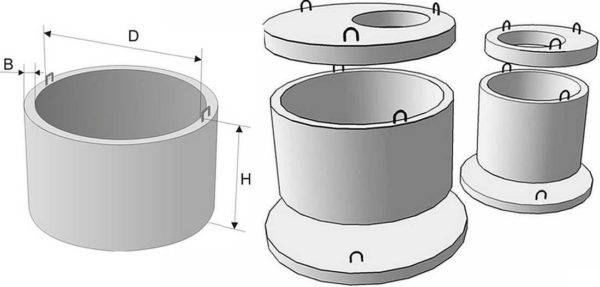

Diameter size. A rather important indicator can be called the diametrical size of the rings: the larger the indicator, the greater the displacement. It is recommended that larger diameter options be selected only if deep structures are not possible.

The width of one section: the larger this indicator, the easier it is to build wells. With an increase in width, the weight of one section also increases significantly. Therefore, when using special equipment at the time of construction work, you can choose sections with a large width indicator.

Wall thickness. The strength of one section depends on a variety of indicators, including wall thickness. The higher the wall width, the greater the strength of the ring, but its weight and cost also increase. The wall thickness is standardized.

The brand of concrete used. There are quite a few different brands of concrete, each has its own characteristics.

High-strength concrete has increased strength, but at the same time the cost increases significantly.

Particular attention should be paid to the quality of the workpiece reinforcement. The reinforcing layer takes on most of the load, is a critical element

A sign of good reinforcement is the presence of wire mesh. Due to the complexity of the production process, low quality rings can be found on sale, the reinforcement of which is represented by only a few sections of thin wire.

The correspondence of the forms of each section is even an important indicator. If one of the sections has a deviation in shape, then it will be difficult to create a sealed structure.

Another important recommendation is that before purchasing the considered materials for sewer wells, you should check that the seller has a quality certificate

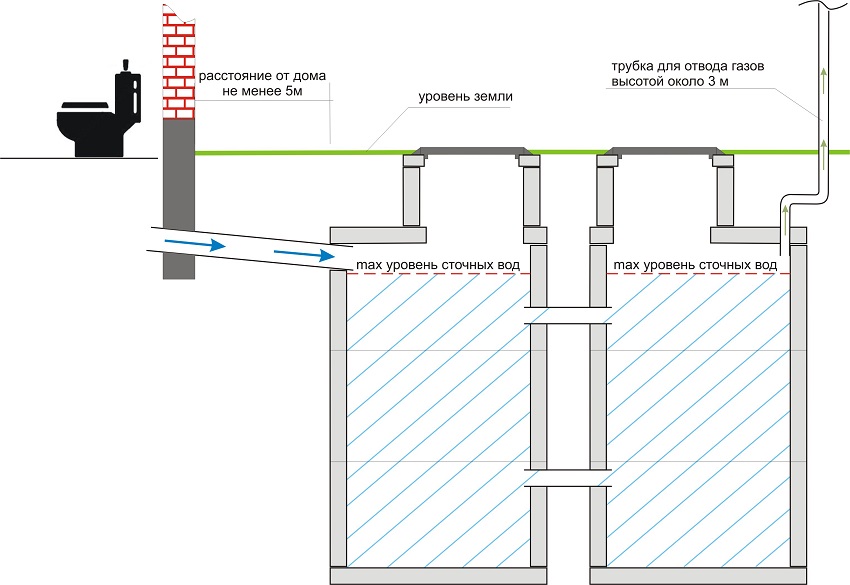

Varieties of sewer rings and their scope

To drain sewage, pipes are usually used, which are made of polymeric materials, cast iron, ceramics, asbestos cement, reinforced concrete, mainly these products have a small diameter, with the exception of structures made of lightweight plastic components. If a large pipeline diameter is required for laying underground utilities, the weight of long pipes becomes too large for transportation and installation of the line, so it is constructed from short rings.

Due to the cheapness, wide sewer rings are made only from concrete, and this material has no competitors today. With the development of modern technologies and the trend of using polymers in all areas, analogues of concrete products have appeared on the market relatively recently - polymer sand rings, which are used only for the construction of vertically installed structures.

If in the urban planning sphere, underground horizontal communications are laid from reinforced concrete rings for transporting organic waste, storm and gray wastewater, they are used as protection for water supply and gas pipelines, then in the household economy their use is of a different nature. In individual sections, reinforced concrete sewer rings serve as the main elements in the construction of the following structures:

Water wells.Installation of wells for the intake of drinking water from reinforced concrete rings is one of the most popular ways of supplying water to individual residential buildings in urban and rural areas. The shaft is dug out manually or mechanized, after which sewer wall rings with a lock are immersed in it. If a well is made of concrete rings on the site, the depth of the structure can reach 30 m - in this case, a submersible electric pump is used to draw water.

Septic tanks. From do-it-yourself sewer rings, some homeowners build septic tanks or settling tanks using structures with a closed bottom and top.

Drainage wells. Installation of reinforced concrete rings for sewerage in households is one of the most common areas of their application. The sewage waters purified in individual septic tanks are disposed of at their site, using aeration fields or drainage wells for additional purification and directing the effluents underground. Many people mount the drainage chamber with their own hands from reinforced concrete rings, installing several elements with a locking connection on top of each other in a vertical position.

Rice. 2 Engineering structures from reinforced concrete rings

Viewing wells. Engineering structures of this type are needed for sewers in a private house in cases where the underground main has a large length or branches. For cleaning, preventive maintenance and inspection, wells of small diameter are placed along the sewer pipeline. They are designed to access inspection hatches installed in pipes for cleaning them in case of blockages and monitoring the state of the line.

Caisson wells.A well made of reinforced concrete rings is often used to place pumping equipment in it, to protect a well water source from freezing and precipitation when it is taken by a submersible electric pump or a surface pumping station. The depth of such structures usually does not exceed 2 m, during installation they often use rings with a finished bottom or top floor with a hole for a hatch, another installation option is to install separate round plates for the bottom and upper manhole. Also for caisson wells, experienced users purchase ready-made structures with built-in metal running brackets located along the entire height of the wall.

Settling tanks. Often in private households, especially in rural areas, residents deprived of access to centralized sewerage share waste disposal. They install a separate toilet for faeces on the street, and gray water after washing dishes, washing, cleaning rooms and other household needs is drained through sewer pipes into a drainage sump built of concrete rings.

Cellars. Concrete rings with a bottom can be used in a private area for the construction of cellars designed to store fruits and vegetables deep underground in winter and summer.

horizontal passages. When laying utilities under roads, for transferring water masses to the other side of highways and railways, reinforced concrete rings of large diameter are often used, which are easier and easier to lay one after another than to immediately stretch a heavy long pipe.

Rice. 3 Excavation for wells with special equipment

The size of the rings for the well according to GOST

For the manufacture of well rings, concrete grade M200 is used.Its components are cement, sand, crushed stone and water. To improve the strength characteristics, steel reinforcement is installed in the mold

Please note that concrete products with reinforcement inside are a separate category. So if you need reinforced concrete rings for the well, they must be looked for separately. Not all factories produce such products

Not all factories produce such products.

Dimensions of rings for a concrete well: inner diameter, height and wall thickness

Deciphering the marking

For drinking wells, only one type of well rings is often used - KS. In the marking, two digits through a dot follow. For example, SC 10.6. The first digit is the inside diameter in decimetres. One decimeter is equal to ten centimeters. To find out the diameter of the ring in centimeters, this first figure must be multiplied by ten (essentially, just add a zero at the end). For example, KS 10.6 - internal section 10 * 10 \u003d 100 cm. KS 15.9 - 15 * 10 \u003d 150 cm.

Concrete ring markings indicate internal dimension and height

The second digit in the marking of the rings for the well is the height in decimeters. The translation is similar: you need to multiply by 10 (add zero after the number), we get centimeters. Consider all the same examples: KS 10.6 - height 60 cm (according to GOST, height 590 mm, that is, 59 cm). For KS 15.9 - the height of the ring is 9 * 10 \u003d 90 cm (according to GOST - 890 mm, that is, 89 cm).

In the paragraph below there is an excerpt from GOST 8020-90, which indicates the exact dimensions. If you look at the numbers, we see that the height is rounded everywhere in the marking. Shown more than it should be according to the standard. So keep in mind that in fact the height will be 1 cm less. And this is not a deviation, but compliance with GOST.For example, KS 10.6 is 59 cm in height according to the standard, and if you decipher it, it turns out 60 cm. This should also be taken into account when measuring.

What are the sizes of well rings

It is customary to determine the size of the rings for the well by the inner diameter. It is he who is indicated when marking. The outer diameter can be larger or smaller - depending on whether the ring is of normal strength or reinforced. The table shows the parameters for products of normal strength.

- SC 7.3 and SC 7.9. Inside size - 70 mm, two heights - 29 cm and 89 cm. They are rarely used, as they are too small. Can be used for small storm systems. But they often put plastic ones there - they are more practical and lighter.

- The next size is meter KS 10.3, KS 10.6 and KS 10.9. The internal section is 100 cm, three possible heights: 29 cm, 59 cm and 89 cm. These are almost the most common dimensions. The optimal size of the KS is 10.6 - they are easier to install than those that are 90 cm.

-

The size of the COP 13.9 is rare. For some reason, factories ignore it.

- The next running position is one and a half meters in diameter. SC 15.6 and SC 15.9. This ring size is suitable if you need to store large volumes. It is sometimes used for drinking wells, but more often for septic tanks or septic tanks.

-

Two-meter well rings are available in three sizes: KS 20.6, KS 20.9 and KS 20.12. They are usually used for septic tanks. Drinking wells are sometimes also collected if it is necessary to ensure a large flow of water. As you can see, here for the first time the height of the ring is 119 cm (in the marking 12 after the dot).

- The largest ring size for a well is two and a half meters. COP 25.12. In everyday life, they are rarely used, since it is unrealistic to install them without special equipment.

If we talk about the mass of the rings, then it depends on several factors.The first is the brand of concrete, the type of aggregate. The second is the number and dimensions (mass) of the reinforcement. The third is the wall thickness. So each manufacturer has its own mass. Above is a table of one of the factories

Please note: the wall thickness is indicated from 70 cm to 100 cm. If you look at the GOST table, there is a minimum wall thickness of 14 cm for KS 7. For KS 10 it is already 16 cm, and then 18 cm, 20 cm

So those that will be made to the standard will be about twice as heavy.

For KS 10, it’s already 16 cm, and then 18 cm, 20 cm. So those that will be made according to the standard will be about twice as heavy.

Making a reinforcing frame

The use of reinforcement allows to reduce the thickness of the ring, and hence its weight. At the same time, the strength characteristics of the product and its service life increase.

For a reinforcing frame you will need:

- steel rods with a diameter of 8-10 mm (10 pieces);

- steel wire with a diameter of 8-10 mm (about 5 m);

- thin wire.

Calculate the frame length. To do this, we recall the formula for calculating the circumference of a circle: the number Pi (equal to 3.14, rounded up to 3) must be multiplied by the diameter. We take the diameter of the circle equal to 104 cm, so that the frame passes in the middle of the concrete ring.

We multiply this number by 3, we get 312 cm. We divide this number by 10, we get at 31.2 cm. Round up to 31 cm. So, we lay out the steel rods on a flat surface at a distance of 31 cm from each other.

Next, we weld pieces of wire 315-318 cm long through 160 mm to them.We take the wire a little longer than the calculated length of the frame, so that when the workpiece is rolled into a ring, its ends can be welded or twisted.

We manually bend the mounting loops from thick steel wire and weld them to the frame (you can fasten them with a thin wire). Everything, the frame is ready. If there is no welding machine, then all frame elements can be twisted with a thin wire.

Wire frame for reinforcing a reinforced concrete ring in fig. B consists of steel rods, rings and four loops welded to the wire. On fig. A concrete ring without a frame with holes instead of eyes for lifting. For reinforcement, only one wire ring is laid on top of the holes (+)

Wire frame for reinforcing a reinforced concrete ring in fig. B consists of steel rods, rings and four loops welded to the wire. On fig. A concrete ring without a frame with holes instead of eyes for lifting. For reinforcement, only one wire ring is laid on top of the holes (+)

Varieties of sewer rings and their scope

To drain sewage, pipes are usually used, which are made of polymeric materials, cast iron, ceramics, asbestos cement, reinforced concrete, mainly these products have a small diameter, with the exception of structures made of lightweight plastic components. If a large pipeline diameter is required for laying underground utilities, the weight of long pipes becomes too large for transportation and installation of the line, so it is constructed from short rings.

Due to the cheapness, wide sewer rings are made only from concrete, and this material has no competitors today. With the development of modern technologies and the trend of using polymers in all areas, analogues of concrete products have appeared on the market relatively recently - polymer sand rings, which are used only for the construction of vertically installed structures.

If in the urban planning sphere, underground horizontal communications are laid from reinforced concrete rings for transporting organic waste, storm and gray wastewater, they are used as protection for water supply and gas pipelines, then in the household economy their use is of a different nature. In individual sections, reinforced concrete sewer rings serve as the main elements in the construction of the following structures:

Water wells. Installation of wells for the intake of drinking water from reinforced concrete rings is one of the most popular ways of supplying water to individual residential buildings in urban and rural areas. The shaft is dug out manually or mechanized, after which sewer wall rings with a lock are immersed in it. If a well is made of concrete rings on the site, the depth of the structure can reach 30 m - in this case, a submersible electric pump is used to draw water.

Septic tanks. From do-it-yourself sewer rings, some homeowners build septic tanks or settling tanks using structures with a closed bottom and top.

Drainage wells. Installation of reinforced concrete rings for sewerage in households is one of the most common areas of their application. The sewage waters purified in individual septic tanks are disposed of at their site, using aeration fields or drainage wells for additional purification and directing the effluents underground. Many people mount the drainage chamber with their own hands from reinforced concrete rings, installing several elements with a locking connection on top of each other in a vertical position.

Rice. 2 Engineering structures from reinforced concrete rings

Viewing wells.Engineering structures of this type are needed for sewers in a private house in cases where the underground main has a large length or branches. For cleaning, preventive maintenance and inspection, wells of small diameter are placed along the sewer pipeline. They are designed to access inspection hatches installed in pipes for cleaning them in case of blockages and monitoring the state of the line.

Caisson wells. A well made of reinforced concrete rings is often used to place pumping equipment in it, to protect a well water source from freezing and precipitation when it is taken by a submersible electric pump or a surface pumping station. The depth of such structures usually does not exceed 2 m, during installation they often use rings with a finished bottom or top floor with a hole for a hatch, another installation option is to install separate round plates for the bottom and upper manhole. Also for caisson wells, experienced users purchase ready-made structures with built-in metal running brackets located along the entire height of the wall.

Settling tanks. Often in private households, especially in rural areas, residents deprived of access to centralized sewerage share waste disposal. They install a separate toilet for faeces on the street, and gray water after washing dishes, washing, cleaning rooms and other household needs is drained through sewer pipes into a drainage sump built of concrete rings.

Cellars. Concrete rings with a bottom can be used in a private area for the construction of cellars designed to store fruits and vegetables deep underground in winter and summer.

horizontal passages.When laying utilities under roads, for transferring water masses to the other side of highways and railways, reinforced concrete rings of large diameter are often used, which are easier and easier to lay one after another than to immediately stretch a heavy long pipe.

Rice. 3 Excavation for wells with special equipment