- Battery piping

- Why you need a bypass

- Bypass installation

- Installation

- Mechanism designs

- Tips & Tricks

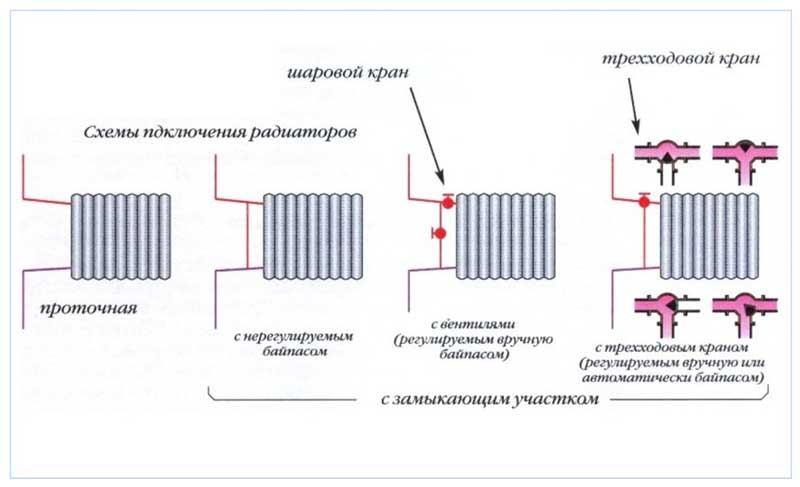

- Types of bypass in the heating system.

- Fixed bypass pipe

- Manual bypass

- Automatic bypass

- Injection automatic bypass

- Movement design

- Mounting the device

- Multi-storey building heating system

- Installation on the pump

Battery piping

When installing the system yourself, be sure to take into account the requirements for heating elements, in particular the bypass. Often it is installed in the places where radiators are attached.

Next, we will consider the issue of using a bypass in a heating system more carefully.

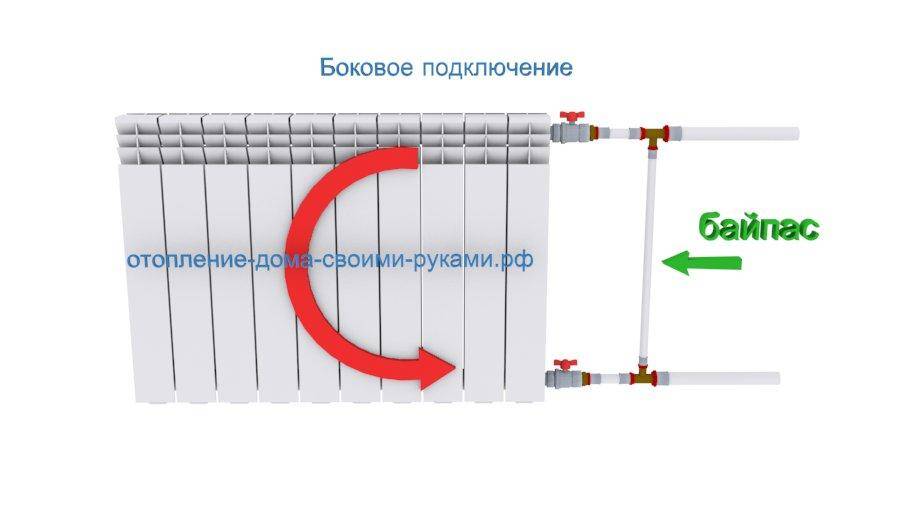

Radiators are tied in a simple way

Radiators are tied in a simple way

Why you need a bypass

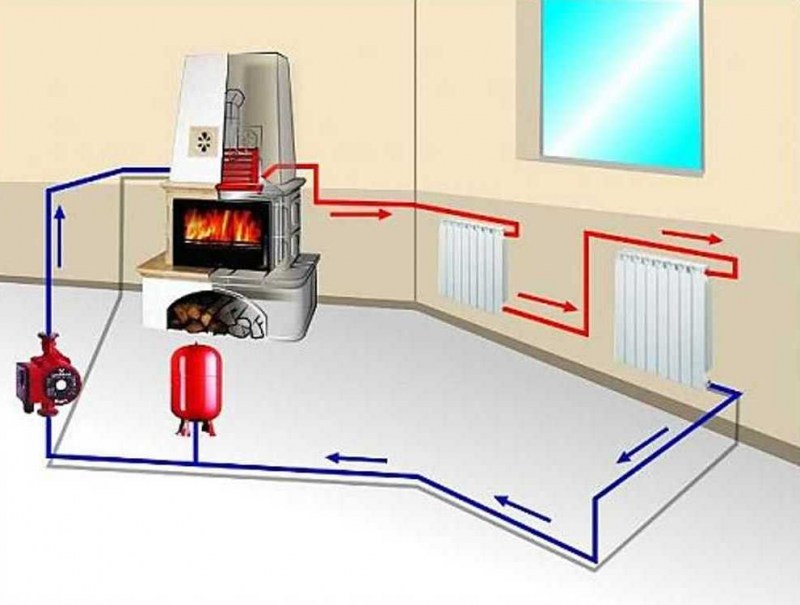

Previously, single-pipe heating was used in the construction and home improvement. This greatly simplifies the execution of work, and also reduces costs. At the same time, two collectors were installed in the elevator unit, which are responsible for the supply and processing of the coolant. Further heating was developed according to different schemes:

- Top feed. A pipe ran from the collector to the top floor. The coolant was supplied upward through this riser. After that, he went down, passing through all the radiators.

- Bottom feed. In this case, the coolant begins to flow into the radiators already when lifted up.Such a series connection of devices has characteristic disadvantages.

Both in the first and in the second case, the connection is made sequentially. If a problem occurs on some equipment, you will have to turn off the system completely.

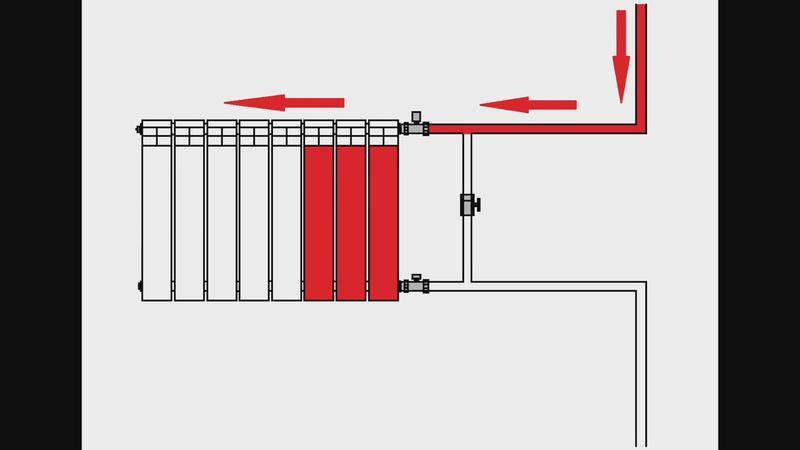

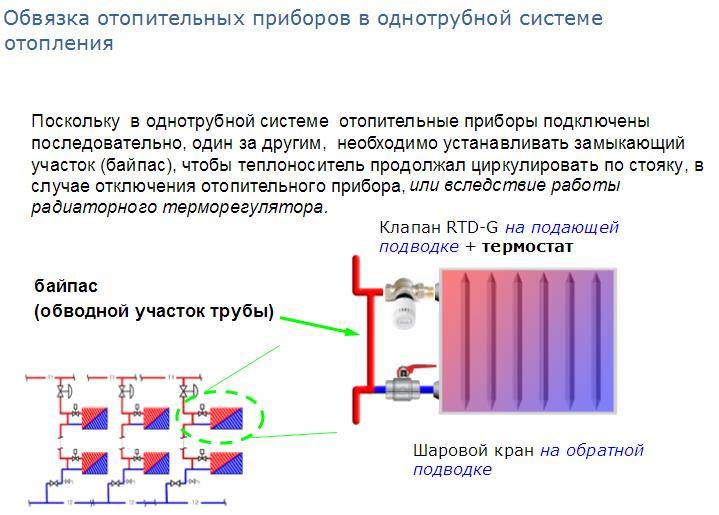

The problem is solved by including special jumper pipes in the system. If necessary, the radiator is cut off by taps from the main system without disturbing its operation. This makes it possible to easily repair the battery.

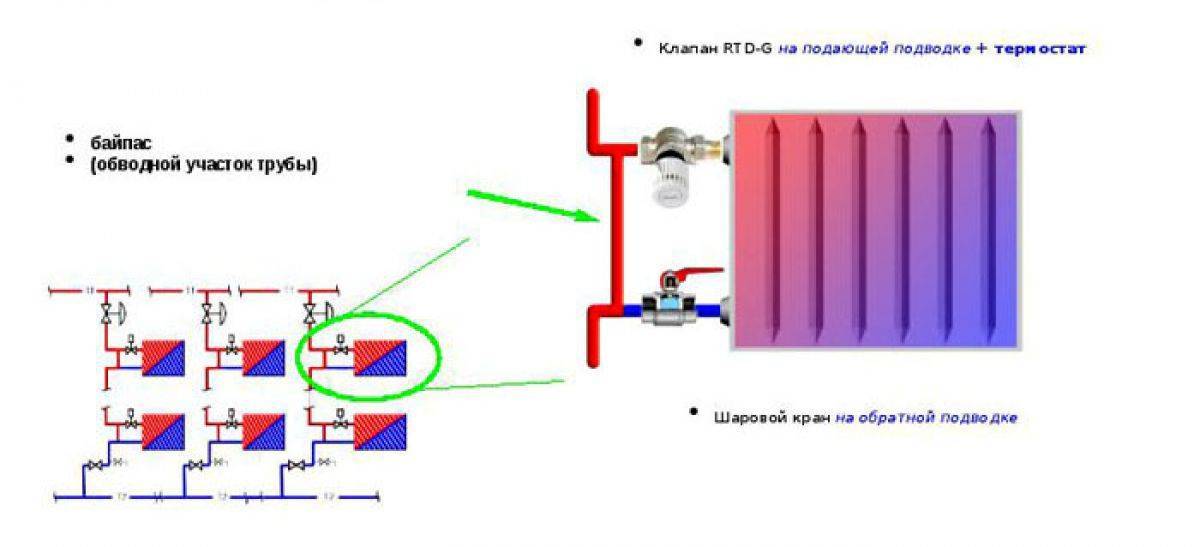

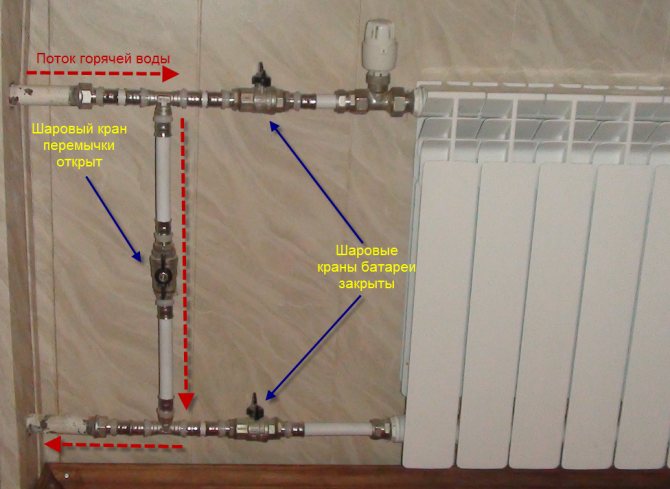

The jumper is placed closer to the battery

The jumper is placed closer to the battery

This is not the only reason for using a jumper in heating. The space is heated by radiators. If there is a bypass with valves, the owners of the apartment have the opportunity to independently adjust the supply of coolant. Thus, temperature control in the house is not difficult.

The ligation tube has a different shape

The ligation tube has a different shape

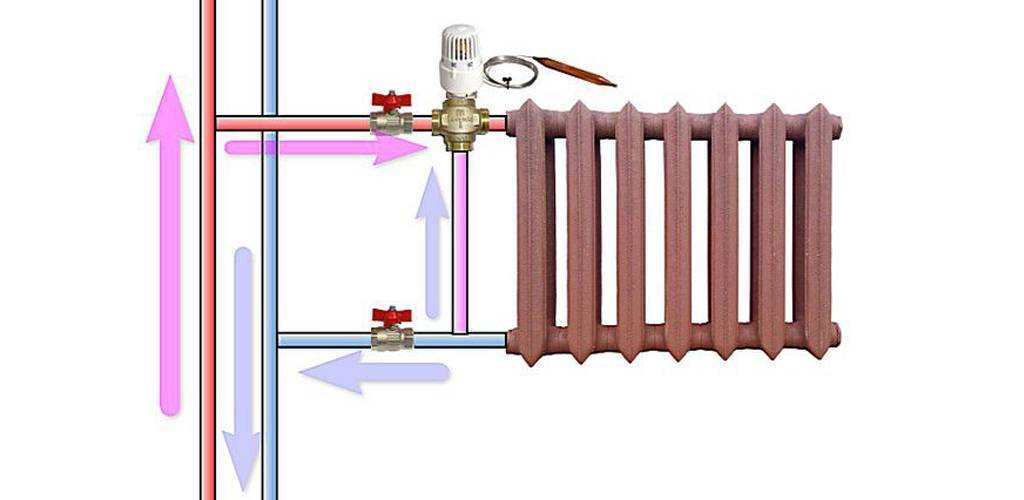

Bypass installation

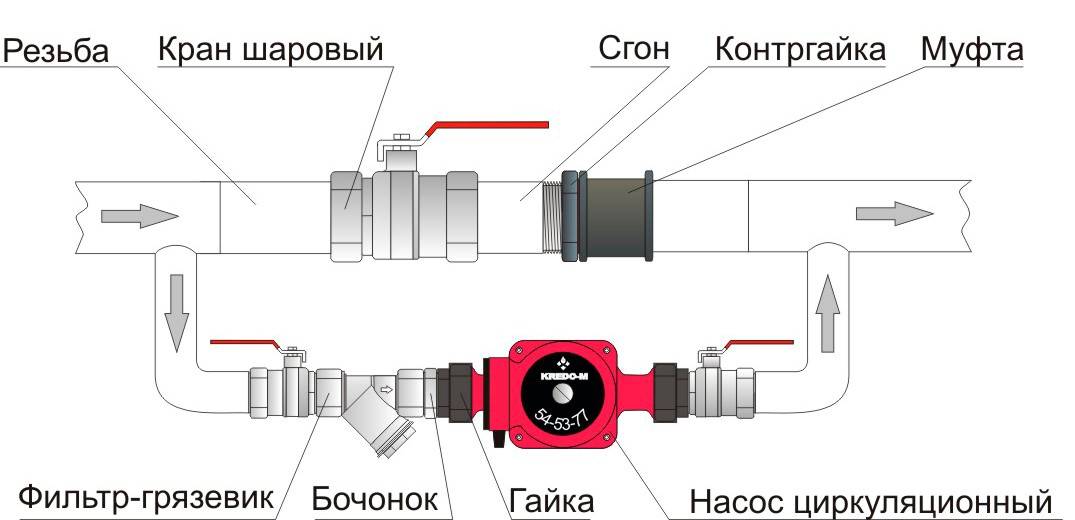

To carry out the installation of heating, you must have certain knowledge and skills. This takes into account the way the pipeline is assembled. To do this, use a threaded and fitting connection, as well as soldering pipes. Having these skills will make the job easier. In this case, it is worth considering important rules and recommendations of experts:

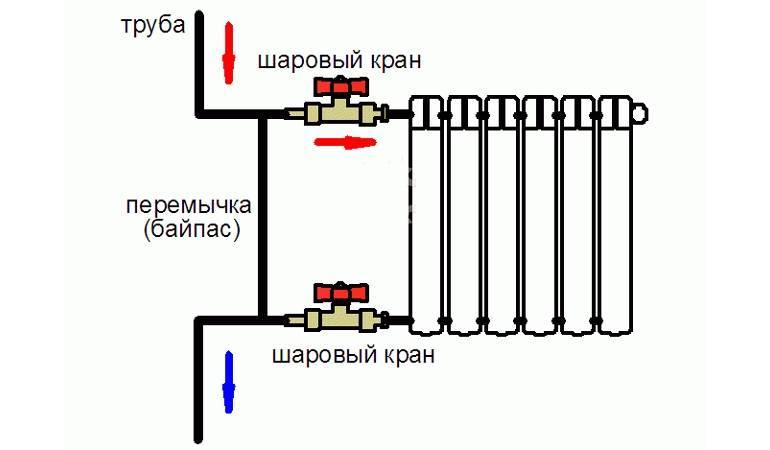

- Valves are not used between riser and bypass. Otherwise, the circulation of the coolant is disturbed.

- On the vertical pipe of the riser, the jumper is mounted in close proximity to the battery. At the same time, a place is provided for the installation of shut-off valves. The valves are mounted on both sides of the radiator.

- Bypass valves should not be installed unnecessarily. If you install taps on the jumper, the circuit will be unbalanced.In a stand-alone system of a private house, this allows the flow to be redirected. In a multi-storey building, this option is ineffective and is a violation of the rules.

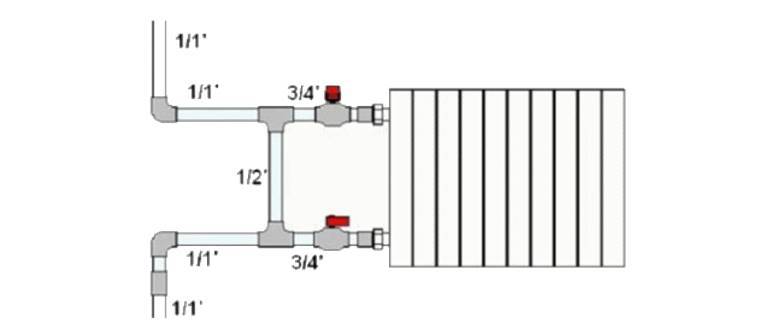

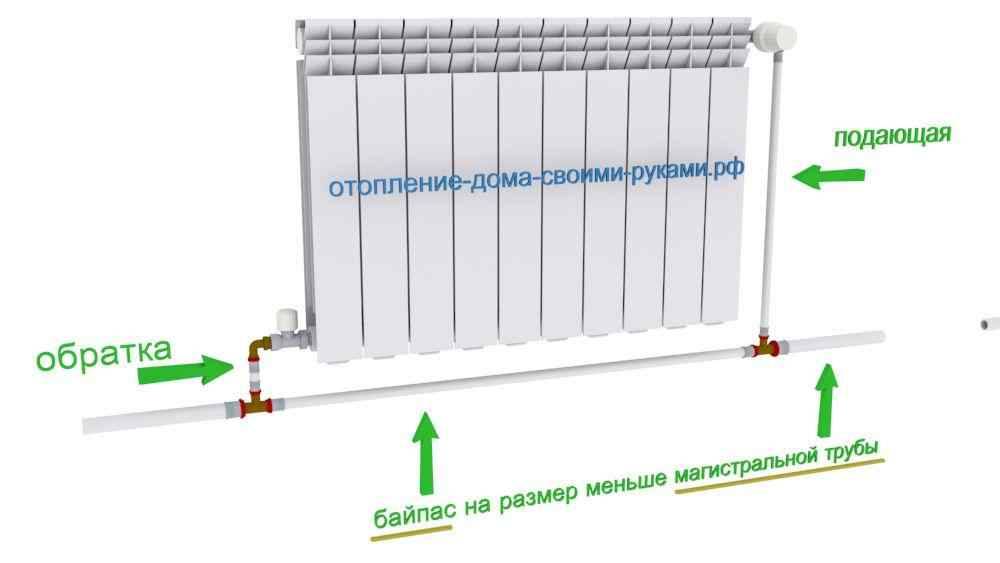

- Pipe size is important. The diameter of the insert is two sizes smaller than the section of the stand. The branch pipes going to the radiators are used one size smaller. In the horizontal scheme, the ratio of sizes is somewhat different.

Compliance with the dimensions of pipes and nozzles will ensure the normal operation of the system, according to the laws of hydraulics. Installation features directly depend on the type of material used. If we are talking about a metal pipeline, then it is enough just to weld a jumper and install taps.

Installation is carried out in different ways.

Installation is carried out in different ways.

The use of polypropylene or metal-plastic pipes involves the use of special fittings. Bypass can be built independently from a pipe of the right size or you can purchase a ready-made part.

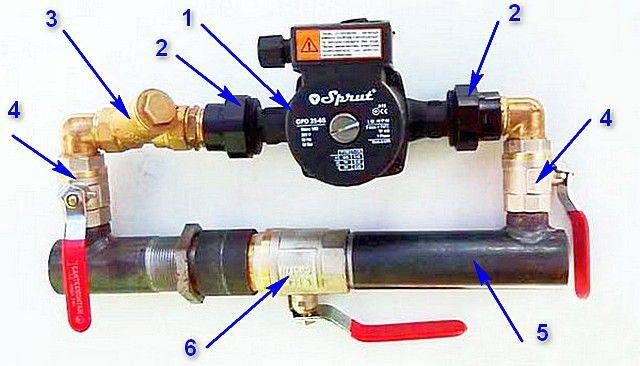

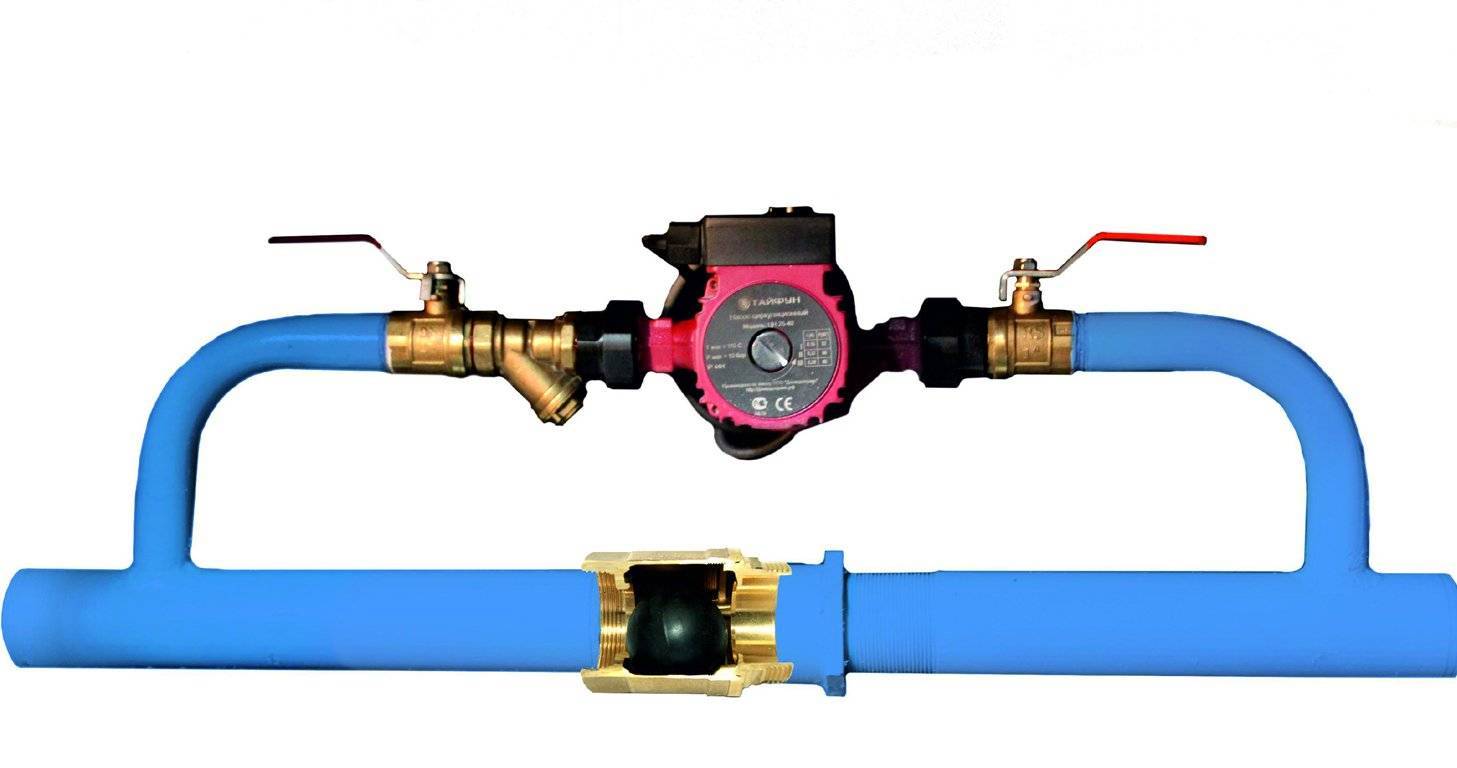

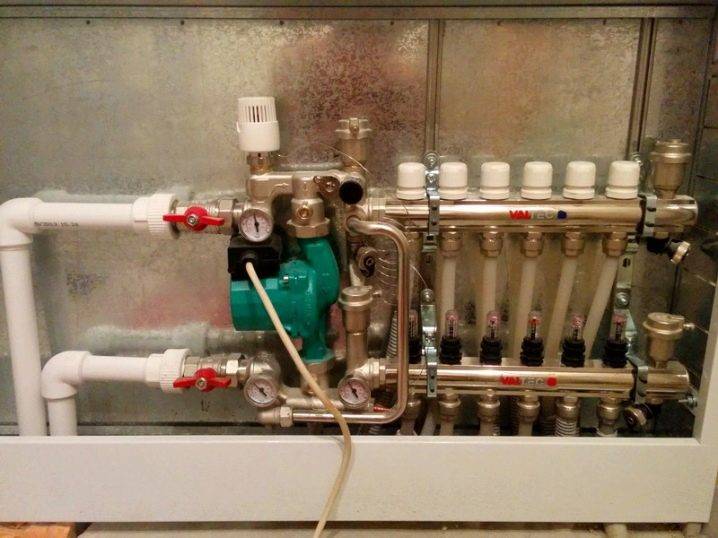

The pump is often installed on a jumper

The pump is often installed on a jumper

Installation

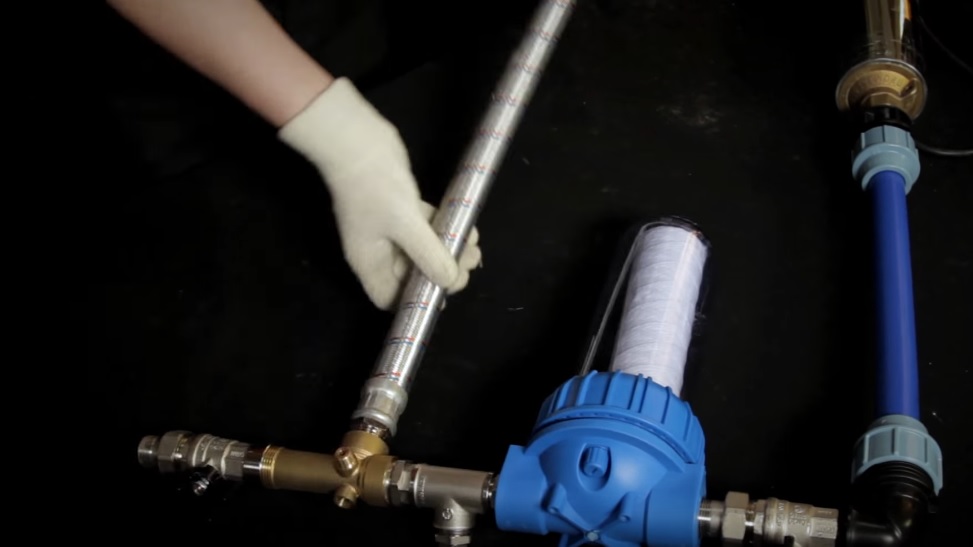

One of the key requirements - the narrowing of the jumper compared to the pipe to which it is connected, is already familiar. Violation of this rule will not allow the liquid to fully penetrate into a particular device. The bypass is installed as far as possible from the riser, but it requires maximum proximity to the serviced device. It is forbidden to mount jumpers in any other way than horizontally - this can lead to increased accumulation of air bubbles. Before starting work, 100% of the water from the system is supposed to be drained.

Often they try to install bypasses using welding machines. First, the mechanism will have to be removed, and after that, choosing the most convenient point on the pipe that delivers water, make holes in this place.They are formed in such a way as to match the diameter of the jumper. It is first inserted as tightly as possible, and then welded. Now you need to mount the locking parts on the thread to which the radiator was previously connected. And, finally, the heating battery is installed in its original place, where it must be included in the system and attached with brackets to the wall.

It is also possible to do everything with your own hands. Before starting work, you will again have to turn off the radiator from the system, dismantle it.

Then:

- a bypass is screwed onto the inlet pipe using branded couplings;

- opposite edges serve to fasten the locking fittings;

- transfer the fixation points of the dismantled device;

- put it in the newly allotted area;

- connect to the system correctly, as follows from its device;

- fix the battery using brackets.

Given the great complexity of modern heating systems, it is recommended to entrust the installation of bypasses to professionals. Even better, if everything is done at the same time as installing or replacing other components. High-quality installation necessarily includes pressure testing after assembly, since only this procedure will show whether all the work has been done correctly or not. But at the same time, self-installation should not cause any special problems. The main thing is to carefully calculate everything and eliminate errors.

It is advisable to use fully finished products or form them from separate blocks. When there is no experience, it is advisable to choose ready-made designs, this reduces the risk of errors. As a matter of principle, the bypass should not be installed directly on the riser, however, excessive proximity to the heating equipment is too bad.Then the operation of the device will be disrupted, and its effectiveness will be insufficient. Directly at the bypass there should be positions for support or ready-made fasteners.

Excessively removed fasteners when heated turn the pipe and make it ugly in appearance. If you want to revive the old heating circuit, install a bypass block with a circulation pump. Additionally, ball valves (not lowering fluid speeds) and a check valve are required

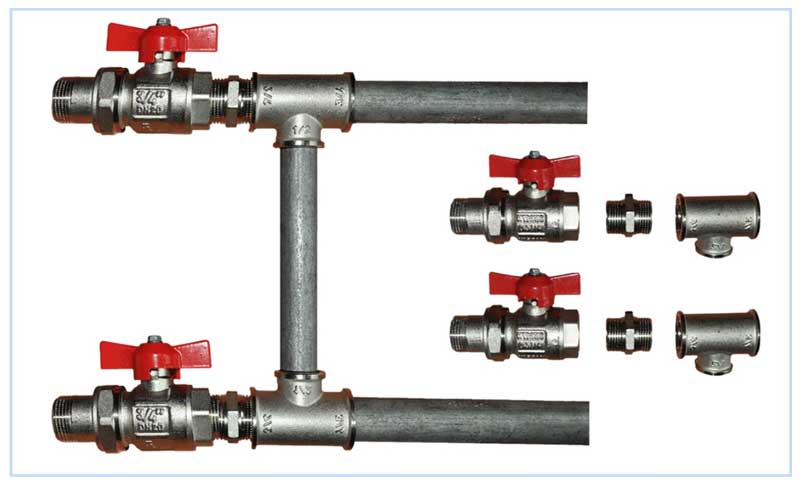

Maximum attention should be paid to the selection of locking valves and determining the diameters of the working parts. A pair of tees and ball valves is mounted on each bypass pipe

Getting acquainted with a certain device, you need to focus on its intended purpose. This determines whether a control valve, a thermal regulator or a return valve is required. You need to install all the parts along the course of the water, the countdown is from the filter. Carefully check that the parts are of high quality and work smoothly. The appearance of pores, especially large irregularities in the weld, is unacceptable; the parts connected by means of a thread are normally unscrewed, dismantled without undue effort.

Mechanism designs

In general, the following elements may be included in the bypass design:

- Pipe.

- Circulation pump.

- Valves. There should be two valves. There are several types of bypass valves, which will be discussed below:

- Moving stem valves. The internal lumen of the pipe when using such valves is blocked by a rubber washer.A feature of this type of cranes is that they are repaired without much difficulty. The disadvantage of representatives of this type is that the internal clearance of such taps is less than the nominal two times, which contributes to the loss of coolant.

- Ball valves. This type of faucet closes the lumen with a metal ball that has a lumen of a certain lumen. When the valve is fully opened, the internal clearance is not less than the nominal one, so there is no loss of coolant. However, this type also has a drawback - with a long non-use, the ball sticks to the seal, as a result of which the faucet handle simply does not give in to force.

- Stop valve. The shut-off valve is a valve on a straight line. If it is absent, then the water, driven by the pump on the bypass, enters the direct line, and then back to the jumper. So it will circle along one small contour. Therefore, a valve is needed that will prevent the flow of coolant to the pump. When choosing this valve, the following two options can also be noted:

- Ball valve. The characteristics of such cranes are discussed above.

- Check valve. Its device includes a metal ball that is able to close the entrance under water pressure, so that human intervention is not required here. When the pump is turned on, under water pressure, the valve will close on its own, thereby ensuring the correct operation of the system.

Tips & Tricks

If you are going to install a bypass in the central heating, then you must notify the representatives of the housing and communal services about this (in writing). They must coordinate the temporary shutdown of heating from the boiler room.

Each installation of gas equipment in an apartment or a private house is accompanied by an order from the project owner from a public or private designer. We advise you to check all the nodes indicated in the papers so that after you accept the project there are no misunderstandings due to the absence of something on the diagram, but the presence of this part in the finished product.

In the case of installing an electric boiler with a power of up to 5 kW, a project order is not needed.

But the installation of the system must be carried out with an invited specialist, in order to avoid critical errors.

When buying a boiler, pay attention to quality and safety certificates. This will save you and those around you from unexpected breakdowns and accidents.

When the pipeline is assembled using soldered PVC pipes, it is necessary to monitor the pressing force at the moment of soldering the joints. Excessive pressure on the heated solder ends will lead to blockage of the heat exchanger through force.

Excessive pressure on the heated solder ends will lead to blockage of the heat exchanger through force.

Types of bypass in the heating system.

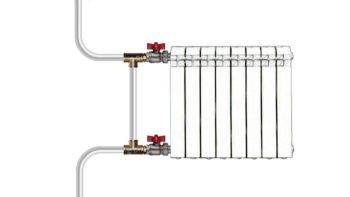

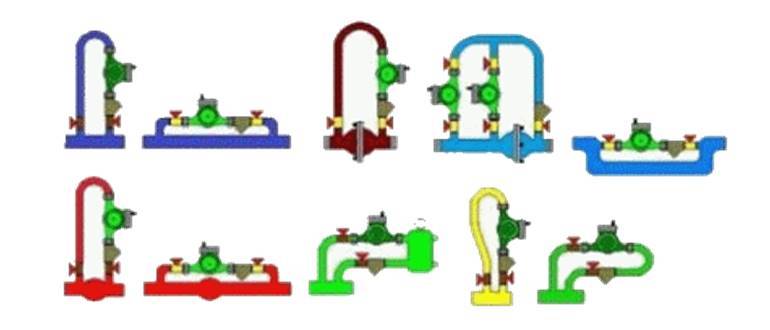

Fixed bypass pipe

Standard pipe without additional elements. The flow of the coolant through such a pipe passes in a free mode. Bypasses of this type are usually used when installing batteries. When installing this type of bypass pipe, it is worth remembering that the liquid from the two pipes will choose the one with the larger diameter (less hydraulic resistance). Accordingly, the diameter of the vertical bypass pipe cannot exceed the diameter of the main pipe.

When installing a horizontal bypass, its diameter is usually equal to the diameter of the main pipe. The pipe leading to the heater must be narrower.Here the law applies that a medium with a high temperature tends to rise due to its lower specific gravity.

Manual bypass

This is a pipe with a ball valve built into it. The choice of this particular type of valve is due to the fact that in the open position it absolutely does not interfere with the flow of fluid, and therefore does not provide additional resistance. This type of bypass pipe is convenient in terms of adjusting the amount of fluid passing through it. It is worth noting that the constituent internal parts of the ball valve can stick to each other. As a result of this, it sometimes needs to be simply turned, for prevention. This type of bypass found its main use in the installation of batteries of a 1-pipe line and in the piping of hydraulic pumps.

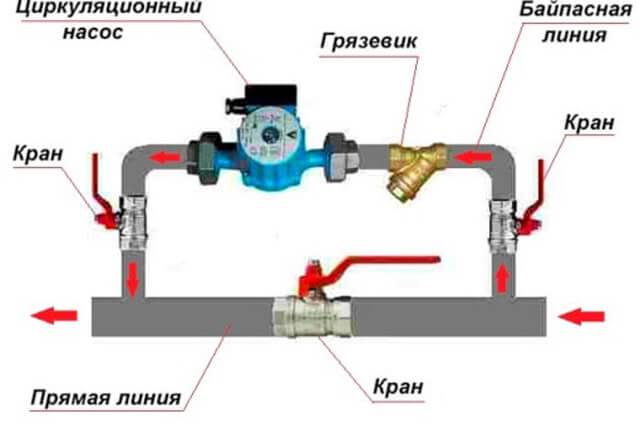

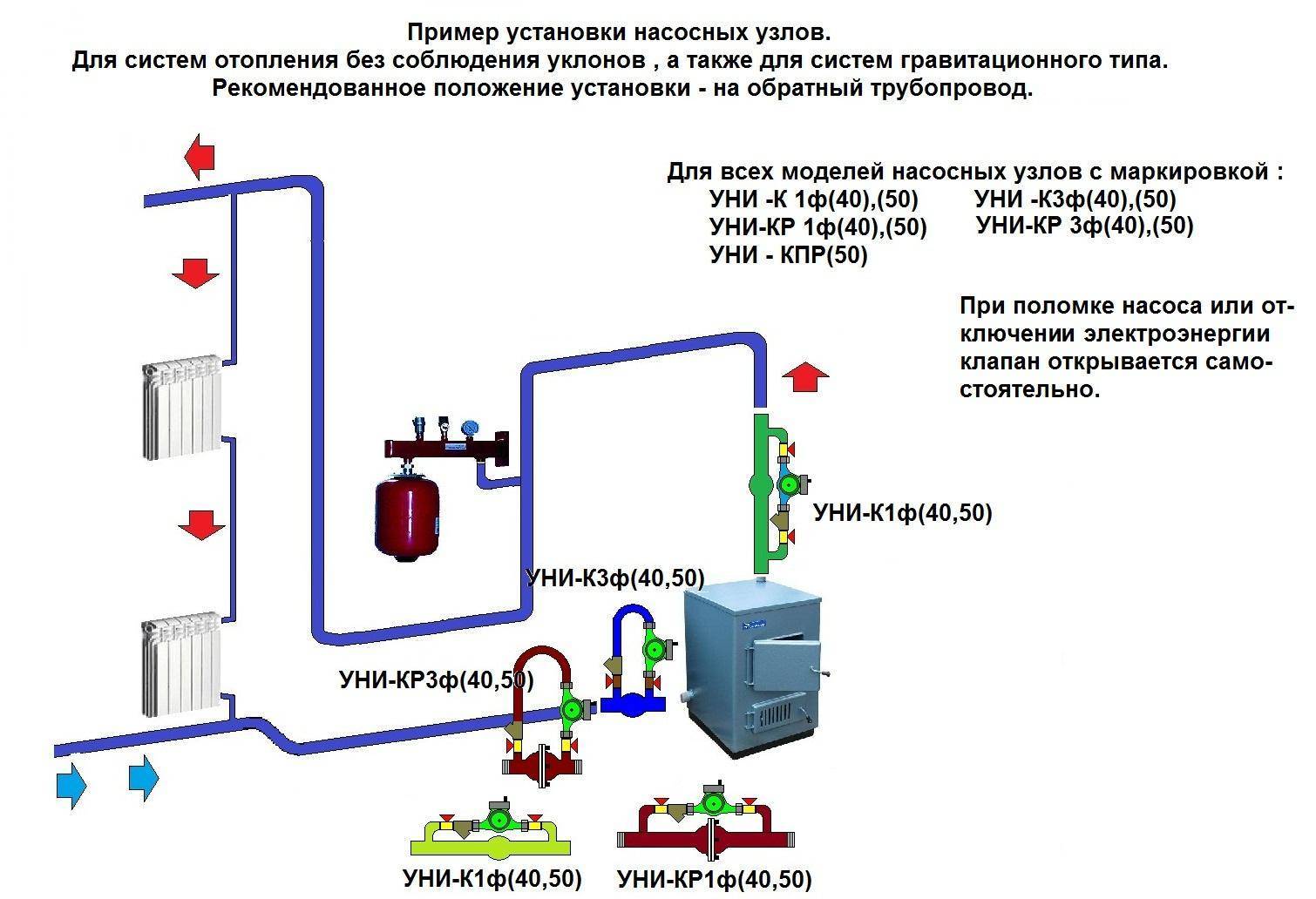

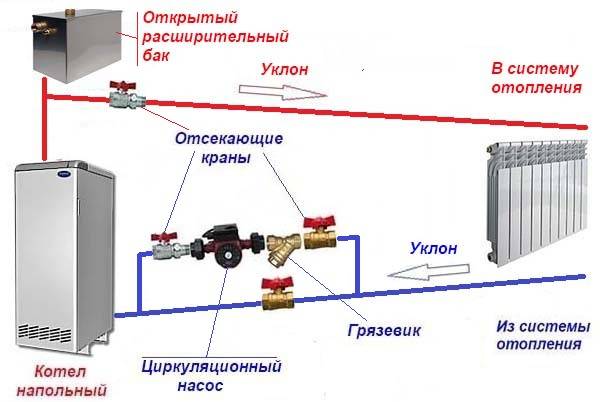

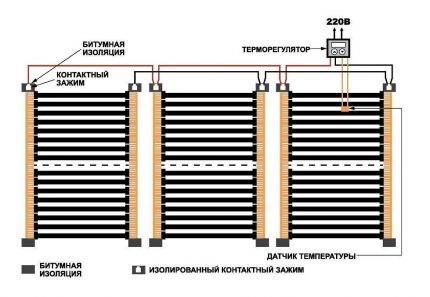

Automatic bypass

Found application in tying the pump of a gravitational heating system. The liquid in such a system almost always circulates without the participation of a pumping device. In this case, the electric blower is mounted in the system to increase the speed of the coolant current. This reduces heat loss and increases the overall efficiency of the system. Liquid in this type of bypass is redirected automatically. When the heating medium passes through the device, the bypass pipe closes automatically. When the pump stops due to various reasons (breakdown, power failure, etc.), the liquid is redirected to the bypass. There are several types of automatic bypasses:

Injection automatic bypass

The injection automatic bypass is based on the principle of a hydraulic elevator. On the main line, a pumping unit is installed located on a narrower bypass pipe.The ends of the bypass pipe partially go into the main line. The flow of liquid into the inlet pipe is created due to the occurrence of a rarefaction area near it. This area arises due to the pumping unit. From the outlet pipe, the coolant exits under pressure with acceleration. Due to this, the reverse flow of the liquid is excluded. In the event that the pumping unit is not working, water flows by gravity through the bypass.

Movement design

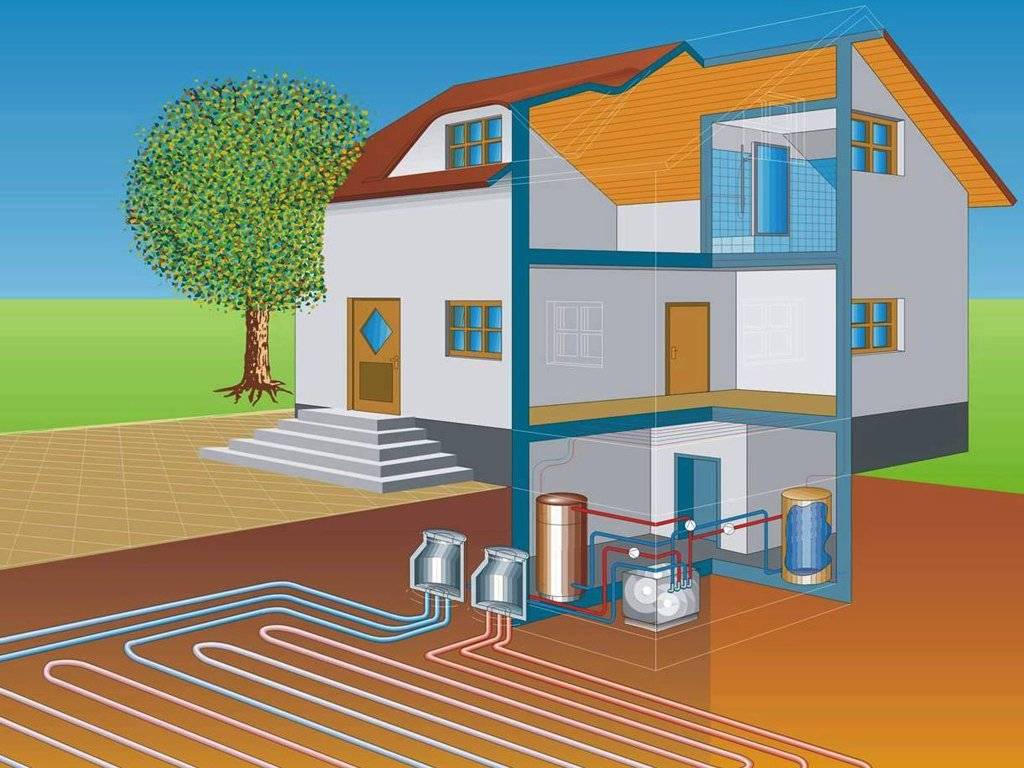

One of the most popular schemes for the heating system of an individual house can be called a scheme where the central water supply line is preserved, and the circulation pump is installed in a parallel pipe.

Before you make a bypass into the heating system, you should consider: the design of this device depends on its area of \u200b\u200bapplication:

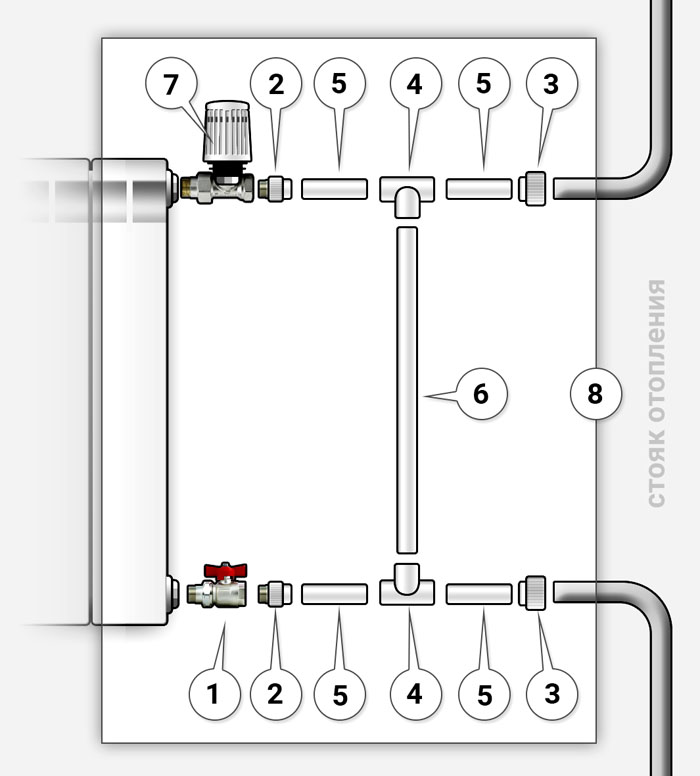

- near the radiator, a product is installed, consisting of a jumper, as well as 2 ball valves;

- such a device includes several parts: a circulation pump, a filter, two taps, as well as an additional tap for the main circuit;

- you can also install a pump to automatically control the temperature of the room, put in place of ball valves thermostats that turn off, if necessary, the passage of the coolant to the pump if a certain temperature is reached in the room.

The shut-off valves are a ball valve, as well as a check valve, the need for which in the heat supply system is justified. A non-return valve can replace a faucet. When the circulation pump is turned on, the valve is closed. If the power fails, the check valve will open automatically, allowing the system to switch to natural circulation.

Therefore, it is important to correctly select both the bypass design and the shut-off valves. When there is no valve, the pump is turned on along a small circuit of the system formed by a pipeline and a bypass. The check valve device requires a ball to cover the pipe lumen and a plate with a spring

The installation of such a valve in the heating system is due to its advantages, because it works without the presence of a person. When the circulation pump is turned on, the water pressure closes the valve

The check valve device requires a ball to close the pipe lumen and a plate with a spring. The installation of such a valve in the heating system is due to its advantages, because it works without the presence of a person. When the circulation pump is turned on, the valve closes under water pressure.

However, in terms of reliability, the valve is still inferior to the valve, since abrasive impurities are present in the coolant.

Experts recommend using only a high-quality valve from trusted manufacturers, since if the ball valve leaks, repairs won't help..

Mounting the device

Installing a bypass in the heating system does not cause any particular difficulties; you can do it yourself

It is only important to adhere to a few requirements:

- select the bypass section, which will be smaller than the diameter of the supply and return, so that, if necessary, the water flow rushes around the battery;

- the device should be mounted closer to the heater and farthest from the riser;

- it is necessary to place an adjusting valve between the radiator and bypass inlets;

- instead of ball valves, thermostats can be used, thanks to which the process of removing the heat carrier can be automated;

- when using a product made by oneself, before installing a bypass in the heating system, it is necessary to carry out welding work;

- when installing the device, it must be mounted near the boiler in such a way as to prevent overheating of the pump.

Bypass - such a seemingly simple detail, is important in order for the heating work in an individual house to be as useful as possible. It allows not only to simplify, when necessary, the repair of the radiator, but also to achieve savings in heating costs by 10%. If the selection and installation of the device is done correctly, all requirements are taken into account, then the operation of the heating equipment will not cause unnecessary trouble to the owners

If the selection and installation of the device is done correctly, all requirements are taken into account, then the operation of the heating equipment will not cause unnecessary trouble to the owners.

Multi-storey building heating system

Multi-storey heating system at home is quite complex and its implementation is a very responsible event, the result of which will affect all the people in the building.

There are several schemes for heating multi-storey buildings, each of which has both its pros and cons:

- The single-pipe heating system of a multi-storey building is vertical - a reliable system, which makes it popular. In addition, its implementation requires less material costs, ease of installation, parts can be unified.Among the shortcomings, one can be noted, in the heating season there are periods when the air temperature outside rises, which means that less coolant enters the radiators (due to their overlap) and it leaves the system uncooled.

- The two-pipe heating system of a multi-storey building is vertical - this system allows you to directly save heat. If necessary, the thermostat closes, and the coolant will continue to flow into unregulated risers, which are located on the building's stairwells. Due to the fact that with such a scheme gravitational pressure arises in the riser, heating is often organized using the lower gasket of the distribution line.

- The two-pipe horizontal system is the most optimal both in terms of hydrodynamic and thermal performance. This system can be used in houses of various heights. Such a system allows you to effectively save heat, and is also less vulnerable even in cases that were not taken into account by the project. The only drawback is the high cost.

Before proceeding with installation work, it is necessary to design heating. As a rule, the design of the heating system of a multi-storey building is carried out at the design stage of the house itself. In the process of designing the heating system, calculations are made, and a multi-storey heating scheme is developed up to the location of pipes and heating devices. At the end of the work on the project, it goes through the stage of coordination and approval in state authorities.

As soon as the project is approved and all the necessary decisions are received, the stage of selection of equipment and materials, their purchase, and their delivery to the facility begins.At the facility, a team of installers is already starting installation work.

Our installers perform all work in compliance with all standards, as well as in strict accordance with the project documentation. At the final stage, the heating system of a multi-storey building is pressure tested and commissioning is carried out.

The heating system of a multi-storey building is of particular interest; it can be considered using the example of a standard five-story building. It is necessary to find out how heating and hot water supply functions in such a house.

Two-story heating scheme at home.

The five-story house implies central heating. the house has a heating main input, there are water valves, there may be several heating units.

In most homes, the heating unit is locked, which is done to achieve security. Despite the fact that all this may seem very complicated, the heating system can be described in accessible words. The easiest way is to take a five-story building as an example.

The house heating scheme is as follows. Mud collectors are located after the water valves (there can be one mud collector). If the heating system is open, then after the mud collectors, through the tie-ins, there are valves that stand from processing and supply. The heating system is made in such a way that water, depending on the circumstances, cannot be taken from the back of the house or from the supply. The thing is that the central heating system of an apartment building operates on water that is overheated, the water is supplied from the boiler house or from the CHP, its pressure is from 6 to 10 Kgf, and the water temperature reaches 1500 ° C.Water is in a liquid state even in very cold weather due to increased pressure, so it does not boil in the pipeline to form steam.

When the temperature is so high, the DHW is turned on from the back of the building, where the water temperature does not exceed 700 ° C. If the coolant temperature is low (this happens in spring and autumn), then this temperature cannot be sufficient for the normal functioning of the hot water supply, then the water for the hot water supply comes from the supply to the building.

Now you can disassemble the open heating system of such a house (this is called an open water intake), this scheme is one of the most common.

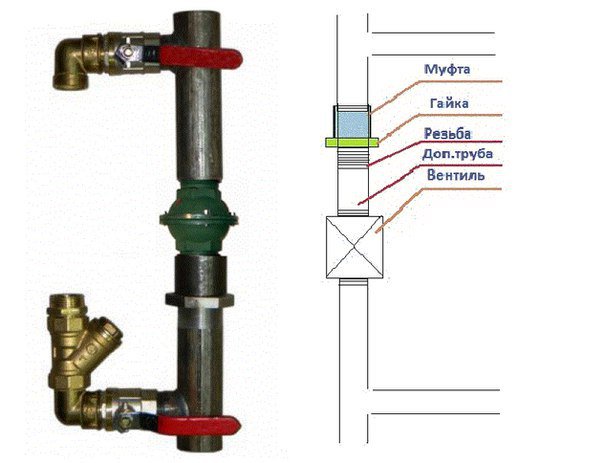

Installation on the pump

Bypass for circulation pump with ball valve

Why is a bypass needed in the heating system in the area where the electric pump is installed? It would be more accurate to say that the pump is installed directly on it. This is practiced when an electric supercharger is placed in the gravitational circuit, the one in which the circulation is carried out by gravity. It increases the flow rate and thus the efficiency of the circuit becomes higher. This is due to the fact that at a higher speed the coolant reaches the extreme radiator with less heat loss.

There are two options for installing a bypass for a circulation pump:

- to a new circuit;

- to an existing circuit.

There is no difference in installation.

What you need to pay attention to is the presence of shut-off valves on the central line between the bypass pipes. This is necessary so that the coolant passes through the bypass for the circulation pump, and also so that a reverse flow is not created. To understand why, let's take a step-by-step look at how it works:

To understand why, let's take a step-by-step look at how it works:

- when the pump is running, it accelerates the coolant;

- water from the bypass enters the main and begins to move in both directions;

- in one direction (necessary), it leaves unhindered, and in the second side it encounters a check valve;

- the valve closes and thus prevents circulation in both directions.

That is, the water after the pump presses on the valve plate more than before it, since the speed of the coolant behind the pump will be higher. As planned, when the pump is turned off, the coolant stops pressing on the check valve and does not close it. This allows water to circulate by gravity along the main line without entering the bypass. In practice, the bypass for heating with non-return valve does not work as expected.

Therefore, before installing a bypass in a heating system with a check valve, you need to understand that, in fact, installing a pump on a bypass will not make any sense. With such success, it could be put directly on the highway, while deliberately refusing to use the heating circuit autonomously. Do I need a bypass in the heating system in this case? It turns out that no.

If instead of a check valve you put an ordinary ball valve, then you yourself will be able to control the vector of water circulation along the circuit. Let's look at how to bypass the heating system on which the pump will be installed. In such a scheme, it consists of separate elements:

- threaded pipes that are welded into the line;

- ball valves - installed on both sides;

- corners;

- coarse filter - placed in front of the pump;

- two American women, thanks to which the pump can be removed for inspection or repair.

If you make a bypass in the heating system with your own hands, it is important to observe the correct location of the pump on it. The impeller axis must be horizontal and the terminal box cover facing upwards. If the terminal box cover faces downwards when installed correctly, its location can be changed by unscrewing the four screws on the housing

Such an arrangement is necessary so that there is free access to the terminals responsible for connecting the power supply, and also to prevent the coolant from getting on them in the event of a leak.

If, when installed correctly, the terminal box cover faces downwards, its position can be changed by unscrewing the four screws on the housing. Such an arrangement is necessary so that there is free access to the terminals responsible for connecting the power supply, and also to prevent the coolant from entering them in the event of a leak.