- Features of pneumatic transport systems

- Video: Ecovent aspiration systems

- Types of aspiration systems

- Installation of aspiration systems

- Evaluation of the work of aspiration in the workshop

- The suction system can have different types

- Features of the installation of such structures

- Advantages of suction systems

- 3 Design stages

- The principle of operation and functioning of the aspiration unit

- The principle of operation of the centrifuge

- The principle of operation of the vacuum generator

- Clean work from A to Z

- How it works

- Classification

- According to the layout of the constituent elements:

- Design features of aspiration systems

- The nature of air circulation

- Aspiration process

- Equipment for aspiration plants

- System calculation

Features of pneumatic transport systems

Such devices not only collect and eliminate industrial waste, but are also capable of supplying bulk materials for their subsequent processing. This is not only sawdust or other wood waste, but also crops.

A diverter valve can be installed on the pneumatic transport. Then the waste can actually be sent to different places of unloading.

Strict requirements are imposed on the quality of pneumatic conveying units. So, they must be resistant to wear of the air ducts, they must not be clogged.If a plug or congestion forms in the pneumatic conveying system, this will stop the operation of all ventilation equipment. To quickly remedy the situation, hatches for urgent cleaning are equipped in places of possible blockages.

Suction and pneumatic conveying systems require precision in design and installation. Otherwise, an accident may occur or the health of the employees of the enterprise will suffer. This task can only be entrusted to professionals. This is especially true for large enterprises where it is necessary to install centralized ventilation systems with the connection of several machines at once.

Video: Ecovent aspiration systems

- Mikhail, Lipetsk — What discs for metal cutting should be used?

- Ivan, Moscow — What is the GOST of metal-rolled sheet steel?

- Maksim, Tver — What are the best racks for storing rolled metal products?

- Vladimir, Novosibirsk — What does ultrasonic processing of metals mean without the use of abrasive substances?

- Valery, Moscow — How to forge a knife from a bearing with your own hands?

- Stanislav, Voronezh — What equipment is used for the production of galvanized steel air ducts?

Types of aspiration systems

Depending on the design, aspiration ventilation systems are divided into two types: monoblock and modular.

A monoblock suction unit is a unit that combines all the components of the system and is completed at the factory. The equipment is delivered with specified characteristics, therefore, to equip a particular facility, it is necessary to select a model with suitable characteristics. The advantages of this type of aspiration systems include:

- small, in comparison with the modular installation price;

- ease of installation and connection;

- compact dimensions;

- readiness for operation.

Typically, monoblocks are small aspiration units designed to service production facilities with a relatively small amount of dust emission. Since the unit is delivered in a ready-made kit, it can be difficult to choose equipment whose characteristics correspond to a particular object. Performance mismatches can adversely affect equipment performance.

The modular aspiration system is designed specifically for a specific object, taking into account its individual parameters:

- the volume of the premises being discussed;

- technological processes taking place there;

- air quality, composition of pollutants, etc.

Thanks to this, a high level of efficiency of the suction system is achieved. It corresponds to the production facility where it is installed, provides high-quality cleaning without excessive energy consumption. This type of suction system is suitable for medium and large industrial enterprises, for which the use of monoblocs is impractical. The disadvantages include a rather high level of capital expenditures for design and installation, the complexity of implementation work and extended commissioning time.

In addition, air aspiration systems are classified according to the pressure developed by the fan into the following classes:

- low-pressure - pressure level up to 7.5 kPa;

- medium pressure - pressure in the range from 7.5 kPa to 30 kPa;

- high-pressure - pressure more than 30 kPa.

Installation of aspiration systems

In order to begin the installation phase of the filtration system, design work is first carried out

This process is very important, and therefore special attention is paid to it.

It is important to say right away that an incorrectly carried out design and calculation stage will not be able to provide the necessary air purification and circulation, which will lead to bad consequences. For successful drafting and subsequent installation of the system, several points must be taken into account:

For successful drafting and subsequent installation of the system, several points must be taken into account:

It is important to determine the amount of air consumed per aspiration cycle, as well as the pressure loss at each point of its intake.

It is important to correctly determine the type of dust collector. To do this, you need to choose it correctly according to its own parameters .. Carrying out calculations and drafting a project is not a complete list of what needs to be done before starting the system installation process

In other words, we can say that installing filters is the simplest and last thing that professionals take on.

Making calculations and drafting a project is not a complete list of what needs to be done before starting the installation process of the system. In other words, we can say that installing filters is the simplest and last thing that professionals take on.

The requirements for labor protection and the ecological state of the environment around operating enterprises are constantly increasing. Cleaning systems are also being improved. This article briefly discusses the aspiration process, types of systems and the principle of operation.

An aspiration system is a type of air filtration and purification used in production shops with high pollution technological processes.

First of all, these are metallurgical, mining, paint and varnish, furniture, chemical and other hazardous industries.The main difference between aspiration and air ventilation is that pollution is collected directly at the workplace, global distribution throughout the workshop is not allowed.

Evaluation of the work of aspiration in the workshop

Evaluation of aspiration performance in industrial production is given by:

- by the total amount of disposed waste;

- in relation to "non-disposal of harmfulness" to the "initial harmfulness" of the technological process. That is, in the air volume that has passed through the deep cleaning system, the amount of dust that has escaped disposal is determined.

Basically, the performance of the aspiration system is reduced by all kinds of leaks in the connections in the piping system and filtration sleeves. They create up to 15 - 20% loss of aspiration efficiency and make it necessary to install more powerful electric motors on cyclone fans. Therefore, it is necessary to periodically carry out inspections and scheduled preventive repairs on operating systems to eliminate defects at the joints of pipelines and filtration sleeves.

The suction system can have different types

Today, an aspiration system of a modular type or a monoblock dust removal system can be used at an enterprise. The monoblock design is mobile and completely autonomous - such an aspiration system is usually located in the immediate vicinity of the waste collection site. If it is required to make a design according to the individual order of the client, then a modular aspiration system is used - in most cases it includes low-pressure fans, air ducts, separators.

The aspiration system in the form of a centralized automated complex significantly exceeds individual shop installations in terms of efficiency.

Cleaning up emissions into the atmosphere is a necessary part of every environmentally responsible production.

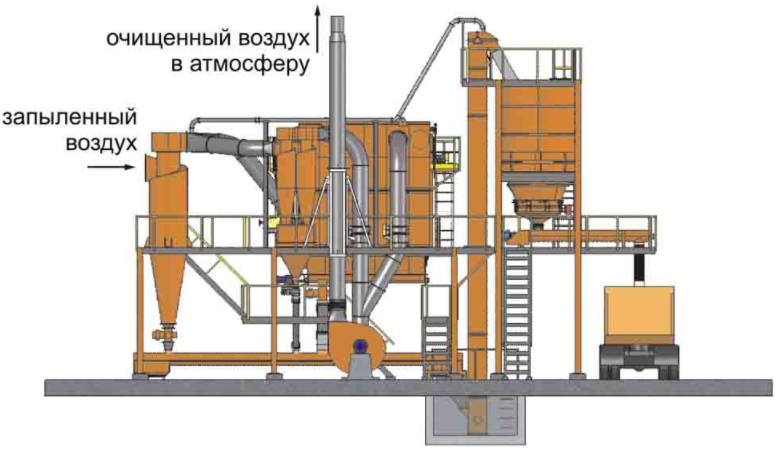

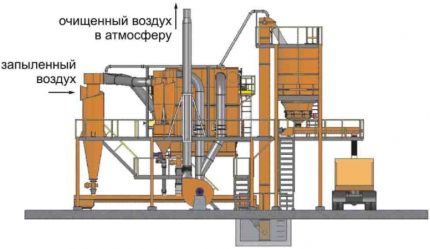

It should be noted that the aspiration system can be recirculating or direct-flow:

- The recirculation aspiration dust and gas cleaning system returns the air in whole or in part after cleaning into the production room.

- Direct-flow aspiration systems capture polluted air from the workshop, purify it in dust-collecting units and then release it into the atmosphere.

However, regardless of the type, the aspiration system is developed taking into account the required power, which entails an accurate drawing up of a planar diagram, where the specification and environmental characteristics of the air ducts are indicated without fail. If the project - a central vacuum cleaner is compiled correctly, then this equipment will not only clean the workshop from harmful emissions and dust, but also return the warm purified air back to the room, which can significantly reduce heating costs.

Dust removal systems at a woodworking enterprise - a compartment for bag filters with unloading into storage bags.

Dust and gas cleaning of a metalworking shop in industrial production - 3 years of effective work.

Features of the installation of such structures

Since significant amounts of contaminants are transported through the air ducts of aspiration systems, such structures are also subject to increased requirements for strength, in contrast to supply ventilation systems.

For their manufacture, steel with a thickness of 1.2 to 5.0 mm is used, and for fittings it is recommended to take steel, the thickness of which is 1.0 mm greater than the duct material.

For air ducts of aspiration systems, strong sheet steel, at least 1.2 mm thick, should be used. Detachable connections will facilitate the process of cleaning the system from contamination

It is forbidden to fasten the suction ducts with clamps on the suspension. It is only allowed to use clamps fixed with brackets, in some cases chains are used as fasteners.

The maximum distance between brackets should be three meters for pipes with a diameter of more than 40 mm and four meters for structures with a diameter of 400 mm or less. These parameters will ensure sufficient structural strength and reduce the risk of duct breakage during operation.

Another feature of aspiration ducts is that they often have to be disassembled in order to clean them of dirt accumulated on the walls. In addition, as a result of rapid wear, individual elements have to be replaced periodically.

For this reason, it is recommended to use quick-release connection elements for mounting structures, rather than traditional flanges, which quickly fail due to frequent disassembly and assembly.

In order to prevent the accumulation of pollution in the design of the aspiration system, it is necessary to give the air ducts the correct slope, which depends on the calculated speed of movement of air masses

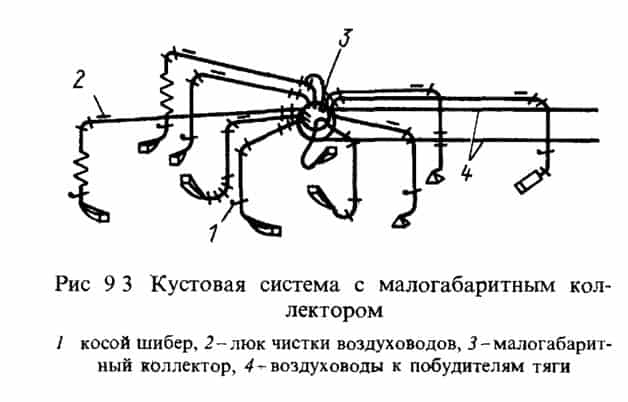

To adjust the air flow, oblique dampers are used, which show less resistance to flow and better prevent the accumulation of contaminants.The use of regulating throttle valves in aspiration systems is not recommended.

It is very important that the air ducts are located at the right angle.

The position of the structure depends on the set air flow rate, which is determined by the nature of the contaminants to be removed. So, to ensure a speed of about 20 m / s, a slope of 60 ° is needed, for a speed of 45 m / s - an angle of less than 60 °, etc.

If the nature of the pollution makes it possible to predict the accumulation of sticky dust in the air ducts, then it is recommended to design such industrial aspiration systems initially with the expectation of the maximum speed of movement of air masses.

In small suction systems, a polyethylene hose of a suitable diameter can be used for suction devices. This is a convenient, but not too durable element that will eventually have to be replaced.

To facilitate the cleaning process of the structure, special liners made of film, paper and other suitable materials are inserted inside the air ducts. Ordinary household and even some industrial fans are not suitable for aspiration systems, even if they have a sufficiently high performance.

We need devices with increased resistance to wear, which can work for a long time under high load without interruption.

A common problem with low efficiency suction systems is air loss. To prevent this phenomenon, experts recommend choosing fans with some power reserve. Air losses in practice can reach 30% compared to calculated data.

Incorrect choice of local suction can adversely affect the entire system. It is impossible to choose such an element without taking into account the features of the technological process.

In some cases, an umbrella-type shelter will be effective, in others - a “showcase”, a fume hood, a cabin, etc. This point must be agreed with the technologist at a particular production.

Most of the aspiration plants are designed to move purified air into the atmosphere, but sometimes such air masses are returned to the production room (+)

Most of the aspiration plants are designed to move purified air into the atmosphere, but sometimes such air masses are returned to the production room (+)

For rough air purification from dust, dust bags, non-permeable dust chambers, bunkered gas ducts, dry cyclones and other similar devices are used, depending on the nature of the dust.

For medium cleaning, scrubbers are often used, while fine cleaning is done with a set of tools that may include a cyclone-type electrostatic precipitator and a bag filter, in some cases a high-pressure venturi or other suitable units are used.

Advantages of suction systems

The operation of a high-quality aspiration system is directly related to energy savings. How? Workshops that are not equipped with such equipment are forced to simply ventilate the room. Otherwise, the dust will greatly clog the respiratory tract of workers and interfere with work. Workers will often get sick. Strong fumes from, say, paints, adhesives, and solvents harm the body's metabolism.

A person who works in bad conditions will surely begin to feel an unpleasant weakness in a couple of weeks. That is, you can not leave the room with polluted air. Ventilation seems like a cheap way to solve the problem. But in reality it will cost much more.In cold seasons, millions of joules of energy are literally thrown into the wind every hour, which was spent on heating the room and on various stages of production. The cleaning system allows:

- Save energy for heating thanks to the aspiration system;

- Provide working people with normal working conditions;

- Protect equipment by removing dust from the air;

- Return the purified air back to the room;

- Remove not only small chips, but also microparticles of wood and other dust.

Shredded wood waste must be removed from the atmosphere. Moreover, modern installations are capable of capturing particles up to 5 micrometers in size. Some systems are capable of cleaning the atmosphere from dust by 99%, giving out almost clean air at the outlet.

source

3 Design stages

Proper design of a modular system is the key to its effective operation. Before you start creating a project, you need to assess the technical condition of the room where the installation will be located, check the performance of the existing ventilation system.

The volume of air that will pass through the aspiration structure is the main indicator of its operation. The larger it is, the more expensive the installation and operation of the cleaning system will cost.

In the planning process, it is important to choose the right components in order to reduce initial and operating costs.

A more rational approach involves a preliminary calculation of the distribution of supply flows, the choice of filters and a device for air suction (onboard suction, structures such as "shelter", "umbrella" and others). This will make it possible to create a unit that will effectively aspirate air even in heavily polluted production, while the load on the system will not be excessive, the working life of the fans will increase, and the filters will not have to be changed too often.

The principle of operation and functioning of the aspiration unit

Near the landing site, on a universal stand, the tubes (mouthpieces) of a vacuum cleaner and an apparatus for saliva gadfly are attached. A special tip is inserted into the upper fragment of the tubes. The effect of removing saliva is due to the vacuum that is created by all of the above methods.

The aspiration suspension, which has already been cleaned, passes through the outlet and the separator. It then ends up in the sewer. If you remove one mouthpiece from the base of the holder, then all the tubes of the suction system will be depressurized. In order for saliva to pass through the selected tip, the remaining channels must be securely blocked. Units for aspiration drainage have found application in all dental offices and clinics.

The principle of operation of the centrifuge

Vacuum pumps function for a long time and reliably if the spent suspension with air mass does not get into them. The separator reliably copes with this problem. Its main component is the separation vessel. The liquid under the influence of suction forces enters the tank through the inlet and the filter, which separates it from the air mass.Through the outlet, air enters the pump, and the slurry (which has a heavier weight) settles to the bottom.

The low pressure created in the container by the pump or pomp closes the outlet valve located at the very bottom of the canister. When the dentist puts the mouthpiece back into the holder, the throttle automatically opens and the suspension flows out into the sewer on its own. Fluid can be forced out with a pump.

A sensor is built into the container, which determines the height of the filling column, which will prevent the vessel from overflowing. If the liquid level reaches the meter, the pump stops its operation and the process of pumping out the suspension begins. When the water column drops to a certain value, another sensor is triggered and the aspiration process continues. This system has a big disadvantage, because it automatically interrupts the aspiration process, which can interfere with the operation of the patient. It turns out that the larger the capacity of the separator, the less often the work will be interrupted.

Experts believe that the best aspiration systems are the products of Cattani (Italy). The units of this brand are considered the most balanced in terms of price and quality.

The principle of operation of the vacuum generator

These devices, as mentioned above, have a different structure. Therefore, the principle of operation of different vacuum generators has its own characteristics. For example, an air dynamo has its own distinctive features. Here, the suction system begins its work immediately after being removed from the mouthpiece holder. The air hose is attached to the inlet directly from the dental unit.

If the generator is made at the factory in a standard way, then the used air masses will be removed through the muffler. To throw them out, the doctor will need to connect a special hose and take it outside. If the suction system has a centralized design, then pumps and generators of the same type are used, but the power of these devices will be much higher.

Clean work from A to Z

NZMK offers a full range of services for the design of equipment, automation systems and electrical equipment - from a single supplier. In the field of aspiration systems, we offer:

- Design

- Manufacturing

- Mounting

- Commissioning

- Modernization

- Service maintenance

The suction system manufactured at NZMK is a complete and effective solution for your production tasks. A wide range of standard components, along with the modular design of the equipment, allows you to design and install an aspiration system that fully meets your requirements.

How it works

Air pollution is an inevitable part of many manufacturing processes. To comply with the established sanitary standards for air purity, aspiration processes are used. With their help, dust, dirt, fibers and other similar impurities can be effectively removed.

Aspiration is suction, which is carried out by creating an area of low pressure in the immediate vicinity of the source of pollution.

To create such systems requires serious special knowledge and practical experience.Although the operation of aspiration devices is closely related to the operation of ventilation systems, not every ventilation specialist will be able to design and install this type of equipment.

To achieve maximum efficiency, ventilation and aspiration methods are combined. The ventilation system in the production room must be equipped with a supply and exhaust complex to ensure a constant supply of fresh air from outside.

Aspiration is widely used in the following industries:

- crushing production;

- wood processing;

- manufacturing of consumer products;

- other processes that are accompanied by the release of a large amount of substances harmful to inhalation.

It is far from always possible to ensure the safety of employees with standard protective equipment, and aspiration may be the only way to establish a safe production process in the shop.

Removal of contaminants using systems of this type is carried out through special air ducts that have a large angle of inclination. This position prevents the appearance of so-called stagnation zones.

An indicator of the effectiveness of such a system is the degree of non-knocking out, i.e. the ratio of the amount of contaminants that have been removed to the mass of harmful substances that have not entered the system.

There are two types of aspiration systems:

- modular systems - stationary device;

- monoblocks - mobile installations.

In addition, aspiration systems are classified according to the level of pressure:

- low-pressure - less than 7.5 kPa;

- medium pressure - 7.5-30 kPa;

- high-pressure - over 30 kPa.

The complete set of aspiration system of modular and monoblock type differs.

Monoblocks consist of the following elements:

- fan;

- separator;

- waste accumulator.

The separator is a filter for cleaning the air passing through the device. The waste accumulator can be both stationary, i.e. built-in monoblock, and removable.

Such a unit can be purchased ready-made and simply installed in a place suitable for performing aspiration procedures. At the same time, it is not difficult to connect them to existing centralized systems.

Modular systems are more difficult to install and more expensive, but their use is much more efficient than when using monoblock structures. Such systems are not typical, they are first designed taking into account specific conditions and tasks.

This takes into account a number of factors:

- characteristics of the production facility;

- features of the technological process;

- the quality of the transported medium, etc.

Usually this is a centralized system, which consists of a set of air ducts and a suction unit. For large enterprises, a system with not one, but with two or more such blocks can be used.

The material of air ducts can be different, depending on the nature and amount of pollution that is supposed to be transported through them.

Ferrous metal structures are considered the most durable, but they are also the most expensive. In any case, individual sections of the air line are hermetically connected using bolted flanges.

Among the advantages of aspiration systems are:

- relative simplicity of design;

- compatibility with various types of production equipment;

- safety for the environment;

- the possibility of automating work;

- increasing the fire safety of the premises, etc.

The disadvantages of such installations include, first of all, the increase in energy costs, especially with improper design, as well as the low resistance of metal air ducts to wear. These points should be considered when choosing a suitable design.

Classification

Aspiration systems are classified:

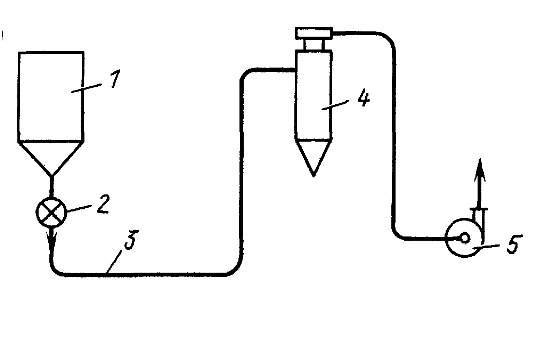

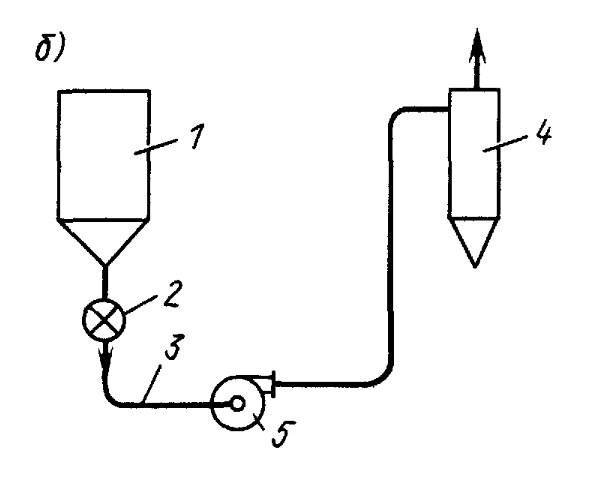

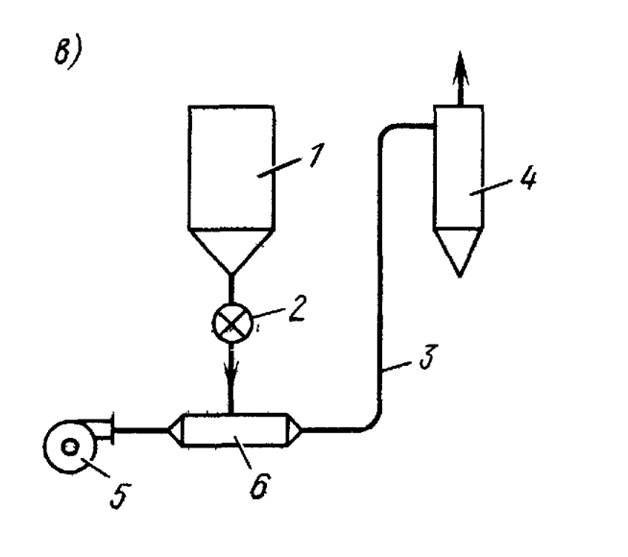

According to the layout of the constituent elements:

Suction systems. This scheme is the most rational, because already purified air passes through the fan. But Such aspiration systems are limited by pressure losses up to a fan of 9.5 kPa.

Suction-pressure aspiration system. This scheme is used for significant pressure losses in the ventilation system. It uses only dust fans, since air that has not yet been purified passes through the fan and ordinary air can not stand it.

Pressure suction system. Such a scheme of the aspiration system is used when the passage of air mass through the fan is unacceptable.

Design features of aspiration systems

According to the design features, aspiration systems are divided into:

Collector. These include all three previous schemes.

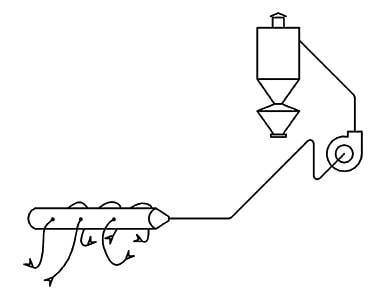

Artisanal. The range of the handicraft scheme is limited and does not exceed 30m.

The most commonly used collector scheme.

The nature of air circulation

The nature of air circulation

- Direct-flow. In such aspiration systems, air, after being cleaned from dust in a dust-collecting unit, is released into the atmosphere.

- Recirculation.In these aspiration systems, the air, after cleaning in the dust collecting unit, is completely or partially reused, that is, it is returned to the room. This helps to reduce heating costs, as it reduces heat loss.

Aspiration process

The aspiration device provides air intake, which is polluted with dust and harmful substances. The aspiration rate depends on the selected system and its main components. The Rapid Oxygen Purification Unit is a self-contained aspiration and filtering system that ensures the correct air flow in the room.

Aspiration is a simple process of removing dust and gas that is generated from the main production.

The ventilation system in certain parts of the production room can be turned off from the general cleaning mine. The number of valves and fans depends on the degree of contamination of the room in which the equipment or other devices are located. The aspiration unit works properly with a constant intake of air masses from the room. The system is monitored once every six months in case of emergency breakdowns or system failure.

The aspiration device enters the air duct, which provides complete air filtration in the building. The aspiration rate depends on the power of the installed device. The quality of air masses determines the well-being of workers and maintenance personnel who are in the workshop or at the enterprise every day.

The well-being of workers and maintenance personnel working at the enterprise depends on the quality of air masses.

Component parts of ventilation provide intake of air masses and removal of dust from the premises.The reverse start of purified oxygen occurs automatically. The design of the future workshop is not complete without the layout of the air duct, as an overall and complex structure. The aspiration rate is calculated at the stage of excusable work.

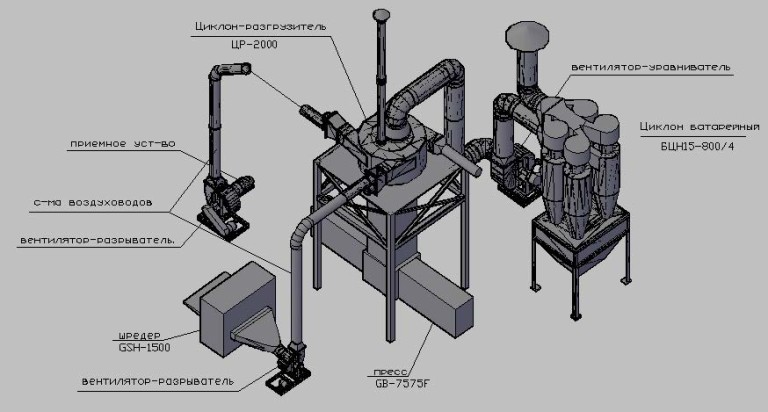

Equipment for aspiration plants

Monoblock suction in a woodworking shop

Monoblock suction in a woodworking shop

For each specific workshop, both the ventilation system that creates and controls air flows in the room, and the aspiration units, which are engaged in the direct removal of the smallest solid particles before they enter the air space of the workshop or into the atmosphere, are developed jointly.

Deep air aspiration units are of two types:

- Monoblock, when a completely autonomous installation is created with a closed process for the selection, collection and disposal of dry dust particles. Therefore, it usually consists of one or more fans, filters and a special container for the concentration of the selected waste.

- Modular, when a single system is designed with air ducts connected to different workplaces, low and high pressure fans, separators, containers for collecting and storing waste. Such systems can be created both for a separate workshop and for the whole complex of production facilities of the plant.

The main equipment of aspiration plants include:

- Cyclones. This is a two-chamber ventilation device that creates a high degree of centrifugal air rarefaction: large particles are concentrated in the outer chamber, and small particles accumulate on the surface of the inner one.

- Filtration sleeves and pipelines. When passing through them, the polluted air flow loses a significant part of the solid inclusions on their walls.

- Filters and settlers.They can be installed both instead of atmospheric cyclones and on pipelines at transitions to ventilation.

- Catchers for large particles and metal chips. They are installed directly near the workplace, for example, next to machines.

- Press and waste containers.

System calculation

In order for the operation of the aspiration system to be effective, it is necessary to make its correct calculation. Since this is not an easy task, this should be done by specialists with extensive experience.

If the calculations are made incorrectly, then the system will not work normally, and a lot of money will be spent on rework.

Therefore, in order not to risk time and money, it is better to entrust this matter to specialists for whom the design of aspiration and pneumatic transport systems is the main work.

When calculating, you need to take into account a lot of factors. Let's consider just a few of them.

- We determine the air flow and pressure loss at each aspiration point. All this can be found in the reference literature. After determining all the costs, a calculation is carried out - you need to sum them up and divide by the volume of the room.

- From the reference literature, you need to take information about the air velocity in the aspiration system for different materials.

- The type of dust collector is determined. This can be done by knowing the throughput performance of a particular dust collecting device. To calculate the performance, you need to add the air flow at all aspiration points and increase the resulting value by 5 percent.

- Calculate the diameters of the ducts. This is done using a table, taking into account the speed of air movement and its flow rate. The diameter is determined individually for each section.

Even this small list of factors indicates the complexity of calculating the aspiration system.There are also more complex indicators, which can only be calculated by a person with a specialized higher education and work experience.

Aspiration is simply necessary in modern production. It allows you to comply with environmental requirements and maintain the health of personnel.