- Petrol generators up to 7 kW

- Huter DY6500L

- CHAMPION GG6500

- Makita EG6050A

- Operating characteristics

- The design and principle of operation of generators

- How to choose a generator for a gas boiler

- Minimum required power

- Synchronous or asynchronous

- Voltage

- Frequency

- The presence of a through neutral

- Other criteria

- Room preparation

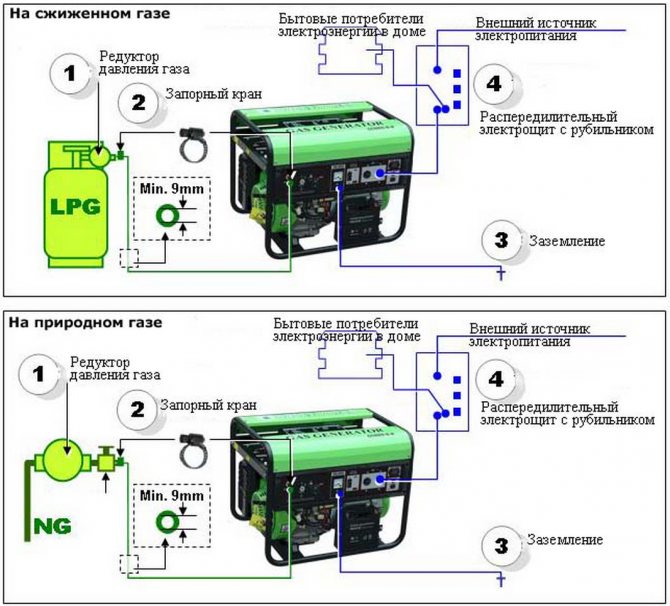

- Connecting the gas generator to the main gas

- Conclusion

- Overview of manufacturers of boilers with a generator

- Why the boiler does not work from a generator

- 6. Champion 3400W Electric Start Dual Fuel Portable Inverter Generator

- Which generator to choose for a heating boiler: gasoline, diesel or gas?

- Inverter generator for heating boiler and its advantages

- What to choose: a household generator or an inverter for a boiler?

- Why does the boiler go out when the light is turned off

- What are gas generators

- Criterias of choice

- Varieties of gas generators

- What power is needed?

- 7. WEN DF475T 4750W 120V/240V Dual Fuel Electric Start Portable Generator.

- Conclusions and useful video on the topic

Petrol generators up to 7 kW

Huter DY6500L

The four-stroke Huter 188f OHV engine, which is equipped with this gasoline unit, has a carburetor power system. It is started by means of both a manual and an electric starter.

Very important: Before each start-up, the oil level must be checked and replenished if necessary. Machine Features:

Machine Features:

- maximum power - 5 500 W;

- active power - 5000 W;

- engine - 13 hp;

- cooling - air;

- phases - 1 (220 V);

- number of cylinders - 1;

- tank capacity - 22 l;

- generator - synchronous;

- noise - 71 dB;

- muffler - available;

- sockets - 2 (220 V), a pair of terminals 12 V;

- battery life - 10 hours;

- weight - 73 kg.

You can use the unit to maintain the performance of lighting systems, but only within acceptable limits. As a backup source, it is used in medical, children's institutions, offices and at home.

CHAMPION GG6500

This gasoline single-phase power plant is manually started. It can provide uninterrupted power supply to construction sites, small industries, country houses. You can take it on trips. The maximum total connection power is 5,500 W at 220 V. Gasoline consumption is 3.33 l / h at full load. Tank volume — 25 l. Battery life - 10 hours.

The output voltage is highly accurate. The nominal value of the unit is 5,000 W. The generator is synchronous, two-pole, self-excited. There is protection against excessive loads. The unit weighs 73 kg. The noise level is very low.

Makita EG6050A

The gas generator is equipped with a four-stroke single-cylinder engine with an overhead camshaft (OHV), a powerful AVR alternator that automatically stabilizes the voltage. The engine is started by means of an electric starter or manually. When the oil level reaches a critical value, the sensor automatically turns off the engine.

The unit generates both alternating current 230 V at a frequency of 50 Hz and direct current 12 V.

| Parameter | Unit measurements | Meaning |

| Engine | 190F | |

| Pa | Tue | 6 000 |

| Engine volume | cm3 | 420 |

| PN | Tue | 5 500 |

| Tank capacity | l | 25 |

| Number of outlets: Alternating current Direct current | PCS. PCS. | 2 1 |

| The amount of oil in the crankcase | l | 1,1 |

| The weight | kg | 100,5 |

| Producing country | Japan |

Operating characteristics

Evaluating the performance when choosing a generator will help you choose the one that suits you for all the electrical appliances turned on at the same time. The energy generated by the generator should be enough to provide the electrical appliances you listed with a surcharge of 20% in order to avoid emergency situations.

Petrol generators with different performance characteristics

Petrol generators with different performance characteristics

More general selection:

- Up to 1.5 kW - suitable for portable use.

- 2-5 kW is the average, most popular option for providing energy to a small or medium-sized country house.

- 5-15 kW - gas generators for use in medium and large cottage houses.

- More than 15 kW - for mini-production and cottages with a large amount of electrical equipment.

When selecting a generator, it is worth considering that the above parameters represent the rated power of the generator, but not the maximum. If the maximum indicator is exceeded, the operation of all devices will last several minutes at best.

The design and principle of operation of generators

The main structural elements and components of the generator:

1. Frame - a steel structure, inside which all other nodes are attached.

2. An internal combustion engine is a source of mechanical energy.

3. Generator (alternator) - a converter of mechanical energy into electrical energy.

The alternator converts the mechanical energy of the rotating shaft of the electric motor into electrical energy.

Its main elements:

- Fixed stator, consisting of a core and a winding;

- Movable rotor (electromagnet) located inside the stator;

- The motor shaft rotates the rotor, causing changes in the magnetic field of the stator, an induction current occurs.

The method of transferring the magnetic field to the stator windings depends on the design of the alternator, which can be:

1. Synchronous - using brushes (brushes - sliding contacts on the rotor).

2. Asynchronous (brushless) - the residual magnetization of the rotor is applied to the stator.

How to choose a generator for a gas boiler

Minimum required power

The first thing you should pay attention to, having decided on the type of fuel used and the presence of an inverter, is the power of the generator. Calculating the power of the generator is simple: it is equal to the total starting and operating power of all connected devices

It is also recommended to lay a margin of 20-30%.

The required power to ensure the operation of a gas boiler is indicated in its operating instructions as electricity consumption or power consumption (section of technical characteristics). Usually these are small values \u200b\u200bof the order of 120-180 watts. Approximately the same amount (on average 150 W) is consumed by the circulation pump, if any, and approximately the same amount is consumed by the turbine in turbocharged boiler models.

In total, if only a gas boiler is connected to the generator, the minimum required power = 120-180 + 150 + 150 + 20-30% = 504-624 W or 0.5-0.62 kW.

Synchronous or asynchronous

| Synchronous | Asynchronous |

| The voltage value and its frequency are maintained stably and with high accuracy | The voltage value and frequency change in a relatively large range |

| Vulnerable to electrical overloads at start-up and in set mode | Resistant to electrical overloads at start-up and in set mode |

| More expensive, more complex design and higher maintenance requirements | Cheaper, simpler and more reliable, low maintenance |

Synchronous generators are an excellent solution when ultra-accurate current characteristics are needed, and the network often experiences severe voltage fluctuations. In the case of a limited budget, a conventional asynchronous generator is sufficient; you can protect the operation of the heating system from voltage surges in the domestic power supply network using a stabilizer (or an inverter-type generator, where it is already installed) and a UPS (uninterruptible power supply).

Voltage

Voltage fluctuations can affect the boiler electronics. For expensive models of gas boilers with multifunctional automation, it is better to take care of the quality of the voltage coming out of the generator.

Frequency

As a rule, volatile gas boilers are designed for a frequency of 50 Hz, which is indicated in the operating instructions for the model. Almost all generator models (with the exception of more powerful industrial ones) are designed for a frequency of 50 Hz. If the frequency is different, the boiler controller will fail.

The presence of a through neutral

There are phase-dependent and phase-independent gas boilers, as indicated in the instructions.

If phase-independent models of boilers do not cause any difficulties, then for the normal operation of phase-dependent boilers, it is necessary to have a through neutral or virtual zero. Most generator models do not have a pronounced phase.In this case, it is necessary either to select a generator with a clear phase and zero, or to connect the generator through a transformer. There is also experience in accepting a terminal with a high potential for grounding as a phase.

Other criteria

Having decided on the main technical criteria, you can pay attention to:

- run time - conventional household generators cannot run continuously 24/7 because the engine needs cooling breaks. If larger models can often work for 12-16 hours or more, then compact gasoline models weighing up to 10 kg are limited to 3-5 hours of continuous operation;

- start method - there are models with manual and automatic start. The latter are more convenient, able to provide absolute autonomy of the heating system, but autostart is used mainly on more expensive and powerful models;

- noise level - depends on the operating speed of the engine, the possibility of adjusting the power and the presence of sound insulation. Usually, compact, low-power gasoline generators have a soundproof casing.

Room preparation

Most often, the installation of gas generators takes place in the basement, boiler room or other suitable room in the house. Operation of the system is allowed at positive temperature.

The room where the gas generator will operate must meet all the requirements for boiler rooms:

- Room volume - from 15 cubic meters;

- The room must be equipped with forced ventilation;

- Exhaust fumes from the generator must be vented outside. For this, a special gas pipe made of metal is used. It is put on the exhaust pipe, fixed with a clamp and taken to the street;

- It is forbidden to install gas generators operating on liquefied fuel in basements and other underground premises.

Requirements for the power system

Electric generators using various types of gas may have a number of requirements for fuel and gas pipeline:

- Gas generators operating on natural main fuel. Regardless of real overloads, such devices require a certain gas pressure inside the main network. The optimal value is at the level of 1.3-2.5 kPa. Gas is supplied to the generator at a pressure of 2-6 kPa. A valve is installed at the tie-in section into the main gas pipeline, if necessary, shutting off the gas flow for the power plant.

- Gas generators using liquefied fuel during operation. The main pressure should not go beyond the range of 280-355 millimeters of water column. The requirements for gas pressure are similar to those for natural gas. If a cylinder is used to power the gas generator, it must be equipped with a valve, in addition to this, a pressure regulator or a reducer.

- There are other requirements for the connection scheme:

- A gas generator equipped with a manual start must be used.

It is unacceptable that the inlet pressure of the flow regulator be higher than 1.6 MPa.

Connecting the gas generator to the main gas

The main or bottled gas can serve as a power source for gas generators. It is relatively easy to connect the device to a gas cylinder, and with certain knowledge, all work can be done by hand. There is no need to obtain any permissions.

Before connecting the gas generator to the main network, it is necessary to carry out preliminary coordination with the gas supplier. A list of specific actions can be seen in the regulatory documents that are valid today. The owner of the generator must have a certificate for its purchase, as well as a technical passport for the device.

In the process of coordination with the necessary authorities, a number of important issues are resolved:

- Making the required corrections and additions to the technical project.

- Development and conclusion of a legal agreement between the consumer and the supplier of the generator for the maintenance of the gas unit. The service price is determined separately.

- Development and signing of a tripartite agreement on the division of responsibilities and duties. Each of the parties - the seller of the device, the buyer, as well as the gas service, are solely responsible for their part of the work.

According to the current rules, in the process of connecting the electric generator, some documents will be needed:

- Technical passport of the gas power generator, issued at the time of purchase of the device.

- Certificate of conformity

- If the operation of the gas generator is planned at high-risk enterprises, the technical supervision department issues a separate certificate authorizing the installation of the unit.

Conclusion

In most cases, installing a gas generator indoors will eliminate the problem of power outages.

First of all, you need to decide what exactly the gas generator is for. If frequent shutdowns of the main power supply are not planned, the connection of the unit to the main gas pipeline is not required, bottled gas can be dispensed with. You don’t have to go through the authorities, coordinate, seek permission.It is enough to follow the instructions attached to the specific model of the gas generator.

At the same time, if you want to ensure a completely uninterrupted supply of electricity, it makes sense to use a gas generator connected to the main line and equipped with an autostart function. In this case, contact with the local gas service is inevitable.

Overview of manufacturers of boilers with a generator

Let's consider specific examples of domestic boiler systems that exist today, in which the principle of using exhaust gases (combustion products) for generating electricity has been successfully implemented. The South Korean company NAVIEN has successfully implemented the above technology in a HYBRIGEN SE boiler.

The boiler uses a Stirling engine, which, according to the passport data, generates electricity with a power of 1000W (or 1kW) and a voltage of 12V during operation. The developers claim that the generated electricity can be used to power household appliances.

This power should be enough to power a household refrigerator (about 0.1 kW), a personal computer (about 0.4 kW), an LCD TV (about 0.2 kW) and up to 12 LED bulbs with a power of 25 W each.

Navien hybrigen se boiler with built-in generator and Stirling engine. During the operation of the boiler, in addition to the main functions, electricity is generated on the order of 1000 W of power.

Of the European manufacturers, Viessmann is engaged in developments in this direction. Viessmann has the opportunity to offer two models of boilers of the Vitotwin 300W and Vitotwin 350F series to the customer's choice.

The Vitotwin 300W was the first development in this direction.It has a fairly compact design and looks very similar to a conventional wall-mounted gas boiler. True, it was during the operation of the first model that the "weak" points in the operation of the engine of the Stirling system were identified.

The biggest problem turned out to be heat dissipation, the basis of the operation of the device is heating and cooling. Those. developers faced the same problem that Stirling faced in the 40s of the last century - efficient cooling, which can only be achieved with a significant size of the cooler.

That is why the Vitotwin 350F boiler model appeared, which included not only a gas boiler with an electricity generator, but also a built-in 175l boiler.

The storage tank for hot water is made in the floor version due to the large weight of both the equipment itself and the liquid prepared for sanitary purposes

In this case, the issue with the problem of cooling the Stirling piston using water in the boiler was effectively resolved. However, the decision led to the fact that the overall dimensions and weight of the installation increased. Such a system can no longer be mounted on the wall like a conventional gas boiler and can only be floor-standing.

Viessmann boilers provide for the possibility of feeding the boiler operation systems from an external source, i.e. from the central power supply networks. Viessmann positioned the equipment as a device that provides for its own needs (operation of boiler units) without the possibility of extracting excess electricity for domestic consumption.

The Vitotwin F350 system is a boiler with a 175l water heating boiler. The system allows you to heat the room, provides hot water and generates electricity

In order to compare the efficiency of using generators built into the heating system. It is worth considering the boiler, which was developed by the TERMOFOR companies (Republic of Belarus) and the Krioterm company (Russia, St. Petersburg).

It is worth considering them not because they can somehow compete with the above systems, but to compare the principles of operation and the efficiency of generating electrical energy. These boilers use only firewood, pressed sawdust or wood-based briquettes as fuel, so they cannot be put on a par with models from NAVIEN and Viessmann.

The boiler, named "Indigirka Heating Stove", is oriented to long-term heating with wood, etc., but is equipped with two thermal electricity generators of the TEG 30-12 type. They are located on the side wall of the unit. The power of the generators is small, i.e. in total they are only able to generate 50-60W at 12V.

The fundamental device of the Indigirka stove allows not only to heat the room, but also to cook food on the burner. Complementing the system - two heat generators for 12V with a power of 50-60W.

In this boiler, the Zebek method, based on the formation of an EMF in a closed electrical circuit, has found application. It consists of two dissimilar types of material and maintains contact points at different temperatures. Those. developers also use the heat generated by the boiler to generate electrical energy.

Why the boiler does not work from a generator

In practice, it often happens that the appliances are working, the refrigerator, the TV, but the boiler does not want to start.Theoretically, it is enough to correctly power the boiler from the network and the heating process will start. This may not happen for the following reasons:

- The gas boiler must be in good condition. Mains voltage 190 - 250V.;

- If there is a stabilizer for the mains, the boiler is powered directly bypassing the stabilizer;

- The generator has its own AVR regulator, so the joint operation of two stabilizers may cause conflict;

- Phase-dependent boilers must be connected "0" to the ground. Create high-quality grounding;

- Monitor the correctness of the scheme for connecting the boiler to the mains;

- It is enough to turn on the semiautomatic device on the generator in order to automate its operation and exclude counter switching on;

- Before connecting the generator to the boiler, you must first know "o" and close it to the ground.

6. Champion 3400W Electric Start Dual Fuel Portable Inverter Generator

Another hugely popular Champion generator is larger than a conventional inverter generator, but with more power and propane capability.

Dual-fuel inverter generators are not common, but they are great for transportation and noise reduction, so this model is worth considering if you can afford it. With over 3000 watts, this model is very close in power to much larger generators.

Despite the small fuel tank, this inverter still has a decent runtime of over 7 hours on petrol and more impressively over 14 hours on a propane tank. You can also get double the power by connecting a second inverter.

Convenient electric start with 3-position ignition switch - battery included, plus quick access panel allows you to access all controls in one place. Noise level: 59 dBA. Frequency 60 Hz

Pros and cons

PROS:

Compact design with good capacity

Relatively quiet

Long run time on propane

Possibility of parallel connection

MINUSES:

High price

Which generator to choose for a heating boiler: gasoline, diesel or gas?

The advantages of using a generator are obvious. Such equipment is economical in operation, does not require additional costs, is reliable, and most importantly, ensures uninterrupted operation of the boiler. How to choose a generator for the boiler? It is worth studying the distinctive features of such devices, which differ depending on the type of fuel used:

- Gas generators

– . Natural and liquid gas can be used as fuel. The advantages of such a system are its environmental friendliness, the absence of additional costs and the need for refueling (when connected to a gas pipeline). - Diesel generators for heating boilers

-, because its motor resource is almost 2 times higher than that of similar models running on other types of fuel. In operation, such devices are quite profitable, which is also a definite plus, because fuel consumption is almost a third lower than that of the gasoline version. - Gasoline generators for the boiler -

, which is widely demanded due to its low price and small size. The design is easy to move from place to place, which is convenient.

The principle of operation of any generator is quite simple.The fuel is burned in the internal combustion engine, and the energy obtained as a result of this process is converted into electric current. According to the type of generated electric current, there are single- and three-phase models, but the second option is a universal solution, and therefore more common.

Inverter generator for heating boiler and its advantages

Separately, it is worth considering an inverter generator for a boiler, the key difference of which from standard equipment is the use of an inverter system and

This made it possible to ensure the generation of high quality electricity and obtain an accurate sinusoid, which is especially important if a boiler with a sensitive automatic system is installed.

The cost of such equipment is quite high, but all the costs more than pay for the following advantages:

- Compactness - the small size and light weight of the device make it easy to move it from place to place if necessary. This allowed to significantly expand the scope of such equipment.

- Lack of noise - the operation of the boiler from the generator does not create additional inconvenience, because all sounds are effectively eliminated by special silencers.

- A minimum of operating costs is one of the main advantages of such a system. A high level of efficiency can be achieved by precisely matching the load and engine speed.

- Durability - such a mechanism is reliable and designed for a long period of active operation, which makes such an acquisition really profitable.

- The output will be a pure sine wave.

An inverter generator for a heating boiler is a compact power plant, thanks to which the equipment will work in standard mode, despite power outages. If we evaluate the benefits of acquiring such a device, taking into account its price, it is worth considering that buying a new boiler will cost much more. And there is no doubt that it will be required - constant power outages can disable even the most reliable automation, it's only a matter of time. Therefore, saving on the purchase of an inverter is simply not practical.

What to choose: a household generator or an inverter for a boiler?

Which boiler generator do you prefer? The answer to this question depends on what requirements apply to the future device. If power outages occur quite rarely and last for short periods of time, then you can save money and purchase a gasoline generator. It is much cheaper than analogues and is characterized by mobility.

A diesel generator will cost an order of magnitude more expensive, but its purchase is relevant if problems with power outages are by no means uncommon. In this case, it is more profitable to pay more, but to get confidence that the heating system will function in any conditions.

If the house is gasified, then it is beneficial to use a gas generator for gas boilers, once and for all forgetting about the need to refuel the system with fuel.

A significant advantage of the inverter system is that it allows you to provide an autonomous power supply without significant additional costs. You can buy an ordinary household generator, but an inverter is an order of magnitude more reliable, safer and more productive.In addition, taking into account the costs of operation, such equipment is cheaper as a result. Don't buy a cheap generator. This is the first barrier to the reliable operation of the boiler.

Why does the boiler go out when the light is turned off

In the event of power outages or breakdowns in the electrical network, the boiler automation is unable to perform its functions and immediately turns off the burner. This is ensured by the very design of the gas valve: it is pressed by the current passing through the coil.

If there is no current, it closes immediately.

Power outages, unfortunately, are not uncommon for Russia. So the owners of the boilers have to sit in a cold house, although gas may be present in the line. It cannot be ignited without electricity, and interference with the boiler device can lead to a fine from the technical supervision authorities, as it leads to violations of fire safety.

What are gas generators

The main difference between different gasoline power plants is the power they are capable of producing. The power of a gas generator is calculated in kilowatts. The size of the generator also depends on the power of the generator. The smallest gas generators are light and can be carried with one hand. They put out several hundred watts of power. Such generators are not suitable as a full-fledged power source for the home, and can only power one or two appliances. Medium-sized generators produce 2-5 kilowatts of energy. Such generators are enough to fully supply the premises with electricity. Power is comparable to that supplied from a conventional network. Such generators consume a lot of fuel, are large in size and heavy.Many manufacturers make generators with a frame and wheels to make them easier to transport. The most powerful generators are designed to provide electricity to large rooms like workshops. They are bulky and heavy, consume a lot of fuel and are completely unsuitable for home use.

The main difference between different gasoline power plants is the power they are capable of producing.

Engines of different gasoline power plants differ in tact. There are two-stroke and four-stroke engines on sale. The first ones are less reliable powerful ones, they give out energy up to one kilowatt. Designed for occasional use solely as a backup power source. With constant use, they wear out quickly. Four-stroke engines are more powerful and more stable. They are many times better than two-stroke and are more practical and durable. Suitable for serious tasks.

Gasoline generators have different types of generator devices. There are asynchronous and synchronous generators. Synchronous generators are preferable, since during their operation there are fewer power surges, which reduces the risk of failure of some electrical devices. Such generators are ideal for home use, but they have a significant drawback - they are sensitive to the external environment: moisture, cold and dampness. Asynchronous generators are bad with jumping voltage, but they are made in a sealed case, which is why they can be used in harsh conditions: in rain, severe frost and snowfall.

Separately, it is worth mentioning inverter gasoline generators.These are generators that are distinguished by stable voltage, compactness and better performance (quiet, emit less harmful fumes). Such generators are primarily used to power servers, computers and other electronic systems, but they can also be used for domestic purposes, if they are not confused by the relatively high cost.

Inverter gas generator

Criterias of choice

To purchase a suitable gas generator for a gas boiler, you need to take into account a number of factors related to the quality of the power supply system, the characteristics of the heat generating device and pumps that promote the circulation of the coolant. Among all the characteristics of the gas generator, it is imperative to pay attention to the parameter of the permissible mode of its operation, taking into account at the same time the frequency and duration of switching on the device

However, the optimal solution for a particular boiler will be selected only after determining all the criteria for equipment that produces electricity and runs on gasoline:

Among all the characteristics of the gas generator, it is imperative to pay attention to the parameter of the permissible mode of its operation, taking into account at the same time the frequency and duration of the device. However, the optimal solution for a particular boiler will be selected only after determining all the criteria for equipment that produces electricity and runs on gasoline:

- Dimensions depending on the area of the room in which the installation of the unit is planned. With a decrease in the size of the device, its price increases.

- Power depending on the same parameter of the gas boiler and other connected devices.

- The quality of the output current, since imported boilers have an increased sensitivity to this characteristic. Therefore, for such models, it is necessary to choose a device that produces a stable voltage of the required parameters.

- The degree of noise, which in conventional gasoline generators is from 50 to 80 decibels. The noise level of inverter gas generators is much lower.

Cost is also an important parameter. It is not recommended to purchase cheap equipment, as in most cases it will be of poor quality. Therefore, the probability of failure not only of the boiler, but also of other devices used to heat the facility increases.

Varieties of gas generators

Gasoline generators for boilers differ from each other in the number of engine cycles. There are push-pull devices, characterized by small dimensions and affordable price. Four-stroke units are also produced. This type of device is economical and more reliable.

Gasoline generators also differ in engine design:

- Asynchronous devices, characterized by the absence of windings. This simple design ensures the reliability of the engines. They do not tolerate power surges and have a significant sensitivity to starting loads.

- Synchronous devices, characterized by a more complex design and good resistance to inrush currents. Their rotors have an excitation winding. It is powered by direct current, which allows you to create a magnetized rotor, which is equipped with collector rings. At the same time, the gas generator for gas boilers itself has contact brushes. However, they differ in a short operational period.Although modern models of gasoline generators are produced without brush mechanisms. This design allows synchronous devices to adapt to the load, as it were. As a result, they manage to stabilize the output voltage.

Gasoline generators for boilers using gaseous fuel also differ in how they are turned on. There are models with manual and automatic start. Disabling them is done in the same way.

What power is needed?

The choice of a gas generator always begins with the calculation of the power of the device. It must be taken with a margin of 20 to 30%. To determine the required value, it is necessary to add up the operating and starting powers of those devices that will be powered by a gasoline generator. In most cases, devices from 650 W to 2.5 kW are available to consumers.

A gas boiler is a modest consumer of electrical energy. When determining the power of the gas generator, it is also necessary to take into account the presence of a circulation pump in the heating system.

Its power is usually no more than 150 watts. About the same amount consumes turbocharging. It is also necessary to take into account the power of the electric ignition. It is approximately 120 watts at a time. As a result of simple computational processes, it turns out that a generator is required, the power of which is approximately 0.5 kW. This value must be increased by 20-30%.

7. WEN DF475T 4750W 120V/240V Dual Fuel Electric Start Portable Generator.

WEN consistently delivers quality low cost generators and this model is no different. It has decent power for a good run time of 11 hours on petrol and 7 hours on propane.

Relatively low cost despite the fact that it has an electric starter, folding handles, a fuel type switch. All of this comes with a 2-year warranty and affordable service.

The voltage can be easily changed from 120V to 240V, ideal for power tools and emergency backup power.

Pros and cons

PROS:

low cost

Easy to move

MINUSES:

Sockets with limited power

Conclusions and useful video on the topic

Features of choice and connection gas generator:

Recommendations for choosing a generator:

Recommendations for choosing an autonomous power plant by type of fuel:

Which type of generator start to prefer:

Having dealt with the main selection criteria and determined the total power of electrical appliances that will need backup power in the event of a power outage, you can begin to choose the best option. And our rating of generators, the most popular among buyers, will help you decide.

How often do you have power cuts and do you have a generator? If yes, then share your experience of its operation - in the feedback block you can leave comments and add a photo of your generator, as well as ask your questions to our experts and other site visitors.