- Do-it-yourself wood preservative, recipe

- Video about recipes and methods for making do-it-yourself wood preservatives:

- Features of the preparation and application of antiseptic at home

- Recipe for copper sulphate

- bitumen paste

- Other options for protective solutions

- Tips for using solutions:

- What is included in the ready funds?

- Stages of wood processing

- Processing rules

- Do-it-yourself wood preservative, recipe

- Water mixture preparation and wood treatment with copper sulphate

- The process of applying antiseptic

- Training

- Whitening

- Application

- End processing

- Fire retardants for wood impregnation

- The choice of antiseptic

Do-it-yourself wood preservative, recipe

Wood is particularly vulnerable to insect attacks in the spring when they wake up, and also in the fall when the bugs seek shelter before the onset of cold weather.

Given this feature, it is important to treat the following elements with an antiseptic composition twice a year, namely:

- wooden fences;

- garden furniture and accessories;

- wooden elements of the exterior decoration of the house.

Untreated wood will not last long and will break down under the influence of sun, rain, wind.In addition, the material loses its visual appeal and becomes brittle. Shading solutions can not only protect the material well, but also give it a better look.

Untreated wood will not last long and will break down under the influence of sun, rain, wind

Factory-made solutions are considered the most effective, since their composition is well balanced. The disadvantage of ready-made antiseptics is their high price, as well as high toxicity, since potent chemicals are added to them.

Do-it-yourself antiseptic may not differ much in composition from the purchased one and have high protective properties. The main advantage of a self-made solution is that the cost of all ingredients is cheap and, if desired, strong chemistry can be abandoned. This is especially true for those who want to process wood inside the house.

A wood treatment solution can be prepared according to the following recipe using the available ingredients. These include:

- Bitumen.

- Gasoline or diesel fuel, diesel fuel.

- Waste engine oil.

It is worth deciding which solvent will be used. If you want the antiseptic to harden faster, it is better to give preference to gasoline, which evaporates quickly and the mixture dries out faster, respectively. However, if you need to saturate the wood well, then mixtures in the preparation of which diesel fuel was used have deeper penetration. According to experts, bituminous antiseptics dissolved in diesel fuel penetrate into the layers of wood by 5-7 mm.

This is especially important when it comes to the processing of roof parts or other wooden products located in wet areas.

Warming wood antiseptic at the stake

Preparing an antiseptic is not difficult. First of all, bitumen is recommended to be heated to a liquid state in a metal container on a fire. Periodically it must be stirred to dissolve the lumps. Upon reaching a homogeneous, liquid mass, the container is removed from the fire and allowed to cool slightly. Next add engine oil and the selected solvent. In this case, the mixture must be stirred. The composition is ready and you can start using it.

The recipe recommended above is suitable only for outdoor work or for use in non-residential premises. It is better not to use it in an apartment or house, since the evaporation of chemicals can cause irreparable damage to human health. For indoor use, it is worth choosing biological, natural antiseptics. They are slightly inferior to chemistry, but absolutely harmless and do not cause allergies.

The composition of natural impregnation is simple and according to the recipe, ingredients such as hemp or linseed oil must be added to the mixture. Such an antiseptic strengthens the tree, protects against moisture, dirt and insect pests. Wood impregnated with natural oil does not crack or dry out.

After treating a wooden surface with natural oils, it is worth giving it a better appearance and making it resistant to mechanical stress. To achieve this goal, the wood is treated with wax and turpentine, which are mixed in a ratio of 1:1.

Video about recipes and methods for making do-it-yourself wood preservatives:

If you are interested in do-it-yourself wood preservative, the composition of the product, then in this article you will certainly be able to find out the recipe for the mixture. Some of them are only suitable for indoor use, while others are suitable for outdoor use.

Features of the preparation and application of antiseptic at home

Do-it-yourself preparation of an antiseptic must be carried out, observing safety precautions. Use hand and respiratory protection when dissolving components.

Make sure that all components of the recipe are added strictly in the specified amount.

When applying a homemade antiseptic, you need to follow a few rules:

Liquid components are applied with a spray gun, thicker ones with a brush.

During application, as well as during preparation, protective suits and other means are used.

The room must be made dry and well ventilated.

Pay attention to the hazard class of the substances included in the composition. This is true not only for the factory composition, but also for the one that had to be made by hand at home .. If it is necessary to process components or structures of complex shape, use additional tools for applying the substance

Follow the instructions when working with antiseptics, including if you must first make them yourself.

If you need to process components or structures of complex shape, use additional tools for applying the substance. Follow the instructions when working with antiseptics, including if you must first make them yourself.

Recipe for copper sulphate

Compositions based on copper salts, including copper sulfate, are one of the most common recipes offered in order to make them yourself. They are cheap to manufacture and have minimal danger to the person involved in their manufacture and application to the final structure.

The recipe for this composition is as follows:

- The amount of copper sulfate should be equal to half of the entire dry part of the mixture. The second half is sodium bichromate technical. Both components are mixed together.

- A kilogram of this substance must be made and dissolved in 9 liters of water. Based on this proportion, other ratios can be calculated.

- After dissolution, 5.5 ml of 9% table vinegar is added to a liter of the resulting solution.

Features of the preparation of this mixture:

- Copper sulfate is poorly soluble in water, therefore, before pouring the dry mixture into water, the water must be heated to 50 degrees. This will speed up the dissolution.

- Mixing is best done in a closed canister. Despite the fact that the vitriol antiseptic is safer than others, it has harmful fumes. A closed canister will reduce their number and protect human health.

bitumen paste

Bituminous pastes have good protective qualities and are suitable for use with materials buried in the ground. But their disadvantages are the high toxicity of the components, flammability and the inability to use indoors (due to the toxicity and strong odor of the components and the finished mixture).

If the bituminous paste turned out to be the most suitable for use in a particular situation, then it is done as follows:

- The composition of the paste includes not only the bitumen itself, but also gasoline or diesel fuel. The latter is necessary as a thinner: with a diesel engine, the mixture will solidify more slowly and will have time to soak the material well, while gasoline, on the contrary, will accelerate the solidification.

- The bitumen is poured into a cooking container and placed over a fire source.

- Heat the bitumen until it liquefies. Stir to get rid of lumps.

- The diluent is poured in in small portions, controlling the possibility of splashing out.

- It is recommended to add fuel at a concentration of about 20-30% of the total mass.

It will take at least a few hours to make this antiseptic. Therefore, it is recommended to carry out such work away from residential premises and cooking "at home" is very limited here.

Other options for protective solutions

There are also methods of protection with salts: sodium fluoride, ferrous sulfate (ferrous sulfate). Such aqueous compositions are much safer than the copper-vitriol mixture and even safer than the bituminous paste. But of the minuses can be called the lack of the desired effect, if you make these funds at home. They are usually used when working in residential areas, to prevent contamination of the material or as an aid.

Production is carried out according to the scheme, as in the preparation of a solution of copper sulfate, but saline solutions can be prepared at home with a lower degree of protection. But despite this, you should use gloves and cover the body with clothing, as contact with saline solution on the skin can cause irritation.

Tips for using solutions:

For interior work, it is possible to use less concentrated salt impregnations. It is recommended to apply the solution with a wide brush or with a spray gun.

Impregnation based on copper sulphate requires a long time of impregnation and thorough drying.

Solutions can be stored for several days after preparation.

Before creating a mixture, it is recommended to familiarize yourself with the characteristics of the wood intended for processing in order to avoid errors in the dosage of components. For self-preparation, you need to spend a lot of time, as well as pre-select the components. In addition, almost all of the above impregnations are only suitable for external use, because. toxic. That is why, for safety reasons, it is better to use high-quality LuxDecor wood impregnation products.

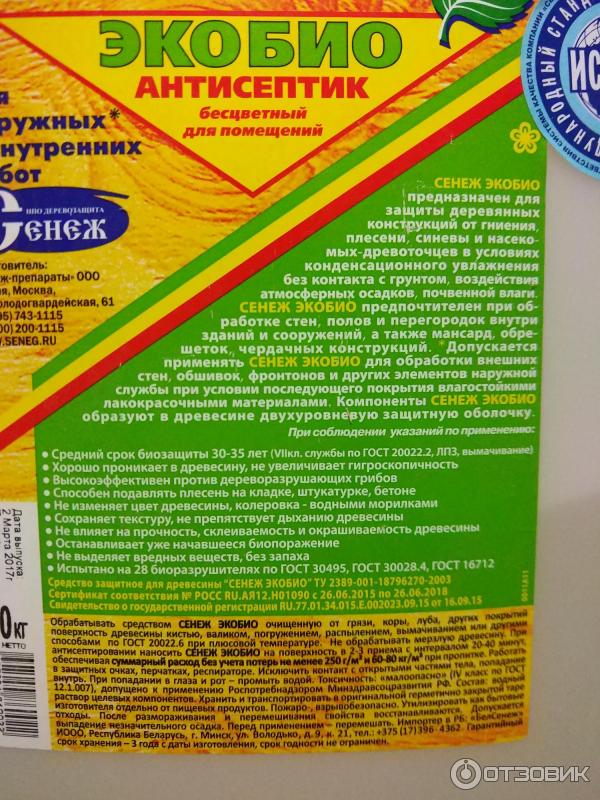

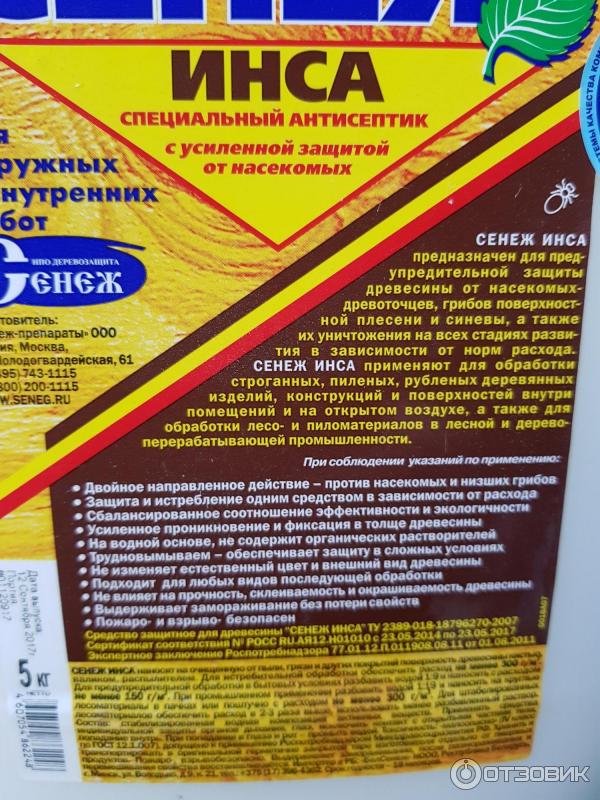

What is included in the ready funds?

There are several categories of wood preservatives that differ in the main component: oil, organic, water, combined. Funds on the water base are suitable for processing inside the building, and for facades it is better to choose an antiseptic that is more resistant to moisture. The advantages of a water-based preservative are low toxicity, no odor, making wood refractory. The disadvantages are poor resistance to moisture and the need to apply additional aqueous formulations.

Antiseptics based on oils (coal, anthracite, shale) are suitable for treating houses from the outside, arbors, benches, fences, because they do not let water and oxygen through and protect against insects.Compared to aqueous solutions, oil solutions have a smell, are more toxic, and therefore should not be used indoors.

Organic non-oily products for the treatment of wood materials contain sodium and phenol compounds. Drying, they form a thin film that protects the material from exposure to water and the sun. Organic solutions can be applied inside and outside the building. After drying, a layer of varnish or paint should be applied over them. In addition, organic antiseptics give the tree a greenish tint, and when it comes into contact with metal parts, they cause corrosion.

Combined antiseptics provide comprehensive protection for wood, protecting it from fire, moisture, insects and microorganisms. Combinations may include:

- iron or copper sulfate (disinfect, change the color of the surface);

- oxydiphenyl (effective against fungus, does not change the appearance and strength characteristics of the tree);

- sodium fluoride (has an antibacterial effect, penetrates deep into the layers of the tree);

- ethyl mercuric phosphate (toxic antiseptic, used only for outdoor use).

Before applying the combined antiseptic agent, it is necessary to prepare the surface, clean it of dirt and grease, and dry it thoroughly. It is recommended to apply an antiseptic in several layers, since flame retardants are included in the composition, which should soak the material well. The disadvantages of an organic agent include high cost and toxicity until the final drying.

Stages of wood processing

Untreated wood is subject to many adverse factors.First of all, wood is afraid of moisture, under the influence of which it swells, after which fungus and mold appear on a wet surface, and then the tree begins to rot and collapse.

Microorganisms and insects are another problem faced by the owners of wooden buildings. Having settled in the wood, the bugs sharpen the tree from the inside, the surface of which becomes like a sieve. Fire is an element that can completely destroy a wooden structure. Every trouble can be prevented if the house is treated in a timely manner with special means.

Wood processing is carried out both for preventive and curative purposes. In the first case, the wood is processed at least three times.

- Primary processing is carried out before the construction of the house, if logs processed at the production stage are purchased, this stage can be skipped. Raw lumber must be coated with a preservative antiseptic. If construction is not expected immediately, you need to put the logs in a cool, dry and well-ventilated place without access to moisture and precipitation. Thus, it is possible to protect lumber from decay for the entire period of storage.

- The next processing is carried out immediately, as the log house is placed under the roof. The antiseptic is applied in two layers on the outer and inner surfaces of the house. Particular care should be taken to process the ends of the logs, as well as parts that are in direct contact with the foundation. This stage can be carried out when the outside air temperature reaches 10-12 degrees.

- After that, the house is allowed to settle and sit down. The shrinkage process lasts from six months to one and a half years, and then the last processing of the timber or logs is carried out.This stage implies the behavior of a complex multilayer processing of a log house, which for many years will protect the house from any adverse biological and natural factors.

The moisture content of the wood during the final processing should be no more than 20%.

Processing rules

When applying an antiseptic to wood, you should always adhere to safety precautions, the rules of which are always present in the documentation for it. Further, it should be remembered that there are such substances and structures, the application of an antiseptic to which must be carried out after a certain time period (a year, two, etc.). It is also recommended that when processing structures with bioprotection, change the drug every period after its use. Microorganisms and insects can simply get used to the drug used and develop immunity.

Modern types of bioprotection for wood, as a rule, do not have a strong odor. To achieve the desired effect, it is recommended to process the tree with them in several layers.

Before processing, make sure that the wood is clean and dry. To clean it, you should use an iron scraper. If cleaning is not possible, the use of a solvent is recommended. If the lumber is wet or frozen, it is worth refraining from processing, since in this form the impregnating ability of the antiseptic is significantly reduced. Before processing the entire surface of the tree, the areas that are already damaged, the sawing places, are first processed. And after the drug is applied as described above.

If the wood is damp, then the antiseptic can be applied either with a brush, roller or spray gun.Most drugs act as insect repellents, but do not completely destroy them. For their complete destruction, alcohol-based substances are used. They are injected with a syringe into wormholes, and then all the wood is processed.

Do-it-yourself wood preservative, recipe

Wood is particularly vulnerable to insect attacks in the spring when they wake up, and also in the fall when the bugs seek shelter before the onset of cold weather.

Given this feature, it is important to treat the following elements with an antiseptic composition twice a year, namely:

- wooden fences;

- garden furniture and accessories;

- wooden elements of the exterior decoration of the house.

Untreated wood will not last long and will break down under the influence of sun, rain, wind. In addition, the material loses its visual appeal and becomes brittle. Shading solutions can not only protect the material well, but also give it a better look.

Untreated wood will not last long and will break down under the influence of sun, rain, wind

Factory-made solutions are considered the most effective, since their composition is well balanced. The disadvantage of ready-made antiseptics is their high price, as well as high toxicity, since potent chemicals are added to them.

Do-it-yourself antiseptic may not differ much in composition from the purchased one and have high protective properties. The main advantage of a self-made solution is that the cost of all ingredients is cheap and, if desired, strong chemistry can be abandoned.This is especially true for those who want to process wood inside the house.

It is recommended to treat wood twice a year with an antiseptic composition.

Water mixture preparation and wood treatment with copper sulphate

Solutions of salts in water are prepared by dissolving a given amount of salt in heated water. Heating is necessary to increase the speed and completeness of dissolution.

There are various proportions for treating wood with sodium fluoride and iron or copper sulphate: a weak solution of sodium fluoride is used to impregnate wooden surfaces of domestic structures. Its content is from 0.5 to 4% (from 50 to 400 g per 10 liters of water), depending on the design purpose. Inside the house, it is enough to use less concentrated mixtures, while on the street (arbors, benches) it is better to use saturated solutions. To visually control the completeness of the application, 10 g of potassium permanganate (potassium permanganate) is added to the resulting solution.

Intense coloration will not be permanent and will disappear shortly after the surface has been coated. The solution should be applied with a spray gun or a wide brush; sulfate mixtures with a target component content of 10-20% (1-2 kg per 10 l of water) are used to treat pillars and structures buried in the ground. Such compositions require particularly thorough drying and a long impregnation time in order to improve the effect of the application. The quality of applying the antiseptic is controlled by the degree of color of the product, which is facilitated by the rich color of the vitriol solution.

In the resulting preparation, parts of the wood are soaked, which will be further exposed to negative external influences. To prepare the water mixture, you will need a source of hot water, a container for cooking and a spatula for mixing. Using the solution after settling makes it possible to load it into the sprayer, improving the uniformity of the coating and reducing reagent consumption. You can apply impregnation immediately after cooling. The solutions can be stored for several days until suitable weather conditions are established. The preparation of aqueous solutions can be done at home or outdoors.

At home, you need to be especially careful not to spill excess solution on things or in hard-to-reach crevices. The total preparation time for an antiseptic rarely takes more than an hour. To avoid errors in the dosage of components, study the characteristics of the wood you are going to process. There are complex approaches to processing, including cutting off a layer of wood and varnishing a salt-soaked surface.

The process of applying antiseptic

Training

The main task of preparing the wood surface is to allow the impregnation to be absorbed without hindrance. To achieve high-quality protection, the tree is pre-cleaned or washed. Resinous areas are scraped off, and if this does not help, they are wiped with a solvent. The mold is removed with a scraper or a metal brush, if necessary, discolored. As a result, the surface should be dry and clean, without any surfactants (eg detergents), fats, oils, resins.

Whitening

Before proceeding with the treatment of wood with a protective antiseptic, make sure that it is free of blue, mold and rot.Otherwise, a bleaching and sanitation procedure will be required. For this, special compounds are used that destroy wood-staining and wood-destroying fungi, remove gray plaque, restoring the wood to its natural color, and prepare the surface for protection.

With it, you can brighten the darkened areas and restore the original color of the natural material. The agent is applied with a sponge or brush on the surface of the wood and left for some time (from 2–3 hours to 0.5–2 days), after which the bleach residues are thoroughly washed off. If necessary, the procedure is carried out again. To prevent re-damage of wood after bleaching (and taking into account the purpose of the wooden structure), the material is treated with an antiseptic. The cost of 1 liter of bleach is from 80 rubles.

You can not replace specialized bleaches with cheaper household ones. After all, the concentration and composition of active substances in specialized formulations is selected in such a way as to most effectively affect the pathogens of wood biolesions without changing its physical and mechanical properties. After processing and drying, the surfaces remain absolutely safe for people and pets.

V33

Window frames, doors and other elements of the facade are protected with masking tape.

V33

To ensure optimal adhesion of protective and decorative materials, the wooden substrate must be dry and clean. All dirt and mold are removed. The surface is treated with sandpaper, grit P220.

V33

Then it is thoroughly cleaned of dust.

V33

Treated with a universal antiseptic for wood.After it dries (after 12 hours), “Decorative Wood Protection Glaze V33” is applied, which allows the wood to breathe and at the same time protects it from moisture and ultraviolet rays.

Application

The direction of movement of rainwater and abundant condensate is perpendicular to the horizontally fixed lining. The joints of the boards make it difficult for water to drain. Moreover, through them, it can penetrate the skin, causing it to become excessively moist and slow to dry. Because of this, the time between repairs on the facade is reduced. Therefore, experts recommend the horizontal method of sheathing for fairly dry climatic zones and on houses with large roof projections. Rainwater and condensate drain quickly through a vertically fixed lining, and the wood is less adversely affected by moisture. This option is optimal for homes located in humid climates where they are exposed to strong atmospheric influences.

Tikkurila

Tikkurila

Tikkurila

Tikkurila

Tikkurila

End processing

Finishing the ends of logs is extremely important. The fact is that moisture evaporates from the side surfaces of logs and timber more slowly than from the ends and end cuts. After processing these areas with special compounds, a vapor-permeable membrane is formed on their surface. It protects the ends from excessive absorption of moisture and the occurrence of biodamage, regulates the rate of evaporation of moisture and allows the tree to breathe. Due to its high elasticity, the membrane retains its integrity during natural wood deformations. The products strengthen the wood, and they can be used on already cracked ends so as not to increase the depth of existing cracks and prevent the appearance of new ones.The cost of 5 liters - from 980 rubles.

The temperature of the environment and the ends to be processed must be at least 10 ° C, while the humidity of the wood can be any.

Fire retardants for wood impregnation

Fire retardant impregnation for wood.

Having made a wooden structure, it is necessary to protect it not only from mold, fungi, moss, but also from the effects of fire. For these purposes, flame retardants are used for wood coatings. Special substances give wood fire-repellent properties. They prevent the spread of fire, facilitate the extinguishing of a fire that has arisen and prolong the ignition time of wood.

To give wooden structures special properties against the action of a flame, 2 types of impregnation are used: compositions based on aqueous solutions of salts and wood processing LMK.

A fire retardant composition, including non-poisonous inorganic salts, is applied to rafters, attic lathing, details of premises and offices.

Before starting work, prepare the following tools and materials:

- alkaline cleaning solution;

- solvent;

- bucket;

- roller or brush.

Before applying the composition, the wood is dried, cleaned of dust and dirt. Permissible humidity of the treated wooden surface is 30%.

The composition for impregnation is stirred with a spatula before application, and then applied with a brush or roller to the work surface. The work is carried out at temperatures up to +5 ° C. The coating is carried out with protective gloves to avoid contact of the composition with the skin of the hands.

Flame retardant compositions create protection against fire of the 1st degree with full preservation of all the properties of wooden coatings.A self-made solution is suitable for use in country, residential and industrial buildings and does not adversely affect human health.

Having studied the market for agents that prevent the destruction of wood, you can prevent the premature death of wooden structures by creating special solutions with your own hands.

We make hand sanitizer for wood

.

When I was looking for information on this issue, I found only about bitumen, its heating and application. Will someone really impregnate the truss system with heated bitumen? And if we are talking about a tree that will be in the ground, then it is easier to saturate it with used engine oil - in any car service they will be happy to hand you (or maybe hand over) the required amount - only your own container!

SENEZH Fire-bio does not protect

from the appearance of fungus, mold and other nasty things, for nothing, which costs 1550 rubles / 25 liters. I can send a photo - they made a gazebo in SNT "Artist" in 2012. In 2014, the owner calls and says that moldy

covered the whole gazebo

. I arrived and got 25,000 rubles and 5 days of work by two carpenters - to dismantle everything, clean it (and we also covered it with yacht varnish - it grows right under the varnish), soak it with anti-mold, then with decorative impregnation.

Instruction:

We take a canister of 25 liters.

We buy iron vitriol (protects against the appearance of mold, fungus, moss, and, if available, kills) 100 gr. - on the market 70 rubles.

and potassium permanganate (for color) 10 gr. - in a pharmacy 50 rubles (water-based color can also be used).

We breed for 20 liters (not a typo - for 20 liters).

Stir and apply with a brush or roller (faster).

The price of such an antiseptic is 120 rubles + 20 liters of tap water (becausewe were forced to install counters, then let's take 1 ruble / 1 liter, i.e. 20 rubles). TOTAL 160 rubles for 20 liters

!!!

Why did I write this - I'm tired of the fact that they are trying to “divorce” us for money everywhere!

P.S. And one more thing: wood bleaches are made on the basis of chlorine - it also costs not 500 rubles / 5 liters like Senezh EFFO. I'll try to make it with my own hands, I'll write.

In this article: wood preservative antiseptics; how to make an antiseptic preparation yourself; ready-made antiseptics - types and characteristics; recommendations on the choice and use of preparations for wood protection.

The most ancient, if not classical, material for the construction of any building on Earth was and remains wood. This building material is present on our planet everywhere and in abundance, thus providing earthlings with a permanent structural material for building houses and decorating them. However, wood is far from ideal - it is exposed to microorganisms and insects, ultraviolet radiation, it changes its volume depending on the degree of humidity inside the room and a series of warm / cold seasons outside the building, causing deformations in the building structure. In addition, wood is flammable. How to be the owner of a wooden house, is it really possible to demolish it and build a brick or stone one? Not at all, it is only necessary to timely process the wooden structures of the house with preparations that have antiseptic, moisture-proof and fire-retardant properties.

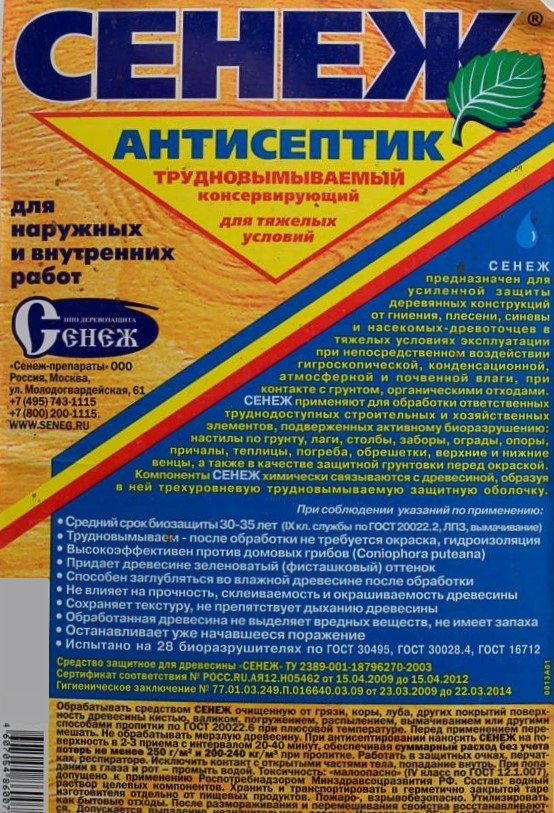

The choice of antiseptic

Before choosing bioprotection for wood during construction work, you should decide on the parameters described above: where the structure will be located (outside, inside), its tasks, the quality of the tree, part of the tree, species and others.Inspect lumber for lesions that need to be repaired. In their absence, consider what it is planned to use an antiseptic for. And to provide for everything that is planned from the construction of wood. You should also consider how to process wood: by applying a composition to the surface or by impregnation, and only then choose. At the same time, one should not forget about the different functional effects of such bioprotection for wood.

If the wood preservative is of good quality, its label will clearly describe the composition, information on the environmental friendliness and toxicity of the substance, as well as instructions for use. Additionally, documents confirming the passage of laboratory tests and the conclusions of the sanitary and epidemiological station are attached to it.

Silicone-based compounds have become popular antiseptics for wood, which have excellent moisture repellency and good vapor permeability.

It is also necessary to always consider what kind of structure should be built. For example, for a tree that will be in contact with the ground (foundation, log house and other buildings) or other moisture-containing materials, substances from the manufacturers Senezh and Neomid will be suitable. On wood, such substances should be applied in several layers, giving each to dry for at least seven hours.

Further, there is such a bioprotection for wood, which, when applied, changes the shade of the tree to light green and is not washed out during the operation of the structure. They use the wood's natural moisture to ensure deep penetration. These types include Senezh Eurotrans, Neomid 460, and Aquatex.

If the roof rafter system was built with flaws, then the wooden rafters must be treated with biosecurity. At the same time, it is necessary to take into account the natural features of the area where the structure is being built: if the humidity is high, then the tree must be protected from fungi and mold; in a dry climate, protection from insect pests is required. It is not recommended to apply several different substances on 1 surface in order to avoid reactions with each other. The market offers such antiseptics for wood bioprotection that are effective in such cases: Olympus, Senezh, Drevotex and Rogneda.

In the event that pests have already settled in a wooden structure or its surface has begun to infect mold and fungi, it is necessary to use such preparations that not only protect against external influences, but are also able to treat already affected areas. Almost all modern wood preservatives can not only protect, but also fight bioinfections. However, the following bioprotection products for wood stand out: a series of products from Tikkurila and a paste for antiseptic treatment of PAF-LST.

When building wooden structures indoors, it is necessary to choose such antiseptics that are harmless to people, but effective in influencing biocontamination. Among the high-quality bioprotections, funds from Tikkurila are distinguished. Although recently, domestic Senezh and Neomid are in no way inferior to the leader in terms of efficiency, but at the same time they act in the economy segment, that is, they have a lower price.

For outdoor work, bioprotection from Pinotex is recommended. It often becomes necessary to treat wood that is old or already painted.For this, antiseptics intended for this are used, which create a protective layer on top of the paint. These include antiseptics "Waltti Techno" and "Homeenpoisto".