- Why is it making noise

- Materials for soundproofing a sewer riser

- Suitable sound insulators

- Silent sewer installation rules

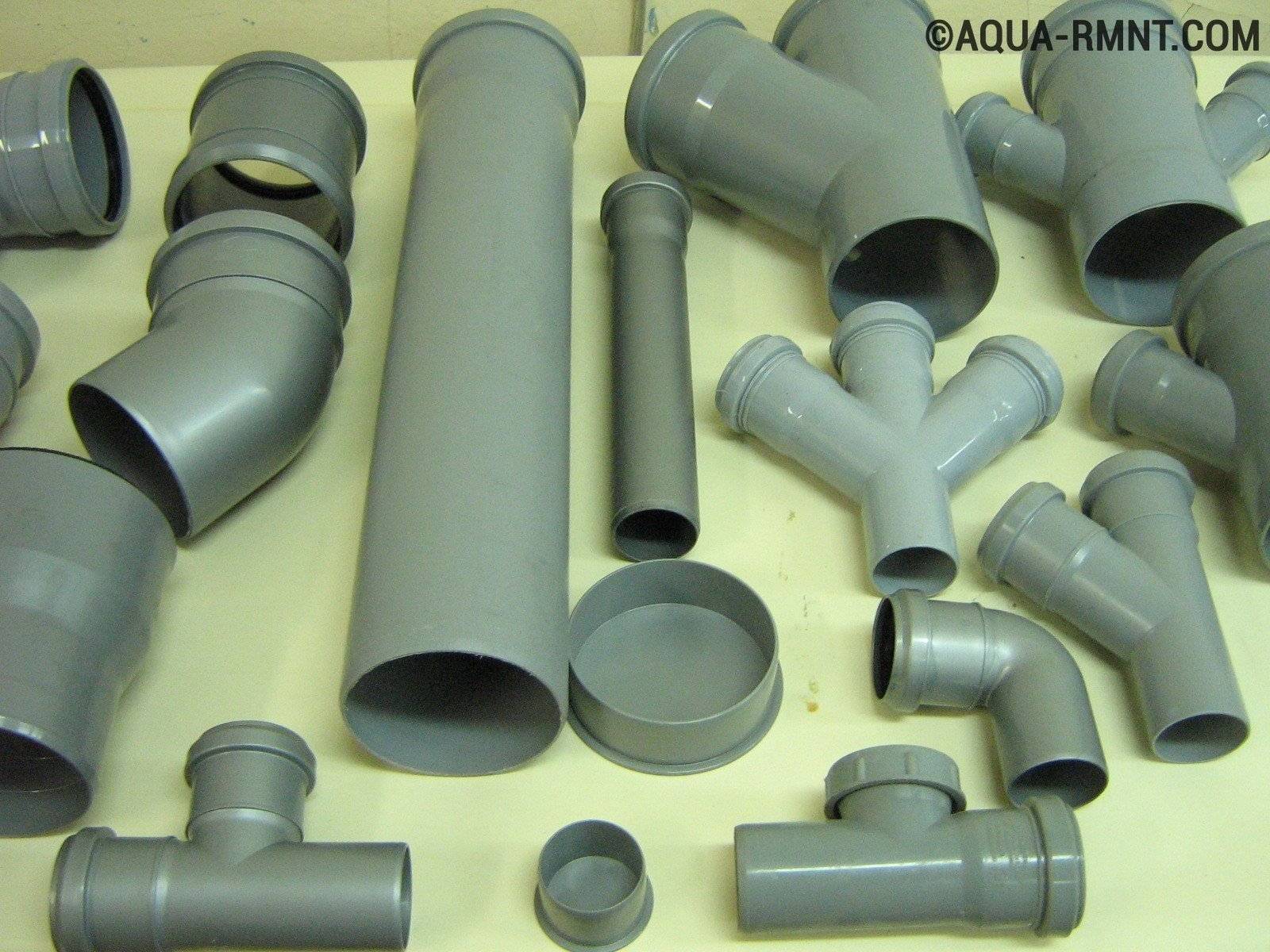

- Varieties of materials

- Refurbishment and redevelopment of the apartment

- What is prohibited

- Completion

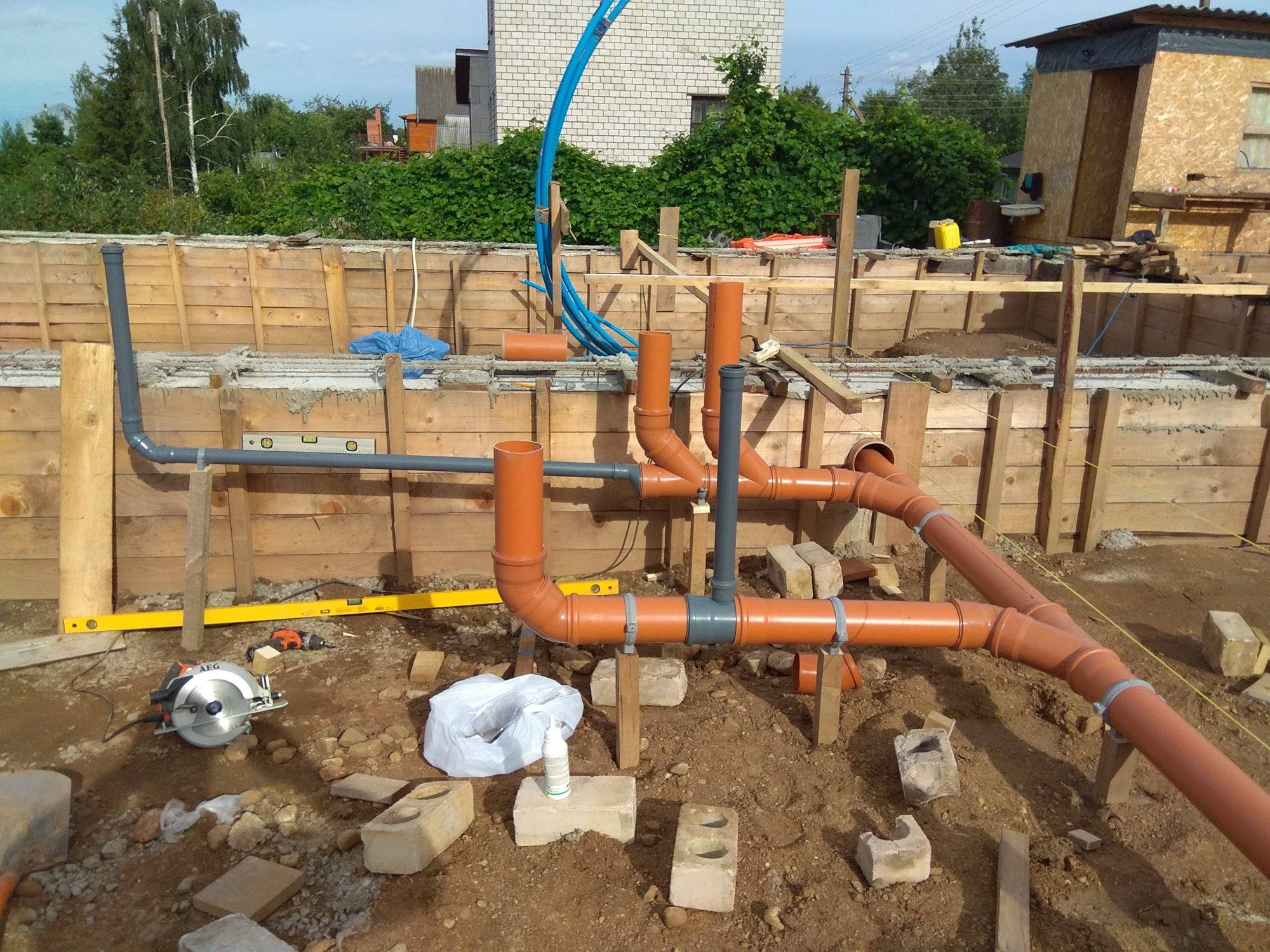

- Pipeline installation: fastenings and slopes

- How to choose?

- Mounting

- Noise absorbing materials

- Foamed polyethylene

- Styrofoam

- Materials for soundproofing a sewer riser

- Soundproofing membranes and roll materials

- Shell made of mineral wool or styrofoam

- Soundproofing a sewer riser with a box

Why is it making noise

The concept of “quiet” sewerage also arose because today many people in their apartments have plastic - reliable, but at the same time very noisy - risers that do not allow residents of apartments in multi-storey buildings to live in peace. Sewage and water pass through these pipes so clearly that it seems that this water is about to end up right in your apartment.

Why is this happening?

From the point of view of acoustic vibrations, any hollow pipe is an ideal waveguide: constantly reflected from the walls, sound can travel quite long distances with minimal loss of amplitude.

But this is in the pipe, and beyond?

In order for the sound to propagate outside the pipe, which we are actually observing, a combination of two factors is necessary:

- Pipe weights

. It should be insignificant, otherwise the power of the acoustic vibration is simply not enough to make the walls resonate; - Strong pipe walls.

In plastic, everything is in order with this - both high density and solidity of the structure.

Relatively recently, this problem was not relevant at all due to the fact that all pipelines in multi-storey buildings were made of cast iron, which made all sounds and processes inside these pipes inaudible.

The fact is that there are many reasons why users prefer plastic pipes. Let's look at the properties of two similar materials, identify all their advantages and disadvantages.

Cast iron

Plastic

Cast iron pipes weigh a lot, it is very difficult to transport them, as well as install them.

Plastic pipes are light, and it is very easy to work with parts from the presented material.

The shape and pipes are susceptible to corrosion, which means that their optimal life is not as long as we would like.

The presented material does not corrode, does not rot, and, what is very important, does not rust, thus it is the best option for pipes, because the service life of such material is really long.

Installation and dismantling of such pipes is extremely difficult.

The system under consideration is very easy to assemble into a single structure, and disassembled into separate parts.

From all of the above, we can draw an unambiguous conclusion - a PVC pipe system has more advantages, and therefore more expedient than cast iron pipes.

But, as in any other case, not everything is as smooth as we would like, and one cannot do without minuses. In this case, the disadvantage of plastic pipes is the lack of sound insulation, which makes their operation not very convenient.

.

Let's take a closer look at how such a small but significant minus can be eliminated with your own hands and at no extra cost. Let's start with an overview of each of the available methods.

Materials for soundproofing a sewer riser

The bathroom is a wet area. In the technical cabinet, the temperature is several degrees higher. The air is heated by the DHW system. Shelves often store detergents containing active chemicals. Therefore, the selected coating must be resistant to increased dampness and caustic fumes.

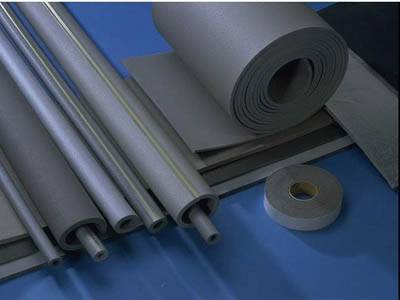

As a rule, roll materials are used. Insulators dampen vibrations due to their soft structure. Thin flexible fibers and walls absorb waves, acting as shock absorbers. Dampness and aggressive substances will quickly destroy them, so the products must have a protective shell. If there are leaks, they must be repaired before starting work.

Suitable sound insulators

- Polymer and porous rubber membranes are produced in rolls. An example is Alufom R-TK. The width of the canvas is 1 m, the thickness is 8 mm. When finishing, penoizol based on foamed polyethylene, penofol with a foil coating are often used. The fabrics are attached with glue. It is better to use different materials that differ in their permeability for different frequencies. To achieve a good result, lay two double layers.

- Mineral wool shell - it is a soft plate wrapped around the pipe and fixed with aluminum tape.The plate has a foil coating on the outside. There are analogues of expanded polystyrene, but they do a poor job and serve mainly for insulation. Their structure consists of bubbles with hard plastic walls that resonate when subjected to vibrations at a certain frequency.

- Foam rubber - it is short-lived and quickly becomes unusable in a humid environment. It is used as a temporary protection. The channel is wrapped in wide pieces, wrapped with rope or wire on top. It is more convenient to fasten foam rubber with clamps.

- Multi-layer cake made of mineral fiber and waterproofing film. Exposed fibers cannot stay in a humid environment for a long time. The condensate fills the voids, increasing their permeability. The fibers settle under the weight of the droplets, forming large air pockets. To solve the problem, a plastic film is laid on both sides. It protects the interlayer from the effects of the external environment and from condensate coming from the cast-iron or plastic inner surface.

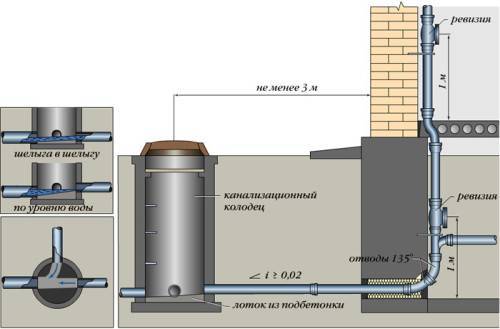

Silent sewer installation rules

Sound insulation of the sewer network should be taken into account at the design stage of engineering networks. This is due to the fact that in most modern buildings the laying of communications is carried out in a closed way. In the future, for work, it may be necessary to open the finishing layer.

Sound insulation of the sewer network should be taken into account at the design stage of engineering networks. This is due to the fact that in most modern buildings the laying of communications is carried out in a closed way. In the future, for work, it may be necessary to open the finishing layer.

To protect against noise, you must follow a few important rules:

It is not allowed to pass pipes through inter-apartment walls;

It is necessary to use special elastic sleeves made of porous polyethylene when laying pipes through interfloor ceilings;

The soundproofing material chosen by engineers to create a silent sewage system must allow pipe deformation and temperature changes in the room without the formation of gaps and through cracks;

Cavities in interior wall panels must be filled with non-shrinking grid concrete.

It is important to note that quiet sewage systems are indispensable in buildings built using prefabricated technologies - panel, frame, modular, prefabricated panel, sandwich panel, block containers or light metal structures

Varieties of materials

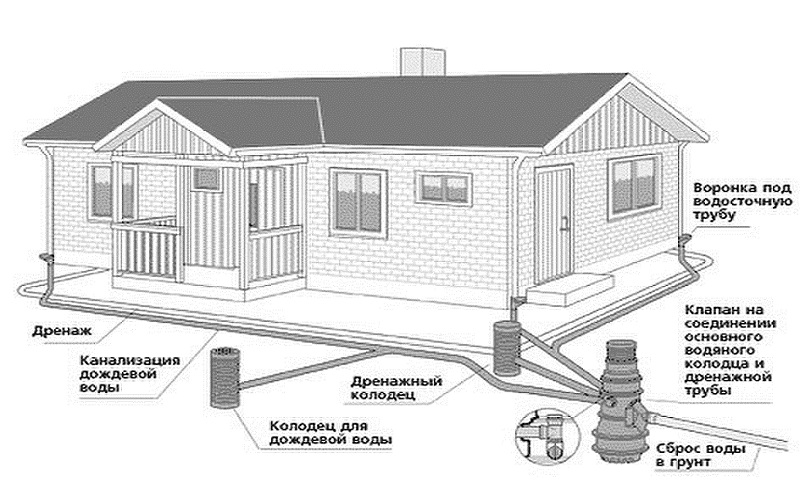

The best solution to get rid of sewer noise is to move the riser. If you take it outside the apartment, then its sounds will not disturb the household. However, these issues should be addressed at the design stage of construction works. As practice shows, such a system is not always equipped and not everywhere, even in new buildings. As a rule, the riser is placed in the bathroom or in the bathroom, therefore, within the framework of the article, only ways to increase the sound absorption of pipes located in the living space of apartment buildings are considered.

Ways to reduce sounds passing through the drain riser can be as follows:

- install silent pipes;

- carry out soundproofing of the riser with your own hands;

- use special clamps to fix the pipe;

- fix soundproofing material;

- build a decorative box, stuffing inside with soundproofing material.

Silent sewer pipes relatively recently appeared on the construction market.They are distinguished by increased density and a thicker wall, as well as special components. The most commonly used filler is microcalcite, chalk and limestone, that is, fine fractions of grinding carbonate minerals. All this can significantly reduce the sounds of merging drains. Such pipes extinguish not only noise, but also infrasound. However, their prices are much higher than for simple PVC pipes, and they serve no more than two decades.

Noise isolation is carried out with a variety of materials, and even a novice master can do it. The most commonly used modern materials are polyethylene foam, as well as porous rubber or isopropylene. Many people buy polyurethane foam and in vain. It is an excellent conductor of sounds, so the unpleasant effects may not only not decrease, but, on the contrary, become more pronounced.

Their use prevents the transmission of noise to the walls and, accordingly, reduces vibration and the emission of infrasonic vibrations. The place where the riser passes, as well as at the points of contact with the ceilings, must be sealed with porous rubber. This also helps to reduce the severity of the transmission of the acoustic effect by ceilings and load-bearing elements of the building.

Not everyone likes the look of the riser wrapped with insulating material; in this case, you can equip the box and close it with decorative finishing materials. By the way, this will create additional sound insulation. However, the riser should not be completely closed with a box, especially if a revision is placed in the bathroom.In addition, it is necessary to provide free access to the water supply, which most often runs close to the sewer riser, in order to repair the downpipe if necessary.

This is important in the event of a breakdown or emergency, as it will help provide quick access to the site of damage and promptly eliminate all shortcomings. Otherwise, you will have to dismantle the entire box and only then proceed with the repair work.

Refurbishment and redevelopment of the apartment

Any changes in the BTI plan and in the technical passport require the approval of the project. Compiling it yourself is prohibited. Only a company with a license to develop project documentation has the right to engage in such activities.

The simplest solution is to return housing to its original appearance. In this case, it will not be necessary to draw up a project and coordinate it with state authorities. If the redevelopment was carried out according to the law and new contours were noted in the BTI plan, you need to contact an engineering company.

When repair work is just forthcoming, a number of prohibitions introduced by the legislation and sanitary and technical standards should be taken into account.

What is prohibited

- Make changes that lead to weakening of load-bearing structures.

- Take actions that worsen the living conditions of the owner and his neighbors. The norms are established by GOSTs and SNiPs. Compliance with these standards is easy to check with the help of engineering equipment. If there is a smell and smudges, a thorough examination will not be necessary.

- Include communications in the area of \u200b\u200bliving rooms.

- Transfer pipes - this will lead to the need to install swivel adapters that reduce throughput.The structure must be straight even on the top floor, otherwise it will be difficult to clean it.

- Change the rebar diameter.

- Carry out its replacement without the consent of the management company. The channels are public property.

Completion

As you can see, the construction of a silent sewer has 2 solutions. It can be made both from purchased silent elements, and equipped with your own hands from auxiliary ones. It is best to build a sewer system from scratch, and it is easier and more efficient.

Let's not leave the noise the slightest chance - let the water only whisper.Skolan dB meets the maximum requirements of the III highest degree of sound insulation according to DIN 4109 and VDI 4100. Tests carried out in 2002 by the Institute of Building Physics. Fraunhofer v. Stuttgart in close to real operating conditions, confirmed the outstanding sound insulation properties of Skolan dB, as evidenced by the test reports P-BA340/2002 and P-BA/341/2002.

Strength and tenacitySkolan dB pipes are corrosion-resistant, durable and resistant to aggressive agents. Wastewater. Due to their smooth surfaces, they do not form build-ups. Pipes are available in nominal diameters from DN 56 to DN 200. Thanks to fast, reliable socket connections, the system is very easy to lay and install and meets any requirements of demanding customers.

Quality assuranceOur pipes and fittings of the Skolan dB system are subject to constant quality control. We have a quality management system certified according to DIN EN ISO 9001 DQS, reg. No. 289722-QMO 8, ISO environment: 14001:2004.

home improvement With regard to the growing demands in residential construction, Skolan dB meets all expectations in terms of economic and environmental solutions and significantly contributes to improving the quality of housing and increasing the value of real estate.

Trust your hearingThe unique Skolan dB silent system is a high quality mineralized polypropylene product. This material gives Skolan dB excellent mechanical and acoustic properties, which creates ideal conditions for future use in the construction of above-ground structures (cottages, apartment buildings, industrial buildings, hospitals, hotel complexes, etc.).

Noise in sewer pipesThe flow and fall of sewage in pipes create air and structure-borne noise in the building. For example, sewage impacts at high flow rates in places such as bends, tees lead to the formation of significant noise. The biggest problem in the engineering communications of a building is the spread of structure-borne noise in the area of pipeline attachment and in places where walls and ceilings pass through.

Skolan dB prevents the spread of noise

Skolan dB is a pipe system made of sound-absorbing material that is resistant to hot water. The system is suitable for use in sewer networks according to DIN EN 12056 and DIN 1986-100. Pipes and fittings are made of mineralized polypropylene. The special molecular structure and high material density of 1.6 g/cm³ (+/- 0.05) ensure the absorption of not only airborne but also structure-borne noise.

After the massive transition from cast-iron sewer pipes to plastic ones, a problem arose associated with increased noise in the operation of sewer networks.

Noise effects from the movement of drains in pipelines can adversely affect the microclimate in the house and cause inconvenience to residents.

To solve problems with excessive noise, you can use the so-called silent drainage system. Silent internal sewerage, included in the premium segment, is made of thick-walled polypropylene pipes with a special filler to reduce noise levels.

Pipeline installation: fastenings and slopes

High-quality installation of the pipeline cannot be carried out without indicating on the sewerage scheme the places and methods of fastening, as well as slopes. The slope angles are marked in places of forced stops. They provide arbitrary emptying of pipes, which is necessary during operation. The device of pipelines provides the following slope angles, changes depend on the transported medium (in degrees):

- gaseous medium: 0.002–0.003;

- liquid highly mobile substances - 0.002;

- acidic and alkaline environment - 0.005;

- substances of high viscosity or quickly hardening - no more than 0.02.

If the design does not provide for a slope, then the diagram must reflect how the pipes will be emptied. Also on the plan, it should be noted the places in the foundation where the bolts for the mounting supports will be located. Shifts during pipe installation must not be allowed.

It is important to take into account that the moving elements must be installed in such a way that it is possible to freely move the pipeline, for example, to extend

How to choose?

PVC is a material that, according to its physical and technical characteristics, is already a very good insulating material. Its sound-absorbing ability is well known, which is why there is no need to use additional sound insulation when installing plastic pipes. However, such a need may arise if it is necessary to reduce the severity of vibration. In this case, the place of contact of the pipe with the ceilings, regardless of what material is used, must be dressed in a special sleeve. The space between it and the pipe itself must be filled with sealant.

The first option is optimal. When the riser is made of cast-iron pipes, then it is possible to replace their individual parts with plastic, while fragments of the old pipe with crosses remain in place, and plaque inside these sections is removed by any means such as "Mole" or "Shumanit". Between them, pieces of PVC pipes are mounted. With this method, the basic building structures remain unaffected, and the work of replacing cast iron with plastic is greatly simplified, and the cost of such repairs is lower than if it were necessary to change the entire riser completely.

This method is also good "by sound", since in this case the pipe is divided into sections about 3-5 meters long. This leads to a sharp drop in the resonant islands in the spectrum of sounds, and the gaps between these very "islands" are wider than the resonant zone itself. Thus, the unpleasant sound is not only reduced, but also its character changes. From a psychophysical point of view, it becomes safe for humans. Another plus is that in case of breakage, one separate fragment can be easily replaced.

If the riser has already been replaced, it is not necessary to break it in order to install fragments of cast iron with crosses. A whole riser of PVC pipes is well insulated from resonant structures as follows:

- from the walls with special damping clamps;

- from overlapping with a polyethylene cup with polyurethane foam. In this case, it is by no means necessary to look for special cylinders on sale. In any store there is a large assortment of inexpensive "alternative" pipes for fan noise insulation, cuts of which with a larger diameter can be used as a glass. To do this, you need to cut it vertically and “fit” the pipe with it. It should be borne in mind that it is not recommended to fill the space between the glass and the pipe with anything other than PPU, since only polyurethane foam can reduce the level of sound waves.

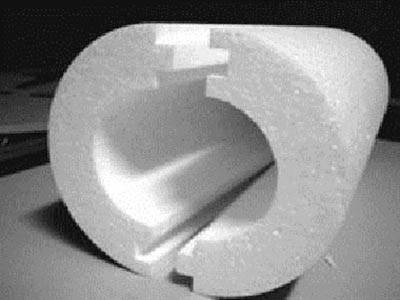

And finally, it makes sense to get rid of harmless "rumblings" and "gurgling". For this, the pipes are wrapped with a foam shell. It is quite easy to install. It should be fixed, snapped and fixed with construction tape. This method is ideal for a flat pipe. But if there are curved surfaces on the riser, then you should give preference to polyurethane foam, which takes any desired shape. It is more expensive, so some users purchase polyethylene foam, which has perfect sound insulation. However, this material is very short-lived, after one season it turns sour and, as a result, disintegrates.

An even bigger mistake is made by those who use mineral wool to improve sound absorption. To begin with, in accordance with current sanitary standards, this material is strictly prohibited for use inside residential premises.Because it releases microneedles into apartments, leading to skin diseases and problems with the respiratory system. And besides, mineral wool absolutely does not dampen infrasound, so its use is not only dangerous, but also pointless.

Mounting

Soundproofing sewer pipes is easy. Even a novice home craftsman will cope with this work, however, you need to know some installation technology features. There are three main methods of isolation, such as:

- the use of foam shells;

- using the installation of roll material;

- soundproofing by installing a drywall box.

For a residential building, a combination of the second and third methods is preferable. The pipes are first wrapped in roll material, and then the entire riser is “hidden” behind the box. To do this, you must perform the following steps:

prepare the pipes, make sure they are tight, so that later there is no unpleasant problem associated with leaks;

wrap pipes with any suitable roll material; a variety of options are offered for sale for every taste and budget;

make markings for the box on the wall, while it is important to keep in mind that its walls should be placed at least 5–7 cm from the sewer pipe;

install a profile along the marked lines using self-tapping screws or dowels;

- fasten the third profile from the wall to the floor;

- attach jumpers in increments of 40-50 cm from each other;

- drywall sheets must be attached to the finished box, while it is better to use its waterproof varieties. Be sure to provide a hole for arranging an inspection hatch;

- having screwed one side of the box, the resulting space should be filled with soundproofing material;

- sew up the box and finish the finish.

Insulation using roll material is quite simple:

- the necessary material is selected;

- the surface of the pipes is degreased;

- pipes are treated with vibration damping material, which is rolled with a roller;

- at the last stage, the pipes are wrapped with a roll coating, and adhesive construction tape fixes it on top.

Noise absorbing materials

If the sewer pipeline has already been installed, and the noise level during its operation is high, an additional insulating layer can be made. For this, various types of materials are used.

They should have good sound absorption properties. For this, polymer roll products are best suited.

Foamed polyethylene

In the process of its manufacture, polyethylene is mixed with a foaming agent, as a result of which the structure of the material changes. A lot of hollow cells are formed that are not connected to each other.

Insulating pipes made from this material can absorb sound waves. Vibration is the source of all noise. It occurs when water moves inside the line and is transmitted to the surface of the pipes.

Further propagation of a sound wave through a layer of foamed polyethylene is practically impossible. It begins to resonate in the air cells, which leads to its partial or complete attenuation.

Styrofoam

This material is widely used not only for sound absorption, but also as a heat insulator.Since it belongs to the group of solid polymers, it is necessary to purchase special composite boxes for installation.

They are easily mounted on an already installed pipeline, trimming can be done with a hacksaw or a knife. For each pipe diameter, it is necessary to purchase a box of the appropriate size.

Despite the increase in the purchase cost, compared to foamed polyethylene, the effect of installing foam boxes will be much greater.

Materials for soundproofing a sewer riser

Very dense materials can reflect sound - heavy concrete, silicate brick, pressed rubber and other analogues. It is inconvenient to use them in the bathroom.

"Extinguishing", noise absorption is calculated on the fact that around the pipe, with the closest possible fit to it, there is a layer of sound-absorbing material. This includes loose, friable and fluid substances, both dense liquid and sand can absorb noise. But taking into account the design features of the sewer, porous materials in the form of a “shell” or winding are convenient.

Soundproofing membranes and roll materials

To absorb and partially isolate the noise coming from engineering communications, the industry offers membranes with additional layers of protection from foamed rubber or polymers, as well as with a foil layer. Usually the material has an adhesive fastening, is pressed close to the pipe and wrapped around it so that the edges of the sheet converge not end-to-end, but with an overlap.

| Alufom R-TK | Material composition |

In fact, this material simultaneously performs the functions of thermal and sound protection.

In addition to the named material, you can use almost any roll materials for sound and heat insulation, for example, Zvukoizol, Folgoizol, Stopzvuk, Penofol, Energoflex, polyethylene foam.

Their effectiveness will depend on:

- composition, number and thickness of layers;

- mounting method - simple wrapping or mounting with glue, with a snug fit to the pipe (more efficient solution).

With a significant noise level, you can use two layers of the same material or a layer of different ones. For example, foamed polyethylene in two layers on glue and on top of a soundproof membrane in one layer (overlap).

The proposed master class shows a ready-made solution for soundproofing based on rolled foil material, suitable metallized adhesive tape and special ties for installation.

Shown here is a variant with independent cutting and fastening of rolled material with adhesive tape over the entire surface of the riser and adjacent areas.

Shell made of mineral wool or styrofoam

This type of sound insulation of the sewer riser in the apartment is selected clearly according to the diameter of the riser and requires additions to protect the joints and adjacent sections of the pipeline.

The pipe is enclosed in a "shell", connecting the halves of the hollow cylinders with a special adhesive edge (pictured above) or adhesive tape. The installation of such insulation is shown in the video, however, the efficiency of the system for sound absorption is not too high - heat losses are much better removed.

Soundproofing a sewer riser with a box

In this case, the rigid structure performs two functions - it serves as an additional barrier to the penetration of noise and gives an aesthetic appearance to communications.If a bulk noise absorber is used, the third function of the duct is to limit the specified volume for the filler.

Creating a box of drywall or similar sheet rigid materials is discussed in detail in the article "How to close the pipes in the toilet." At the same time, if it is necessary to make a duct only for a sewer riser, it is advisable to use a variant with a reduced cross section of the structure.

The soundproofing itself is carried out using mineral wool or specialized materials, for example, Knauf Acoustic wool. After that, a box is mounted - it will protect the loose winding from mechanical influences and hide its unsightly appearance. The installation process of the box is discussed in detail in the video.

Backfilling bulk materials into a box is a rarely used method. In this case, sand, sawdust, expanded polystyrene granules and other similar materials are used as a noise absorber.

It is important to understand that the revision and repair of the riser in this case is very difficult, and the appearance of a leak may not be noticed in a timely manner.

This method of soundproofing a sewer riser with your own hands in an apartment is not very appropriate, it is more suitable for a private house.