- No. 4 - Bosch Gas 6000W WBN 6000-24 C

- Turbocharged or naturally aspirated?

- The choice of coolant

- Differences between floor and wall boilers

- Single-circuit and double-circuit wall-mounted gas boilers

- About DHW heating

- Turbocharged gas boilers: how to choose, principle of operation, advantages and disadvantages

- Kinds

- Varieties of natural gas boilers

- The principle of operation of a turbocharged boiler

- Advantages and disadvantages of equipment

- Pros and cons of single-circuit units

- Advantages and disadvantages of double-circuit boilers

No. 4 - Bosch Gas 6000W WBN 6000-24 C

The 4th place in the ranking is occupied by the Bosch Gaz 6000 W WBN 6000-24C model. This German unit has a power of 24 kW (adjustable from 3.3 to 24 kW). Heat exchangers: copper - for heating, stainless steel - for hot water supply. Fuel consumption - no more than 2.8 m3 / h. Productivity on hot water – 7 l/min. Dimensions - 70x40x30 cm.

Advantages:

- multilevel protection system;

- profitability;

- high efficiency (92 percent);

- availability of an automatic diagnostic system;

- ease of installation.

Flaws:

- some users note periodic clicks during operation;

- energy dependence.

All the minuses of the device pale before the German build quality and guaranteed safety. The optimal combination of reliability and cost is noted.

Turbocharged or naturally aspirated?

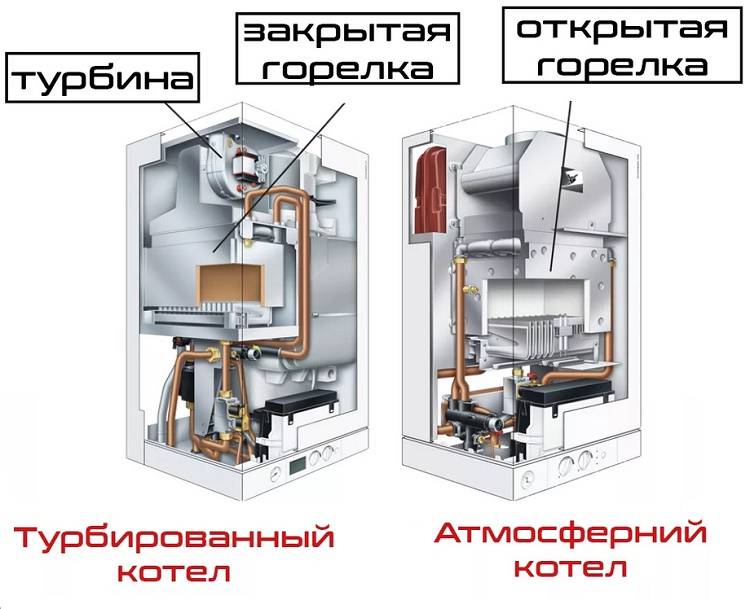

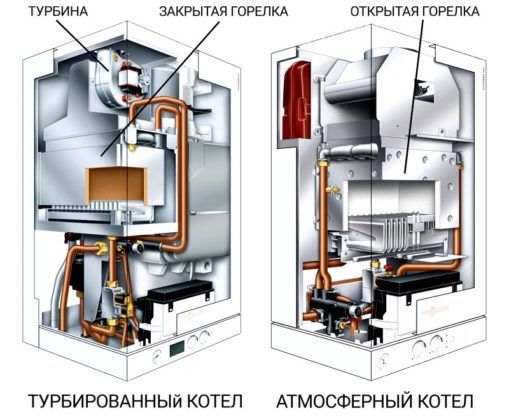

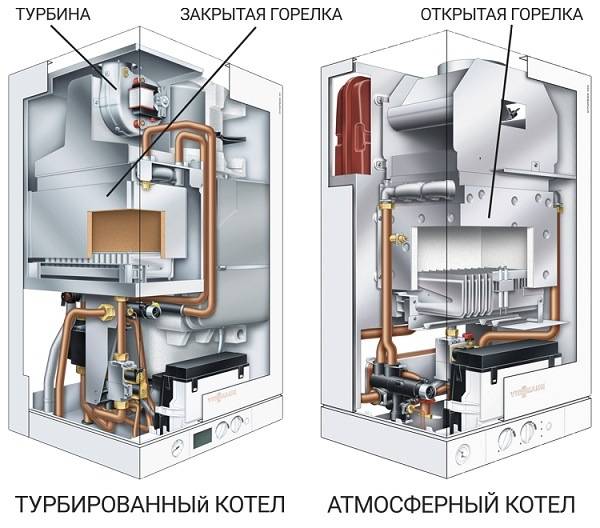

When the buyer is faced with the choice of which boiler is better to choose: turbocharged or atmospheric, all the features of their design and operation should be considered.

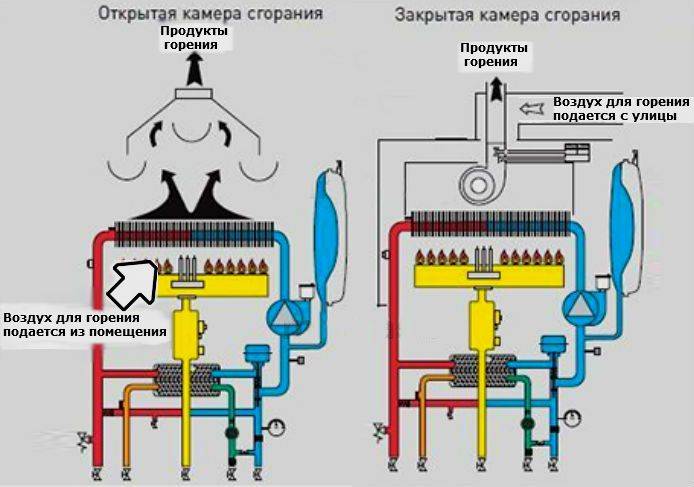

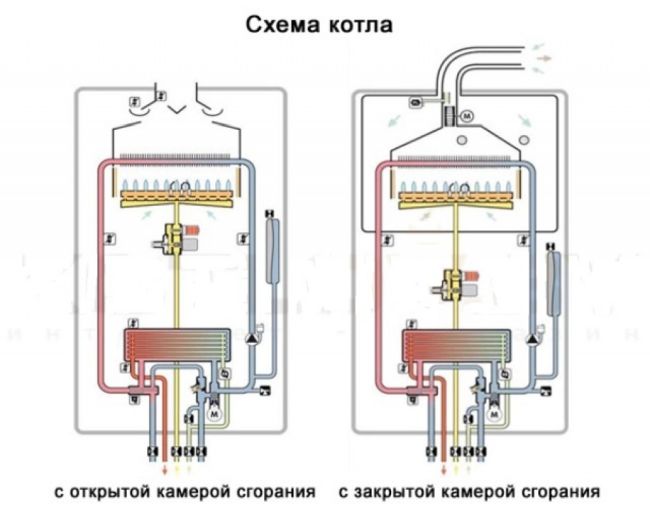

The main difference is that in an atmospheric boiler the process of fuel combustion occurs in an open way with natural air exchange, therefore such equipment is often called convection equipment. Such boilers are connected to a standard chimney, and the air for the combustion process is taken from the boiler room.

When using atmospheric boilers, there is an increased gas consumption and strict installation requirements, regulated by SNiP. Also, atmospheric equipment must not be used in multi-storey buildings and during installation it is impossible to cover the case with decor.

In a turbocharged boiler, the combustion chamber is closed. Forced air exchange and removal of flue gases by means of a turbine are used. During operation, the air from the furnace is not used for fuel combustion.

Therefore, the norms allow the installation of such equipment in small rooms, decorating the case, near the meter. Turbocharged gas boilers are connected to a coaxial chimney, which serves both for the intake of outside air and for the removal of combustion products.

Therefore, the main difference compared to atmospheric boilers is forced air exchange and smoke removal.

The choice of coolant

Usually two options are used:

- water. Experts recommend pouring distilled water if the volume of the system allows it. This method avoids the formation of lime deposits, but it will not protect against freezing pipes in winter;

- ethylene glycol (antifreeze).It is a liquid that does not freeze when circulation stops. Contains a set of anti-corrosion additives, does not form scale, does not have a destructive effect on polymers, rubber, plastic.

For systems that need to be drained frequently, water is the best and most economical choice. The use of antifreeze is recommended for heating circuits operating in difficult conditions.

Differences between floor and wall boilers

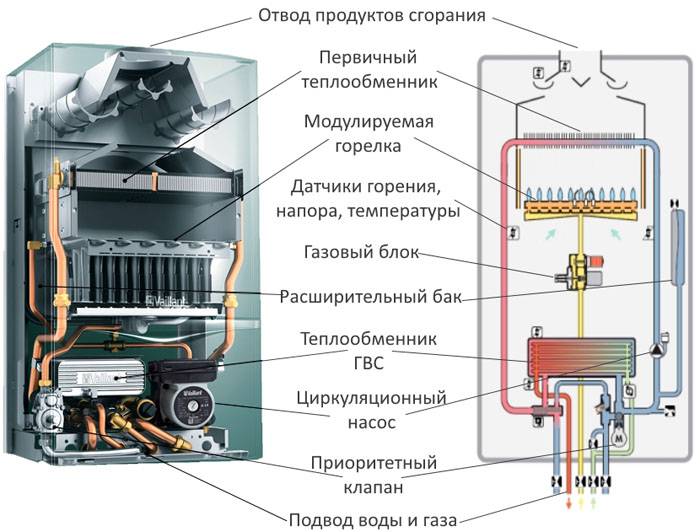

As a rule, a wall-mounted single or double-circuit atmospheric gas boiler is a kind of mini-boiler room with a built-in expansion tank, a circulation pump, and an electronic control board. Options for equipping with a valve for connecting an indirect heating heater and weather-dependent programmers are possible.

The main advantage of a wall-mounted boiler is its compactness, light weight, high functionality, ease of installation. Such a unit is ideal for installation in cramped conditions, operation in a residential area is allowed. Modern mounted boilers have sufficient power to heat a house up to 200 sq.m.

Compact wall-mounted gas boiler fits perfectly into the modern interior of the room

Floor boilers have large overall dimensions, and their weight can be 3 times higher than the weight of a wall-mounted boiler with similar parameters. This is due to the fact that floor-standing units, unlike wall-mounted units, are equipped with cast-iron heat exchangers.

The service life of such boilers is 20-25 years. At the same time, wall-mounted boilers with steel or copper heat exchangers will last you 8-10 years.

Single-circuit and double-circuit wall-mounted gas boilers

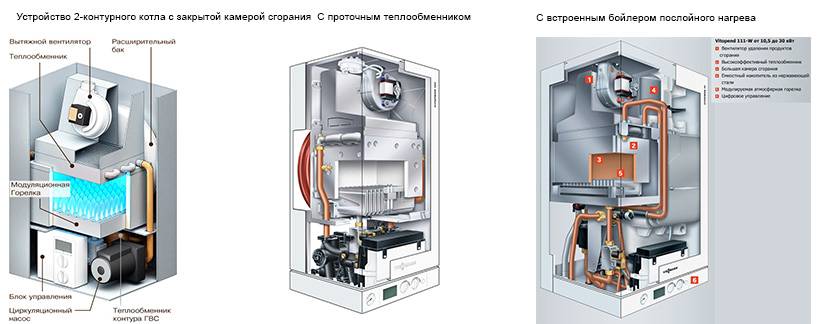

Depending on their design features, gas boilers are divided into two main types: single-circuit and double-circuit. A single-circuit boiler has a simpler device and is used only for heating the working fluid in the heating system. It uses one burner. The double-circuit wall-mounted boiler is simultaneously used for both heating and hot water supply. It is equipped with two burners and two heat exchangers that can work independently of each other. As a rule, such devices use a flow-type water heater, which is able to provide enough warm water for a small family of two or three people. If you need a large amount of warm water, you can install an additional storage heat-saving tank - a boiler.

A double-circuit boiler costs much more than a single-circuit boiler and takes up more space, so installing it only makes sense if you do not have other sources of hot water (central hot water supply or electric boiler). Depending on their performance, wall-mounted double-circuit boilers can produce from 4 to 15 liters of hot water per minute.

Let's look at the features and performance characteristics of the most popular boiler models from various manufacturers.

About DHW heating

As stated in the recommendations above, double-circuit wall and floor boilers with flow heat exchangers are effective at low water consumption (1-2 consumers).In addition, for heating water, they are completely disconnected from the heating system, since this function is a priority for the controller.

In a cottage with two bathrooms, a laundry room and a kitchen, a wall mount with a flow heat exchanger will not be enough. There are 2 options here:

- Mounted or floor heater with built-in storage tank with a capacity of 45 to 100 liters.

- The floor single-circuit unit working together with an indirect heating boiler. You can also apply a mounted modification with one heating circuit.

The latter option is suitable for providing any water flow for hot water supply. Only this wish should be foreseen at the stage of buying a gas boiler, choosing it with a power margin of 1.5-2 times the heat demand. If you do not take into account the additional power for hot water supply, then the generated thermal energy will not be enough to heat the home.

Turbocharged gas boilers: how to choose, principle of operation, advantages and disadvantages

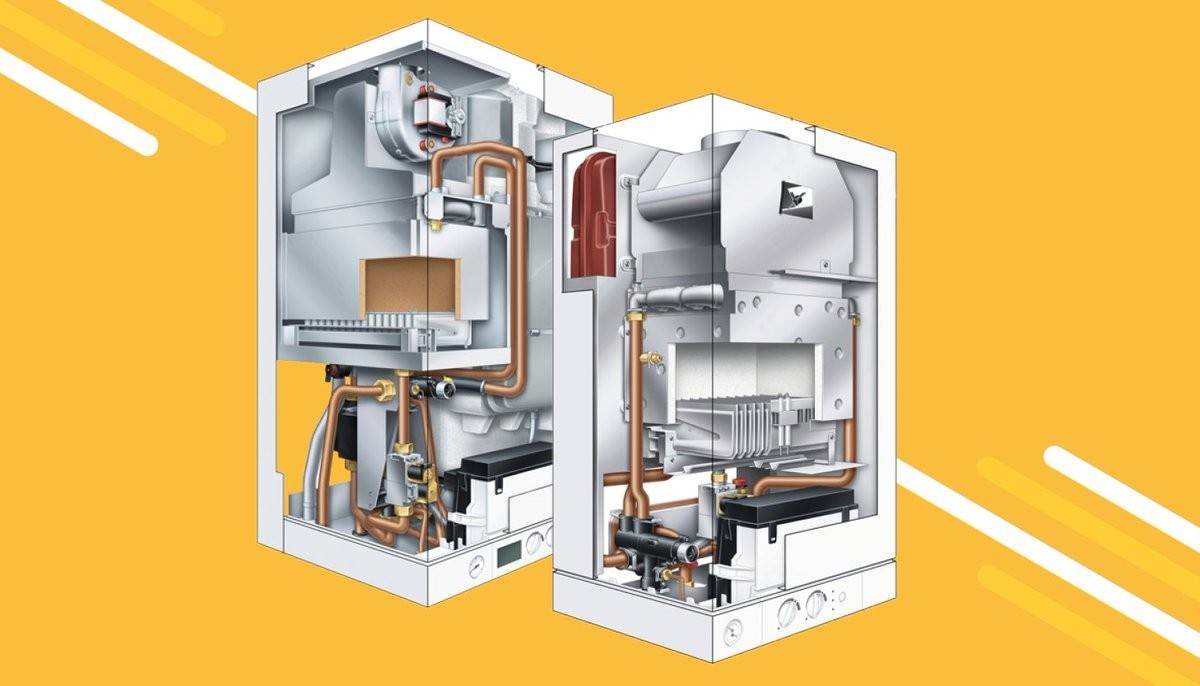

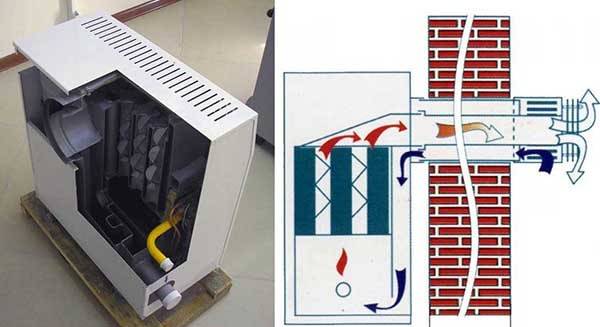

A turbocharged gas boiler is a compact size boiler, which is usually mounted on a wall and has a closed gas combustion chamber and is designed for local water heating systems with forced circulation, photo 1.

Photo 1. Turbocharged boiler in the interior of the kitchen

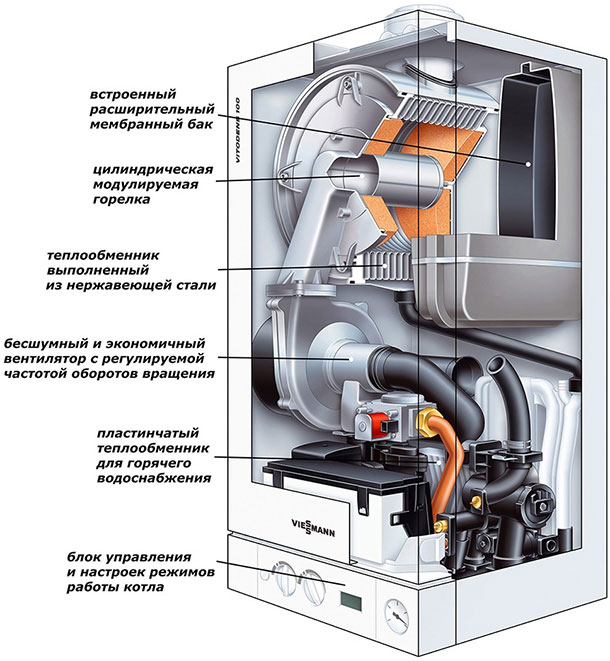

Turbocharged gas boiler - tips for choosing, main features

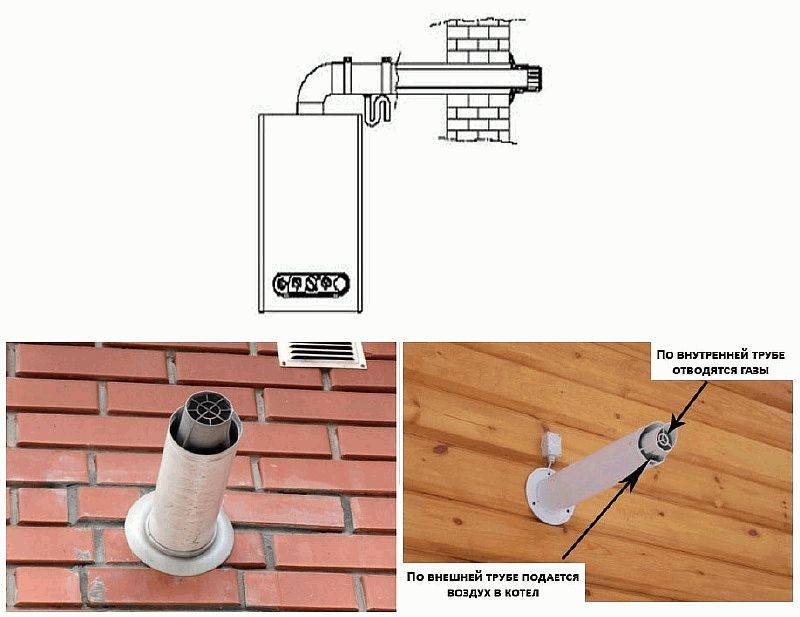

This type of boiler is provided with an oxygen supply using a forced draft fan through a two-channel chimney. One of the differences between this boiler and other types is the design of the chimney; The chimney consists of two pipes - a pipe in a pipe. Through the outer pipe (larger diameter) air is supplied to the boiler, ensuring the combustion of gas, and through the smaller pipe (internal) smoke and gas combustion products exit, photo 2.Such boilers are very often installed in cramped conditions, where it is not always possible to install a standard chimney system or in small buildings.

Turbocharged boilers can have different types of chimneys:

- vertical chimney;

- horizontal chimney;

- vertical two-channel chimney;

- connection to the chimney.

Basically, turbocharged boilers are made double-circuit.

Photo 2. Chimneys of turbocharged boilers

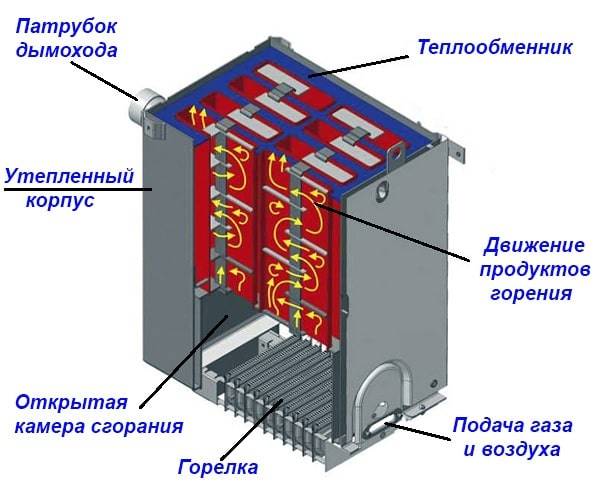

The principle of operation of a turbocharged boiler

A closed-type combustion chamber is installed in a turbocharged boiler. With the help of a fan through a coaxial chimney pipe (diameter not less than 110 mm), air enters the chamber to maintain combustion of the gas supplied from the nozzles. The products of gas combustion are removed by the turbine with the help of a fan to the outside.

Such boilers are equipped with automation that allows you to automate the process of the boiler. The closed-type combustion chamber of wall-mounted turbocharged boilers is usually made of copper or its alloys. The chamber of floor boilers is usually made of cast iron, which ensures a longer operation of the boiler (20 - 30 years and more), and the service life of wall-mounted boilers is approximately 10 years and more.

In connection with the use of the copper chamber of the boiler, in order to avoid rapid wear and burnout, such boilers are produced with low power - up to 35 kW.

Examples of the design and principle of operation of turbocharged boilers are shown in photo 3.

Photo 3. Examples of the design of turbocharged boilers

Advantages of turbocharged gas boilers

- air for gas combustion comes from outside the house (from the street), and not from the room, the combustion chamber is sealed;

- installation of a conventional vertical chimney is not required;

- the ability to install the boiler in a non-residential area inside the house (pantry, kitchen, bath, etc.). There is no need to build a separate building (boiler room);

- compact dimensions of the boiler;

- Efficiency of turbocharged boilers - 90 ... 95%, high energy savings (low gas consumption);

- high productivity of water heating (for 1 minute - 10 ... 12 liters of hot water);

- electronic control system for automation of the boiler operation process (not for all types);

- high safety - there is no possibility of carbon monoxide and unburned gas entering the premises. The presence of automatic devices and sensors that control the operation of the boiler and are capable of emergency shutdown of the boiler;

- simplicity of the device of the chimney.

Disadvantages of turbocharged gas boilers

- high cost of the boiler and parts during repairs;

- dependence of the boiler on electricity.

The most common and high-quality turbocharged boilers are presented on the market by such manufacturers:

- Ariston, Immergas, Baxi (Italy);

- Vaillant, Junkers (Germany),

Tips on how to choose the right turbocharged boiler

1. When choosing a boiler, it is necessary to proceed from the following data:

- the size of the living area and the volume of heated premises;

- the amount of heat loss in the premises, which depends on the quality and thermal conductivity of the walls, windows, floor and roof. This parameter lies in the range of 90 ... 250 W / m 2. For a well-insulated building, this figure is 100 ... 110 W / m 2;

- you should decide on the type of boiler: double-circuit (with additional water heating) or single-circuit (only for building heating). In this case, the intensity and amount of use of hot water should be taken into account.You can use the following data in determining the power of the boiler for heating water, based on the condition that all devices will be turned on at the same time:

Kinds

There are several design options for floor single-circuit boilers. They differ from each other in various ways.

Combustion chamber type:

- atmospheric (open). The air directly surrounding the boiler is used, and the smoke is removed by natural draft. Such models are connected only to the central vertical chimney;

- turbocharged (closed). To supply air and remove smoke, a coaxial type chimney is used (a pipe in a pipe), or two separate pipelines that perform the functions of air intake and supply to the boiler and flue gases.

According to the material of the heat exchanger:

- steel. The most common option used on inexpensive models.

- copper. The serpentine design increases the path of the liquid passing through the heating zone. Such nodes are installed in expensive models of top manufacturers;

- cast iron. Are established on powerful and massive units. Cast iron heat exchangers demonstrate high performance, efficiency, and are capable of developing large unit power values. They are used for units from 40 kW and above.

Heat transfer method:

- convection. Conventional heating of the coolant in the flame of a gas burner;

- parapet. Able to do without a heating circuit, being a kind of analogue of a conventional stove;

- condensation. The coolant is heated in two stages - first in the condensation chamber, from the heat from the condensing flue gases, and then in the usual way.

NOTE!

Condensing boilers are able to fully work only with low-temperature systems (warm floor), or with a temperature difference in the street and in the room of no more than 20 °. For Russia, these conditions are not suitable.

Varieties of natural gas boilers

The division into wall and floor models of boilers is understandable - the first are made in a hinged version, the second are placed on the floor. Those and others are divided into types according to the principle of work:

- Atmospheric. They are equipped with an open combustion chamber where air enters from the room where the gas boiler is located. The name says that the combustion process takes place at atmospheric pressure in the furnace.

- Supercharged (otherwise - turbocharged). They differ in a closed chamber, where air is supplied by forced injection (supercharging) by means of a fan.

- Condensing. These are turbocharged heat generators equipped with a special circular burner and a ring-shaped heat exchanger. The goal is to burn the fuel as efficiently as possible, taking away thermal energy from the water vapor released during combustion, causing it to condense.

Both wall-mounted and floor-standing gas boilers are equipped with steel and cast-iron heat exchangers, where the heat carrier for the water heating system is heated by a burner. In addition, heaters can be equipped with a second water heating circuit for household needs, providing hot water supply to a private house or apartment.

There is another division of heating units - into single-circuit and double-circuit. To understand which boiler is better to choose for home heating, we suggest that you first familiarize yourself with their strengths and weaknesses.

The principle of operation of a turbocharged boiler

The name "turbocharged" indicates that the boiler has a turbine, that is, a fan that supplies air, supports combustion and removes combustion products. The design assumes a closed type of combustion and a smoke exhaust system with several turns.

When fuel burns, a certain amount of heated gases is released. To increase efficiency through increased heat transfer, the design provides for the passage of these gases through channels where they give off their heat, increasing efficiency. Thus, it is possible to reduce the temperature of the exhaust gases to 100-120°C.

To understand how a turbocharged gas boiler works, you need to understand how equipment with a closed type of combustion works.

Such units are connected to a coaxial chimney or to a pipe-in-pipe system: the inner pipe is used to exhaust gases, and the annulus is used to supply outdoor air.

In equipment of this type, air circulation and smoke removal occurs with the help of a fan, the intensity of which depends on the gas pressure. It's connected to automation.

When the gas pressure changes in the system, the automation sends a signal to change the rotation speed. However, it should be understood that the system is characterized by noise and, in order to reduce its level, at the beginning of the boiler operation, it is necessary to set the minimum mode. The control of the turbine operation mode makes it possible to regulate the degree of heating.

Advantages and disadvantages of equipment

Both types of gas boilers are easy to operate, efficient and durable. And they also have an attractive appearance.

The design of each type of gas boiler is designed to meet the needs of various categories of users, which clearly demonstrates their advantages and disadvantages. And they also provide an opportunity to understand the differences between a single-circuit gas boiler and its double-circuit counterpart, helping a potential buyer make the right choice.

Pros and cons of single-circuit units

Such products are able to provide stable heating of premises of any size, number of storeys, remoteness from the heat exchanger.

And, in addition, single-circuit boilers:

- more reliable than their double-circuit counterparts, the design of which is more complex, which leads to a slightly larger number of breakdowns;

- easier to maintain, which is also caused by design features;

- cheaper.

An important advantage is that single-circuit units can become the basis for connecting other equipment. That will expand their functionality and increase the comfort of living.

You should always remember that if necessary, provide hot water in the premises, along with a single-circuit boiler, you will have to buy a storage boiler. And this will lead to significant additional costs. And a set of the listed equipment will take up a lot of space, which can be critical for small apartments.

Connecting storage boilers will provide the premises with hot water. Moreover, water will be supplied hot at any time, which is not always possible to achieve from double-circuit analogues.

In this type of equipment, in the absence of the need for hot water supply, there are no pronounced shortcomings. But otherwise, the lack of universality immediately affects.Which leads to the need to purchase an additional electric heater.

As a result, its joint operation with a single-circuit boiler leads to:

- high costs for the purchase, installation, maintenance;

- a limited amount of water for domestic needs - boilers are most often bought for sharing with single-circuit units, so the question may arise about the rational consumption of water, the volume of which depends on the storage capacity;

- greater load on the wiring.

The last drawback is relevant in cases where the house or apartment has old wiring or powerful electrical equipment is used in parallel. So, it may be necessary to upgrade the wiring and select a cable with a larger cross section.

You should also be aware that a set of a single-circuit boiler and a boiler takes up significantly more space than one double-circuit boiler. And with limited space, this can be a significant drawback.

Advantages and disadvantages of double-circuit boilers

Units that belong to the specified type with some restrictions, but are still capable of providing hot water to two systems at once (heating, hot water supply). They also take up less space than their boiler counterparts. As a result, double-circuit boilers are more convenient to use.

Both types of gas boilers are easy to operate, efficient and durable. And they have an attractive appearance.

In addition, the competitive struggle of manufacturers has led to the fact that the difference in the cost of both types of units is gradually leveled.

Therefore, today you can find a double-circuit boiler whose price exceeds that of a single-circuit product slightly.Which in some cases can also be considered an advantage.

If we talk about the disadvantages of double-circuit boilers, then the most important is the inability to instantly provide hot water of the same temperature to all points of water consumption in a house or apartment.

So, in their heat exchangers, the amount of water that is needed right now is heated. That is, the stock is not created. As a result, the water temperature may differ from what is expected or change during use. This happens when the pressure changes, for example, after opening / closing the second tap.

When using a double-circuit boiler, often the water temperature differs at two different points of water intake - hot water can be delivered to the desired point with a delay, and significant. Which is inconvenient and leads to additional costs

As for installation, the installation of double-circuit boilers is a more complicated procedure, especially at the design stage. Since you will have to follow the numerous recommendations of the manufacturer