- Aluminum battery device

- Technical characteristics of aluminum heating radiators

- Advantages and disadvantages of aluminum radiators

- Rules for the location of the battery and wiring diagrams

- Types of heating radiators and their comparative characteristics

- Standard

- Cast iron

- Aluminum plate

- Bimetallic

- Low

- Cast iron

- Aluminum

- Bimetallic

- Cast iron

- Aluminum

- Bimetallic

- Heat dissipation of one section

- Calculation

- For sectional

- For Whole

- Radiator selection

- And now about the disadvantages of bimetal radiators

- Features of operation and power calculation

- Accessories for mounting the device

- Mayevsky crane

- Mounting brackets

- duct extension

- Heating bimetallic devices

- Some myths and recommendations for choosing

Aluminum battery device

Considering the device of an aluminum heating radiator, it should be noted that the design of the battery can be one-piece or sectional.

Considering the device of an aluminum heating radiator, it should be noted that the design of the battery can be one-piece or sectional.

Sectional aluminum heater consists of 3-4 separate sections. As a rule, titanium, silicon, zinc are added to aluminum. These metals make the product more durable and resistant to tearing and corrosion. All sections are connected to each other with a threaded connector. Silicone gaskets are used to seal the connection.Inside, the radiators are polymer-coated to prevent the possibility of battery rupture.

Whole aluminum radiators consist of profiles. Profiles are produced by extrusion.

No additional metals are added to aluminum radiators.

What gives plasticity to the material. The profiles are connected to each other by welding. Such a connection is characterized by high strength and reliability. Like sectional, solid models of radiators are covered with a polymer layer inside.

What gives plasticity to the material. The profiles are connected to each other by welding. Such a connection is characterized by high strength and reliability. Like sectional, solid models of radiators are covered with a polymer layer inside.

Depending on the production method, radiators are made by casting, extrusion and anodized products (made from aluminum of a higher degree of purification).

Technical characteristics of aluminum heating radiators

In view of the high technical characteristics, many decide to buy an aluminum radiator for heating an apartment. The main technical parameters include:

- operating pressure. It is in the range from 10 to 15 atmospheres. In residential apartments, the working pressure can exceed the norm by 3-4 times. In this regard, such radiators are rarely installed in city houses. But for private houses - such a heater would be an ideal solution;

- pressing pressure. It is in the range from 20 to 50 atmospheres;

- heat transfer coefficient. For a standard section, it is 82-212 W;

- the maximum temperature of the coolant can reach +120 degrees;

- one section can weigh from 1 to 1.5 kg;

- the capacity of each section is from 0.25 to 0.46 l;

- the distance between the axles can be 20, 35, 50 cm. There are models in which this parameter can reach 80 cm.

The manufacturer indicates the parameters for each radiator model in the device passport.Given the technical characteristics of aluminum heating radiators, their price is quite justified and depends on the type of battery, the number of sections and the manufacturer.

Advantages and disadvantages of aluminum radiators

Before you buy aluminum heating radiators, you need to consider what advantages and disadvantages this device has.

Before you buy aluminum heating radiators, you need to consider what advantages and disadvantages this device has.

The main advantage of aluminum batteries can be called compactness and much less weight than cast iron systems. You can read more about cast iron radiators here. The equipment warms up very quickly and perfectly transfers heat to the room. The service life is long enough. Another advantage is the division into sections - it is possible to choose the desired length of the battery. It should be noted that the price for aluminum radiators is indicated per section. This makes it easy to calculate the approximate cost of a sectional device.

Because the equipment is small and light, it is easy to install. Installation can be carried out even on a plasterboard wall. Modern models look aesthetically pleasing and stylish. Aluminum is easy to work with. This allows manufacturers to experiment with battery design. You can choose an option for any interior. Most of all, aluminum radiators are suitable for autonomous heating systems. Despite the high technical characteristics and a lot of advantages, the price of aluminum heating batteries is quite affordable.

The disadvantages of aluminum radiators include low resistance to corrosion. And this can greatly affect the overall condition of the battery. Aluminum is naturally a fairly active metal.If the oxide film covering the surface is damaged, the protective layer will collapse due to hydrogen evolution. To improve the anti-corrosion properties, a polymer coating is used. If the battery does not have a polymer coating, then the taps on the supply pipes must not be closed. Otherwise, under pressure, the battery may burst.

The disadvantages of aluminum radiators include low resistance to corrosion. And this can greatly affect the overall condition of the battery. Aluminum is naturally a fairly active metal.If the oxide film covering the surface is damaged, the protective layer will collapse due to hydrogen evolution. To improve the anti-corrosion properties, a polymer coating is used. If the battery does not have a polymer coating, then the taps on the supply pipes must not be closed. Otherwise, under pressure, the battery may burst.

Today, aluminum batteries occupy a leading position in sales of heating equipment.

Many people prefer to buy this type of heater and because of the relatively low cost. For aluminum heating radiators, the average price per section is about 230-300 rubles.

Rules for the location of the battery and wiring diagrams

In addition to the characteristics, the connection of heating radiators is very important, one of the factors affecting the efficiency of the heating system is the choice of the right place to locate the product. True, in most cases it is predetermined in advance - the new battery, most likely, will stand in place of the old cast iron one, which has been there since the building was built.

But still, here are a few recommendations for the proper placement of the radiator.

How to install a radiator with your own hands

Firstly, it is desirable to place the battery under the window. The fact is that it is a "bridge" through which the cold from the street enters an apartment or cottage. The presence of a radiator under the window forms a kind of "thermal curtain" that interferes with the process described above. In this case, the battery should be placed strictly in the middle of the window, and, preferably, occupy up to 70-80% of its width. What is a pressure convector and how to install it, you can see on our page.

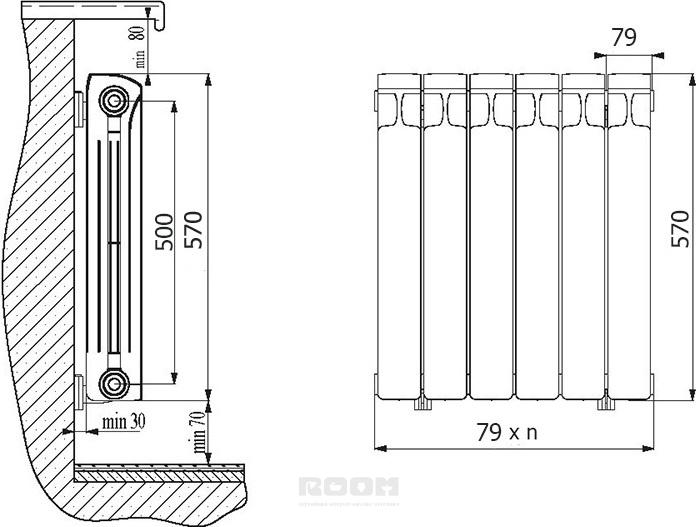

Secondly, from the floor to the radiator should be at least 80-120 mm. If there is less, then it will be inconvenient to clean under the battery, a huge amount of dust and debris will accumulate there. And if the radiator is located higher, a certain amount of cold air will collect under it, which requires warming up and, as a result, worsens the operation of the heating system. In addition, a too small distance to the window sill negatively affects the battery efficiency.

Thirdly, a distance of 2.5-3 cm is allowed between the back of the radiator and the wall. If it is less, the processes of convection and the movement of warm air flows are disturbed, and, as a result, the battery works less efficiently and wastes part of the heat in vain.

All of the above principles for placing a heating battery are presented in the diagram above.

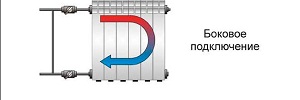

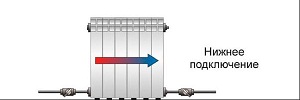

Table. Standard schemes for connecting heating batteries.

| Name | Description |

|---|---|

Side connection | Due to the specifics of the location of the risers of heating systems in residential buildings, such a battery connection scheme is the most common. It is quite easy to implement, the efficiency of the radiator is average. The main disadvantages of this connection method are visible pipes and inability to fit batteries with a large number of sections. |

Diagonal connection | The second most common radiator connection scheme. The main advantage is the uniform circulation of water throughout the battery, and, as a result, high efficiency. |

Bottom connection | A similar scheme is often used in country houses - many cottage owners prefer to hide heating communications under the floor so that they do not spoil the appearance of the room.But at the same time, the lower connection of the radiator is 12-15% less efficient than the diagonal one. |

Types of heating radiators and their comparative characteristics

The size of the heating device is a significant characteristic that is paid attention to when choosing, as it determines the power and space occupied in the room.

Standard

In addition to the size, heating radiators also differ in the material of manufacture.

Photo 1. Bimetallic radiators of standard size. Such devices are usually installed in apartments.

Cast iron

Heating systems common in Soviet times, which remain in communal apartments in the 21st century, are cast-iron batteries. Characteristics of standard cast iron products:

- average height - 50-60 cm;

- length of one section - 7-8 cm;

- power limit - 0.15-0.17 kW;

- working pressure - 9-10 atmospheres.

Aluminum plate

The material of such heaters quickly transfers heat from the liquid into the room.

In addition, these devices are much lighter than cast iron heating systems, and the flat plates of the body look much more modern. But their dimensions are similar, the differences are revealed in the technical characteristics:

- average height - 60-70 cm;

- long one component - 7-8 cm;

- thermal ceiling - 0.17-0.19 kW;

- working pressure - 16 atmospheres.

Bimetallic

These radiators outwardly do not differ from aluminum ones, since the body is made of the same material, but steel tubes are placed inside them, which protect the structure from water hammer, high pressure and improve thermal conductivity.

Characteristics of standard models:

- the height of the section and, accordingly, the whole product - 40-50 cm;

- component length - 8 cm;

- maximum power - 0.19-0.21 kW;

- withstand pressure during operation - 20-35 atmospheres.

Photo 2. Design of a bimetallic heating radiator. The arrows indicate the component parts of the device.

Low

Low radiators are the most compact among all types of radiator appliances.

Cast iron

Since such products were produced according to strict standards, their sizes do not differ in variety. Neat cast-iron radiators of small sizes are made to order by figured casting. Dimensions and values:

- section height - 40-50 cm;

- component length - 5-6 cm;

- thermal ceiling - 0.09-0.11 kW;

- working pressure - 9 atmospheres.

Photo 3. Low radiator made of cast iron. The device is white in color with a fairly modern design.

Aluminum

Small aluminum radiators are much more common, as production is not so long ago and technology continues to improve. The small size determines the scope of their use: such devices are installed in kindergartens, utility rooms, heated garages, attics and verandas. Characteristics:

- height - 50 cm;

- section length - 6-7 cm;

- temperature maximum - 0.11-0.13 kW;

- operating pressure - up to 16 atm.

Bimetallic

The scope of application of bimetallic heaters of small sizes is limited to the same category of room types that are presented for aluminum devices.

The list is supplemented only by office premises at a considerable height - due to the high pressure in the pipes of skyscrapers and business centers. Characteristics:

- product height - 30-40 cm;

- the length of one section is 6-7 cm;

- power ceiling - 0.12-0.14 kW;

- withstand pressure during operation - up to 28-32 atmospheres.

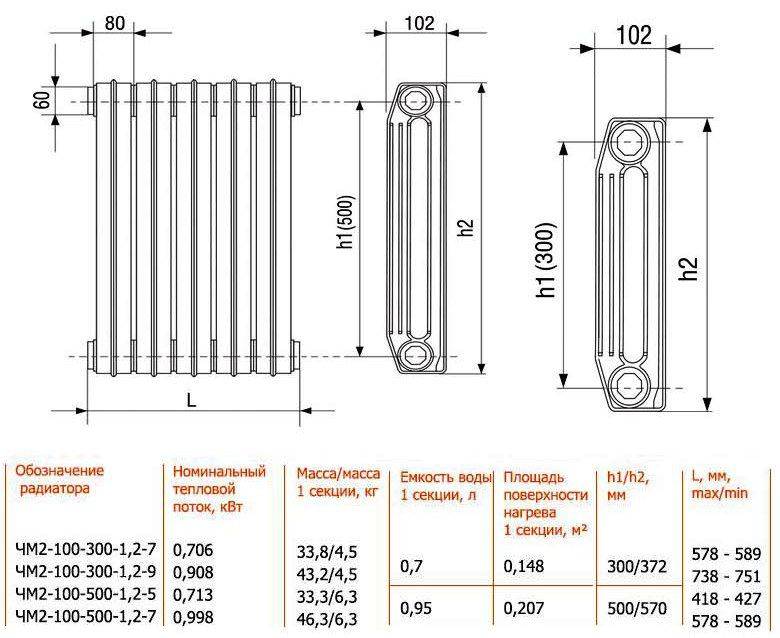

Cast iron

Here, the dimensions of cast iron products are not much different from other categories: all factory models are standard in size, as they were produced according to GOSTs.

High cast-iron radiators are purchased in specialized foundries (not so cheap). Characteristics of devices of this type:

- height of the body of the heating system - 80-90 cm;

- length of one section - 7-8 cm;

- temperature ceiling - 0.18-0.21 kW;

- the maximum pressure is about 9-12 atmospheres.

Aluminum

Here the choice is much wider: for cramped rooms where long radiators do not fit, it is better to purchase narrow but high aluminum models. They, as a rule, have only 4 components, but this is fully compensated by their length. Characteristics:

- The height of the product is up to two meters.

- The length of the section is about 10-12 cm.

- Maximum power - 0.40-0.45 kW.

- Pressure ~ 6 atmospheres.

Attention! It is strictly forbidden to use this type of radiators in central heating systems - the battery simply cannot withstand such pressure

Bimetallic

The steel core of bimetallic batteries does not allow them to be very high, since the circulation of water through it will be difficult.

However, even half the size, compared with a fully aluminum counterpart, is enough to heat a spacious room. And the value of the maximum pressure level is simply amazing:

- The height of the heating system is ~ 80-90 cm.

- The length of the component is 7-8 cm.

- Thermal ceiling - 0.18-0.22 kW.

- Working pressure - from 20 to 100 atmospheres.

Heat dissipation of one section

Today, the range of radiators is large. With the external similarity of the majority, thermal performance can vary significantly.They depend on the material from which they are made, on the dimensions, wall thickness, internal section and on how well the design is thought out.

Therefore, to say exactly how many kW in 1 section of an aluminum (cast-iron bimetallic) radiator can only be said in relation to each model. This information is provided by the manufacturer. After all, there is a significant difference in size: some of them are high and narrow, others are low and deep. The power of sections of the same height of the same manufacturer, but different models, may differ by 15-25 W (see the table below STYLE 500 and STYLE PLUS 500) . Even more tangible differences can be between different manufacturers.

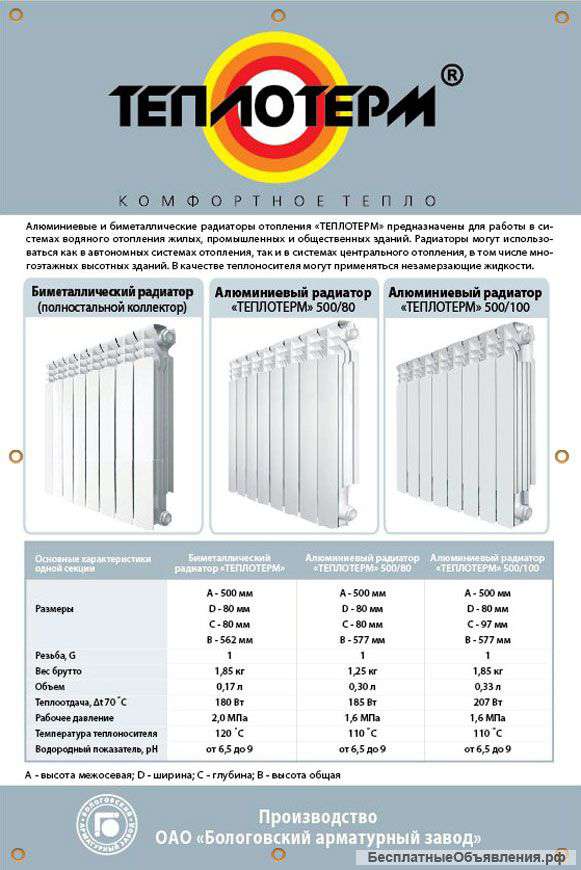

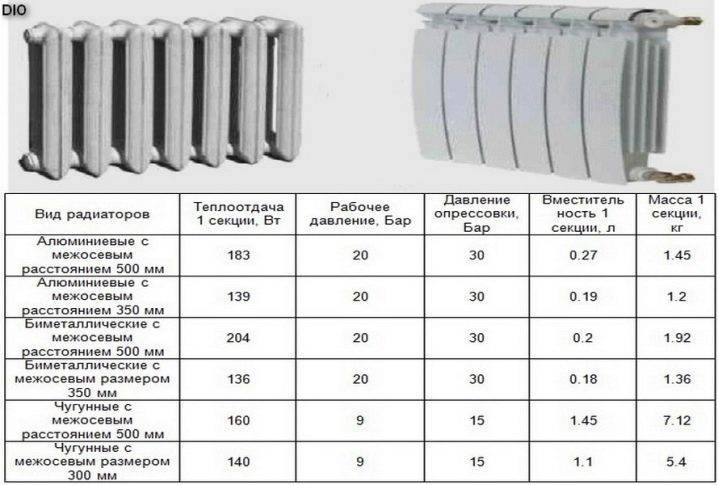

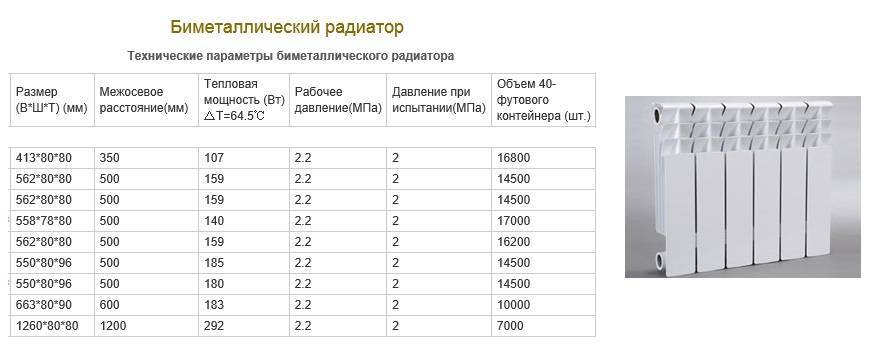

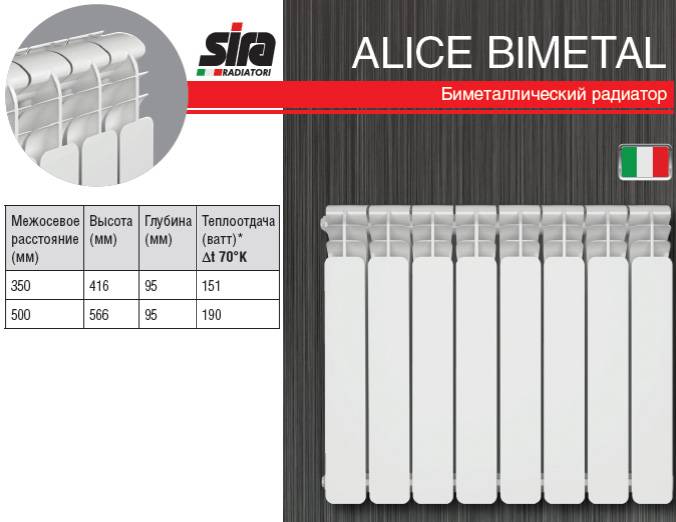

Technical characteristics of some bimetallic radiators

Please note that the heat output of sections of the same height can have a noticeable difference. However, for a preliminary assessment of how many sections of batteries are needed for space heating, we deduced the average values of thermal power for each type of radiator

They can be used for approximate calculations (data are given for batteries with a center distance of 50 cm):

Nevertheless, for a preliminary assessment of how many sections of batteries are needed for space heating, we deduced the average values of thermal power for each type of radiator. They can be used for approximate calculations (data are given for batteries with a center distance of 50 cm):

- Bimetallic - one section emits 185 W (0.185 kW).

- Aluminum - 190 W (0.19 kW).

- Cast iron - 120 W (0.120 kW).

Calculation

For sectional

If the required room is of non-standard sizes, then it is better to choose a sectional heating device.The number of segments must be correctly calculated so that there are no extra costs or lack of heat.

By volume. It is produced in the following sequence:

Determination of heat demand according to the norms. According to building codes, the amount of heat required for a room is 41 watts per cubic meter, however, these calculations apply to insulated buildings. If the building is poorly insulated, then the indicator must be increased to 50 W / m3. If there is a layer of insulation on the walls of the room, and plastic windows are also installed, the indicator is reduced to 30 - 34 W / m3.

Calculate the required number of sections. The first step is to calculate the volume of the room that needs heaters.

We will consider using the example of a room with a width of 4 m, a length of 5 m and a ceiling height of 3 m. We multiply the values \u200b\u200band get a volume of 60 m3.

Determining the heat demand for an apartment. The apartment is with medium insulation without an additional layer. The value for it approaches 41 W/m3. We multiply the indicator with the volume of the room, the result is 2460 W

This amount of energy is needed to provide heat to your room.

Pay attention to the amount of heat generated by one section of the battery you have chosen. Modern samples give out power in the following range - 80-212 W

We take for calculation the average value of 170 watts. The amount of heat required is divided by this value, and then the resulting amount is rounded up. We get 15. It is this number of sections that is needed to heat the given room.

There is also an easier way, it is used for rooms with ceilings of 2.6 meters.

Area calculation. With this calculation, you only need to know the length of the walls of the room.Consider the example of a room similar to the previous one, however, the ceilings there will be less than 2.6 meters. In this calculation, a demand of 100 W / m3 is taken, regardless of the conditions.

- We calculate the area of the room. It is 20 m2.

- Determining the amount of heat required for heating. We multiply the need by the area, as a result, 2000 watts come out.

- Now you need to find out what heat transfer one section of the battery has. As in the previous calculation, we take a value of 170 watts. The need for the room is divided by it, and the result is rounded up. According to the calculations, it was obtained that 12 sections are needed for the room given in the example.

For Whole

The calculation of heat for solid batteries does not differ from sectional ones until the stage of calculating the amount of heat required by the room. If in the previous examples you divided the obtained value by the heat output of the section, then here you are comparing the heat indicators. Necessary for the room and the one that corresponds to the heating device you have chosen.

If the number of watts produced by the battery is lower, it is necessary to install an additional climatic device that will make it possible to cover the lack of necessary heat.

Both types of calculation assume that the height of the ceilings in the room does not exceed 3 meters, so they will not work at a higher height. In such rooms, the number of sections is already determined by heating engineers.

Radiator selection

You should start by choosing a radiator, and the main criterion for choosing will be the operating pressure for which the radiator is designed.For a private house with its own heating system, a radiator with a working pressure of 6-7 atmospheres will be enough, but if you need to connect a radiator to the central heating system of an apartment building, it must withstand a pressure of at least 10 atmospheres.

Currently, the consumer is offered two options for aluminum radiators - standard or European and reinforced. The latter can operate under pressure up to 12 atmospheres. When connecting to a central heating system, it is necessary to choose among reinforced radiators.

The number of sections plays a big role

Next, you need to decide on the required number of sections. To do this, we determine the amount of heat. Necessary for heating the room and divide by the heat transfer of one section of the selected radiator.

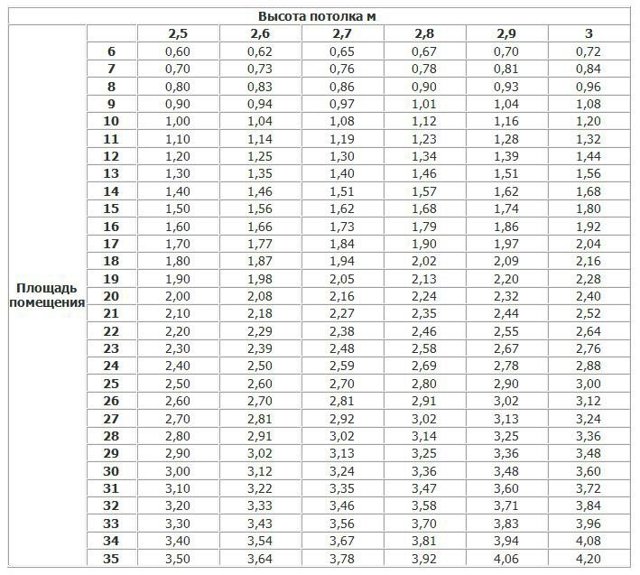

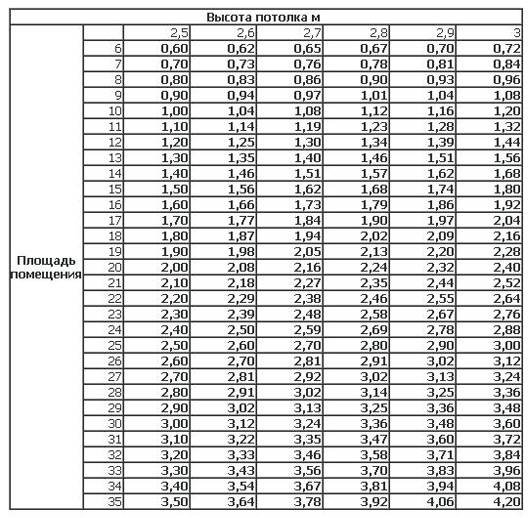

The amount of heat required for a standard room can be taken equal to 1 kW per 10 m 2 of the room area. For non-standard premises and more accurate calculations, we will use the finished table:

Radiator power table

It should be remembered that a battery connection diagram of more than 12 sections must be double-sided, diagonal or saddle. With a one-sided battery connection scheme from a large number of sections, a "pocket" of cold water will form on the side of the radiator opposite to the pipes. "Extra" sections simply will not work, we get harmful ballast.

Using forced injection, the battery can be extended up to 24 sections even with one-sided supply, but in this case the radiator must be reinforced.

It should be remembered that it is necessary to supply the coolant to reinforced radiators under high pressure only through metal pipes.Metal-plastic can not withstand such pressure, and the consequences will be the saddest.

It should also be taken into account that the heat transfer of the radiator indicated in the documentation is relevant only for one-sided or diagonal supply of coolant to the radiator. When using the bottom feed, feel free to subtract 10-15 percent.

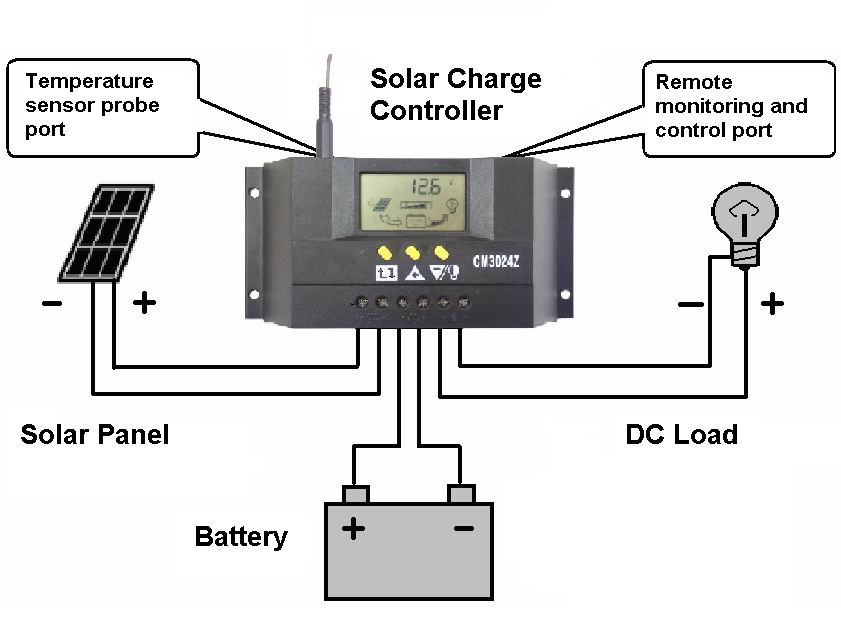

If the heating system is installed in a private house, then it is possible to choose the general scheme for organizing heating - one- or two-pipe.

And now about the disadvantages of bimetal radiators

The most significant disadvantage of these batteries can be called their high cost. They are much more expensive than the usual cast iron radiators. However, bimetal products look much neater, fitting well into a modern interior. And in terms of life expectancy, they are ahead of other types of batteries.

It is also bad that when exposed to both water and air at the same time, the steel pipes of the core can begin to “eat up” corrosion. And this happens when, during a repair or an accident, water is drained from the heating system. And the pipes also rust from antifreeze, which is often present in the heating systems of small houses. In this case, bimetallic sectional batteries must be abandoned - it is better to take either solid or completely aluminum ones.

This option is also acceptable - radiators with a copper core and an aluminum case. The oxide film on copper pipes is strong enough - it will save them from corrosion. You can use stainless steel instead of a copper core - also a good option.

Features of operation and power calculation

Calculation of sections of aluminum radiators

Aluminum and bimetal radiators are high-tech products, the production of which uses unique technologies. Processing of raw materials, casting and painting have reached a qualitatively new level.

But in order for the heaters to function successfully, there are a number of requirements for them:

When operating the indicated devices, they must not be allowed to come into contact with copper parts. Aluminum and copper have bipolar charged atoms, which, interacting with each other, trigger the mechanisms for the development of electrochemical corrosion. Therefore, it is desirable to replace copper parts with bronze or brass ones.

Be sure to immediately install automatic air ducts. If this is not done, then in the first weeks you will have to manually bleed oxygen.

Features of battery operation

It is important to make a competent calculation of the sections of bimetallic radiators and aluminum batteries. This is a responsible operation, the successful implementation of which determines the degree of comfort in the cold season. Nobody wants to spend extra money, so we will give a completely understandable and simple instruction that helps to derive the desired formula

A characteristic feature of the described heating devices is the presence of a channel with a large flow area. Considering that the heat transfer of aluminum and bimetallic radiators is 12% higher than that of cast iron ones, it is clear that their sections will need much less

Nobody wants to spend extra money, so we will give a completely understandable and simple instruction that helps to derive the desired formula. A characteristic feature of the described heating devices is the presence of a channel with a large flow area.If we take into account that the heat transfer of aluminum and bimetallic radiators is 12% higher than that of cast iron ones, then it is clear that their sections will be needed much less.

How to calculate the number of sections of bimetallic radiators and aluminum batteries and choose a device of the required power? To determine it, only the area of \u200b\u200bthe heated room is taken into account. The calculation formula is quite simple - 100 watts are needed per square meter of living space with a ceiling height of 2.7 meters.

The number of battery sections is calculated as follows - the area of \u200b\u200bthe heated room is multiplied by one hundred and divided by the power of one section of the radiator (this indicator is necessarily indicated in the technical data sheet of the device). As an example, we give the calculation of bimetallic heating radiators, which must be installed in a living room with an area of 30 sq.m. In this case, we take the power of the standard section equal to 200 watts.

Heating appliances

We multiply 30 by 100, divide by 200 and get 15 sections. To heat the designated room, you must purchase a bimetallic radiator with fifteen sections. To be sure, experts recommend choosing a radiator with a 20% margin, so the final version is 18 sections.

As you can see, the calculator for calculating heating radiators is quite simple, but only for those who know about the above formula. Calculating the number of heaters is also simple. In a room less than 25 sq. m can install one radiator. And where the indicators are higher, to create uniform convection flows, it is better to install two sections.

Accessories for mounting the device

The quality of its operation depends on the parts that go on sale with the radiator.Together with the device, two important components are offered: an air release valve and fasteners. For apartment buildings, they are supplemented with a duct extension.

Mayevsky crane

Serves to remove air from the system. Helps to get rid of gas plugs, superheated steam. Thus, it allows to reduce the pressure that has increased due to the long operation of the boiler. Mandatory for installations in closed-type piping supplemented with a circulation pump.

Reference. It is desirable to have a valve for draining water. It will serve the same purpose as Mayevsky's faucet, affecting the liquid part.

Mounting brackets

They serve as radiator mounts. They must be included with the aluminum device.

Photo 2. Brackets for mounting aluminum radiators. Products are already built into the wall.

They are divided into three types:

- Wood corners.

- Pins for walls made of other materials.

- Anchors for all surfaces.

Plugs are required for all threaded connections. The minimum diameter must be one inch (25.4 mm). For nipples, they are also needed, but without size restrictions.

Sometimes aluminum radiators are wrapped with gaskets with a heat reflection effect. They are placed along the wall, reducing energy loss to the atmosphere. The material for the manufacture is foil or porilex. The substance is often supplemented with another layer of insulation, usually foam.

duct extension

The device is used to increase the thermal conductivity of the radiator. To do this, the latter must contain at least 10 sections.

A lateral connection to the main is mandatory, since aluminum devices convey liquid diagonally

It is also important to have shut-off valves on both pipes.

If the conditions are met, it is not necessary to change the current scheme for installation. Otherwise, it is recommended to invite a plumber.

Heating bimetallic devices

To date, bimetallic radiators are the most in demand, since they combine the advantages of aluminum and steel products. They are ideal for housing with central heating, and their disadvantage is high cost.

STOUT heaters of this type have been specially adapted to the Russian market. They are able to withstand operating pressures up to 100 atmospheres and operate effectively at ambient temperatures up to 135°C.

The manufacturer provides a 10-year warranty for this product. The number of sections can be 4 - 14 pieces and therefore there will be no problems with which batteries to choose for the apartment.

For the production of bimetallic radiators, two metals are used - aluminum and steel. In order to improve technical performance, various silicon compounds are sometimes added to the composition, which increase wear resistance and service life.

Inside the bimetallic product there is a structure consisting of two parts. The first of them is a steel core along which the coolant moves. Its functional purpose is to accumulate thermal energy and transfer it to the second part, made of aluminum. Heat enters the room through the heat exchanger.

The aluminum casing has no direct contact with the working medium. This task is performed by a high-quality steel alloy.Outside, the radiator is covered with enamel paint, and the modern design provides a protective coating.

The strength of steel and the high heat transfer of aluminum make it possible to manufacture highly efficient heating devices that can quickly warm up a room, they are not afraid of pressure drops that occur in the system. They are resistant to corrosion processes.

The steel core can easily withstand a working pressure of 35 - 40 atmospheres, and when tested for strength in production conditions, even 45 - 50 atmospheres. If the house has an unstable heating system, choosing which batteries are best for the room from the entire range, you don’t have to worry that bimetallic devices will fail.

In some models, the cores are made of copper, not steel. They are intended for autonomous systems in which a coolant with the addition of antifreeze functions, and it destroys steel parts.

The outer panel of the radiator has a ribbed structure to enhance heat transfer. Since the design weighs a little, there are no problems with its installation. The inside of the radiator is covered with a special layer with the addition of polymers. It protects the device from the negative effects of abrasive components present in the water.

Today there are no problems with the acquisition of such units: their center distance can be from 200 to 800 millimeters. To determine the number of sections, it is necessary to make calculations.

To make the right choice, you need to know what kind of batteries are available for heating an apartment of a bimetallic type - monolithic and sectional. The first of them are more expensive, but they also have the best technical indicators, and the absence of joints prevents leaks.

Advantages of bimetallic devices:

- ease of installation;

- resistance to high pressure and water hammer;

- light weight;

- stylish look;

- variety of design solutions;

- high degree of heat transfer;

- long service life - about 50 years;

- minimum requirements for the quality of the coolant.

These devices have one drawback and this is their high cost, but it pays off due to a long period of operation and reliability. When solving the problem of how to choose heating radiators, the choice in favor of bimetallic products can be called the best option for apartments with central heating in multi-storey buildings.

There is one circumstance that should be taken into account before buying. Bimetallic products are outwardly similar to aluminum appliances

These designs are difficult to distinguish, so before choosing a radiator for a room, you need to look inside them.

Some myths and recommendations for choosing

Currently, on the network forums dedicated to the subject of heating apartments and private houses, disputes “bimetal or aluminum” do not subside. Numerous opinions are so contradictory that the average homeowner or tenant is unlikely to be able to make the right decision. Moreover, on the pages of thematic forums there are a number of myths that put a person who is not a specialist in this field into a dead end. Here are some of the main myths:

- aluminum radiators are not able to withstand high network pressure;

- silumin, which is part of aluminum radiators, is subject to rapid corrosion, due to which the entire battery will soon become unsuitable for further operation, and, therefore, preference should be given to bimetallic heating devices;

- aluminum, which is part of the radiators, together with another metal that is in contact with the coolant, creates a galvanic couple and, as a result, is very quickly destroyed under the influence of electrochemical corrosion;

- in contact with dirty coolant water, aluminum releases a significant amount of oxygen into the system;

- steel parts of bimetallic batteries rust very quickly, rot, after which the battery becomes unsuitable for further use;

- as well as many other fantastic statements.

Some of the processes described in these myths actually take place. However, the degree of their influence is so negligible that the battery can serve faithfully for more than a dozen years. Thus, if you bought not a cheap fake, but a high-quality product, performed the installation correctly, you should not worry about the manifestation of the factors described above.

A few tips to help you make the right choice of heating radiators:

- For autonomous heating systems of private houses, it is better to choose aluminum radiators.

- Aluminum-based radiators can be used in the heating systems of apartment buildings. To do this, you need to take into account the magnitude of the working pressure and use products only from well-known world manufacturers.

- In multi-storey buildings (16 or more floors), bimetallic batteries should be chosen for heating systems.

- If the heating system of a multi-storey building includes not only risers, but also horizontal branches, aluminum radiators can be used.

- If there are doubts about the reliability of aluminum batteries, you need to buy and install bimetallic heaters. This will ensure reliable operation.

Aluminum or bimetallic heating radiators connected to the central heating system will provide a comfortable temperature in the home and have a long service life only if they are periodically flushed. The ideal flushing frequency is once a year. If this is not possible, flushing must be performed at least once every 3 years.