- Choosing a generator for the boiler

- UPS requirements for gas boilers and their characteristics

- How to connect a generator

- Criterias of choice

- Varieties of gas generators

- What power is needed?

- Which generator to choose for a heating boiler: gasoline, diesel or gas?

- Inverter generator for heating boiler and its advantages

- What to choose: a household generator or an inverter for a boiler?

- Generator connection features

- Single-circuit heating boilers

- Components of single-circuit equipment

- Varieties of designs

- Advantages, disadvantages of simple devices

- Criterias of choice

- Components and materials for connecting the boiler

- Model overview

- Installation and Maintenance Recommendations

- Why does the boiler go out when the light is turned off

- Advantages and disadvantages of equipment

Choosing a generator for the boiler

For a gas boiler with an electronic control unit, it is preferable to purchase an inverter gas generator. Its price is noticeably higher than a simple one: 20-40 thousand rubles. against 5-7 thousand, but it provides sinusoidal voltage waveform and stable frequency and voltage. In the inverter generator, an unpretentious input rectifier and filter feed the inverter - a DC-to-AC converter with excellent quality.

Before buying a generator, you need to find out what kind of power the boiler and pumps, if any, require. In the simplest case, it is enough to connect the terminals of the gas generator to the boiler power plug and start the generator engine. Then you can fire up the boiler in the usual way.

When electricity appears, the generator can be turned off and switched to the mains.

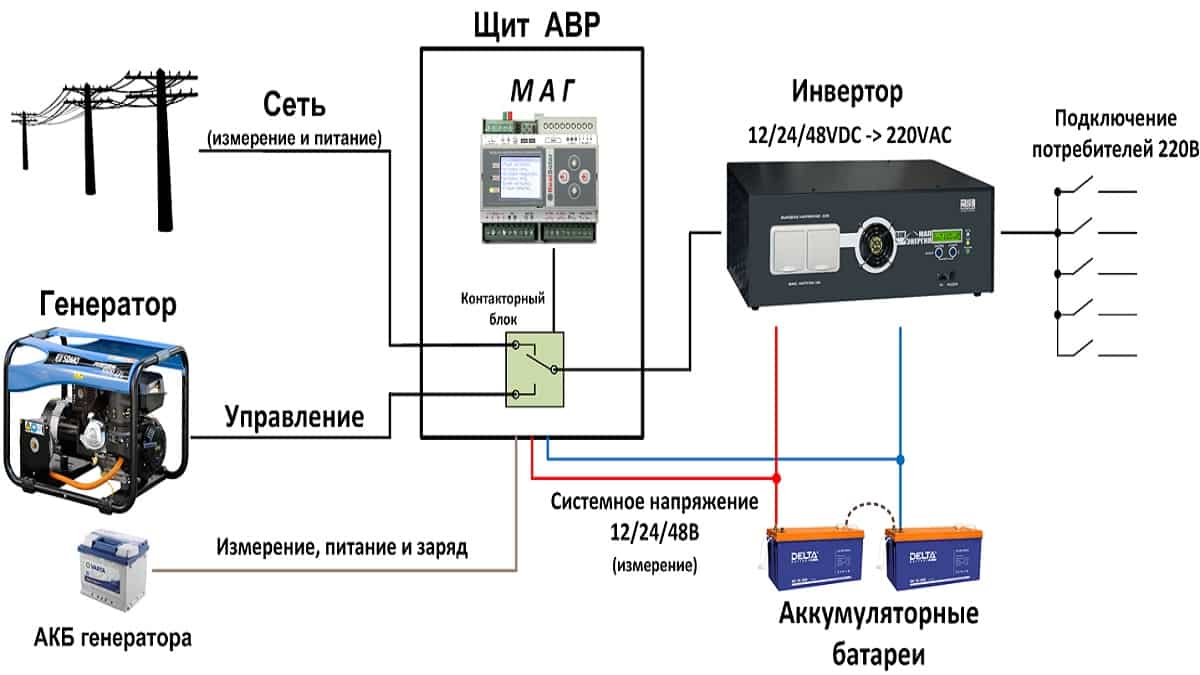

If the pumps in the system have three-phase motors, then the generator inverter must also be three-phase, and the boiler automation will be powered by one of the inverter phases. This applies to sufficiently powerful heating systems that heat medium-sized buildings and large cottages. Such a system should provide for uninterrupted power supply to boiler automation and pumps from an inverter that works together with the mains, through a bypass or even online. The generator is started in such systems to avoid too long discharge of the batteries.

The power of the purchased generator should be selected with a 30-50% margin of the power consumed by the boiler together with the pumps. This will reduce the load on the generator motor and ensure its longevity.

If the boiler can operate from a gas generator, but has a separate neutral and phase, that is, it is not connected with a plug to a socket, but is mounted with a cable into a switchboard, then a special generator connection scheme will be required, which excludes the simultaneous operation of the network and generator. A single-phase inverter generator can be connected to such a boiler in any way, i.e. both its terminals are equal in this case. RCD with this connection should work.

The table shows examples of some 220 V gas generators.

| Model | Power | Reliability | Noise | Price | Weight | launch | Fuel consumption | Working hours | Service | Reviews |

|---|---|---|---|---|---|---|---|---|---|---|

| DDE GG950DC | 625 W | 4 | 65 dB | 4400 rub. | 18.5 kg | manual | 0.72 l | 5.8 h | — | good |

| DENZEL DB950 | 650 W | 5 | 62 dB | 4800 rub. | 17 kg | manual | 0.7 l | 5 h | — | a great |

| FAVORITE PG950 | 950 W | 4 | — | 4990 rub. | 16 kg | manual | — | — | — | — |

| Most Power G800L | 650 watts | 4 | quiet | 5027 rub. | 17 kg | manual | 0.69 l | 4 h | there is | good |

| CHAMPION GG951DC | 650 W inverter | 4 | very quiet | 5250 rub. | 19 kg | manual | 0.65 l | 4.6 h | there is | a great |

| Hammer GNR800B | 600 W | 5 | quiet | 5990 rub. | 18 kg | manual | — | 8 h | there is | great reviews |

| DDE DPG1201i | 1 kW inverter | 4 | 58 dB | 6490 rub. | 12 kg | manual | — | 4.5 h | — | good |

| DDE DPG1201i | 1 kW inverter | 4 | 65 dB | 6610 rub. | 13 kg | manual | — | 5 h | — | normal |

| Eurolux G1200A | 1 kW | 4 | 75 dB | 6680 rub. | — | manual | 0.58 l | 9 h | there is | very stable |

| Caliber BEG-900I | 900 W inverter | 4 | 70 dB | 6590 rub. | 12 kg | manual | 0.52 l | 8 h | there is | works well, lightweight |

| Redbo PT2500 | 2.2 kW | 5 | — | 6990 rub. | 38 kg | manual | — | 14 h | — | — |

| Eurolux G3600A | 2.5 kW | 5 | 77 dB | 9002 rub. | — | manual | 0.8 l | 18 h | there is | a great |

| FAVORITE PG3000 | 2.5 kW inverter | 5 | — | 9620 rub. | 36 kg | manual | — | 13 h | there is | a great |

| Kolner KGEG 5500 | 5.5 kW inverter | 4 | 72 dB | 20493 rub. | 78 kg | manual | 1.6 l | 12 h | there is | good |

| CHAMPION GG650 | 5 kW | 5 | — | 22100 rub. | 77 kg | manual, starter | — | 13 h | there is | very reliable |

| Bort BBG-6500 | 5.5 kW inverter | 5 | 75 dB | 20750 rub. | 77 kg | manual, starter | 1.8 l | 12 h | there is | good |

| Daewoo Power Products GDA 12500E-3 | 10 kW, inverter, 220/380 V, 3 phases | 4 | — | 159000 rub. | 165 kg | manual, starter, auto start | 4.2 l | 5 h | there is | good |

| ENERGO EB 15.0/400-SLE | 12.6 kW, 220/380 V, 3 phase | 4 | 75 dB | 227700 rub. | 135 kg | starter, autostart (AVR) | 4 l | 6.2 h | there is | — |

| EUROPOWER EP16000TE (Honda) | 13 kW | 5 | 77 dB | 293791 rub. | 152 kg | starter, autostart | 5.1 l | 4 h | there is | good power plant |

| ENERGO EB 14.0/230-SLE | 11 kW, 220 V, 1 phase | 4 | 74 dB, with acoustic cover | 554480 rub. | 930 kg | starter, autostart | 3.9 l | 6 h | there is | — |

UPS requirements for gas boilers and their characteristics

When choosing a UPS for a boiler, you should familiarize yourself with their varieties. They are represented by two main types - these are offline and online UPS. Offline systems are the simplest uninterruptible power devices. They do not know how to stabilize the voltage, switching to batteries only when the voltage drops below a certain value - only in this case a stable 220 V appears at the output (the rest of the time, the UPS works as if in bypass mode).

Choose a UPS with a smooth sine wave, this will contribute to a more stable operation of your heating equipment.

The UPS for the online type boiler performs double conversion of electricity. First, 220 V AC is converted to 12 or 24 V DC. Then the direct current is again converted into alternating current - with a voltage of 220 V and a frequency of 50 Hz. In order to reduce losses, high-efficiency inverter converters are used in their design.

Thus, a UPS for a boiler is not always a stabilizer, while heating equipment likes a stable voltage. It also likes when the output is a pure sine wave, and not its rectangular counterpart (a square wave or a stepped approximation of a sine wave). By the way, cheap computer UPSs with a small capacity battery give a stepped sinusoid shape. Therefore, they are not suitable for powering gas boilers.

An uninterruptible power supply for the boiler, represented by a computer UPS, is also not suitable because the battery capacity is extremely small here - the reserve is enough for 10-30 minutes of operation.

Now we will look at battery requirements. When you come to the store to choose a good UPS for a gas boiler, do not forget to purchase a model with a plug-in type battery - it must be external, not built-in. The thing is that external batteries have a higher capacity, up to several hundred Ah. They have impressive dimensions, so they are not built into the equipment, but stand next to it.

Let's see how to choose a UPS for a gas boiler, focusing on the maximum battery life. Considering that accidents on the lines today are eliminated very quickly, and the maximum time for preventive maintenance is no more than one working day, then 6-8 hours of battery life is enough for us. In order to calculate how long an uninterruptible power supply for a gas boiler will work on a full charge, we need the following data:

- Battery capacity in ampere/hours;

- Battery voltage (can be 12 or 24 V);

- Load (indicated in the passport for the gas boiler).

Let's try to calculate how long the uninterruptible power supply for the boiler will work with a power consumption of 170 W from a battery with a capacity of 75 A / h and a voltage of 12 V. To do this, we multiply the voltage by the current and divide by the power - (75x12) / 170. It turns out that the gas boiler will be able to work from the selected UPS for more than 5 hours.And if we take into account the fact that the equipment operates in a cyclic mode (not constantly), then we can count on 6-7 hours of continuous power.

Table for selecting the battery capacity of an uninterrupted battery, depending on the power of the boiler.

When using low-power gas boilers and two batteries with a capacity of 100 A / h each and a voltage of 12 V, the battery life will be about 13-14 hours.

When planning to buy an uninterruptible power supply for a boiler, you need to pay attention to such a characteristic as charging current. The thing is that it should be 10-12% of the battery capacity

For example, if the battery has a capacity of 100 A / h, then the charge current should be 10%. If this indicator is less or more, then the battery will last less than it should.

Maintenance-free batteries can be charged at lower currents, but the time for a full charge will be quite long.

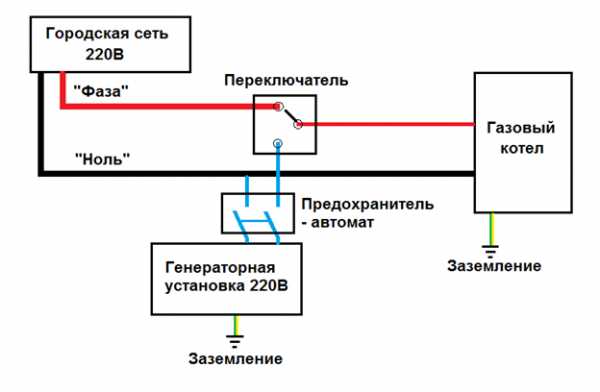

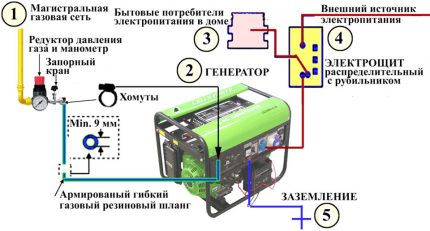

How to connect a generator

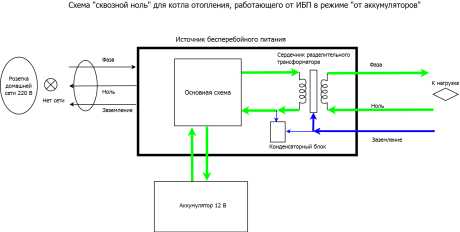

Improper connection of the gas boiler to the generator may result in the inability of the ionization electrode to distinguish the flame in the burner. The unit uses an ionization flame detector. When the air is ionized, the current begins to move between this flame sensor and the burner. In order for the flame to be correctly recognized, a "zero" is needed.

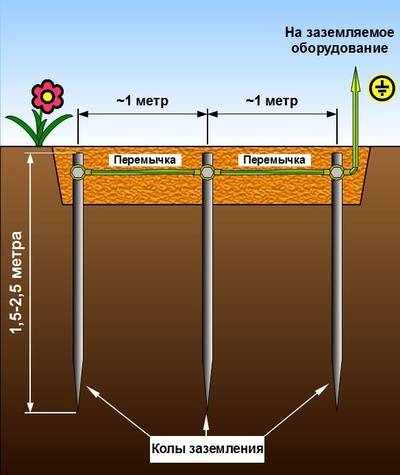

When connecting the gas generator to the boiler, the body is grounded. Based on the design features, most models show “zero”. Otherwise, one of the two contacts is taken as zero.

The boiler is grounded. This is necessary in order to achieve maximum electrical safety. In order to control the flame, the neutral wire must be connected to a protective earth. In the initial state, the network has a clear phase and zero.An isolated neutral generator has two equal outputs. For safety reasons, the generator case is also grounded. It is enough to connect it to a common conductor.

When combining any of the equal outputs of the generator with a special grounding conductor, clearly expressed zero and phase conductors appear on the unit.

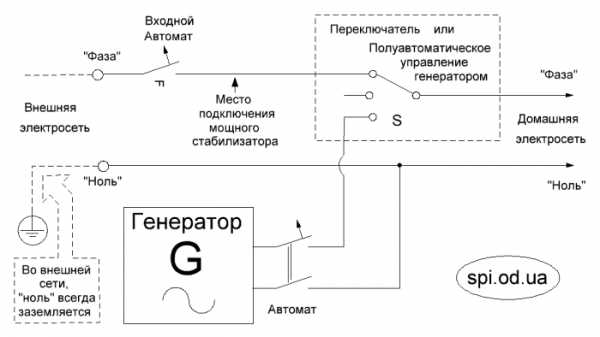

If the boiler does not start from the generator, it is necessary to check whether the gas generator is connected to the mains correctly. In addition, you need to check the serviceability of the operated gas boiler. Also, the mains voltage should not be allowed to exceed 250 volts. In some cases, the external power grid is normalized with the help of a special stabilizer. In this case, the gasoline generator is most often connected directly to the network, bypassing the stabilizer.

If the level of voltage generated by the gas generator is not enough for the operation of the gas boiler, you need to contact the service workshop. Very often, the design of the gas unit includes a built-in automatic voltage regulator. It must be borne in mind that when an external stabilizer is connected immediately after the gas generator, a conflict between both stabilizing systems is possible. This conflict must be avoided.

The centralized power grid always has a grounded zero. Thanks to this, the gas generator can be used without grounding work.

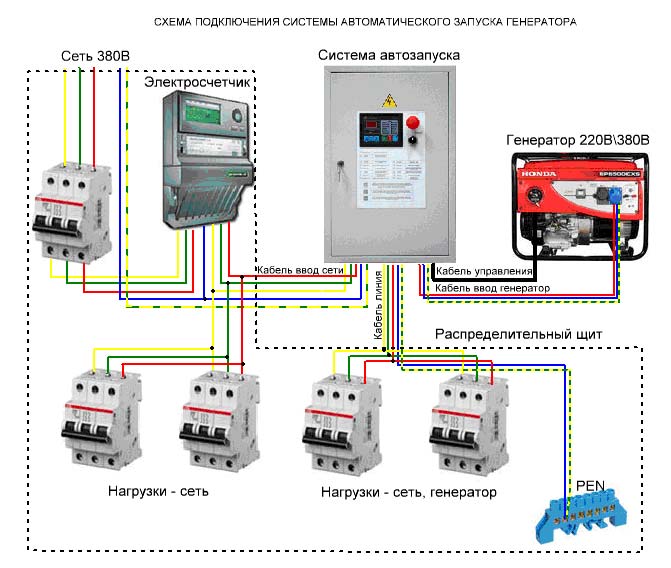

The manual phase switch can be replaced with automation. Automatic system control can provide complete automation of both the generator start-up procedure and a number of other functions. Counter-inclusion is completely excluded.

Before connecting the gasoline generator to the boiler, you must read the installation instructions. The definition of the scope, connection and further maintenance of the device is best entrusted to persons with the necessary qualifications.

In many private housing constructions, gas boilers are the main source of heat. However, for their effective operation, certain conditions are required. Most models of modern gas units are volatile. For them, their uninterrupted power supply is important.

According to statistics, in 85% of cases, the cause of boiler failure is unstable power supply. This is due to the fact that modern automation is extremely sensitive to significant power surges in the network. A stable voltage supply to the heating equipment can be provided by a gas generator for a gas boiler.

Criterias of choice

To purchase a suitable gas generator for a gas boiler, you need to take into account a number of factors related to the quality of the power supply system, the characteristics of the heat generating device and pumps that promote the circulation of the coolant. Among all the characteristics of the gas generator, it is imperative to pay attention to the parameter of the permissible mode of its operation, taking into account at the same time the frequency and duration of switching on the device

However, the optimal solution for a particular boiler will be selected only after determining all the criteria for equipment that produces electricity and runs on gasoline:

Among all the characteristics of the gas generator, it is imperative to pay attention to the parameter of the permissible mode of its operation, taking into account at the same time the frequency and duration of the device. However, the optimal solution for a particular boiler will be selected only after determining all the criteria for equipment that produces electricity and runs on gasoline:

- Dimensions depending on the area of the room in which the installation of the unit is planned. With a decrease in the size of the device, its price increases.

- Power depending on the same parameter of the gas boiler and other connected devices.

- The quality of the output current, since imported boilers have an increased sensitivity to this characteristic. Therefore, for such models, it is necessary to choose a device that produces a stable voltage of the required parameters.

- The degree of noise, which in conventional gasoline generators is from 50 to 80 decibels. The noise level of inverter gas generators is much lower.

Cost is also an important parameter. It is not recommended to purchase cheap equipment, as in most cases it will be of poor quality. Therefore, the probability of failure not only of the boiler, but also of other devices used to heat the facility increases.

Varieties of gas generators

Gasoline generators for boilers differ from each other in the number of engine cycles. There are push-pull devices, characterized by small dimensions and affordable price. Four-stroke units are also produced. This type of device is economical and more reliable.

Gasoline generators also differ in engine design:

- Asynchronous devices, characterized by the absence of windings. This simple design ensures the reliability of the engines. They do not tolerate power surges and have a significant sensitivity to starting loads.

- Synchronous devices, characterized by a more complex design and good resistance to inrush currents. Their rotors have an excitation winding. It is powered by direct current, which allows you to create a magnetized rotor, which is equipped with collector rings. At the same time, the gas generator for gas boilers itself has contact brushes. However, they differ in a short operational period. Although modern models of gasoline generators are produced without brush mechanisms. This design allows synchronous devices to adapt to the load, as it were. As a result, they manage to stabilize the output voltage.

Gasoline generators for boilers using gaseous fuel also differ in how they are turned on. There are models with manual and automatic start. Disabling them is done in the same way.

What power is needed?

The choice of a gas generator always begins with the calculation of the power of the device. It must be taken with a margin of 20 to 30%. To determine the required value, it is necessary to add up the operating and starting powers of those devices that will be powered by a gasoline generator. In most cases, devices from 650 W to 2.5 kW are available to consumers.

A gas boiler is a modest consumer of electrical energy. When determining the power of the gas generator, it is also necessary to take into account the presence of a circulation pump in the heating system.

Its power is usually no more than 150 watts.About the same amount consumes turbocharging. It is also necessary to take into account the power of the electric ignition. It is approximately 120 watts at a time. As a result of simple computational processes, it turns out that a generator is required, the power of which is approximately 0.5 kW. This value must be increased by 20-30%.

Which generator to choose for a heating boiler: gasoline, diesel or gas?

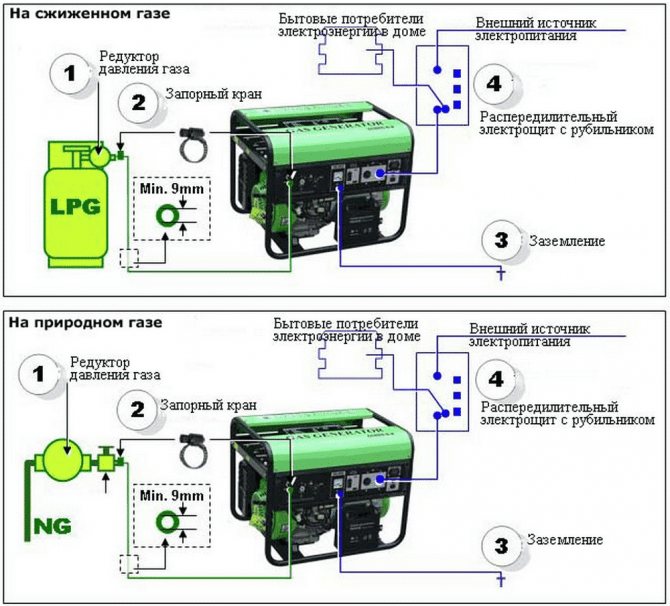

The advantages of using a generator are obvious. Such equipment is economical in operation, does not require additional costs, is reliable, and most importantly, ensures uninterrupted operation of the boiler. How to choose a generator for the boiler? It is worth studying the distinctive features of such devices, which differ depending on the type of fuel used:

- Gas generators

– . Natural and liquid gas can be used as fuel. The advantages of such a system are its environmental friendliness, the absence of additional costs and the need for refueling (when connected to a gas pipeline). - Diesel generators for heating boilers

-, because its motor resource is almost 2 times higher than that of similar models running on other types of fuel. In operation, such devices are quite profitable, which is also a definite plus, because fuel consumption is almost a third lower than that of the gasoline version. - Gasoline generators for the boiler -

, which is widely demanded due to its low price and small size. The design is easy to move from place to place, which is convenient.

The principle of operation of any generator is quite simple.The fuel is burned in the internal combustion engine, and the energy obtained as a result of this process is converted into electric current. According to the type of generated electric current, there are single- and three-phase models, but the second option is a universal solution, and therefore more common.

inverter generator for heating boiler and its advantages

Separately, it is worth considering an inverter generator for a boiler, the key difference of which from standard equipment is the use of an inverter system and

This made it possible to ensure the generation of high quality electricity and obtain an accurate sinusoid, which is especially important if a boiler with a sensitive automatic system is installed.

The cost of such equipment is quite high, but all the costs more than pay for the following advantages:

- Compactness - the small size and light weight of the device make it easy to move it from place to place if necessary. This allowed to significantly expand the scope of such equipment.

- Lack of noise - the operation of the boiler from the generator does not create additional inconvenience, because all sounds are effectively eliminated by special silencers.

- A minimum of operating costs is one of the main advantages of such a system. A high level of efficiency can be achieved by precisely matching the load and engine speed.

- Durability - such a mechanism is reliable and designed for a long period of active operation, which makes such an acquisition really profitable.

- The output will be a pure sine wave.

An inverter generator for a heating boiler is a compact power plant, thanks to which the equipment will work in standard mode, despite power outages. If we evaluate the benefits of acquiring such a device, taking into account its price, it is worth considering that buying a new boiler will cost much more. And there is no doubt that it will be required - constant power outages can disable even the most reliable automation, it's only a matter of time. Therefore, saving on the purchase of an inverter is simply not practical.

What to choose: a household generator or an inverter for a boiler?

Which boiler generator do you prefer? The answer to this question depends on what requirements apply to the future device. If power outages occur quite rarely and last for short periods of time, then you can save money and purchase a gasoline generator. It is much cheaper than analogues and is characterized by mobility.

A diesel generator will cost an order of magnitude more expensive, but its purchase is relevant if problems with power outages are by no means uncommon. In this case, it is more profitable to pay more, but to get confidence that the heating system will function in any conditions.

If the house is gasified, then it is beneficial to use a gas generator for gas boilers, once and for all forgetting about the need to refuel the system with fuel.

A significant advantage of the inverter system is that it allows you to provide an autonomous power supply without significant additional costs. You can buy an ordinary household generator, but an inverter is an order of magnitude more reliable, safer and more productive.In addition, taking into account the costs of operation, such equipment is cheaper as a result. Don't buy a cheap generator. This is the first barrier to the reliable operation of the boiler.

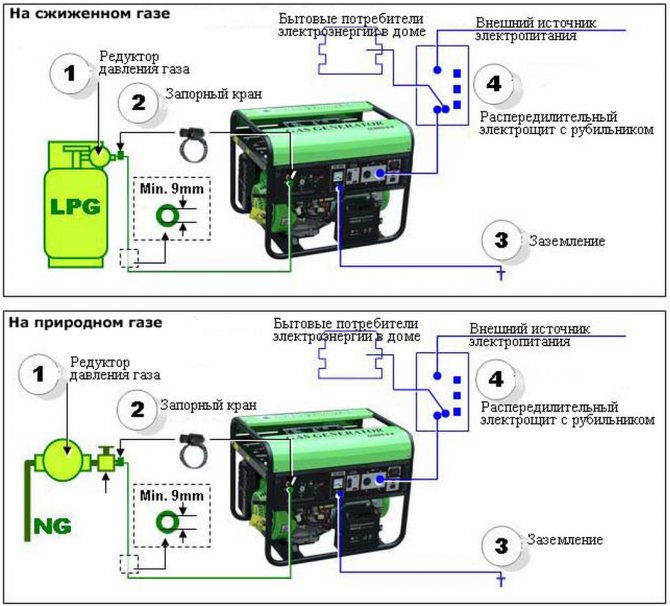

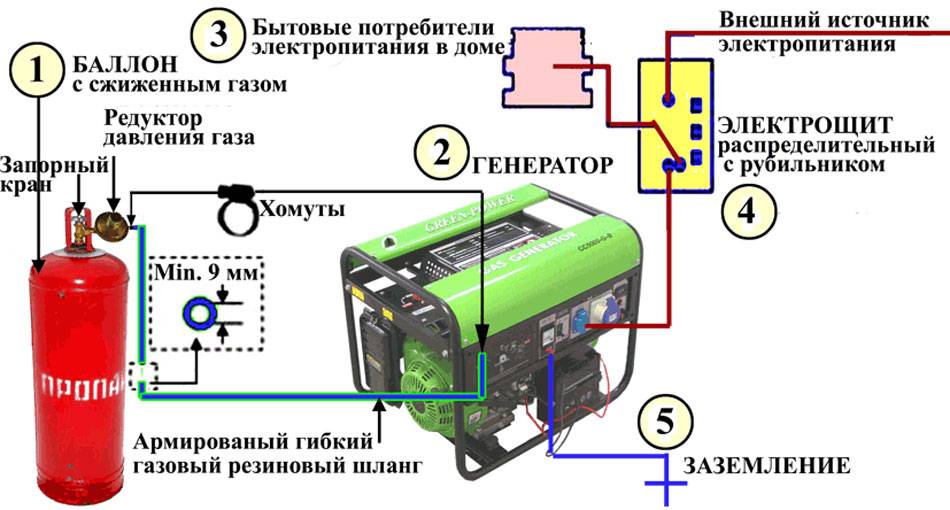

Generator connection features

It is important to remember: since the device functions as a result of burning fuel, care must be taken to exhaust the processed gases. A minimum of one meter of free space must be left around the generator in order to have access to the device for refueling, repair and manual start

Before connecting the generator to a gas boiler, you should read the instructions. Connection to the network is made in the switchboard, which is equipped with an automatic fuse.

Both networks must not mix. For connection, it is recommended to use a copper cable, the cross section of which depends on the power of the gasoline generator.

A prerequisite is to ground the boiler and generator. The boiler connection diagram presented by us with grounding

A prerequisite is to ground the boiler and generator. The boiler connection diagram presented by us with grounding

Grounding is carried out for safety reasons and for the appearance of a "zero", without which the flame recognition system will not function and the boiler will not turn on. If the generator is installed on the whole house, it is grounded through a common network.

In order for the operation of the boiler from the generator to be correct, the sinusoid of the output current is 50 hertz. Deviation from this value may cause problems with starting the boiler. A voltage stabilizer will help to cope with this difficulty.

The sequence of connecting the gas generator to the gas boiler:

- find the necessary contacts in the generator set and boiler automation (use the diagram in the instructions);

- connect the wires and isolate them;

- ground appliances.

Despite the simplicity of actions, it is better to entrust the connection to specialists.

Single-circuit heating boilers

The task of the unit, which has one circuit, is only to heat the premises, to create a comfortable temperature in them. To provide hot water, other equipment is attached to it - an indirect heating boiler. From the name it is clear that there is only one circuit in the device, therefore the principle of its operation is quite simple. Thanks to the fuel that has entered the combustion chamber, the coolant circulating through the pipes inside the device is heated. Its movement is provided either by a circulation pump (gas, electrical equipment), or a temperature difference (natural circulation in non-volatile boilers). To guarantee high-quality heating, water must circulate in the circuit constantly.

To organize hot water supply to a single-circuit unit, it is necessary to connect an additional circuit. As a rule, this role is played by a boiler. Connecting does not cause difficulties, but such a "tandem" has disadvantages. Connecting an additional circuit causes unstable operation of the boiler. The reason is the different amount of heat required to heat water: more of it is consumed in the morning and evening. Firstly, the boiler will have to be reconfigured, supplying more fuel. After the end of the period of maximum water intake, the device will start working again only for heating, which inevitably leads to excessive fuel consumption.

Components of single-circuit equipment

These structures include:

- fan;

- gas block;

- chimney;

- Control block;

- gas burner and heat exchanger combined with it;

- housing, control board with self-diagnostic sensors;

- thermostat, temperature sensor;

- three-way valve;

- circulation pump.

In non-volatile models, there are no devices powered by the mains. Their design is as simple as possible, but such devices are designed for areas where there is no power supply, so they cope with their work.

Varieties of designs

According to the place of installation, single-circuit boilers are divided into floor and wall-mounted.

- Floor-standing units installed either directly on the floor or on a stand. They are heavy weight and high power. Many models are equipped with the most efficient devices - cast-iron heat exchangers, the payoff for them is the greater weight of the structures. There are boilers that allow you to create a cascade connection, but they are intended for large buildings.

- Wall structures. These are compact devices that are usually attached to load-bearing walls. Since the weight of such models is very limited, wall-mounted boilers often do not have high power.

Single-circuit units are also classified according to the type of combustion chamber. It can be open or closed.

- Atmospheric - open. In this case, the air comes directly from the room, which must be equipped with an efficient ventilation system. Smoke extraction is ensured by natural draft in the chimney.

- Turbocharged - closed. In such models, air is taken in by a fan that blows air from outside. The same device creates the pressure necessary to remove the combustion products.

Models of single-circuit boilers may have other, additional functions.These include programming the operating mode, the possibility of remote control, which allows you to include equipment in the "smart home" system, etc.

Advantages, disadvantages of simple devices

The only function can be considered a minus, however, single-circuit equipment has advantages.

- Equipped with an automatic security system. It allows you to choose the optimal mode for operation, which means it can reduce fuel consumption.

- Variability. Single-circuit boilers allow you to create completely different heating distribution systems for rooms, which can significantly increase the life of the unit.

- The package of modern models includes air temperature sensors outside the home. Depending on their readings, the fuel supply is regulated, the temperature in the pipeline decreases or rises.

Simplicity, reliability of the design, high power and the absence of its losses during heat transfer, ease of control, adjustment of the unit - these are the advantages that become decisive for many. If water heating is not required for the needs of the family, then the lower price of single-circuit models is added to the list of pluses.

Criterias of choice

Considering that the main task that will be implemented through the generator has already been determined - connecting to heating equipment, half the work has already been done, since in order to complete this task it is necessary to choose a device that will provide a stable output voltage. Of course, it is best in this case to purchase a mini-power plant. However, this kind of equipment is much more expensive than low-power generators. But they also have a voltage regulator.

Watch the video, selection criteria:

If it was decided to buy a simpler model, then you should pay attention to the following parameters:

Power. The larger it is, the more productive the device will be, but at the same time, fuel consumption will also increase. It follows from this that it is necessary to select equipment with a sufficiently capacious fuel tank. Some users prefer to use a gasoline-gas generator, that is, a universal model. To implement such an undertaking, it will be necessary to slightly modify the design of the gasoline device.

The question is, why not immediately buy a gas model? The fact is that gasoline appliances have a number of advantages: low cost, ease of maintenance, relatively low level of noise emitted during operation, ease of transportation. Therefore, this option is preferable, besides, it is quite easy to make a gasoline-gas autonomous generator out of it.

Thus, the operation of a gas boiler from an autonomous gas generator can be a way out of the situation if power surges are regularly observed or emergency situations occur with a power outage. But with all the positive aspects of this solution, it is not always possible to implement it, especially if the simplest generator is chosen.

Components and materials for connecting the boiler

As mentioned above, some users after purchasing a gasoline device, using a special kit, modify the original design. This allows you to significantly save fuel (up to 40%). Therefore, this tactic is very common. To get a gasoline-gas autonomous generator at the output, you must perform the following steps:

- Replace the gasoline jet with a gas jet, both elements differ in the diameter of the hole - the last option has a smaller one;

- Install "mixer";

- Install a gas reducer for a universal gas generator.

The result is a more advanced device that will still be reliable in operation, but at the same time will save on costs, since the generator for the boiler is operated on an ongoing basis.

Model overview

Focusing on the power and reliability of the engine, you can pay attention not to the Vepr ABP 4.2-230 Vx-BG model. Attracts engine performance - Honda GX 270, as well as a large tank - 25 liters. The power of the device is 4 kW

However, this is not the cheapest option, as the average cost is 54,000 rubles.

The power of the device is 4 kW. However, this is not the cheapest option, as the average cost is 54,000 rubles.

Watch a video about the Vepr model:

Installation and Maintenance Recommendations

It is not always possible to connect a gasoline generator to heating equipment the first time. The main reason for this is the non-ideal voltage sine wave. If you use expensive equipment, such as power plants, then there will be no problems.

In other cases, you should be prepared for the fact that when connected to the generator, the equipment will work properly, except for the boiler. To solve the problem, use a network stabilizer, but you cannot connect it after the generator, an equipment conflict will occur.

When installing the generator, the boiler must be grounded. At the same time, the issue of exhaust disposal is being addressed.It has been noted that the removal of gases from an autonomous generator when using liquid fuel is required without fail, while in the case of a gasoline-gas device this issue is not so relevant, given that a smokeless, clean exhaust is formed at the outlet.

Thus, when buying the right generator that produces an ideal voltage sine wave, it is quite possible to connect the boiler to an autonomous source of electricity

It is only important to choose a reliable model of a gasoline generator

Why does the boiler go out when the light is turned off

In the event of power outages or breakdowns in the electrical network, the boiler automation is unable to perform its functions and immediately turns off the burner. This is ensured by the very design of the gas valve: it is pressed by the current passing through the coil.

If there is no current, it closes immediately.

Power outages, unfortunately, are not uncommon for Russia. So the owners of the boilers have to sit in a cold house, although gas may be present in the line. It cannot be ignited without electricity, and interference with the boiler device can lead to a fine from the technical supervision authorities, as it leads to violations of fire safety.

Advantages and disadvantages of equipment

The inverter is convenient in that it is not tied to a particular type of DC voltage source. The unit can be powered by a conventional car battery, a generator set with a simple signal rectification principle, or by UPS batteries.

If the module does not have a built-in charger, the owners will have to personally control the level of capacity and the degree of discharge of the device.

Among the main advantages of the device:

- a wide range of models and the ability to choose a product with an almost perfect output sine wave;

- correct operation with all sources of rated voltage and direct current;

- reasonable cost compared to other similar units of similar power;

- no restrictions on increasing the capacity of the battery and the duration of autonomous operation.

The disadvantages include criteria such as:

- lack of control over the level of charging / discharging the battery;

- the threshold setting is not subject to additional correction;

- the need to equip an external communication circuit for automatic activation in the event of a power outage in a residential area;

- high cost of "fancy" modules with a wide range of features.

The final choice of a suitable device is strictly individual. It all depends on how much the voltage “jumps” in the network, how often consumers are disconnected from the supply of the resource by the central electrical system, and how long you have to sit without light.