- The battery does not heat in a private house

- Insufficient boiler power

- Problems with the batteries themselves

- Violation of the circulation of the coolant

- Correct installation

- Instruction

- Bypasses with manual adjustment

- Bypass for the circulation pump: the importance of installation

- Bypass options

- Temperature control in the radiator

- Operation of the system without power supply

- Improvement of the one-pipe system

- Installation in a small circuit of a solid fuel boiler

- Where else is a bypass used?

- Bypass in the underfloor heating water system

- Bypass in the solid fuel boiler system

- Mounting

- Bypass in the boiler room

- Bypass: what is it?

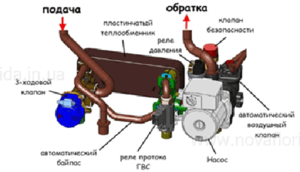

- Automatic bypass

- Installation in a small circuit of a solid fuel boiler

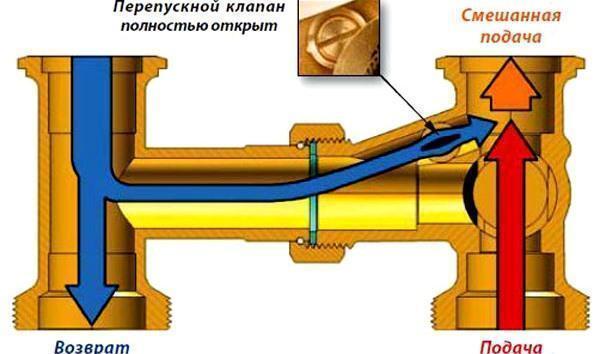

- The principle of operation of the bypass valve

- Multi-storey building heating system

- Conclusion on the topic

The battery does not heat in a private house

The reason that the batteries in a private house do not heat up can be a number of factors. We can only consider the question in a general way. There are various reasons and they are not always obvious. Sometimes such a trifle as a faulty faucet or a clogged chimney can become a stumbling block. Despite this, there are no hopeless situations, the main thing is to determine the reason why the battery in a private house does not heat up, the rest is a matter of technology.

Insufficient boiler power

If the batteries in a private house do not heat well, then one of the reasons may lie in the heating boiler. In your house, with almost 100% probability, it can be argued that the heating circuit is autonomous. So, there is a boiler. It could be:

Why do batteries in a private house not heat well? The reason may be incorrectly selected boiler power. That is, it lacks a resource to heat the required amount of liquid. The first call to the fact that the power is selected incorrectly is the constant operation of the heater, without shutdowns.

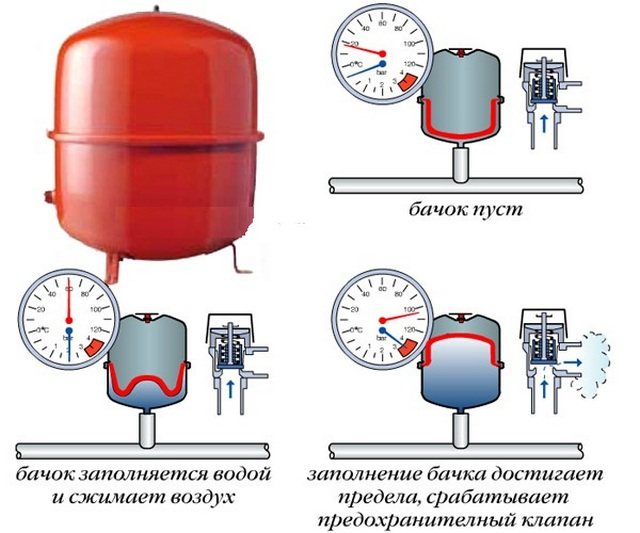

Although in this case the heat exchangers will heat up a little, but. And if the water in them is completely cold, it means that the boiler has broken down or cannot turn on. Modern units have a requirement for a minimum pressure in the system. If this requirement is not met, then it will not turn on. In addition, there is an automation and security system.

Take, for example, a gas boiler. It has a sensor that controls that all gases go into the chimney. It is possible that the chimney or some smoke exhaust pipe is clogged. In any case, the sensor will send a command to the control unit and it will not allow the boiler to turn on.

Problems with the batteries themselves

Batteries do not heat in a private house, what should I do? If no problems were found with the boiler and it is working correctly, then the reason why the batteries are cold must be sought in the circuit itself. Possible options:

- airing;

- pollution;

- insufficient pressure;

- incorrect piping;

- incorrect connection of heat exchangers.

If the batteries are cold, then you need to check all of the above factors. We have already written in more detail about what to do if the batteries do not heat up.The specificity of a private house is that all characteristics can be controlled independently.

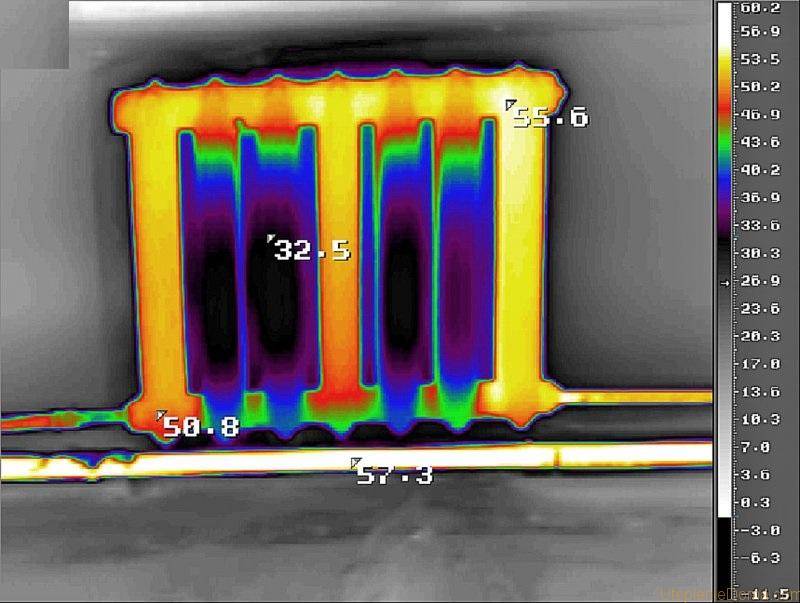

Then make sure that there is no dirt in the pipes and heat exchangers. How to do it? You will have to drain water from cold batteries in a private house. What to do is known, it is necessary to unscrew one end (lower) in the battery and substitute a larger vessel. If black water flows, then there is nothing to think about - this is pollution. It is necessary to flush the circuit to clean water. Sometimes a thick slurry flows out of the radiators along with the water. This is dirt, collected in abundant quantities.

What other reasons could there be why cold batteries are in a private house? If the problem is not in the air or pollution, then the circulation is disturbed. This may be due to low blood pressure. In general, in an autonomous circuit, the coolant pressure does not exceed two atmospheres. If you have new batteries, then look at their passport. In modern heat exchangers, the requirements for working pressure are higher than in Soviet models

Pay attention to it

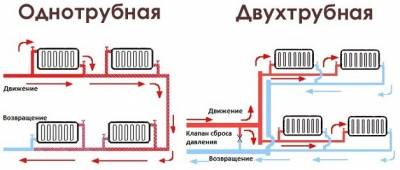

Violation of the circulation of the coolant

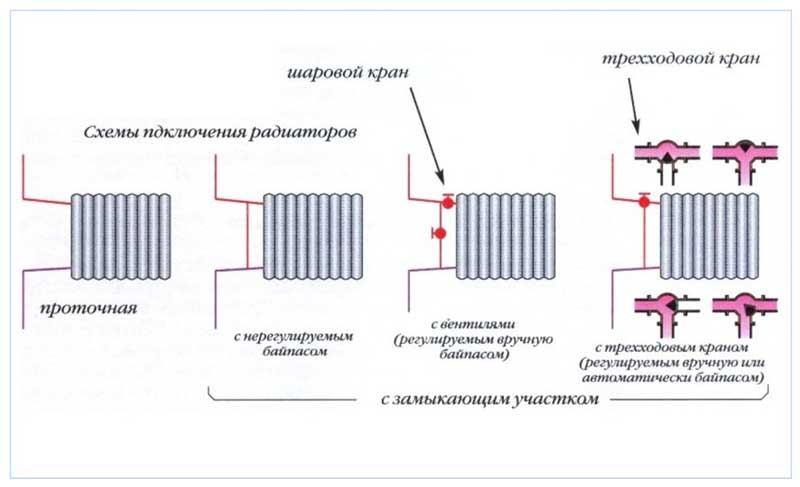

Separately, we consider a violation of the circulation of the coolant due to improper piping and piping of heat exchangers, as a result of which the batteries are cold. In your home, you are free to choose the method of piping. It could be:

- two-pipe heating system;

- single pipe heating system.

It so happened that earlier many preferred a single-pipe heating system, aka Leningradka. It was believed that it was easier and cheaper, but in fact it is not. In addition, in this scheme it is very difficult to regulate the temperature of the heat exchangers as they are remote from the boiler room. The farther from the boiler, the more sections should be. Therefore, it is not uncommon that the last battery in a private house does not heat up.The coolant flows through one pipe. In such a scheme, there is no return.

It turns out that water enters the heat exchanger, cools down there and is again involved in the general flow. Accordingly, after each radiator, the total flow becomes colder. The difference increases with distance from the heating element. As a result, water can come to the extreme heat exchanger almost cold.

In a two-pipe system, tying errors can be made:

- improperly installed shutoff valves;

- incorrect connection of the heat exchanger (there are three types: side, bottom, diagonal);

- incorrectly selected diameter of the branches.

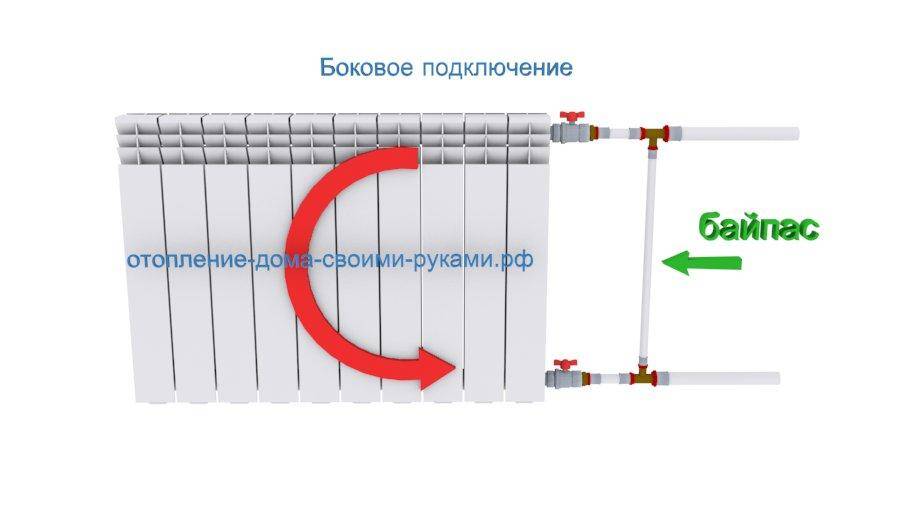

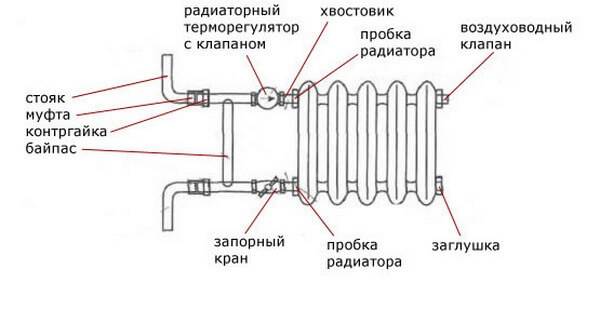

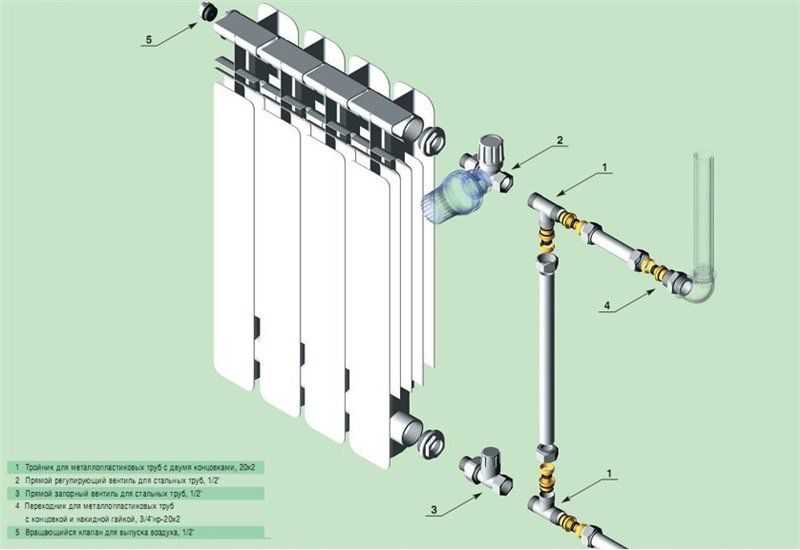

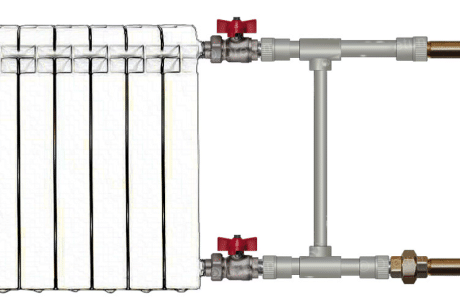

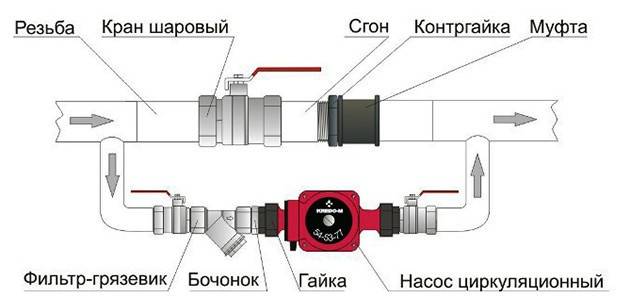

Correct installation

Installing a radiator bypass requires a shut-off valve

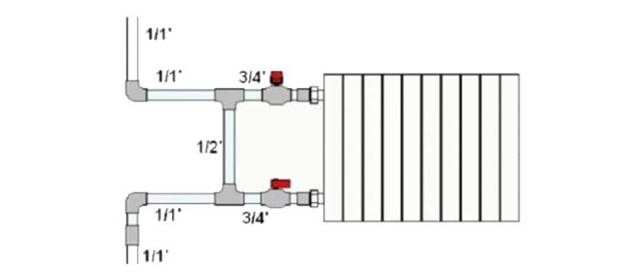

When installing a bypass on a heating radiator, they strictly adhere to the required ratio of diameters, and are also guided by the following rules:

- the bypass line is mounted at the greatest possible distance from the vertical section of the pipeline, as close as possible to the heating battery;

- in the supply section between the bypass and the radiator, a control shut-off device (ball valve or thermostatic head) is installed. Installation of an additional valve at the outlet of the heater will be needed if you decide to protect yourself in case of damage;

- the bypass line is made from a piece of pipe and tees on site, and its installation is carried out both by welding and by means of threaded connections.

Compliance with the following recommendations will help install a bypass circuit on the heating unit:

the bypass is mounted on the return pipe, which avoids overheating of the circulation pump

For the same purpose, the insertion of a parallel circuit is performed at a distance from the boiler;

by placing the bypass section in a horizontal plane, they exclude the formation of air pockets when the heating system is turned on, which is especially important when using "wet" type pumps;

the diameter of the bypass pipes is chosen equal to the connecting size of the circulation pump;

a mechanical cleaning filter is mounted in front of the pump, if you are oriented in the direction of fluid flow.

Bypass design is easy

An important issue is the sealing of joints. In work, it is better to give preference not to a quick-mounted fum tape, but to traditionally reliable tow and sanitary paste. In addition to all other advantages, it is the last combination of materials that will allow, if necessary, to turn the connection back.

Instruction

By following the correct sequence of actions, errors in operation and problems with the functioning of the system during operation can be avoided.

It is especially important to follow the welding procedure, since high heat is associated with the risk of damage to the plastic elements of ball valves.

- Drain the coolant from the heating system.

- Using an angle grinder, cut out a piece of pipe in the return section. Its size should correspond to the length of the drive with the ball valve installed, and the distance to the heating unit is assumed to be 0.5 - 1 m.

- Using a welding machine, weld the corner structural elements on both sides of the tie-in.

- To both sides of the main pipe, weld the short and long threaded sections of the drive.

- Mount the squeegee and install the central valve.

- Install ball valves that block the flow of coolant through the bypass.

- Observing the direction of fluid movement, mount a dirt filter on one of the valves. The place of its installation is chosen before the centrifugal pump in the direction of the coolant.

- Using the fasteners supplied with the pump, mount it on the bypass.

- Pump the coolant into the heating system.

- Turn on the heating and open all locks on the bypass section. After that, inspect all connections for leaks.

- Close the central ball valve and turn on the centrifugal pump. Don't forget to ventilate the pump's working space.

- Check the efficiency of the system at all speeds.

After the inspection of all thermal units and threaded connections of the heating system, it can be considered operational and suitable for further operation.

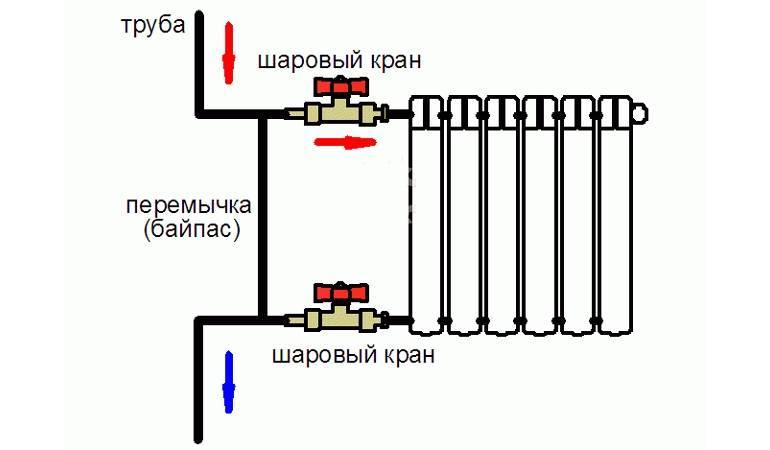

Bypasses with manual adjustment

Bypasses that are manually adjusted (manual bypasses) are equipped with ball valves. The use of ball valves is due to the fact that they do not change the throughput of the pipeline at all when switching, since the hydraulic resistance in the system does not change. This quality makes the ball valve the best choice for bypass applications.

Shut-off valves of this type allow you to control the volume of fluid that passes through the bypass section. When the tap is closed, the coolant moves in full along the main line. The operation of ball valves has one important nuance - they need to be turned regularly, even if there is no need to adjust the system. This is due to the fact that during prolonged stagnation, the taps can become firmly stuck, and they will have to be changed.Sometimes they also install a heating system make-up valve, which plays a significant role.

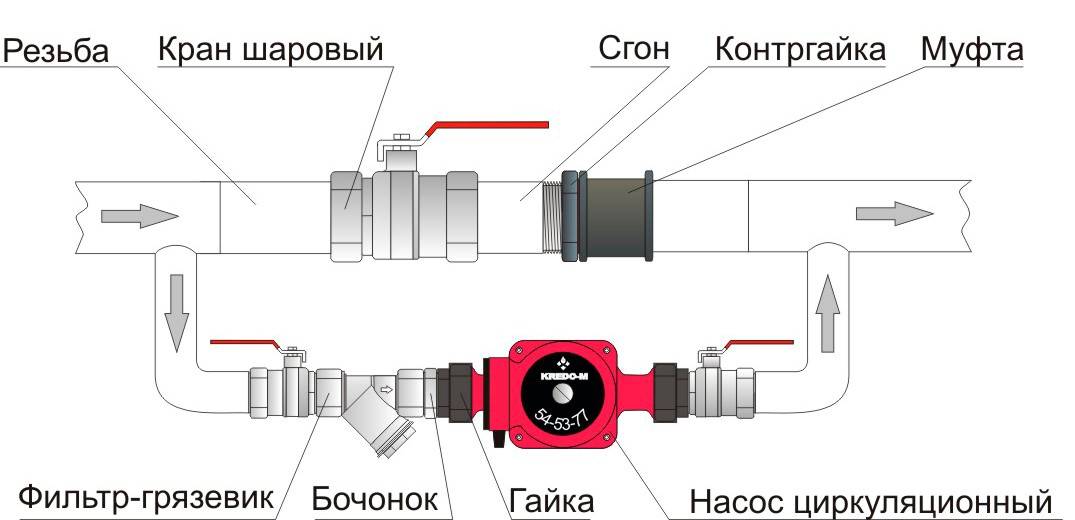

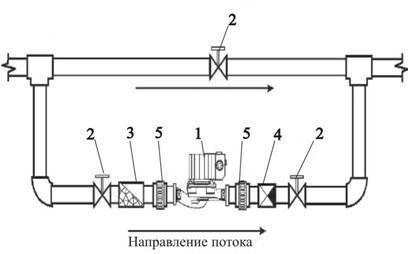

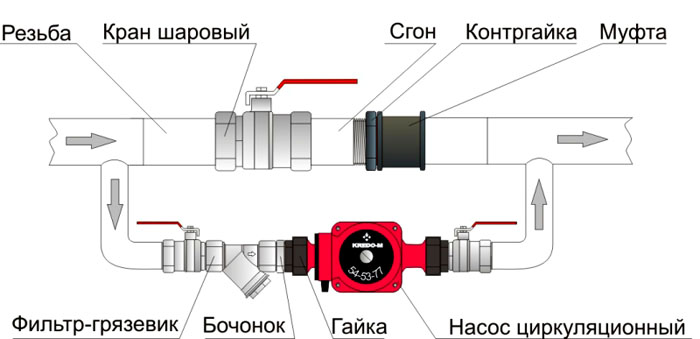

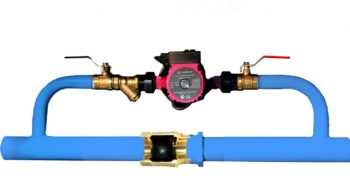

Bypass for the circulation pump: the importance of installation

To minimize heat loss, the use of a bypass in the heating system is required. What it is and what it is for, you need to find out before installing the pump in a forced heating system. The pump must be installed on the bypass and not on the return pipe. It also requires the installation of a check valve, which is needed to prevent a change in the direction of movement of the coolant.

Before installing the pump, you need to consider its location

When installing, be sure to consider the following points:

- for a forced heating system, a regulator is required so that when the electricity is turned off, the circulation of the coolant does not stop;

- the cross section of the regulator for piping the pump should be half the diameter of the main line;

- Before the pump, you need to install a dirt filter to protect the reliability of the equipment.

Ball valves are used as shut-off valves for smooth adjustment of the coolant.

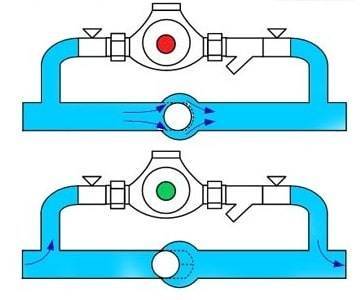

Operation of the bypass jumper in a system with a circulation pump

Bypass options

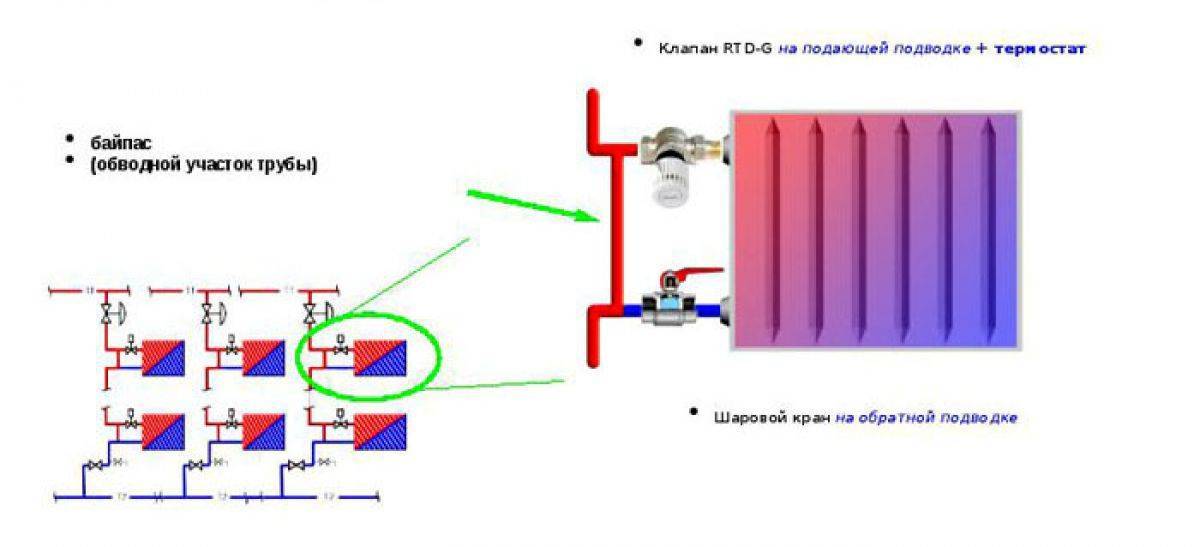

Temperature control in the radiator

In modern heating systems, the process of adjusting the coolant, as a rule, is carried out automatically using heat control devices. An alternative to expensive devices can be a conventional bypass, which will allow you to manually adjust the battery heating temperature.

The bypass on the heating radiator is designed to return excess coolant back to the riser. The adjustment process takes place in mechanical mode, by opening or closing the shut-off and control valves.

In other words, part of the coolant is transported bypassing the shut-off and control valves, i.e. directly into the return line.

It is impossible to carry out repair work on the battery when the heating system is in working condition without a bypass pipeline. Also, the presence of this elementary device simplifies the process of filling or draining the system.

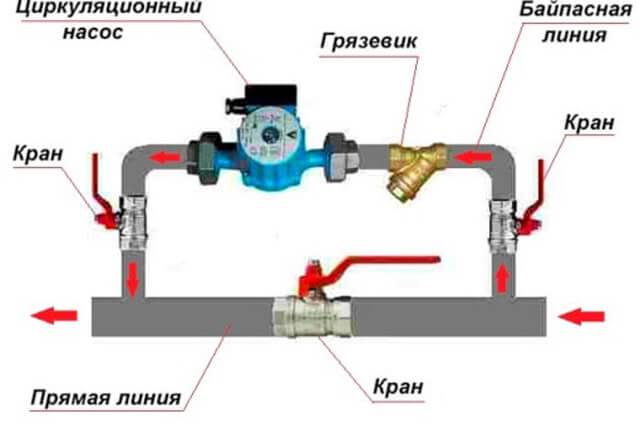

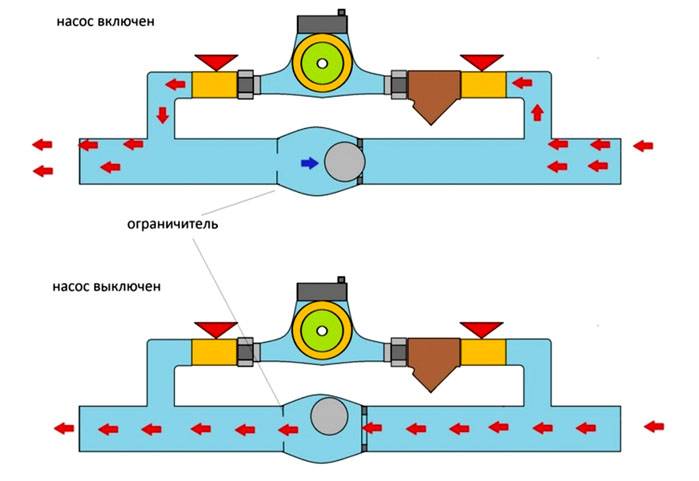

Operation of the system without power supply

Modern heating using a circulation pump implies the mandatory installation of a bypass. This heating system is volatile, and in the event of a power outage, it simply stops working.

The presence of a bypass will solve the problem, since it will allow you to change the forced circulation mode of the coolant to natural.

To do this, the homeowner turns off the water supply tap to the circulation pump and opens the tap on the central pipeline. These manipulations can be performed automatically if a bypass with a valve is purchased.

Installation of equipment on the bypass pipeline is carried out in the following sequence:

- filter element;

- check valve;

- circulation pump.

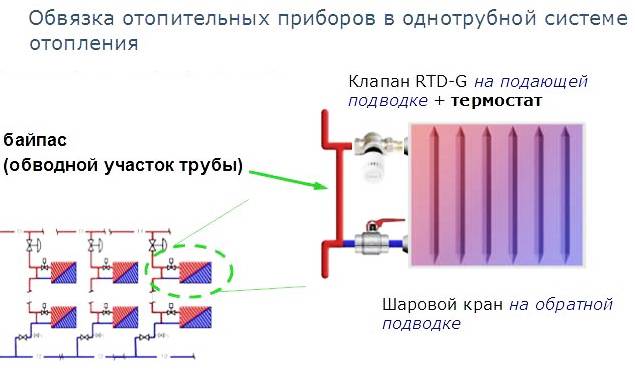

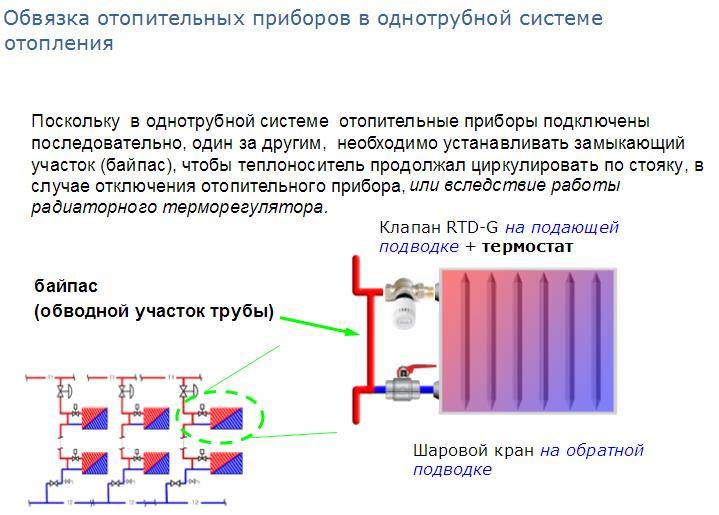

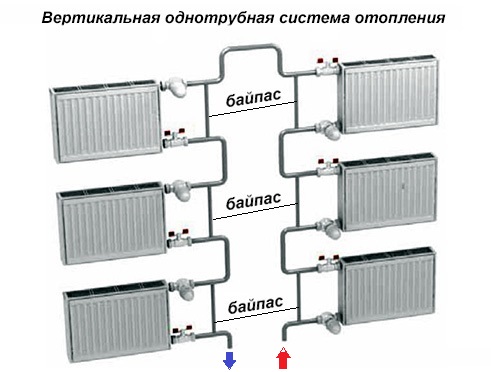

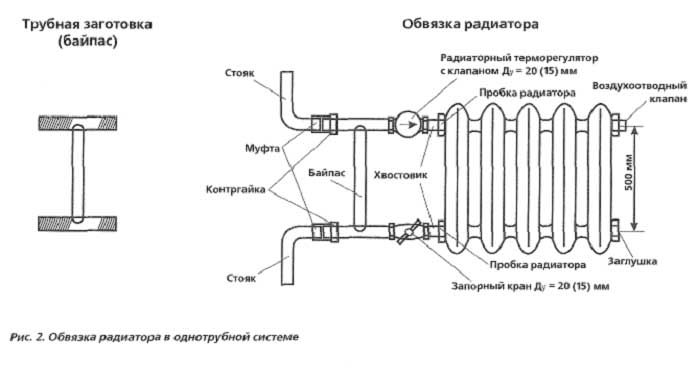

Improvement of the one-pipe system

The single-pipe system is obsolete, but is still found in buildings of the last century. This heating scheme does not keep the temperature regime well, constantly being at extreme values (too cold / too hot).

Installing a bypass in a single-pipe heating system will solve the problem of thermoregulation in the room

When installing this element, it is important to observe the following requirements:

- the jumper is placed as close as possible to the radiator, away from the vertical pipeline;

- battery and bypass must be separated by a shut-off valve or thermostat.

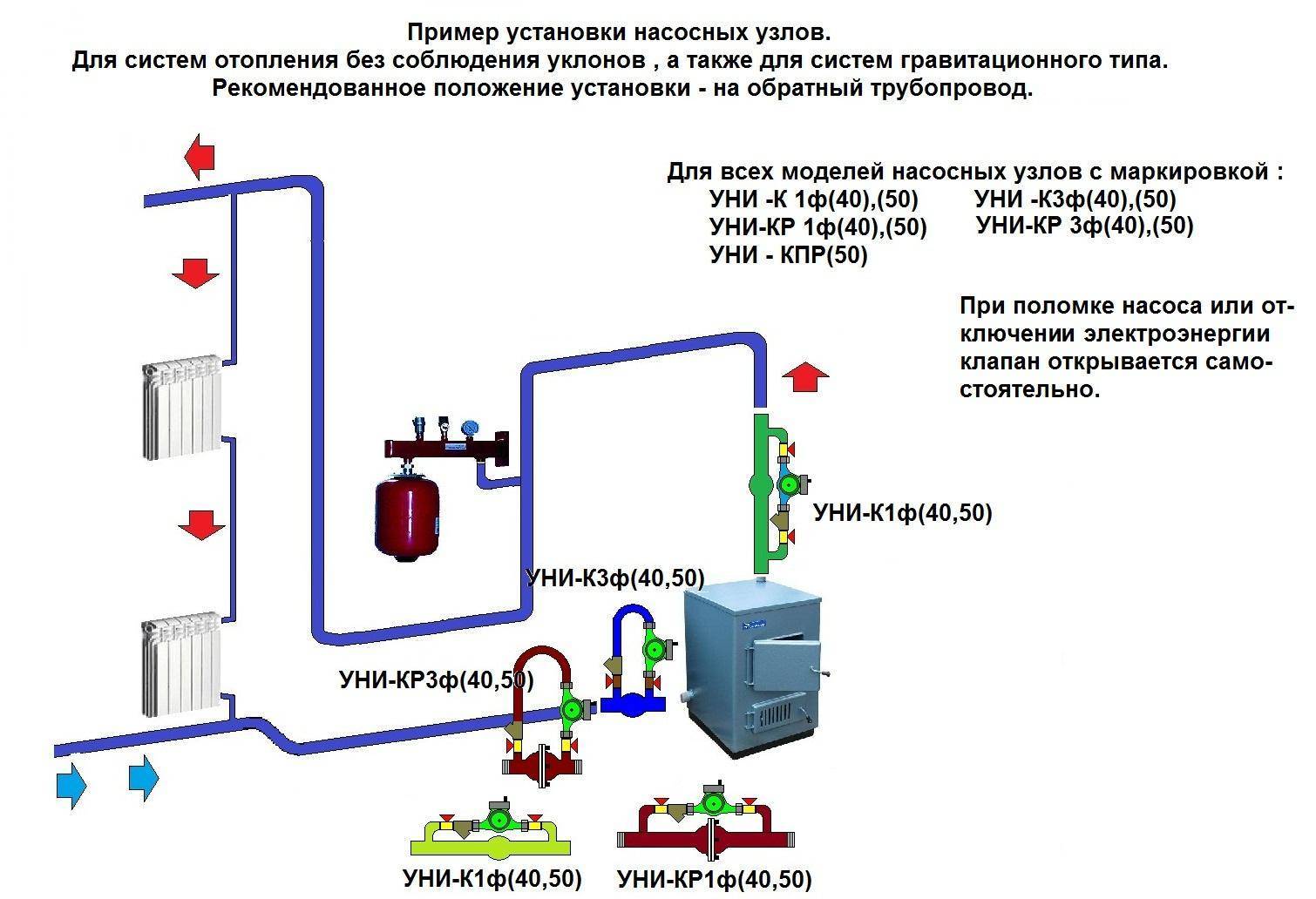

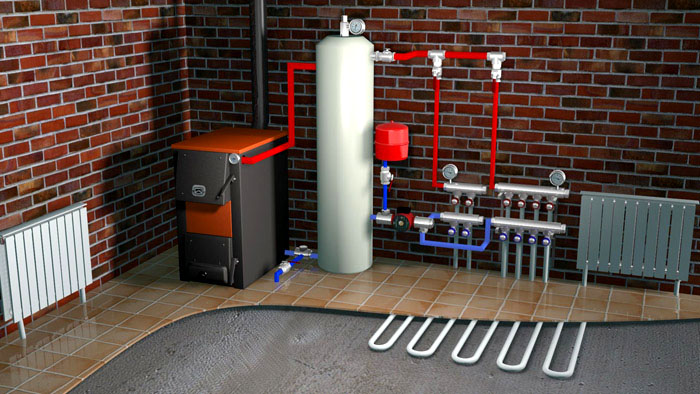

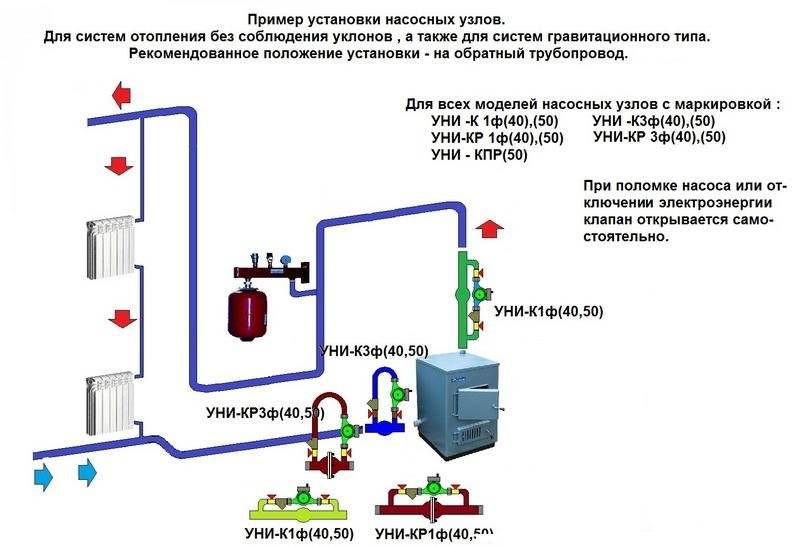

Installation in a small circuit of a solid fuel boiler

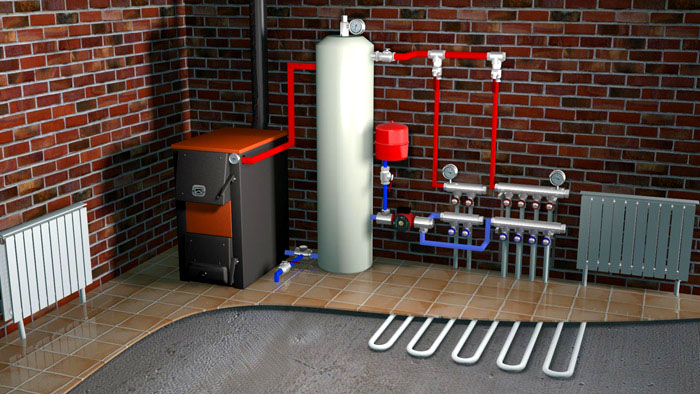

In the classic version of a single-pipe system, the bypass is mounted next to the radiators. When using solid fuel boilers for heating, the bypass jumper is more often used for the entire heating system of the house.

Installation is carried out in the direction of the coolant:

- check valve, pumping equipment and filter system are being installed;

- installation of the assembly in the main pipeline is carried out using couplings;

- an additional tap is placed on the jumper, which allows, if necessary, to shut off the circulation of the liquid.

Installation on the return line of the heating system

Installing a bypass is not considered laborious if you carefully study the work and the nuances of installation. With the right selection of components, the heating system will be more energy efficient and reliable.

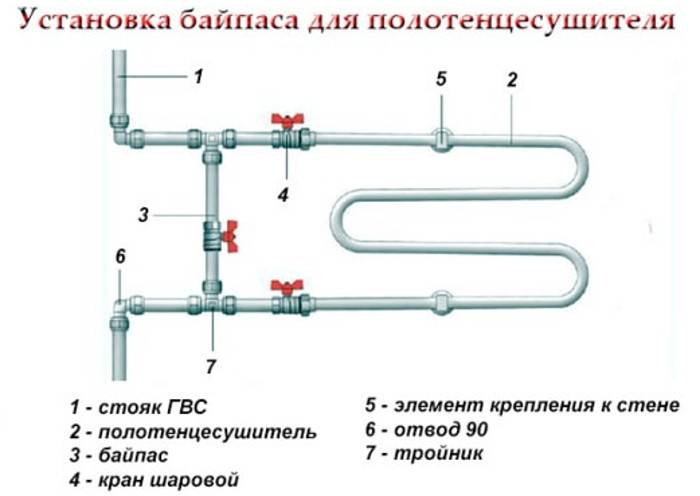

Where else is a bypass used?

In addition, the bypass is installed in the warm floor, in the solid fuel boiler circuit and in other places of the heating system. In each case, the principle of operation of the jumper has characteristic features.

Bypass in the underfloor heating water system

Often, a warm floor is built according to a collector scheme. This makes it possible to ensure the normal operation of the circuit. As a result, normal pressure and temperature indicators are created in different circuits.

Collector-mixing units used in pipe laying allow you to balance the contours of the system as accurately as possible. Often they are equipped with circulation pumps and thermostatic devices. With their help, the coolant of the supply circuit and the return flow are mixed.Thus, the required temperature is created, the pressure in the branches of the system is equalized.

In the process of installing a warm floor, a strapping is installed

In the process of installing a warm floor, a strapping is installed

Despite modern technology, the pump is not able to smoothly change the pressure. The new models have several levels of adjustment. As a result, the capacity and head are controlled by individual balancing valves. Some mixing units are equipped with bypasses with a balancing valve.

In practice, many experts consider such elements unnecessary. Many collector assemblies are designed without a bypass. Despite this, the node performs certain functions. First of all, it is worth noting that the jumper protects the pump from overload, prevents the occurrence of pressure surges. If necessary, the excess coolant is redirected to the return line.

Jumper can be purchased ready-made

Jumper can be purchased ready-made

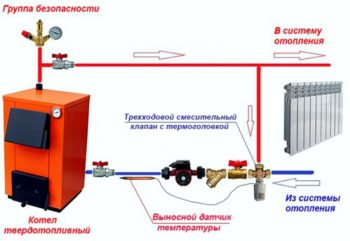

Bypass in the solid fuel boiler system

It is difficult to control the operation of the equipment. During the combustion of solid fuel, a high temperature is created. And that is not all. As a result of the combustion of coal or wood, a lot of smoke is generated, which contains solid suspensions that settle in the form of soot.

When the boiler is started, cold coolant is supplied to it. This creates an increased temperature difference, which manifests itself in the form of condensate on the walls of the heat exchanger. The danger of this phenomenon lies in the clogging of the channels and chimney. Also, condensate adversely affects the condition of cast iron and steel heat exchangers.

Using the strapping, a small heating circuit is created

Using the strapping, a small heating circuit is created

To eliminate such a problem, it is necessary to reduce the time between the arrival and heating of the coolant during start-up.A small circulation circle, which includes a bypass, will help to cope with this. Thanks to it, heating is carried out faster, condensate does not form. A special tap or thermostatic valve is installed on the return line, designed for the standard operating temperature.

There can be multiple jumpers in the system

There can be multiple jumpers in the system Ready pump with jumper

Ready pump with jumper Installation of a steel pipe jumper

Installation of a steel pipe jumper

When the coolant is heated to a certain value, the valve begins to open slightly. Cold water is supplied to the circuit, and hot - to the pipes. Such a smooth start protects the boiler from negative factors. This significantly extends the life of the unit and the heating system as a whole.

Bypass is an important heating element. Therefore, if necessary, plumbers recommend equipping a node in the system. Such a device will increase the efficiency of heating and create optimal conditions for repairing communication elements.

average rating

ratings over 0

Share link

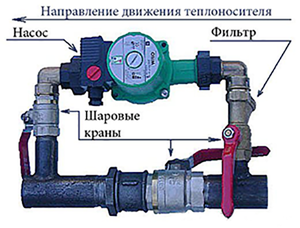

Mounting

bypass in a single pipe system

bypass on the mains pump line

There are 2 options for installing a bypass together with a pump that circulates water in a single pipeline: on a new or old circuit. There is no difference between them either during installation or during heating operation.

When installing a bypass together with a pump, the following rules must be observed:

- Firstly, on the main circuit in the middle of the bypass pipes, it is imperative to install elements that block the pipe. This will allow the coolant to flow through the bypass with the pump, without the effect of backflow.

- Secondly, it is extremely important to place the pump on a bypass structure: the impeller axis must be in a horizontal position, and the lid with stamps must be directed upwards. If there are inconsistencies, the cover can be twisted by unscrewing the four fasteners on the pump housing. Such positioning of the stamps solves 2 problems: it facilitates access to them for connection and, in case of leakage, reduces the likelihood of liquid getting on them.

- Thirdly, only a ball valve should be installed as a constipation, and not a non-return valve.

Because with the valve, the circuit will begin to function like this:

- A running pump accelerates the flow of water in the circuit.

- The coolant flows through the bypass into the main pipeline in opposite directions.

- On the effective vector, it goes without restrictions, and on the reverse vector it is delayed by a check valve.

- It automatically closes and does not allow water to circulate normally through two nozzles.

Thus, an increased pressure of the coolant is created on the valve plate just after the pump, because the flow rate behind it is always faster. In theory, when the pump is turned off, the coolant no longer acts on the valve, which in this case does not overlap.

This makes it possible for the liquid to move by gravity along the main pipeline without falling into the bypass. But in reality, the bypass with the valve does not work as it should.

The problem is that the valve disc generates excessive resistance comparable to a whole meter of pipe. In the conditions of a gravitational circuit, water will not be able to overcome it, and its circulation will stop completely.

Before you mount a bypass in combination with a check valve, you need to know that in fact there is no advantage in mounting the pump on it.

In the event that the valve is replaced by a standard ball valve, it becomes possible to direct the water flow vector in the circuit.

bypass with pump

In order to install a bypass with a pump in the heating circuit, you will need the following set of parts:

- threaded branch pipes welded into the main;

- ball valves mounted on both sides;

- corners;

- pre-filter installed in front of the pump;

- a pair of American women, to dismantle the pump for maintenance and repair.

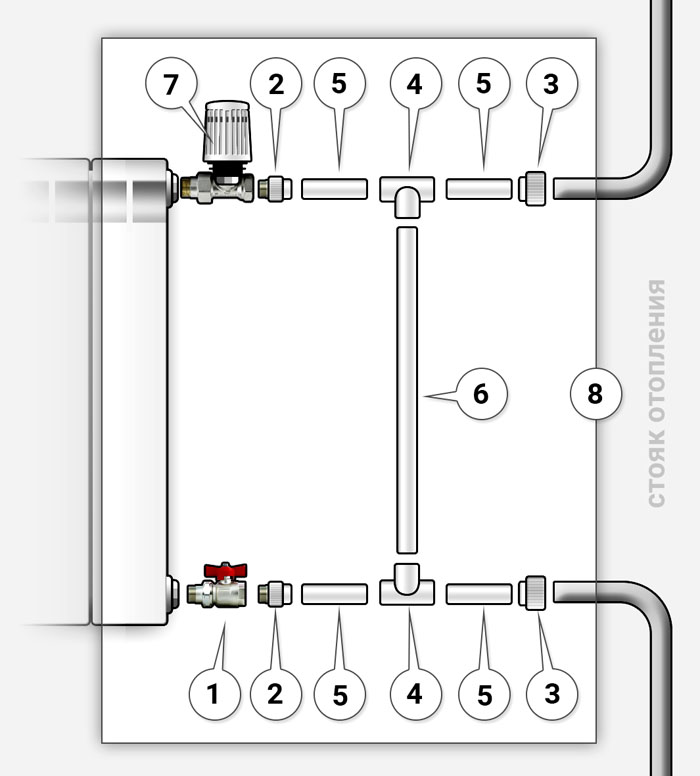

- Installation in front of the radiator. What does it matter. Installation rules: how to install.

A bypass element is installed in front of the radiator in case the water inside it stops circulating for some reason, then its circulation in the rest of the circuit will continue along the bypass, despite the malfunction of one of the elements.

It performs the following functions:

- Provides continuous movement of the coolant along the main heating line.

- Allows you to regulate the temperature of the water in the radiators.

In heating systems with one main circuit, the water circulates in it, successively giving off heat to 1, 2 and subsequent radiators. Thus, with the passage through each next radiator, the thermal energy of water decreases, which means that the first heating element will heat up much better than the last one.

Installing a bypass in heating allows you to mix the hot coolant coming directly from the main with less energy loss with the one that enters the radiators and loses it, which allows you to partially compensate for these losses right on the go, without waiting for it to return directly to the heat generator.

Bypass device:

Installation rules:

- Vertical installation involves connecting the radiator to the riser using a pair of nozzles. The bypass closes them together and is mounted in front of the battery.

- There is no need to install any locks between the main pipeline and the bypass element, this eliminates both human oversight and the possibility of stopping the circulation in the event of a malfunction.

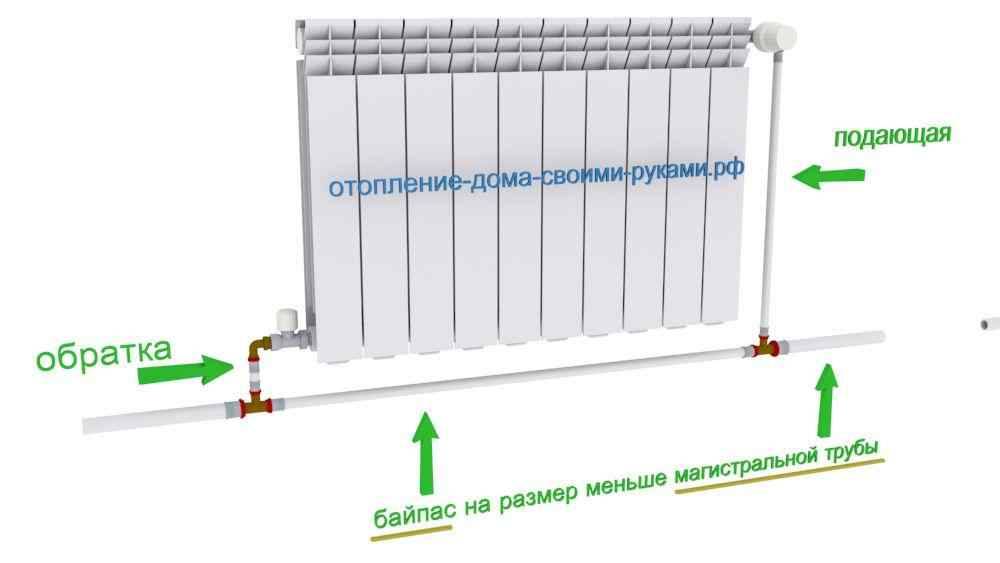

- In a horizontal single-pipe system, the bypass is fixed in a horizontal plane directly in front of the battery. And to ensure circulation, it is necessary to choose its optimal diameter, in relation to the main line and nozzles.

Bypass in the boiler room

In boiler piping schemes, a bypass line is also necessary in 2 cases:

- as a bypass for a circulation pump;

- for organizing a small circulation circuit for a solid fuel boiler.

A pump installed on a bypass pipeline is found in heating systems quite often, sometimes even without special need. The fact is that a one-pipe or two-pipe heating system, originally conceived with forced circulation, can never function when the pump is turned off. She does not have large slopes and increased pipe diameters for this. But the bypass for the pump is exactly what is needed so that the water can flow in a straight line, while the pumping device is not working.

Hence the conclusion: when connecting a system designed for forced circulation to the boiler, it is not necessary to put the pump on the bypass. Turning off and removing the unit in any case will stop the movement of the coolant, so the pump is installed in a straight line.

Another thing is a system adapted to the natural movement of water. It often happens that in order to increase efficiency, they do not just build in a pump, but install a bypass system with a check valve on the line. This allows, in the event of a power outage, to automatically switch to natural circulation, which is reflected in the diagram:

While the pump is running, it presses the valve on the back side with its pressure and does not let the flow flow in a straight line. One has only to turn off the electricity or close one of the taps, as the pressure disappears and the bypass valve opens a direct path to the coolant, the convective movement of water is restored. You can safely remove the pump or clean the sump, the operation of the system will not be disturbed by this, it will simply switch to another mode.

Well, the last place of application of the bypass is the small circulation circuit of a solid fuel boiler with a mixing unit. Here, a jumper connected to a three-way valve allows the heat generator to warm up to a temperature of 50 ºС in order to avoid low-temperature corrosion on the steel walls of the furnace. In this case, the bypass circuit looks like this:

The principle of operation is simple: the valve does not let cold water from the system into the boiler until the coolant circulating through the bypass line is heated to the required temperature. Then the valve opens and passes cold water into the circuit, mixing it with hot water. Then condensation does not form on the walls of the furnace and corrosion does not occur.

Sometimes a bypass is needed in the water supply system. For example, to remove for repair, washing or replacing a heated towel rail in the bathroom. Since it is connected to the DHW riser, its dismantling in an apartment building will create a lot of inconvenience. It is easier to foresee this in advance and put a jumper with a tap when installing the heater.

Bypass: what is it?

The main purpose of this element of the heating main is to return excess coolant to the battery riser. Simply put, through this element, water is transported to the control valves.

- In the absence of this device, it is much more difficult to repair the battery during periods when the system is in operation.

- Installing this element allows you to ensure the operability of the heating main during periods of lack of electricity (if your heating system is connected to an electric boiler).

If there is a power outage in the house, then it is necessary to turn off the taps, through which the coolant is supplied to the pump, and then the tap on the central pipe opens. If you use a bypass with valves in the heating main, you do not have to close the taps manually. This process will take place automatically.

Bypass types:

- with check valve;

- without valve.

Bypasses that are equipped with a check valve are used for circulation pump in the heating line. They are used when the need arises. When the pump is turned on, the valve opens, and, under conditions of increased pressure, the coolant passes. When the pump is turned off, the valve closes. Note that the valve closes automatically.If it turned out that scale got on the bypass, then this can lead to the fact that it will lose its performance.

Using a bypass without a valve as part of the heating mains, it is possible to perform work in one part of the system without the need to completely turn it off. Installing pumping equipment without a valve allows you to connect to the heating system in a place where there was no radiator.

Automatic bypass

one size smaller than riser pipe

Note that the installation of an automatic model must be carried out together with a circulation pump. In such a bundle, they work offline even in cases where there is a power outage. Their work is carried out due to natural circulation.

Installation in a small circuit of a solid fuel boiler

In the classic version of a single-pipe system, the bypass is mounted next to the radiators. When using solid fuel boilers for heating, the bypass jumper is more often used for the entire heating system of the house.

Installation is carried out in the direction of the coolant:

- check valve, pumping equipment and filter system are being installed;

- installation of the assembly in the main pipeline is carried out using couplings;

- an additional tap is placed on the jumper, which allows, if necessary, to shut off the circulation of the liquid.

Installation on the return line of the heating system

Installing a bypass is not considered laborious if you carefully study the work and the nuances of installation. With the right selection of components, the heating system will be more energy efficient and reliable.

The principle of operation of the bypass valve

If an unusual situation occurs, a power outage or a pump breakdown, the pressure stops and the valve automatically closes the jumper, letting the water flow naturally. This allows you to fully automate the heating system. The disadvantage of automatic bypass is sensitivity to water weediness and small contaminants. Before installation, it is recommended to clean the water supply of the AED to eliminate plaque and rust in pipes and radiators.

Before starting work, it is necessary to determine the material of the water supply system. For polypropylene pipes, collapsible connections are used, and the pump unit is first assembled together with the bypass. The branch is connected using tees mounted in the main pipe. With steel version, the pipes are soldered first, then the valve on the bypass. The installation of the bypass system is carried out in the direction of the coolant and must be assembled in a certain sequence.

Assembly diagram:

- Filter;

- check valve;

- Forced pump.

The diameter of the bypass line passage must be equal to the return diameter. Experts recommend that during installation, all cranes be equipped with collapsible fittings. In this case, various situations will be eliminated during the repair.

Before starting installation work on installing the pump, it is necessary to drain the coolant from the system. The entire structure is oriented so that the outlet pipelines are vertical or horizontal, depending on the course of the pipe.

How the bypass line works:

- Collect the bypass section, which will be located parallel to the highway;

- A section equal to the length of the bypass is cut off from the return;

- Tees are installed at the ends of the line;

- Between them, a section with shutoff valves or a valve is mounted;

- The assembled section of the bypass is connected to the main by pipes equal in length.

During installation, it is necessary to leave space for the possibility of subsequent dismantling of the pump and other elements. It is necessary to make the installation correctly, tracing the coincidence of the arrow on the body with the coolant current.

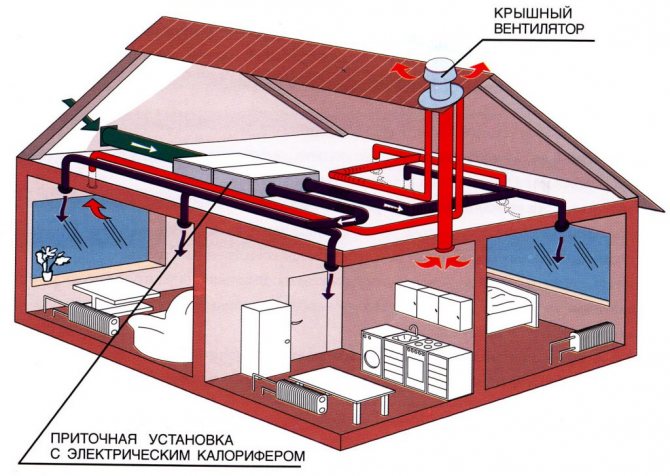

Multi-storey building heating system

The heating system of a multi-storey building is quite complex and its implementation is a very responsible event, the result of which will affect all the people in the building.

There are several schemes for heating multi-storey buildings, each of which has both its pros and cons:

- The single-pipe heating system of a multi-storey building is vertical - a reliable system, which makes it popular. In addition, its implementation requires less material costs, ease of installation, parts can be unified. Among the shortcomings, one can be noted, in the heating season there are periods when the air temperature outside rises, which means that less coolant enters the radiators (due to their overlap) and it leaves the system uncooled.

- The two-pipe heating system of a multi-storey building is vertical - this system allows you to directly save heat. If necessary, the thermostat closes, and the coolant will continue to flow into unregulated risers, which are located on the building's stairwells. Due to the fact that with such a scheme gravitational pressure arises in the riser, heating is often organized using the lower gasket of the distribution line.

- The two-pipe horizontal system is the most optimal both in terms of hydrodynamic and thermal performance. This system can be used in houses of various heights. Such a system allows you to effectively save heat, and is also less vulnerable even in cases that were not taken into account by the project. The only drawback is the high cost.

Before proceeding with installation work, it is necessary to design heating. As a rule, the design of the heating system of a multi-storey building is carried out at the design stage of the house itself. In the process of designing the heating system, calculations are made, and a multi-storey heating scheme is developed up to the location of pipes and heating devices. At the end of the work on the project, it goes through the stage of coordination and approval in state authorities.

As soon as the project is approved and all the necessary decisions are received, the stage of selection of equipment and materials, their purchase, and their delivery to the facility begins. At the facility, a team of installers is already starting installation work.

Our installers perform all work in compliance with all standards, as well as in strict accordance with the project documentation. At the final stage, the heating system of a multi-storey building is pressure tested and commissioning is carried out.

The heating system of a multi-storey building is of particular interest; it can be considered using the example of a standard five-story building. It is necessary to find out how heating and hot water supply functions in such a house.

Heating scheme for a two-story house.

The five-story house implies central heating. the house has a heating main input, there are water valves, there may be several heating units.

In most homes, the heating unit is locked, which is done to achieve security. Despite the fact that all this may seem very complicated, the heating system can be described in accessible words. The easiest way is to take a five-story building as an example.

The house heating scheme is as follows. Mud collectors are located after the water valves (there can be one mud collector). If the heating system is open, then after the mud collectors, through the tie-ins, there are valves that stand from processing and supply. The heating system is made in such a way that water, depending on the circumstances, cannot be taken from the back of the house or from the supply. The thing is that the central heating system of an apartment building operates on water that is overheated, the water is supplied from the boiler house or from the CHP, its pressure is from 6 to 10 Kgf, and the water temperature reaches 1500 ° C. Water is in a liquid state even in very cold weather due to increased pressure, so it does not boil in the pipeline to form steam.

When the temperature is so high, the DHW is turned on from the back of the building, where the water temperature does not exceed 700 ° C. If the coolant temperature is low (this happens in spring and autumn), then this temperature cannot be sufficient for the normal functioning of the hot water supply, then the water for the hot water supply comes from the supply to the building.

Now you can disassemble the open heating system of such a house (this is called an open water intake), this scheme is one of the most common.

Conclusion on the topic

Unfortunately, not all inhabitants install bypasses when they install heating with their own hands. Many people think that this is not the most necessary part.But often you have to deal with the problem of unexpected repair of radiators. And this is where the bypass comes in very handy. If it is not there, then you have to turn off the heating boiler, drain all the coolant, and only then carry out repairs. After completing all the work and installing the repaired radiator, it is necessary to fill the system with coolant and bring it to the required temperature.

This is too long, so the house will quickly cool down. This would not have happened with a bypass. It is only necessary to open the ball valve on it and close the two shut-off valves on the heating battery. Now the radiator can be removed and repaired, and the heating will continue to operate normally.