- The principle of operation of a gas boiler

- Automation of heating boilers

- Types of automation for boilers

- Varieties of automation

- Volatile automation devices

- Non-volatile devices

- The most frequent breakdowns in the control unit

- How does the type of thrust affect the operation of the boiler

- Types of remote control heating systems

- Automation for coal boiler

- Boilers with automatic feeding

- According to the method of ejection of exhaust gases

- Which automation is better

- german

- Italian automatics

- Russian

- Functions and principle of operation of safety automation

- What is a gas burner

- Principles of operation of boilers with automation elements

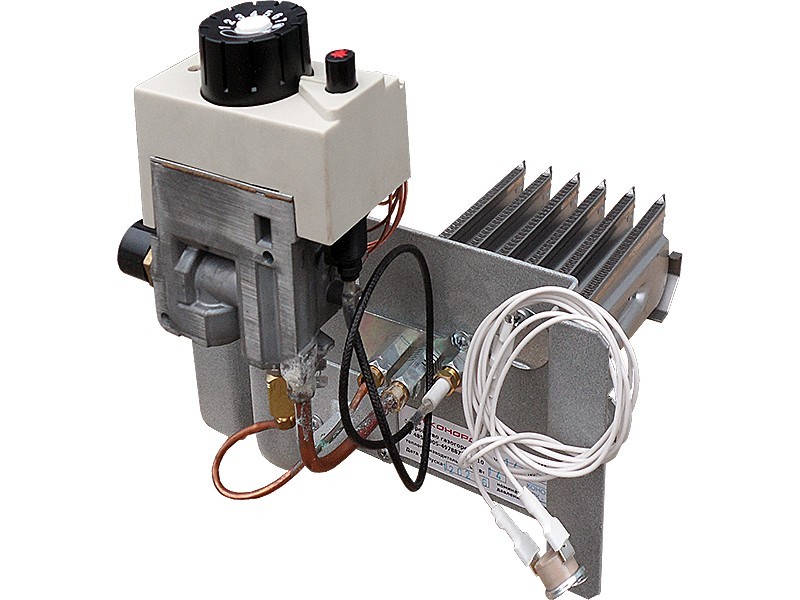

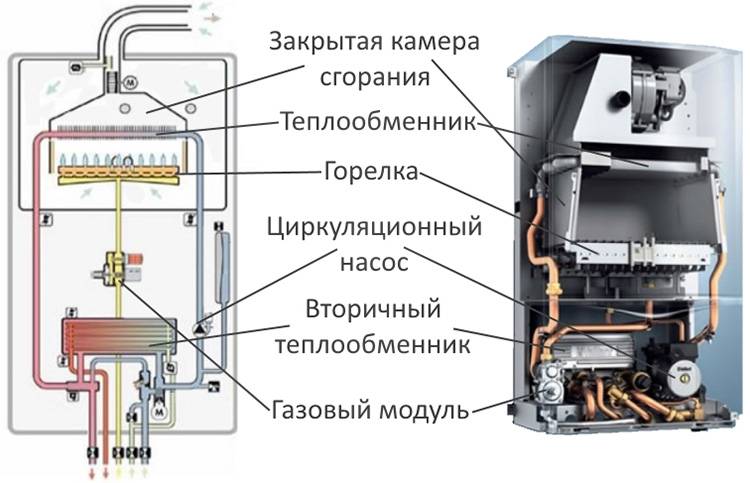

- Design and principle of operation

- How to choose a UPS?

- Advantages and disadvantages

- General classification of gas burners by type of fuel

- Turbocharged types of gas burners and their design differences

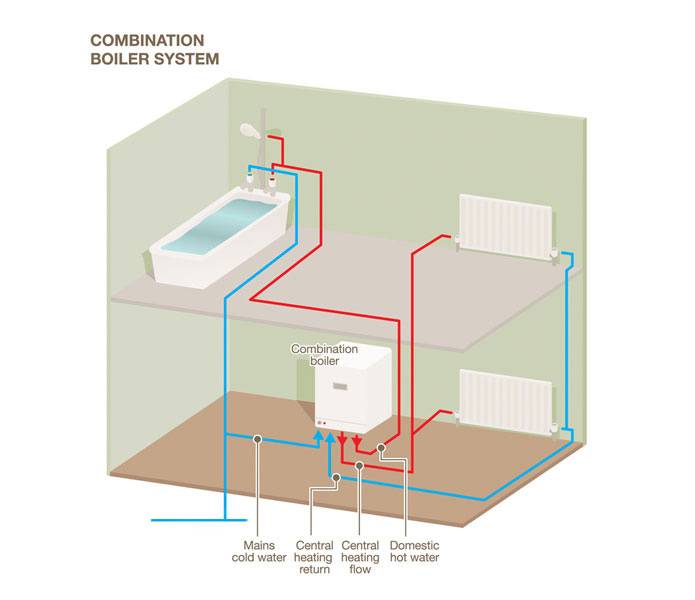

The principle of operation of a gas boiler

This equipment works according to an extremely simple scheme. Natural gas mixes with air, turning into a fuel-air mixture, which is ignited. The flame and hot combustion products of the fuel heat the contents of a special reservoir - a heat exchanger, which is connected to a heating system (CO) with a liquid coolant.

The latter constantly circulates through the system - either only due to convection (natural circulation), or also due to the operation of a special pump (forced circulation).

The device of a wall-mounted double-circuit gas boiler

Flue gases, having given up part of their energy to the coolant, are brought out through the chimney.

Along with conventional boilers, so-called condensing boilers are being produced today. They "know how" to take away more heat from the flue gases, so that they cool down to the condensation temperature of the water vapor contained in them.

It is condensation that is the source of the main part of the additional heat (the processes of changing the state of aggregation are very energy intensive). As a result, the efficiency of the installation increases to 97% - 98%.

Automation of heating boilers

Boiler automation, which you can buy in our store, is an extensive group of devices that perform various functions of controlling the operation of boiler equipment. Each manufacturer offers various types of boiler automation, designed for equipment of a certain type and model, or universal devices suitable for several boilers. If you decide to "buy automation for the boiler" - in our company you can buy automation for boilers, the price of which is optimal, produced by leading companies in the world in a wide range and at attractive prices.

Automatic control systems, which are used in modern boilers to ensure operation in the absence of people, can perform various functions:

On / off, time control;

Changing the operating mode depending on weather conditions, time of day or room temperature;

Shutdown of the boiler in the event of a breakdown or dangerous situation;

Forced air supply to the combustion chamber, etc.

Types of automation for boilers

Modern automation for boilers and burners is represented by a wide range of non-volatile and electrical devices for equipment running on gas, liquid or solid fuel. The most common boiler automation solutions involve the use of the following devices:

Traction measurement sensors: pressure gauges, draft gauges, pressure gauges;

Varieties of automation

Depending on the principle of operation and design features, automation for gas heating boilers can be one of the types:

- Volatile.

- Non-volatile.

Volatile automation devices

These devices are small electronic devices that respond to gas supply by opening / closing a tap. The device differs in constructive complexity.

Tasks that electronic boiler automation allows you to solve:

- Close/open the gas supply valve.

- Start the system in automatic mode.

- Regulate the power of the burner, thanks to the presence of a temperature sensor.

- Turn off the boiler in emergency cases or within the specified operating mode.

- A visual demonstration of how the unit works (what temperature is maintained in the room, to what mark the water is heated, and so on).

Due to the constant growth of consumer requests for ease of use, manufacturers of modern devices offer a number of additional features:

- Management and control of equipment operation.

- Protection of the heating system against a malfunction of the three-way valve.

- Freeze protection of the system.In this case, the device starts the boiler when the room temperature drops sharply.

- Self-diagnostics in order to identify faulty spare parts, failures in the operation of structural elements. This option allows you to avoid breakdowns that can disable the boiler, and, consequently, high material costs associated with major repairs or replacement of equipment.

So the electronic automatic safety of gas boilers ensures smooth operation of the equipment when:

- no jumps;

- the specified temperature regime is precisely observed;

- there are no other problems during long-term operation.

Today, a wide range of volatile-type automation is presented on the market. It can be both with the possibility of programming, and without it. In the first case, you can set the system to work in day-night mode or set different temperature conditions for 1-7 days, taking into account the weather forecast.

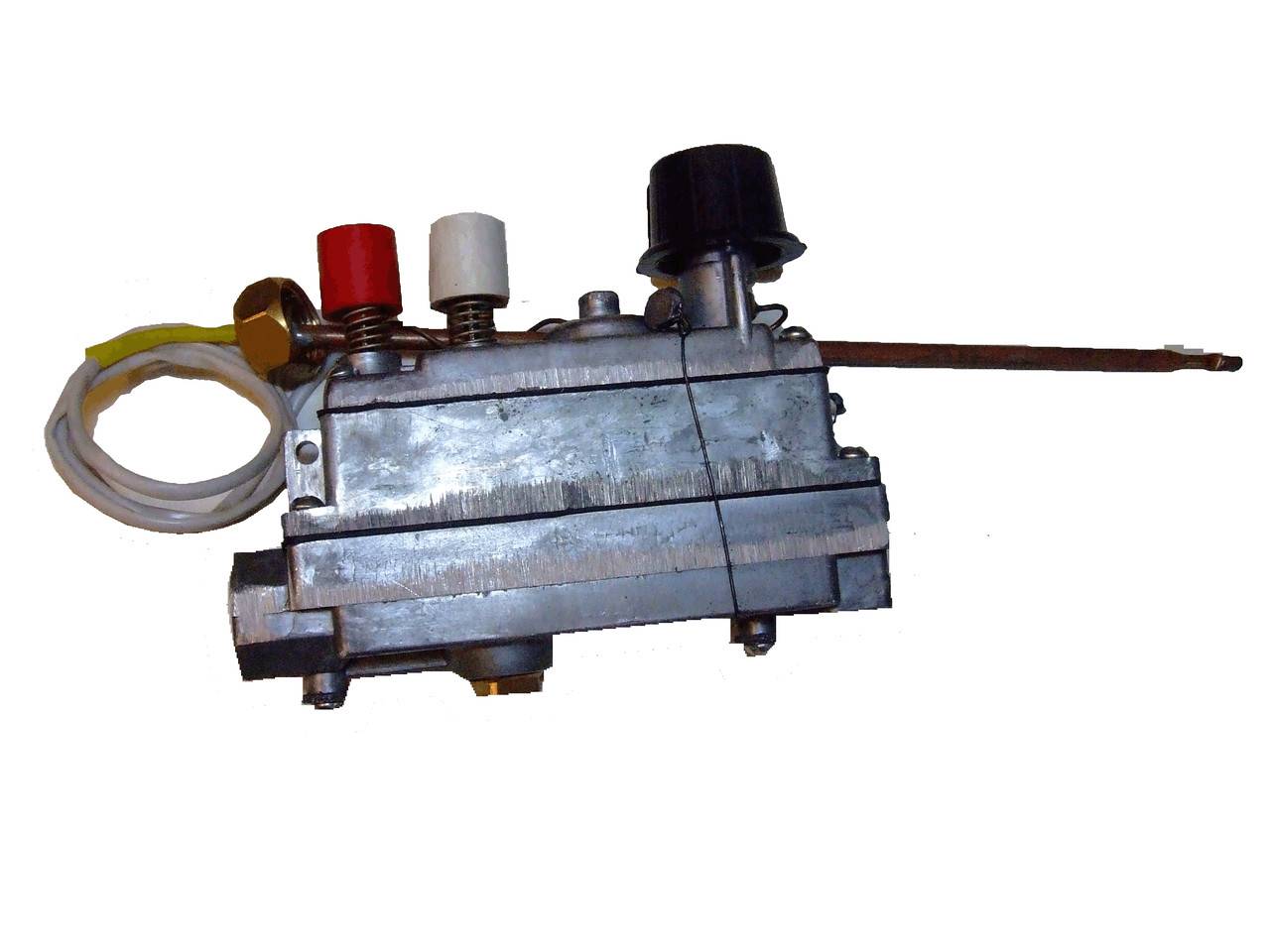

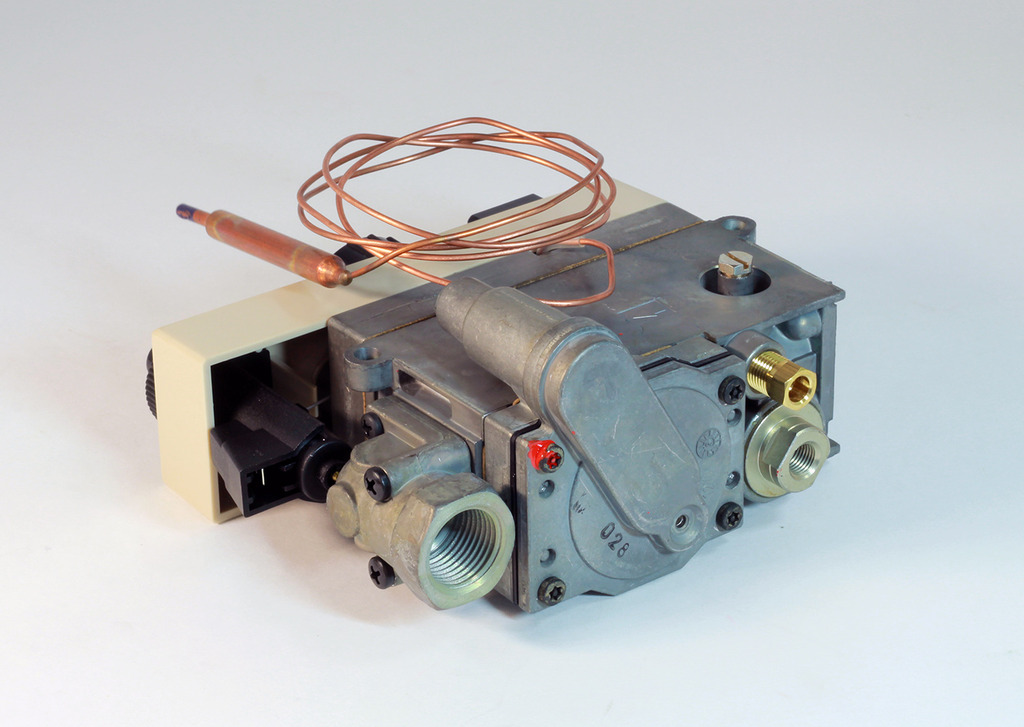

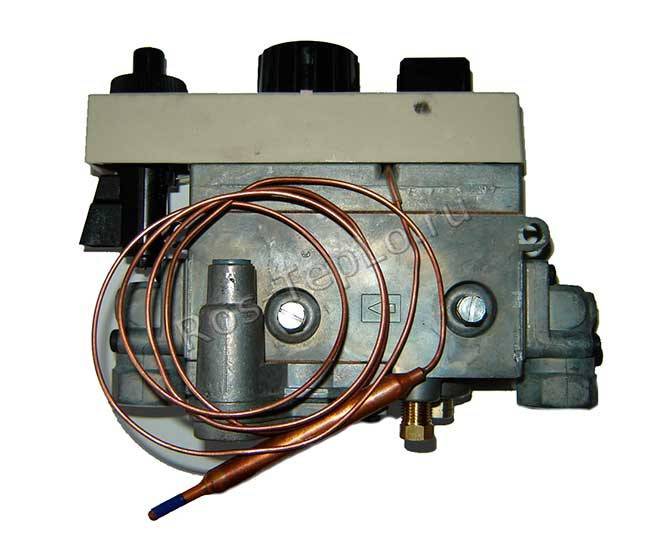

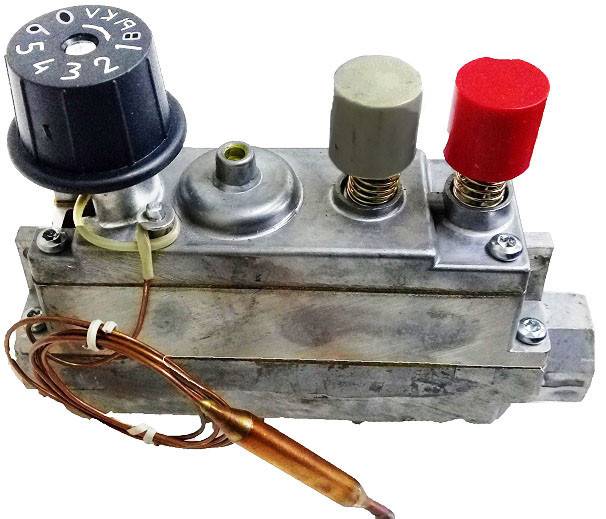

Non-volatile devices

This type of automatic equipment for controlling the operation of gas heating boilers is mechanical. And many consumers prefer it to him.

Main reasons:

- Low price.

- Manual setting, which is simple, which makes it easy to control the device for people far from technology.

- The autonomy of the device, which does not require electricity to operate.

Manual setting is as follows:

- Each device is equipped with a temperature scale from the minimum value to the maximum value. By selecting the desired mark on the scale, you set the operating temperature of the boiler.

- After the unit is started, the thermostat takes over the operation, which controls the set temperature by opening / closing the gas supply valve.

The principle of operation is based on the fact that the gas boiler thermocouple, which is built into the heat exchanger, is equipped with a special rod. The part is made of a special material (an alloy of iron and nickel - Invar), which quickly reacts to temperature changes. Depending on the increase or decrease in temperature, the rod changes its dimensions. The part is firmly connected to the valve, which regulates the gas supply to the burner.

But besides this, today's automation for a gas boiler of a non-volatile type is additionally equipped with draft and flame sensors. They will immediately stop the fuel supply if there is a sharp drop in draft in the chimney or as a result of a decrease in pressure in the pipe.

A special thin plate is responsible for the operation of the flame sensor, which is in a bent state during normal operation of the system. So she holds the valve in the "Open" position. As the flame decreases, the plate straightens out, causing the valve to close. The same principle of operation of the thrust sensor.

The most frequent breakdowns in the control unit

Since the VU is a whole system, failure can occur from any deviation of a component of this system. The most common malfunctions and their causes:

- the burner went out - air got into the gas pipeline;

- heating problems - poor gas supply, lack of oxygen;

- boiler overheating - closed contacts, prolonged operation at high temperatures, factory defective sensors;

- breakdown of the pneumatic relay (draft sensor) - incorrect connection, breakdown of the fan, incorrect chimney system;

- breakage of the temperature sensor - incorrect connection of contacts, short circuit, overheating of the board;

- failure of the pressure switch - low water pressure in the pipes, defective contacts in the board.

Most of these problems are easily fixed, even described in the instructions, but some require the intervention of a specialist.

Do not replace sensors or other parts yourself - it can be dangerous.

How does the type of thrust affect the operation of the boiler

Devices operating on natural draft are called atmospheric. To burn gas, they take oxygen from the room in which they are located. Emission of waste substances occurs through the chimney, from the side it looks like a chimney. Natural draft boilers have the following advantages:

- simplicity of design;

- noiselessness at work;

- relatively low price;

- autonomy - they do not depend on electricity.

Chimney of a gas floor boiler Among the shortcomings, one should keep in mind the unstable operation of the device when the pressure in the gas lines changes. If it decreases, the flame may go out. In such conditions, "blue fuel" is spent very uneconomically. This problem is not faced by those who install boilers with forced draft. Other advantages of such units include the fact that they:

- do not burn oxygen in the room;

- do not require the installation of a vertical chimney;

- can be placed in almost any home.

Operation of the boiler without a chimney Devices that operate on forced draft are called fan or forced draft. For their operation, the installation of a coaxial chimney is required. Through it, oxygen enters for the combustion of "blue fuel", and the substances formed as a result of the operation of the boiler are removed.All this happens with the participation of fans. They perform their functions by making noise, which can cause inconvenience to residents. Other disadvantages of forced draft units are their high cost and dependence on electricity.

Types of remote control heating systems

In addition to the remote boiler control systems presented - using the Internet and using cellular communications, there is a third type, which is called combined. In this case, remote control over the heating boiler can be carried out in any convenient way, both using the Internet and using a mobile phone.

This system has the following modes of operation:

- Automatic - here the gsm controller for the heating boiler executes a number of specific programs, processing information received from external sources.

- SMS - works by transferring the parameters of the temperature sensor to the phone in the form of SMS messages, in this case the controller for the boiler sets up the heating system using the input data.

- Warning - sends alarm SMS in case of critical situations.

- Provisioner - performs remote coordination of related devices, such as heating elements for heating water, a thermostat for electric heaters, an electric boiler control unit or a gas boiler control board.

The equipment for the presented remote control system has the highest cost. However, in this case, remote control can be carried out in any convenient way and from any location.

Automation for coal boiler

The possibilities of the devices are wide enough.Often, sets of heating devices include: a computer that controls the device, a fan or an air turbine.

The advantage of equipment equipped with automation for heating a private house is considered to be a huge saving of precious minutes and money. After all, innovative long-burning boilers can do almost all the work for you - they are able to work without human intervention for quite a long time - up to about 48 hours! The owner of the house only needs to set the desired degree level, and the device will carry out the actions on its own. In addition, you can set the timer for the temperature mode. That is, for example, if the owner of the property leaves it for a certain amount of time, then the minimum temperature regime will be maintained. By the time the tenant arrives, the timer will go off, the house will begin to warm up again to the desired temperature - without human intervention! So, upon arrival, housing will be comfortable, warmed up.

It is important to note that boilers with automation have become so advanced that they are able to independently carry out diagnostics - a safety check, which is a very significant plus.

Boilers with automatic feeding

Today they are considered the most efficient installation - after all, the efficiency reaches 80-85%! Such a unit will definitely provide home comfort. Fuel is poured into the bunker, from there it is fed automatically into the combustion chamber. There is also an add-on that allows you to clean the ash pan automatically - without human intervention. The process of installing boilers is a very painstaking work, so saving is not worth it for your benefit.

According to the method of ejection of exhaust gases

According to how the smoke is removed, there are such types of boilers:

- Chimney.

- Turbocharged.

- Parapet.

The first type is boilers with an open combustion chamber. As the name implies, they require the installation of a solid chimney.

Scheme of a turbocharged double-circuit gas boiler

In turbocharged boilers, the combustion chamber is closed, and the gases are forcibly removed by the built-in fan. Such devices need a coaxial pipe (in fact, these are two pipes one in one: smoke exits through the inner pipe, and oxygen necessary for the combustion process enters the outer pipe). Pipes are laid through the outer walls without mounting a vertical channel.

Parapet. The boilers are similar to the previous version (it also has a closed combustion chamber and a double pipe), but the smoke is removed by natural air circulation, and not by a fan. Therefore, parapet boilers do not need electricity.

Which automation is better

Today, the market for boiler equipment is oversaturated with proposals for the automation of boilers, coming from both imported and domestic manufacturers.

The former are very expensive and capricious, they do not tolerate the working conditions of Russian engineering networks, the latter are less functional. The best automation for a boiler is always its own, that is, produced in a single configuration by the manufacturer.

It is there on the stands that she gets the correct setting with the operating modes of the unit. An equally important factor in boiler room automation is the manufacturer's warranty obligations, which must guarantee its operation for at least a year free of charge and replace the unit in case of failure.

german

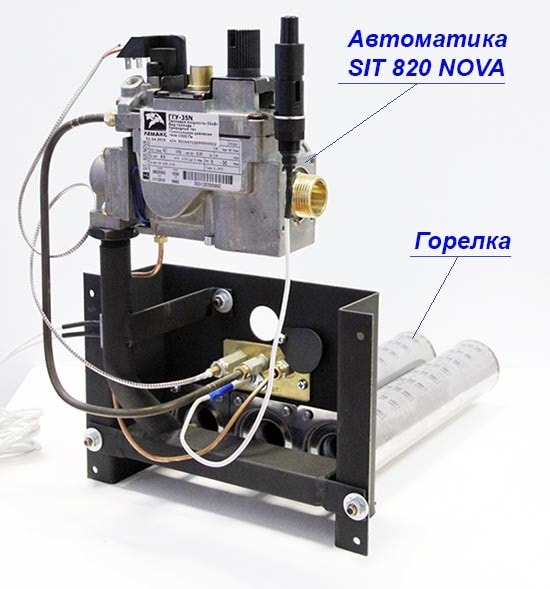

German automation for Vaillant, Honeywell, AEG, Bosch boilers is quite popular in the Russian market, due to its excellent consumer quality, durability and reliability. High level of automation and protection. Recently, German manufacturers have set up automation of condensate boilers that provide efficiency. almost 100%.

Italian automatics

EuroSIT 630 is considered the best Italian automatic system for gas boilers in the world. It is produced in full compliance with EU standards, but at the same time they have a lower price than German systems.

Automation boilers EuroSIT 630 covers all parameters of the boiler, but is very sensitive to the parameters of the gas line and the power grid. For this system, the mandatory installation of input voltage stabilizers.

Russian

Recently, more and more boilers are purchased with Russian automation systems, since they provide a good protection system and reliable boiler control at the lowest price level.

The experience gained with the automation of processes in industrial boilers has been successfully integrated into the operation of domestic boilers using the latest technologies and developments of European manufacturers. Among the large number of Russian companies, especially, the most popular are Neva-Transit and Lemax.

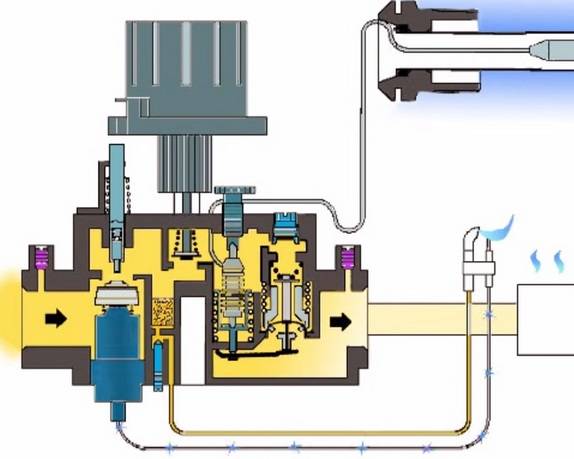

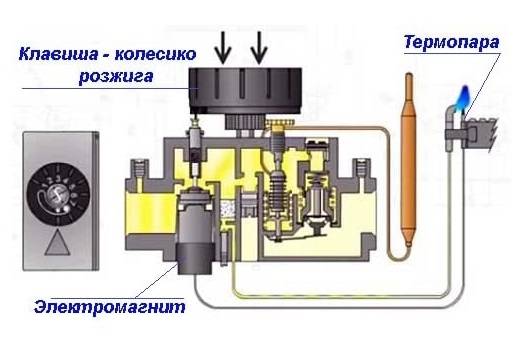

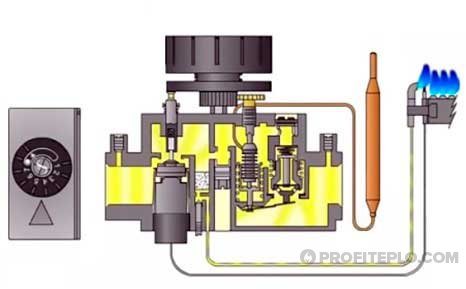

Functions and principle of operation of safety automation

According to regulatory documentation, the security system of automatic gas boilers should consist of equipment that will turn off the system by shutting off the gas in the event of any breakdown. Thus, automation monitors a number of indicators

- Gas pressure. When it drops to a critical point, the fuel supply stops.The action takes place automatically due to the valve mechanism, which is set to a certain value. In volatile applications, the maximum/minimum pressure switch is responsible for monitoring. The membrane with the rod bends with an increase in the number of atmospheres, as a result of which the boiler power contacts open.

- Is there a flame in the burner. In its absence, the thermocouple cools down, stopping generating current. As a result, the solenoid flap of the gas valve does not work and no gas is supplied.

- The presence of traction. When it decreases, the bimetallic plate heats up and changes shape, so the valve stops the fuel supply.

- Heat carrier temperature. The thermostat is needed to maintain the temperature set by the user, preventing the system from overheating.

Schematic arrangement of the operation of the automation controller

The result of these malfunctions can be the shutdown of the main burner and the gas content of the room, which should not be allowed. Therefore, automation should be present on all gas boilers without exception, especially on old-style equipment, where this construct was not provided by the manufacturer.

The functioning of the electronic system is based on receiving information from sensors. It is analyzed by the controller and microprocessor. After processing the data, certain commands are sent to the drives of the unit.

The principle of operation of the mechanics is different. When the boiler is off, the gas valve is closed.Starting the unit involves squeezing the washer on the valve, as a result of which it opens in forced mode and fuel enters the igniter. Its ignition leads to the heating of the thermocouple and the generation of voltage on it, which is necessary for the functioning of the electromagnet. He, in turn, keeps the valve open. Turning the washer, you can adjust the power of the boiler.

What is a gas burner

A gas burner is one of the most important components of any boiler. She is responsible for creating a sustainable flame. This is where the fuel is burned. The received heat rises up to the heat exchanger, where it almost completely passes into the coolant. Combustion products, together with the remaining heat, are somehow removed into the atmosphere.

The device of a gas burner for a boiler is extremely simple - it includes several main components:

The low emission of nitrogen oxides and carbon monoxide during combustion makes the boiler almost ecologically perfect.

- Nozzle - gas is ejected from here;

- Ignition system - provides gas ignition;

- Automation system - controls the temperature;

- Flame sensor - monitors the presence of fire.

Simply put, this is exactly what it looks like. And how these or those types of gas burners differ from each other in various models of boilers, you will find out a little later.

A modern gas burner for a heating boiler is a device that has certain requirements. First of all, quiet operation is important. I immediately recall some models of Soviet instantaneous water heaters, where the flame was noisy with the force of a hurricane

Modern samples burn relatively quietly (attention is also paid to quiet ignition, without pops and explosions). An additional influence on the noise level is exerted by the design of the combustion chambers. Long service life - if you remember the old gas units, they served for quite a long time (in those days everything was done for centuries)

Today, such technologies no longer exist, so burners in boilers often break. There is only one way out - to buy units from trusted brands, which use components of normal quality. As for any Chinese junk from obscure manufacturers, everything is obvious here - you should not take

Long service life - if you remember the old gas units, they served for quite a long time (in those days everything was done for centuries). Today, such technologies no longer exist, so burners in boilers often break. There is only one way out - to buy units from trusted brands, which use components of normal quality. As for any Chinese junk from obscure manufacturers, everything is obvious here - you should not take it.

The same applies to cheap Russian-made boilers - short-lived burners are often installed in them.

Complete combustion of the gas is another important requirement. The burner for a gas boiler must burn the fuel completely, with a minimum release of carbon monoxide and other related components. However, everything depends not only on it - the quality of combustion is also influenced by other nodes.

We must not forget about proper gas removal, for which you need to have a clean chimney with good draft at your disposal.

As for the principle of operation of a gas burner, it is simple:

However, everything depends not only on it - the quality of combustion is also influenced by other nodes. We must not forget about proper gas removal, for which you need to have a clean chimney with good draft at your disposal.

As for the principle of operation of a gas burner, it is simple:

In the burner, the combusted gas is combined with air. At high temperatures, a chemical reaction occurs with the formation of carbon dioxide and water.

- The boiler fixes the discrepancy between the temperature in the heating circuit and the parameters set by the users;

- The gas valve opens, gas begins to flow into the burner;

- At the same time, the ignition system is activated;

- The gas is ignited and a flame is formed.

At the same time, the control of the presence of a flame begins to work - if the fire suddenly goes out, the automation will cut off the supply of blue fuel. As soon as the temperature in the heating system reaches the set limit, the gas supply will be shut off.

The implementation of flame control is implemented in gas burners in different ways. Somewhere there is a simple thermoelement, and advanced boilers with electronics-based automation are endowed with ionization control systems.

Principles of operation of boilers with automation elements

A large role in the operation of a solid fuel boiler is played by a firebox, which performs the functions of a heat exchanger. This is where the combustion takes place.

Around this structural element is a water jacket, which is heated by the hot walls of the fuel. Subsequently, water enters pipes and radiators. In this case, the liquid circulates by gravity without any special pumps.

You can regulate the intensity of combustion of a solid fuel boiler manually, using a gate, or using mechanical dampers.If you want to increase the temperature in the room, then you need to raise the damper, which will increase the flow of air and speed up the combustion process.

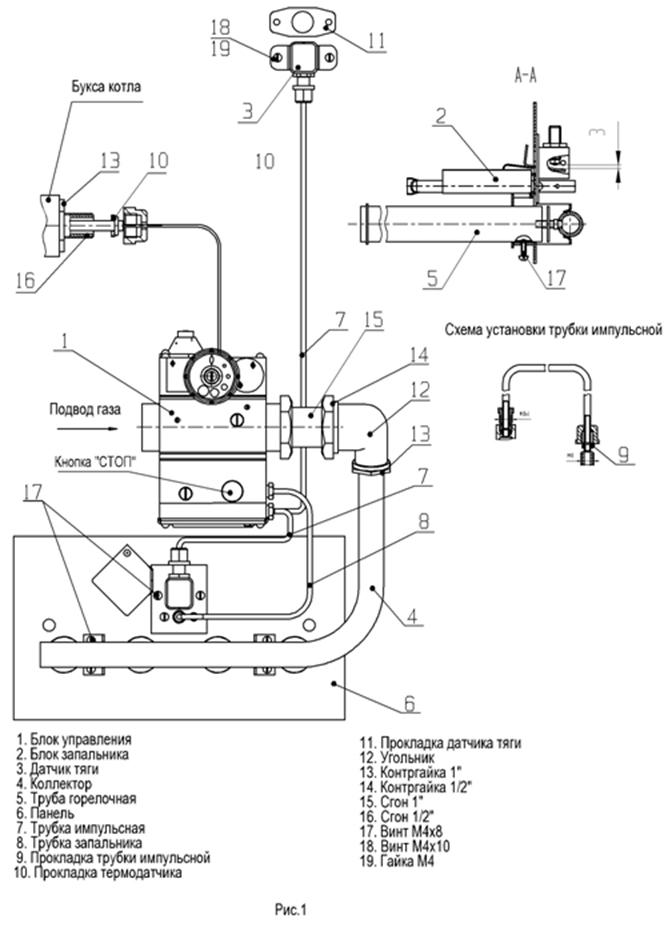

Design and principle of operation

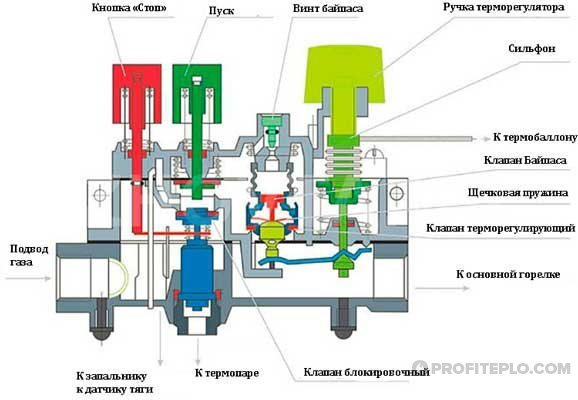

Automation for heating boilers has many components. Conventionally, they are divided into two groups

- Mechanisms to ensure the proper functioning of the boiler.

- Devices for comfortable operation of the heating system.

Responsible for security

- Flame control module. Its main elements are a thermocouple and an electromagnetic gas valve (responsible for shutting off the gas).

- Thermostat - a module responsible for maintaining the set temperature of the coolant and protecting against overheating. It turns on / off the boiler when the temperature of the coolant rises / falls to peak levels.

- The draft control sensor is responsible for cutting off the gas supply to the burner depending on the change in the position of the bimetallic plate.

- A safety valve is needed to control the amount of coolant in the circuit.

Scheme of automatic control of a gas device

Automation for comfort contributes to the removal of some duties from users, as it performs functions such as auto-ignition of the burner, selection of the most efficient operating mode, self-diagnosis, and others.

How to choose a UPS?

When choosing a backup uninterruptible power supply for a gas heater, it is necessary to build on the power consumed by the boiler. The more it consumes electricity in the process of heating the coolant, the more capacious the battery is needed. Otherwise, the battery life will be too short. Power cuts sometimes last for several hours.If the capacity of the uninterruptible power supply is enough for only a few dozen minutes, then there is zero sense from it.

There are three criteria for choosing a UPS for gas heating equipment:

-

Boiler power;

-

Battery type;

-

Operating time from the source.

The selected power depends not only on the boiler itself. If the system has a circulation pump and other volatile devices, without which the normal functioning of the heating is impossible, then this must be taken into account. Their consumption must also be added to the parameters of the boiler. The existing do-it-yourself heating schemes for a private house are very diverse, they often contain a huge amount of "smart automation". However, all these devices consume electricity.

It is impossible to use car batteries for uninterruptible power supply of a gas boiler. Technically, they can be connected. However, they were originally designed for completely different operating modes. The designers laid in them the need for a short-term output of current when starting the car engine.

If they are equipped with the UPS in question, then car batteries will not last long under constant loads. Most of them are simply afraid of deep discharge. Plus, electrolyte evaporation is unacceptable in residential areas.

For gas boilers, batteries made using AGM or GEL technology should be taken. In the first, the electrolyte simply does not evaporate due to the solutions used in the manufacture, and in the second, a special gel is poured between the battery plates instead.

To calculate the capacity of the UPS in a particular case, you should multiply the hours (how long your lights usually turn off) and the power of the boiler (according to the data sheet), and then divide them by a factor of 8.65. For example, for autonomous operation for 12 hours of a 24 kW heater with a power consumption of 130 W, one 24 V battery or two 12 V batteries is required. C = (150 * 12) / 8.65 = 180 ampere-hours. Most 12V batteries are usually 100Ah, so two will be needed.

When choosing a device for uninterruptible power supply of the boiler, you should also look at:

-

The presence of the mark "pure sine";

-

Charge current parameters (from 4 to 20 A);

-

Switchover time to battery (0 to 1 second).

The higher the charge current, the faster the battery will be filled with energy. However, charging too fast is contraindicated for some batteries. If the boiler is equipped with precision electronics, then the transition time from the mains to the battery should be zero. Delays and interruptions in the power supply are not allowed here.

The main point is “pure sine”. If the UPS data sheet says “approximated sine wave” or “stepped approximation of a sine wave”, then such an uninterruptible power supply is designed for computers and TVs. It is impossible to power a gas boiler from it.

Both the circulation pump motors and the burners require an exactly sinusoidal voltage to power them. With a fuzzy sinusoid, parasitic currents arise in the electric motor, causing overheating and burning of the winding insulation. And for the ignition electrodes of the burner, such a supply voltage is completely contraindicated.

Advantages and disadvantages

Heating gas boilers for a private house have their pros and cons, quality characteristics.

Advantages:

- During the operation of the equipment, it is not necessary to monitor the flame. The gas supply is continuous. In the event of an accidental interruption of the heat source, the sensor transmits information to the electric ignition system. After the burner ignition system has been triggered, the process will resume.

- Efficiency is high at low fuel cost.

- Large areas can be heated.

List of shortcomings and difficulties:

- In order to install a technical device, you must contact Rostekhnadzor, submit all documents for the boiler and its installation, as well as a service agreement with an organization that has the right to engage in this type of activity.

- Arrangement of a chimney for exhaust gases.

- Allocate a special room with windows and access to the street.

- An open flame in a gas burner is one of the factors requiring careful attention to safety.

- Use of boilers adapted to Russian conditions.

- To control the leakage of energy resources, an automatic installation is necessary.

Provided that the requirements are met, the operation of gas equipment will be efficient, reliable and safe.

General classification of gas burners by type of fuel

Country houses can not always be provided with natural gas supplied from a common highway. Therefore, the variability of the burners in terms of the use of different types of fuel is provided. If the fuel comes from a gas main, propane-butane gas burners are most likely used for heating boilers.

Main gas-methane is the most affordable natural fuel for boilers. However, now there is no big benefit in the price of liquefied blue fuel (propane-butane mixture).General heating provided by the main pipeline is also expensive.

Gas boilers operating on different types of fuel mixtures have approximately the same design. There is a slight difference in cost, but it is also insignificant (equipment for liquefied fuel will cost more). The burners themselves are slightly different, having different nozzles for liquid fuel and blue gas.

If natural gas is not supplied to the house, propane-butane gas burners are used.

Propane burners require adjustment to this type of fuel with the installation of a jet. When burning, the flames give off a yellowish color, soot accumulates more in the chimney. The jet is responsible for normalizing the pressure.

Modern burners operate in a wide temperature range - from -50 to +50 °C. Part of the equipment can be adapted for other types of energy carriers:

- waste oil;

- diesel fuel;

- fuel oil;

- kerosene;

- propanobutane base;

- arctic diesel fuel.

Modern fixtures often come with both types of nozzles or universal equipment for fuel varieties, which makes them easy to reconfigure.

Homemade gas burners are most often used in solid fuel boilers.

It is safer to purchase simple gas equipment adapted for gas in cylinders. Homemade equipment, although more affordable, but unsafe! Usually carry out "alterations" on the basis of old units.

Turbocharged types of gas burners and their design differences

Among modern gas equipment, many experts prefer closed-type burners for turbocharged boilers.They are self-sufficient in terms of design, suggest the presence of a compact chimney, which can even be diverted into general ventilation with autonomous heating.

The heating unit with a special closed-type combustion chamber receives oxygen from the outside - through a special supply pipe (coaxial chimney). In approximately the same way, combustion products are removed to the outside. Heating equipment is controlled by a sufficiently powerful fan on automatic control.

Fan gas burners also have a drawback - this is the price due to the complex design of the product

Such a device is much more expensive than atmospheric heating equipment. However, for an additional fee, the buyer receives a number of benefits, including autonomous operation in a residential area. This device, thanks to automatic control, has a high level of security.

Turbocharged equipment has the highest efficiency and flexible temperature scheme

Fuel burns almost completely, which is important for environmental performance. There are also disadvantages, including structural complexity, causing difficulties during installation and repair.

Gas burners for combined equipment are most often used in solid fuel boilers. This is a rather complex unit, so all nodes must meet certain requirements for efficiency and safety. The automatic device is able to switch from one type of fuel to another for uninterrupted heat supply. According to this principle, pellet and pyrolysis boilers are arranged, equipped with gas for burners, which drives the ignition process.