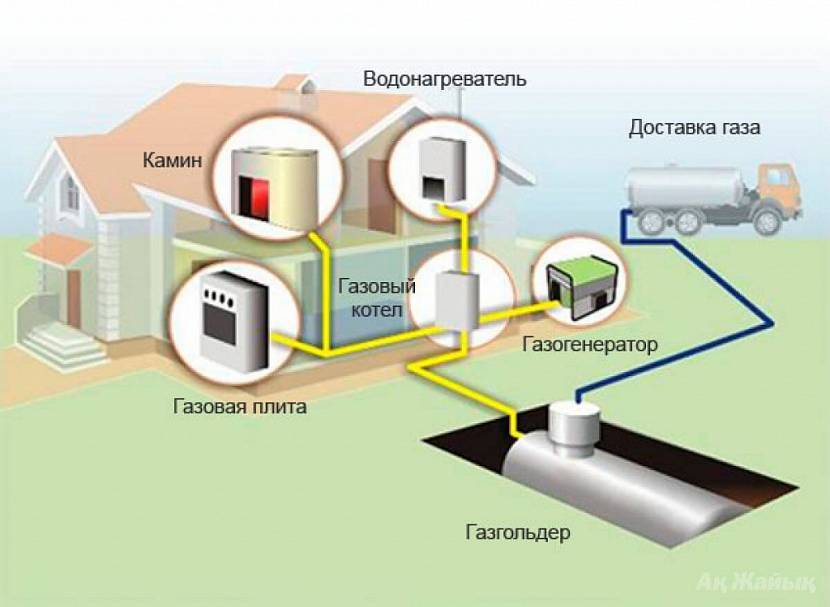

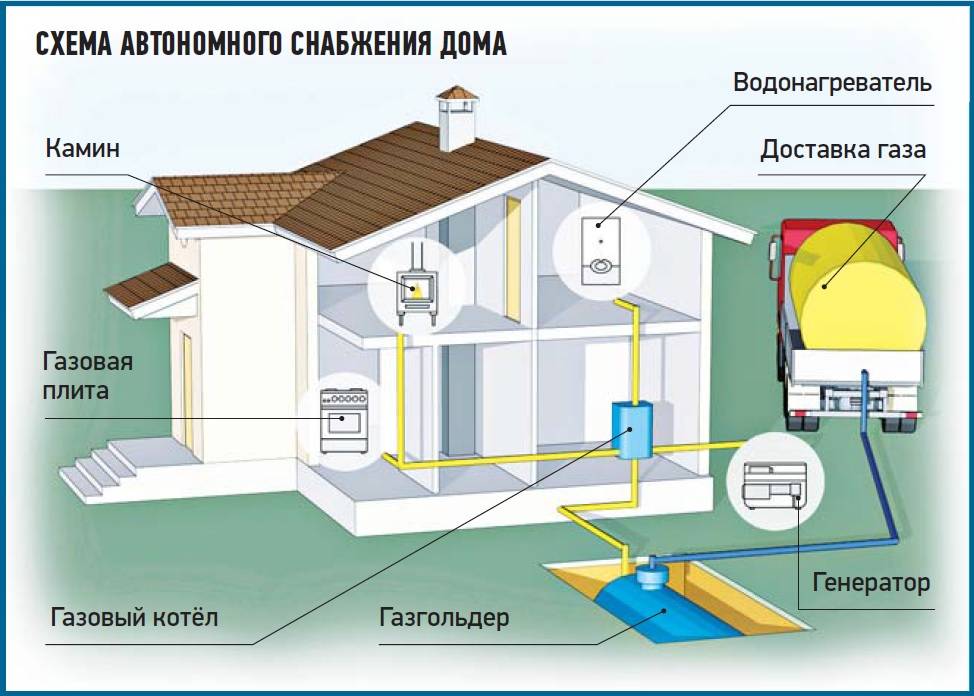

- Elements of autonomous gasification system

- Rules for the arrangement of gas heating

- The procedure for gasification of a private house

- Installation of an autonomous gas pipeline

- Installation of an autonomous gas pipeline

- How is the laying of autonomous gasification

- Stage 1. Study of the site.

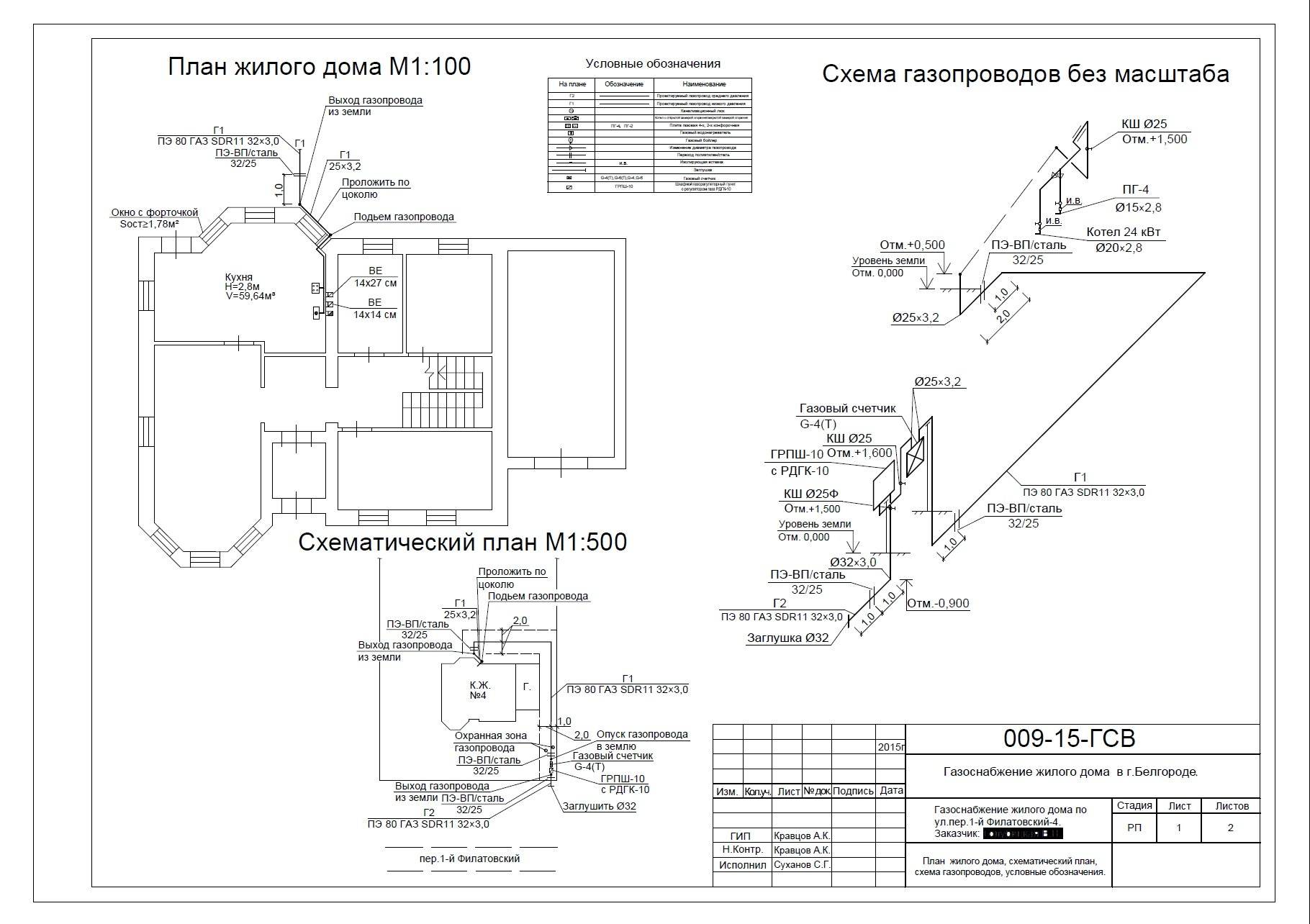

- Stage 2. Drawing up a project.

- Stage 3. Drawing up and approval of the estimate.

- Stage 5. Delivery of the gas tank and pipes to the site

- Stage 6. Laying of autonomous gasification.

- Stage 7. Debugging of the gasification system, delivery of the project.

- Stage 8. Legalization of the installation

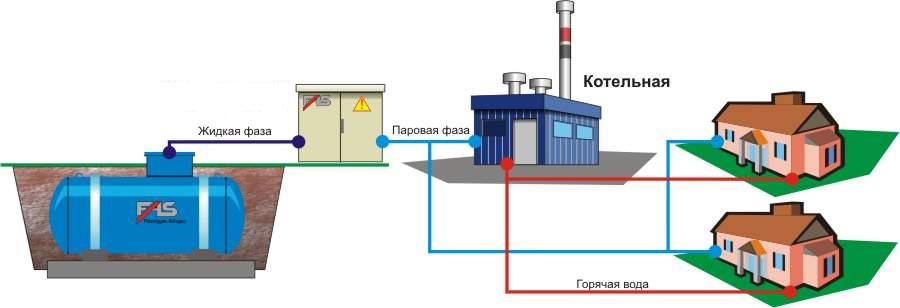

- Gasification of a boiler house or enterprise

- Requirements for a gasified room

- Which houses can be connected to gas supply

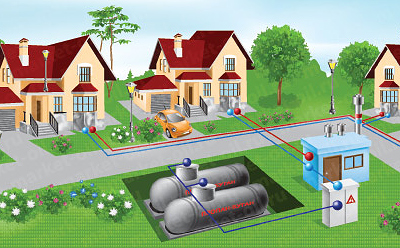

Elements of autonomous gasification system

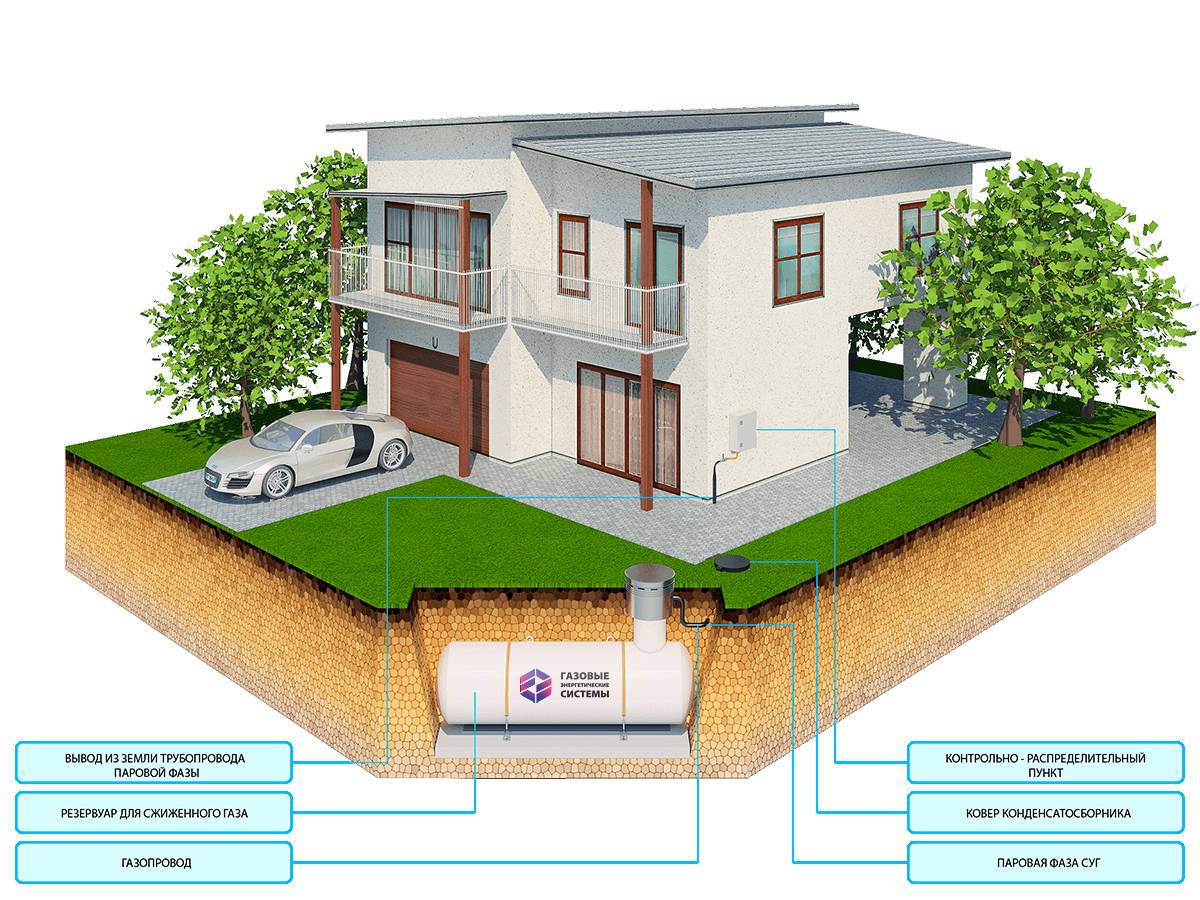

The device of the gas tank and its method of mounting on a concrete slab

The gasification system of any country house should include the following elements:

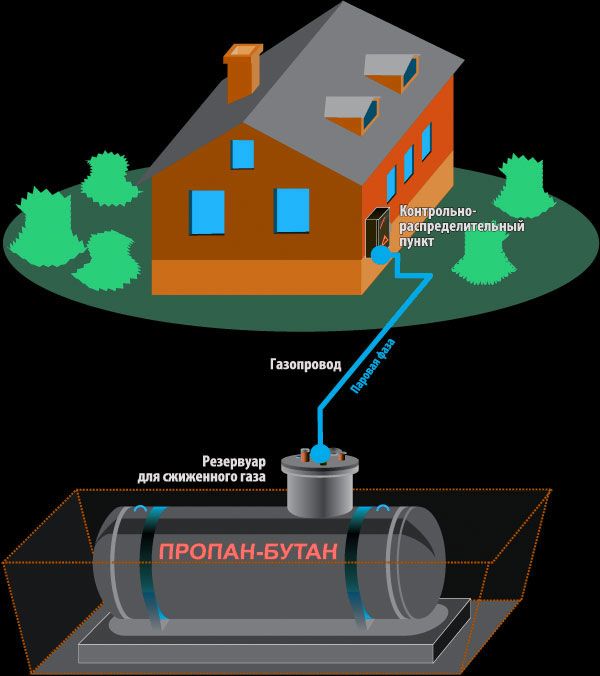

- The gas tank is a sealed tank made of high strength steel. Here, a propane-butane mixture is stored under pressure. The deeper the gas tank must be installed, the more durable the structure must be.

- Reinforced concrete slab - the container must be completely stable. The base eliminates the displacement of the tank in case of any movement of the soil.

- Cathodic-anodic protection - steel is prone to corrosion.Upon contact with the ground, this quality is enhanced, as the metal accumulates electricity, thereby provoking an electrochemical oxidation reaction. The protective system slows down rusting.

-

Butane collector-evaporator - during prolonged cold weather, butane accumulates at the lowest point of the system and shuts off the fuel supply.

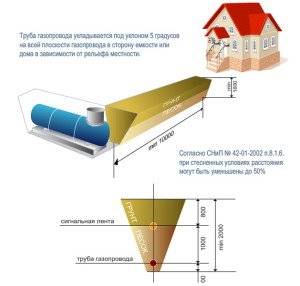

- Gas pipelines - external and internal. The underground part can be made of polyethylene. Lay it at a depth below the freezing level under a slope. However, according to the rules, underground gas supply to the building is prohibited. For this, a basement input is equipped - a structure that includes a steel pipe, a crane and a bellows compensator. The latter provides gas supply to the house with any movement of the soil.

- Shut-off and control valves are taps, relief valves, safety valves, pressure regulator.

- Measuring equipment - sensors and devices for measuring pressure, temperature, accumulation level.

- Gas equipment - stove, boiler, boiler.

Some models are equipped with a manhole through which a specialist can get inside the tank and inspect it. In the basement module, you can install an additional valve that shuts off the gas supply to the house when a leak is detected.

Rules for the arrangement of gas heating

Gasification and the construction of a gas-based heating system in a private house is carried out in several stages:

- Preparation and subsequent approval in the supervisory authorities of the gas heating project.

- Purchase of consumables, boiler and other equipment.

- Connecting the house to the settlement gas networks.

- Installation of gas equipment and piping systems with batteries.

- Filling pipes with coolant.

- Verify functionality by test run.

It is impossible to independently prepare a gas heating project for your country house with all the schemes and calculations without a diploma in heat engineering.

In addition, the generated documentation still needs to be approved by the gas workers. It is best to entrust all these procedures to the employees of the relevant design and installation organization.

The scheme of arrangement in a private house of gas heating should be calculated to the smallest detail. If the boiler is chosen too powerful, it will burn excess fuel. And in case of insufficient capacity, the unit will have to work at the limit of its capabilities, as a result of which it will fail prematurely.

To obtain permission to connect to a centralized highway and to use liquefied gas equipment, it is necessary to obtain a different package of documents. Before deciding on the organization of the gas system, you need to study not only them, but also weigh the pros and cons in order to determine the best option.

The procedure for gasification of a private house

Now it's time to get acquainted with the order of work. So, there are two ways to solve this problem. You can contact a private company that will take care of all the issues related to the design and collection of the necessary documentation. Of course, the services of such offices are not free. You can do this on your own. If you chose the second option, then you should go to the local oblgaz structure, taking with you your passport, documents for the land plot, as well as the technical characteristics of the heating system, and write a corresponding application. After you visit a specialist involved in the development of specifications.

When designing an autonomous gas supply for a private house, some requirements must be observed.For example, a container in which liquefied gas is stored must be located at a certain distance from various structures. The distance is observed as follows:

- to the fence at least 2 meters;

- more than 10 m recede from residential buildings, and 5 m is enough from trees and non-residential premises;

- the distance to wells, hatches, as well as wells should be at least 15 m.

Also, specialists study the properties of the soil, in accordance with its indicators, specifications are compiled. After, having written another application and collecting a number of documents (technical characteristics of the evaporator and reservoir, site plan, external gas pipeline and, of course, the conclusion of previous specialists), you should also contact the gasification design company. Of course, this organization must have the appropriate license. As a result, after registering with a specialized office, you will receive permission to carry out further work.

Only after this paper routine can you start installing the tank and connecting it directly to the gas pipeline of a private house. Moreover, this stage should be carried out only by highly qualified specialists. The only thing you can do yourself is earthmoving, thus saving some money, but wasting time.

Installation of an autonomous gas pipeline

If the owner of the site wants to reduce the cost of installing an autonomous gas pipeline, he can dig a pit for a gas tank on his own. But this must be done in strict accordance with the project. It is better to entrust all other work to specialists so that everything is done in full compliance with safety requirements.

When installing an autonomous gas system, external pipe laying should be used; only permanent connections are used to connect individual sections

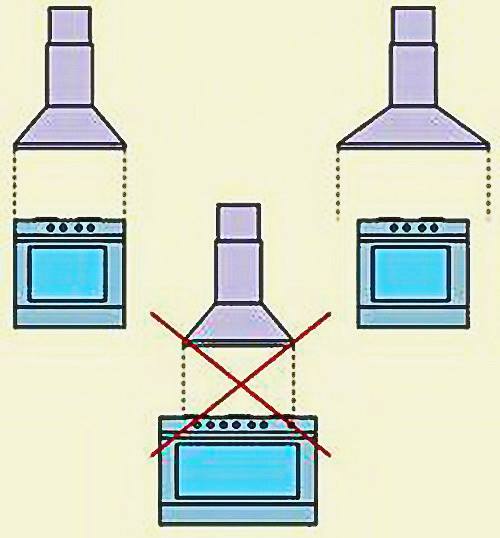

All gas pipes should only be laid openly, they should not be hidden under a screed, false panels or other decorative elements. Carefully consider the layout of pipes for liquefied gas. It is not allowed to carry out such communications in transit through living quarters, through a kitchen or other utility rooms in which appliances that operate on liquefied gas are already installed (or will be installed).

The base for the gas tank must be even and solid, a sand cushion is arranged for it, on which a concrete slab of suitable dimensions is placed

Another categorical prohibition associated with the installation of gas pipes is detachable connections. Of course, connectors are needed at the beginning of the network, i.e. where the network is connected to cylinders or a gas tank. And at the end, when connecting the pipe to the boiler or column, it is also necessary to put a connector.

But along the entire length of the autonomous gas pipeline, the connections must be made only one-piece. The part of the gas pipeline that is laid outside needs to be taken care of additionally. The entire external network should be carefully insulated using special materials that are resistant to fire. In addition, it is necessary to ensure the removal of condensate, this will reduce the likelihood of pipe corrosion.

To reduce the cost of installing an autonomous gas pipeline, you can dig a pit for an underground gas tank yourself, but you must follow the project documentation

The gas boiler must be installed in a separate room - the boiler room. Its area must be at least 15 cubic meters. m. In the room it is necessary to make a window, the opening area of \u200b\u200bwhich is at least half a cubic meter. Such a hole in the outer wall will create an outlet for the blast wave in the event of an accident. If the gas explodes in a room with blank walls, the entire building can be seriously damaged.

At the entrance to the boiler room, you should put a door that opens outward. Another point that should not be neglected is the ventilation of the boiler room. The supply of fresh air must be constant to ensure combustion of the gas. Sufficiently good air exchange must be ensured so that the gas does not concentrate in a room with an open fire in case of accidental leakage.

The gas boiler should be installed in a separate room with a window and a door that opens outwards. Finishing is carried out using fire-resistant materials

Ventilation will also prevent poisoning by combustion products if there are problems with the chimney. If it is not possible to allocate a separate room for the boiler, it is allowed to install some models in the basement or on the basement floor. But in this case, it is imperative to install a system in the room with the boiler to control the level of hazardous gases in the air.

Installation work on autonomous gasification by a gas tank usually takes two or three days. But after their completion, a number of documents should be drawn up and some coordination should be carried out. The tightness test of the finished system should be carried out under the supervision of specialists from the regional gas organization and Rostekhnadzor.

Before backfilling the underground gas tank with sand, it is necessary to wait after its installation for about two to three weeks

After checking, the gas tank is covered with sand, after which you need to wait about three weeks before filling the tank with liquefied gas for the first time. Completion of work must be formalized by an official act of acceptance and transfer. At the same time, they usually conclude a service agreement.

Sometimes it is more convenient to invite different contractors to install the external and internal gas pipeline. In this case, experts recommend delimiting responsibility between the performers and formalizing this moment as a separate act. It also does not hurt to take care of civil liability insurance.

Installation of an autonomous gas pipeline

If the owner of the site wants to reduce the cost of installing an autonomous gas pipeline, he can dig a pit for a gas tank on his own. But this must be done in strict accordance with the project. It is better to entrust all other work to specialists so that everything is done in full compliance with safety requirements.

When installing an autonomous gas system, external pipe laying should be used; only permanent connections are used to connect individual sections

All gas pipes should only be laid openly, they should not be hidden under a screed, false panels or other decorative elements. Carefully consider the layout of pipes for liquefied gas.

It is not allowed to carry out such communications in transit through living quarters, through a kitchen or other utility rooms in which appliances that operate on liquefied gas are already installed (or will be installed).

The process of installing a gas tank in a pit includes a number of traditional steps:

Another categorical prohibition associated with the installation of gas pipes is detachable connections. Of course, connectors are needed at the beginning of the network, i.e. where the network is connected to cylinders or a gas tank. And at the end, when connecting the pipe to the boiler or column, it is also necessary to put a connector.

But along the entire length of the autonomous gas pipeline, the connections must be made only one-piece. The part of the gas pipeline that is laid outside needs to be taken care of additionally.

The entire external network should be carefully insulated using special materials that are resistant to fire. In addition, it is necessary to ensure the removal of condensate, this will reduce the likelihood of pipe corrosion.

To reduce the cost of installing an autonomous gas pipeline, you can dig a pit for an underground gas tank yourself, but you must follow the project documentation

The gas boiler must be installed in a separate room - the arrangement of the boiler room will be required. Its volume must be at least 15 cubic meters. m. In the room it is necessary to make a window, the opening area of \u200b\u200bwhich is at least half a cubic meter.

Such a hole in the outer wall will create an outlet for the blast wave in the event of an accident. If the gas explodes in a room with blank walls, the entire building can be seriously damaged.

At the entrance to the boiler room, you should put a door that opens outward. Another point that should not be neglected is the ventilation of the boiler room. The supply of fresh air must be constant to ensure combustion of the gas.

Sufficiently good air exchange must be ensured so that the gas does not concentrate in a room with an open fire in case of accidental leakage.

The gas boiler should be installed in a separate room with a window and a door that opens outwards. Finishing is carried out using fire-resistant materials

Ventilation will also prevent poisoning by combustion products if there are problems with the chimney. If it is not possible to allocate a separate room for the boiler, it is allowed to install some models in the basement or on the basement floor.

But in this case, it is imperative to install a system in the room with the boiler to control the level of hazardous gases in the air.

Installation work on autonomous gasification by a gas tank usually takes two or three days. But after their completion, a number of documents should be drawn up and some coordination should be carried out. The tightness test of the finished system should be carried out under the supervision of specialists from the regional gas organization and Rostekhnadzor.

Before backfilling the underground gas tank with sand, it is necessary to wait after its installation for about two to three weeks

After checking, the gas tank is covered with sand, after which you need to wait about three weeks before filling the tank with liquefied gas for the first time. Completion of work must be formalized by an official act of acceptance and transfer. At the same time, they usually conclude a service agreement.

Sometimes it is more convenient to invite different contractors to install the external and internal gas pipeline. In this case, experts recommend delimiting responsibility between the performers and formalizing this moment as a separate act. It also does not hurt to take care of civil liability insurance.

How is the laying of autonomous gasification

To perform work on the installation of autonomous gasification, several steps must be followed:

Stage 1. Study of the site.

This preparatory stage is necessary, since it is important to know in what soil the gas tank will be installed in order to protect the tank from undesirable influences. Based on the type of soil of your site, autonomous gasification using an underground horizontal reservoir, the presence of water bodies on it, a project of subsequent work will be drawn up

In fact, this stage is a guarantee of the safety and durability of the operation of the gas tank.

Stage 2. Drawing up a project.

At this stage, we will take into account that autonomous gasification should be equipped taking into account some rules:

It is important to leave the entrance to the gas tank for refueling.

The gas tank should be installed with a distance from the fence of 2 meters, to a residential building - from 10 m, to non-residential buildings - 5 m, to water bodies - from 15 m.

This will ensure that all safety regulations are met.

The project will include:

- Site plan diagram.

- Placement of the gas tank.

- Laying of the protection and grounding system.

- Marking of gas consumption devices.

- Evaporation plants and condensate collectors.

- Gas pipeline scheme.

Stage 3. Drawing up and approval of the estimate.

The cost of arranging autonomous gasification will include:

- The cost of our work

- The price of a gas tank and pipes for wiring.

- The cost of consumables and related services.

When choosing a gas tank, we will focus on:

- The budget you have.

- Needs in volumes of gas consumption.

- Simplicity and ease of maintenance of the gas tank.

- Conditions under which autonomous gasification will be carried out.

Stage 5.Delivery of the gas tank and pipes to the site

Delivery of all necessary equipment is carried out by our forces, which saves you from unnecessary trouble. In addition, you will be sure that all equipment will be delivered without damage, which means it is ready for installation.

Stage 6. Laying of autonomous gasification.

Before laying autonomous gasification, we will prepare a pit in which we will place a gas tank and lay pipes, connect equipment. In this case, all work will be carried out in accordance with the drawn up drawing of the project.

Stage 7. Debugging of the gasification system, delivery of the project.

We connect all gas appliances, diagnose their performance, perform commissioning, check the automation. After that, you can freely operate gas appliances, enjoying the comfort in your home.

Stage 8. Legalization of the installation

The operation of gas installations from autonomous gasification requires legal registration of the installation of a gas tank. This process is a formality that can take a long time if you are unable to collect the proper documents. In the event that you do not register an autonomous gasification installation, you will face a considerable fine. For registration you will need:

- Site plan.

- Design documentation for installation.

- Documents for the installed gas tank.

We will prepare these documents for you. You will only have to take your passport and take the documents to the executive body, where you will be issued a permit to operate the installation.

In addition, we can offer you gas tank maintenance, diagnostics of its correct operation, tank filling.Our experts will tell you how to properly operate the equipped gasification system, when to order gas tank refueling. For systematic maintenance of systems, we recommend that you conclude an agreement with our company. This will ensure the uninterrupted operation of all gas systems, reduce the risk of unnecessary expenses for troubleshooting.

Gasification of a boiler house or enterprise

When gasifying a boiler house, an individual heating point or an enterprise, the same questions arise as when gasifying any other facility, since it takes place according to the same norms and rules established by Russian law. When gasifying your facility, you will first need to carry out pre-project work, then design a gas network, after which construction and installation work is carried out, and finally, coordination and delivery of documentation.

The best solution would be to entrust this work to qualified Gascom specialists.

Construction and design of external and internal gas pipeline networks

One of the most important activities of GASCOM is the design and construction of gas pipelines to gas consumption facilities. We design and build gas pipelines to boiler houses, residential buildings, manufacturing plants, warehouse complexes, business centers. Gasification of an object (construction of a gas pipeline) is a complex multi-stage process. We offer: construction of a gas pipeline on a turnkey basis from obtaining technical specifications to connecting the constructed gas pipeline with subsequent launch of gas.

Preparatory and design work for the construction of a gas pipeline (gasification):

- determination of the technical feasibility of gasification of the facility;

- performance of work on the calculation of fuel for the subsequent receipt of the Technical Specifications;

- obtaining technical specifications for gasification at Peterburggaz LLC, if it is in St. Petersburg or at Gazprom Gas Distribution of the Leningrad Region, if the object is located in the Leningrad Region;

- approval of the act of choosing the route of the gas pipeline;

- obtaining a resolution from the administration for design and survey work;

- geological surveys and geodetic survey of the site;

- control survey of the gas pipeline route;

- design of an external gas pipeline;

- design of the internal gas pipeline of residential buildings, boiler houses, public centers; storage and commercial facilities;

- state expertise of the project (if necessary);

- registration of the project with Rostekhnadzor - the Federal Service for Ecological, Technological and Nuclear Supervision;

- preparation of budget documentation;

- obtaining all approvals of the OPS, USPH, Ministry of Emergency Situations, local governments, related organizations, etc.);

This is interesting: Antifreeze for the heating system - read in full detail

Requirements for a gasified room

When developing an autonomous gasification project, regulatory regulations are strictly observed. Experts scrupulously check each item of the submitted design and estimate documentation.

Based on the conditions for the construction of a frequency house, the methods of laying a pipeline through which gas will be supplied to the dwelling, the type of connected equipment, the requirements for gas networks are determined. If at least one of the points of the requirements and rules is not observed, the project documents are returned for revision.Employees of the technical department of gas services carefully check the documentation.

For residential private buildings, the following rules have been developed:

- within the walls of one dwelling it is allowed to install two boilers (main and backup);

- as a rule, gas equipment is placed in a separate dedicated technical room (boiler room), located on the ground floor of the building;

- installed gas appliances for providing hot water supply, heating and cooking, as well as gas meters must have a passport or other document from the manufacturer;

- household appliances, boilers are connected using flexible or conventional piping made of stainless steel or other approved materials that ensure the safe supply of natural fuel. The recommended maximum hose length is 1.5 m;

- at facilities with installed gas equipment, it is planned to install a gas metering unit (this is a gas meter, pressure sensors, temperature sensors, etc.);

- cocks that shut off the supply of blue fuel to the device are isolated from the flexible pipeline with a special dielectric insert.

If materials with a high flammability class are used near gas boilers, stoves, then they must be lined with non-combustible thermal insulation; in the boiler room, hinged windows should be provided that open quickly in case of an emergency.

The minimum dimensions of the kitchen room where the gas stove is located are determined: the ceiling must be at least 2.2 m high, the windows must be easy to open, it is necessary to leave a small space from the bottom of the door to the floor for through air exchange.At present, it is mandatory to place a special gas supply in the gas supply room. leak detection device gas type "gas-control".

If a gas stove is installed in the kitchen, then the volume of the room should be:

- with 2 burners - at least 8 cu. meters;

- 3 – 12;

- 4 – 15.

There must be at least one meter distance between the gas stove and the opposite wall.

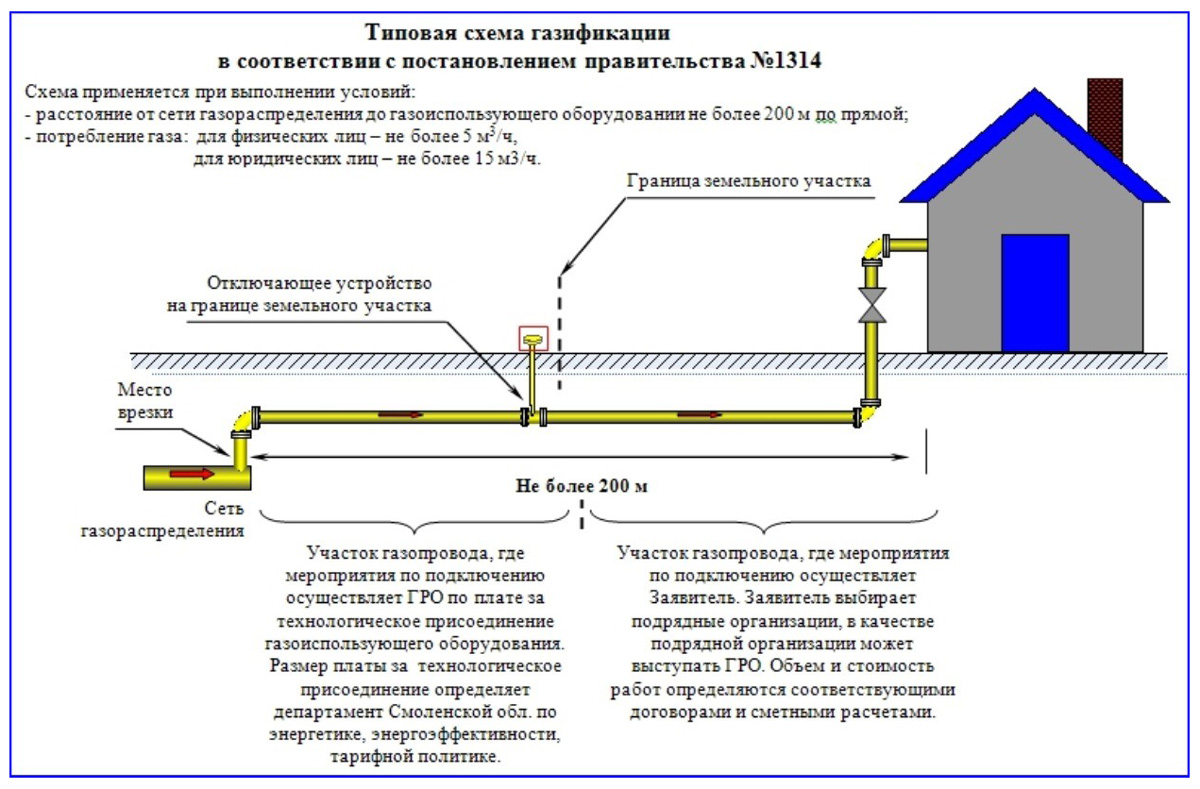

Which houses can be connected to gas supply

Centralized gas supply provides for the transportation and delivery of natural gas to the consumer. Connecting a capital structure to a gas main includes two stages - organizational and technical actions. The set of organizational measures includes the preparation and collection of the necessary technical documentation, the filing of an application for gasification and conclusion of an agreement in case of a positive decision of the gas service.

Technical actions: connecting the gas main to the land, connecting the house to the gas distribution network, installing a gas meter and starting gas.

Gasification of a residential building is clearly regulated by law. According to Government Decree No. 1314, gas connection is allowed to capital construction facilities. If residential, country or garden houses, as well as garages and utility buildings have a strong connection with the ground, that is, they are installed on the foundation and registered as real estate, then there will be no problems with their connection. In any other case, gasification will be denied. An attempt to connect gas supply to non-capital construction facilities is prohibited by law and, depending on the consequences, is punishable by a fine or criminal punishment.In an apartment building, gas is connected to the entire house. To connect capital buildings located on the territory of garage cooperatives, gardening or summer cottages, an application for technological connection is submitted by the owner of the territory.