- Parsing into segments

- How to install an aluminum battery with your own hands?

- Preparatory work

- Radiator Assembly

- Cast iron radiators

- Bimetallic heating radiators which is better selection instructions

- The positive aspects of using bimetallic radiators

- The negative aspects of using bimetallic radiators

- Placement of heating devices

- Bimetal heating devices

- aluminum batteries

- The most accurate calculation option

- Heating Radiator Calculator

- Positive characteristics of cast iron radiators

- Any coolant is suitable for them

- Max working pressure

- Durability

- low price

- Advantages and disadvantages of an aluminum heater

- Copper radiators

- Crimping and working pressure

- Cast iron radiators

- Calculation by area

- An example of calculating the number of radiator sections according to the area of the room

- Working pressure types

- Structural features

- Heat dissipation of one section

Parsing into segments

To properly disassemble an aluminum radiator, you will need a special tool - a nipple wrench, which is made specifically for this job. As a rule, it is not in stores, since it is a product of the mind and labor of plumbing workers. You can get it in two ways.

The first is to try your luck at the local market (if there is one), which sells various used tools and other useful household items. It is likely that there you will find what you are looking for, and at an affordable cost. The second option is to contact any plumbing workshop and ask them for a nipple wrench for rent.

When your search is successfully completed, you can proceed directly to dismantling the equipment. There is a specific order for this procedure.

- The first thing to do is to shut off the water in the riser to which the radiator is connected and drain the coolant from the system. If you are the owner of a private house, you can do it yourself. If you are dealing with a centralized heating system, then such issues can only be resolved through the organization that manages the building. To do this, you need to write a statement and then wait for the arrival of a specialist. By the way, in the case of living in an apartment building, you can carry out such work only during the period when the heating season is already over. Otherwise, you simply will not be able to get permission, because stopping the central heating system will bring cold not only to yours, but also to the neighboring apartments.

- After you have dealt with turning off the water in the system, place containers under the junctions of the radiator and the line to collect the remaining coolant that will flow out during the separation of the equipment.

- Unscrew the fittings connecting the battery to the line. At the same time, check their condition. If you notice any flaws - cracks or “smoothed” threads - then it is better to replace these elements with new ones.Just keep in mind that not all metals are combined with aluminum radiators. For example, fittings made of brass or copper should absolutely not be used, as this may cause an electrochemical reaction, which will lead to the onset of corrosive processes.

- After detaching, remove the radiator from the brackets holding it.

- Now it's time to use the same tool that you worked hard to extract in your time. The nipple key must be inserted into the battery exactly to the place that you are going to dismantle. Then it is necessary to get the end of the tool into the hole intended for this on the connecting element. After you have succeeded, turn the nut in the desired direction by half a turn. In general, for this stage it is advisable to invite an assistant who will fix the radiator in one place while you fiddle with the connections. So, we turned the nut half a turn, go to the one located on the opposite side, and repeat the same operation there. Thus, by gradually unscrewing each element in turn, you can completely separate one section from another. Be careful and patient - each nut needs to be turned just a little, about 5-7 mm. Otherwise, the section may be severely skewed, resulting in damage to the radiator elements, and it will be necessary to replace them.

- After unscrewing the necessary nuts, remove the segment, and then check all the gaskets that come with it. The quality and condition of rubber seals plays an important role. Deformed gaskets can cause leakage. Therefore, in case of the slightest doubt about their suitability, it is better to replace these elements with new ones.Moreover, it is advisable to purchase gaskets made of paronite, since this material has proven itself best. If this is not possible, then try to find at least silicone seals. It is not recommended to install rubber ones, as they quickly fail.

How to install an aluminum battery with your own hands?

This process takes place in stages.

Preparatory work

They begin with the fact that the location of the future installation of the radiator is determined and the brackets are fixed.

For a competent calculation of the installation of the battery, the following construction indicators of indents must be taken into account:

- from 10 cm or more - from the windowsill;

- 3–5 cm from the wall;

- about 12 cm from the floor level.

The bracket is fixed to the wall with dowels. The holes left by the drill are filled with cement.

If the battery is floor type, then it is placed on a special stand, and it is attached slightly to the wall, only to establish its stable balance.

Radiator Assembly

Before starting the battery directly, it is necessary to install it step by step:

- screw in the plugs and radiator plugs;

- docking with shutoff valves;

- collection of thermostats;

- nipples stability control;

- fixing air valves.

Attention! For further correct operation of the valves, it is necessary to install their outlet heads so that they are facing upwards. After completing all the steps, the radiator is fixed to the brackets

After completing all the steps, the radiator is fixed to the brackets.

Hooks are located between sections. Detailed instructions for assembling an aluminum space heating source should come with it.

Cast iron radiators

Cast iron batteries heat up for a long time, but cool down for a long time.The residual heat retention number is twice that of other types and is 30%.

This makes it possible to reduce the cost of gas for home heating.

Advantages of cast iron radiators:

- Very high resistance to corrosion;

- Durability and reliability that have been tested over the years;

- Low heat transfer;

- Cast iron is not afraid of exposure to chemicals;

- The radiator can be assembled from a different number of sections.

Cast iron radiators have only one drawback - they are very heavy.

The modern market offers cast-iron radiators with decorative design.

Bimetallic heating radiators which is better selection instructions

The first heating radiators made from two metals (bimetallic) appeared in Europe more than sixty years ago. Such radiators quite coped with the assigned function of maintaining a comfortable temperature in the room during the cold season. At present, the production of bimetallic radiators has been resumed in Russia, while the European market, in turn, is dominated by various aluminum alloy radiators.

Bimetal heating radiators which are better

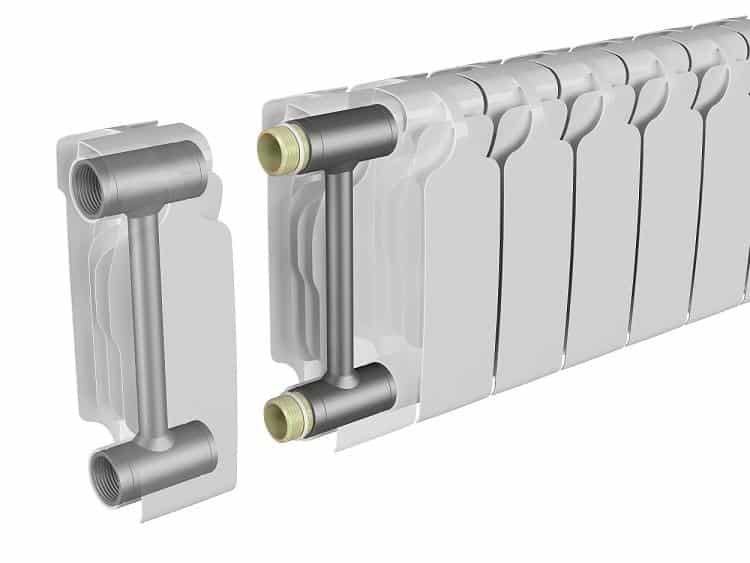

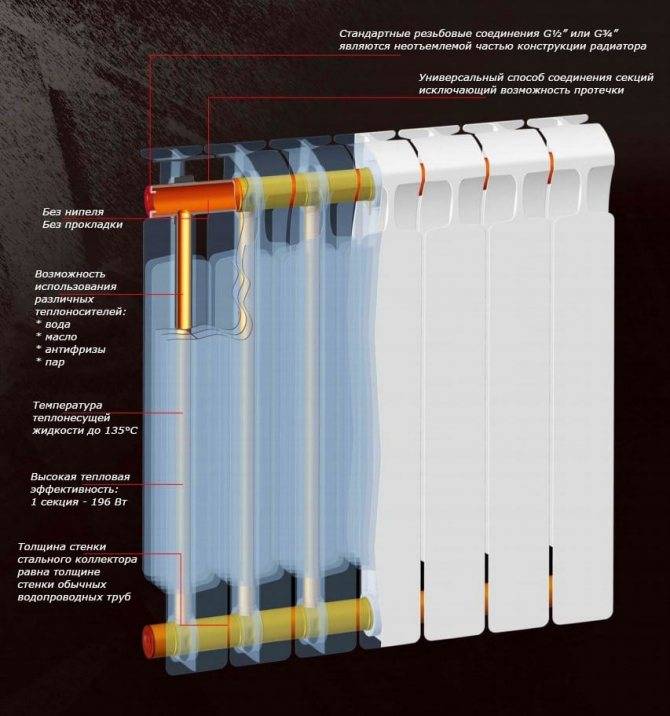

Bimetallic radiators are a frame made of steel or copper hollow pipes (horizontal and vertical), inside which the coolant circulates. Outside, aluminum radiator plates are attached to the pipes. They are attached by spot welding or special injection molding. Each section of the radiator is connected to the other by steel nipples with heat-resistant (up to two hundred degrees) rubber gaskets.

The design of the bimetallic radiator

In Russian city apartments with centralized heating, radiators of this type perfectly withstand pressures up to 25 atmospheres (when pressure tested up to 37 atmospheres) and, due to their high heat transfer, perform their function much better than their cast-iron predecessors.

Radiator - photo

Externally, it is quite difficult to distinguish bimetallic and aluminum radiators. You can verify the correct choice only by comparing the weight of these radiators. Bimetallic because of the steel core will be heavier than its aluminum counterpart by about 60% and you will make an error-free purchase.

The device of a bimetallic radiator from the inside

The positive aspects of using bimetallic radiators

- Bimetal panel-type radiators fit perfectly into the design of any interior (residential buildings, offices, etc.), without taking up much space. The front side of the radiator can be one or both, the size and color scheme of the sections are varied (self-coloring is allowed). The absence of sharp corners and too hot panels makes aluminum radiators suitable even for children's rooms. In addition, there are models on the market that are installed vertically without the use of brackets due to the additionally present stiffeners.

- The service life of radiators made of an alloy of two metals reaches 25 years.

- Bimetal is suitable for all heating systems, including central heating. As you know, low-quality coolant in municipal heating systems adversely affects radiators, reducing their service life, however, bimetal radiators are not afraid of high acidity and poor quality of coolants due to the high corrosion resistance of steel.

- Bimetallic radiators are the standard of strength and reliability. Even if the pressure in the system reaches 35-37 atmospheres, this will not damage the batteries.

- High heat transfer is one of the main advantages of bimetal radiators.

- The regulation of the heating temperature using a thermostat occurs almost instantly due to the small cross section of the channels in the radiator. The same factor allows you to halve the amount of coolant used.

- Even if it becomes necessary to repair one of the radiator sections, thanks to the well-thought-out design of the nipples, the work will take a minimum of time and effort.

- The number of radiator sections needed to heat a room can be easily calculated mathematically. This eliminates unnecessary financial costs for the purchase, installation and operation of radiators.

The negative aspects of using bimetallic radiators

- As mentioned above, bimetallic radiators are suitable for operation with a low-quality coolant, but the latter significantly reduces the life of the radiator.

- The main disadvantage of a bimetallic battery is the different expansion coefficient for aluminum alloy and steel. After prolonged use, creaking and a decrease in the strength and durability of the radiator may occur.

- When operating radiators with low-quality coolant, steel pipes may quickly become clogged, corrosion may occur, and heat transfer may decrease.

- The contested disadvantage is the cost of bimetal radiators. It is higher than that of cast iron, steel and aluminum radiators, but considering all the advantages, the price is fully justified.

Placement of heating devices

It is of great importance not only how to connect the heating radiators to each other, but also their correct location in relation to building structures. Traditionally, heating devices are installed along the walls of the premises and locally under the windows in order to reduce the penetration of cold air flows in the most vulnerable place.

There is a clear instruction for this in the SNiP for the installation of thermal equipment:

- The gap between the floor and the bottom of the battery should not be less than 120 mm. With a decrease in the distance from the device to the floor, the distribution of the heat flux will be uneven;

- The distance from the rear surface to the wall on which the radiator is attached must be from 30 to 50 mm, otherwise its heat transfer will be disturbed;

- The gap from the upper edge of the heater to the window sill is maintained within 100-120 mm (not less). Otherwise, the movement of thermal masses may be difficult, which will weaken the heating of the room.

Bimetal heating devices

To understand how to connect bimetallic radiators to each other, you need to know that almost all of them are suitable for any type of connection:

- They have four points of possible connection - two upper and two lower;

- Equipped with plugs and a Mayevsky tap, through which you can bleed the air collected in the heating system;

The diagonal connection is considered the most effective for bimetallic batteries, especially when it comes to a large number of sections in the device. Although very wide batteries, equipped with ten or more sections, are undesirable.

Advice! It is better to consider the question of how to properly connect two 7-8 section heating radiators instead of one device of 14 or 16 sections.It will be much easier to install and more convenient to maintain.

Another question - how to connect sections of a bimetallic radiator can arise when regrouping sections of a heater in various situations:

The place where you plan to install the heater is also important.

- In the process of creating new heating networks;

- If it is necessary to replace a failed radiator with a new one - bimetallic;

- In case of underheating, you can increase the battery by attaching additional sections.

aluminum batteries

Interesting! By and large, it should be noted that a diagonal connection is an excellent option for any type of battery. Do not know how to connect aluminum radiators to each other. connect diagonally, you can't go wrong!

For closed-type heating networks in private houses, it is advisable to install aluminum batteries, since it is easier to ensure proper water treatment before filling the system. And their cost is much lower than that of bimetallic devices.

Of course, over time, moving along the radiators, the coolant cools down.

Of course, you will have to try before you connect the sections of the aluminum radiator for rearrangement.

Advice! Do not rush to remove the factory packaging (film) from the installed heaters until the finishing work in the room is completed. This will protect the radiator coating from damage and contamination.

The work process itself does not take much time, you do not need any special skill or expensive equipment, you can purchase all the necessary tools at any hardware store.And do not forget, the connection will serve you for a long time and without hassle only if you used high-quality materials in your work and followed all the rules for installing the heating system.

We are talking about exactly what is shown in this picture.

In the presented video in this article you will find additional information on this topic.

The most accurate calculation option

From the above calculations, we have seen that none of them is perfectly accurate, since even for the same rooms, the results, albeit slightly, are still different.

If you need maximum calculation accuracy, use the following method. It takes into account many factors that can affect the heating efficiency and other significant indicators.

In general, the calculation formula has the following form:

T \u003d 100 W / m 2 * A * B * C * D * E * F * G * S,

- where T is the total amount of heat required to heat the room in question;

- S is the area of the heated room.

The rest of the coefficients need more detailed study. Thus, the coefficient A takes into account glazing features .

Features of the glazing of the room

- 1.27 for rooms whose windows are glazed with just two glasses;

- 1.0 - for rooms with windows equipped with double glazing;

- 0.85 - if the windows have triple glazing.

Coefficient B takes into account the features of the insulation of the walls of the room.

Features of the insulation of the walls of the room

- if the insulation is inefficient. the coefficient is assumed to be 1.27;

- with good insulation (for example, if the walls are laid out in 2 bricks or purposefully insulated with a high-quality heat insulator). a coefficient equal to 1.0 is used;

- with a high level of insulation - 0.85.

The coefficient C indicates the ratio of the total area of window openings and the floor surface in the room.

The ratio of the total area of window openings and the floor surface in the room

The dependency looks like this:

- at a ratio of 50%, the coefficient C is taken as 1.2;

- if the ratio is 40%, use a factor of 1.1;

- at a ratio of 30%, the coefficient value is reduced to 1.0;

- in the case of an even smaller percentage, coefficients of 0.9 (for 20%) and 0.8 (for 10%) are used.

The D coefficient indicates the average temperature in the coldest period of the year.

Heat distribution in the room when using radiators

The dependency looks like this:

- if the temperature is -35 and below, the coefficient is taken equal to 1.5;

- at temperatures up to -25 degrees, a value of 1.3 is used;

- if the temperature does not fall below -20 degrees, the calculation is carried out with a coefficient equal to 1.1;

- residents of regions where the temperature does not fall below -15 should use a coefficient of 0.9;

- if the temperature in winter does not fall below -10, count with a factor of 0.7.

The coefficient E indicates the number of external walls.

Number of external walls

If there is only one external wall, use a factor of 1.1. With two walls, increase it to 1.2; with three - up to 1.3; if there are 4 external walls, use a factor of 1.4.

The F coefficient takes into account the features of the room above. The dependency is:

- if there is an unheated attic space above, the coefficient is assumed to be 1.0;

- if the attic is heated - 0.9;

- if the upstairs neighbor is a heated living room, the coefficient can be reduced to 0.8.

And the last coefficient of the formula - G - takes into account the height of the room.

- in rooms with ceilings 2.5 m high, the calculation is carried out using a coefficient equal to 1.0;

- if the room has a 3-meter ceiling, the coefficient is increased to 1.05;

- with a ceiling height of 3.5 m, count with a factor of 1.1;

- rooms with a 4-meter ceiling are calculated with a coefficient of 1.15;

- when calculating the number of battery sections for heating a room with a height of 4.5 m, increase the coefficient to 1.2.

This calculation takes into account almost all existing nuances and allows you to determine the required number of sections of the heating unit with the smallest error. In conclusion, you will only have to divide the calculated indicator by the heat transfer of one section of the battery (check in the attached passport) and, of course, round the found number up to the nearest integer value.

Heating Radiator Calculator

For convenience, all these parameters are included in a special calculator for calculating heating radiators. It is enough to specify all the requested parameters - and clicking on the "CALCULATE" button will immediately give the desired result:

Energy Saving Tips

Positive characteristics of cast iron radiators

Any coolant is suitable for them

While technical hot water gets from the boiler room to the battery, its quality does not get better. However, it was not ideal from the very beginning, and then, following the pipelines, it takes with it a fair amount of impurities. So, a certain liquid is already entering our apartments, which is quite chemically aggressive. This most aggressive water (more specifically, it has a lot of alkalis) also carries with it a bunch of small grains of sand that act like abrasives.

And it begins to actively corrode steel batteries, for example. And grains of sand, like emery, rub their thin walls. And cast iron does not care about all this - after all, it is chemically passive, and the walls of radiators made of this metal are very thick. And in the summer, when water is drained from the system, the cast-iron battery will not rust from the inside.

Max working pressure

The working pressure of cast-iron radiators is from 9 atmospheres or more, depending on the manufacturer and model. They tolerate water hammer well and are therefore often used in district heating systems.

Durability

If you wash cast iron batteries from time to time, and also replace the intersection gaskets as necessary, they will respond to such care gratefully. They will be able to work for fifty years, regularly heating your rooms. By the way, retro-batteries made of cast iron are still alive in St. Petersburg, which were cast at the first factories. More than a hundred years have passed, after all.

low price

If we compare the price of cast iron batteries with the cost of bimetallic products that have become fashionable recently, then cast iron will be much more profitable for the budget. And if you have to buy radiators not for one room, but for several, then the savings will be very, very impressive.

Advantages and disadvantages of an aluminum heater

Aluminum products have a number of positive qualities that are the reason for the popularity of this product.

- Aluminum radiators weigh relatively little, which facilitates their transportation and allows for do-it-yourself installation.

- Such batteries look attractive and can not only heat, but even decorate various rooms.

- Features of the material and well-thought-out design of the batteries cause high heat transfer. Aluminum batteries can significantly save heating costs by reducing the volume of coolant in each section.

- Such batteries quickly respond to a change in the coolant supply: they cool down and cool down almost instantly. This allows you to warm up the premises in a short time and increases the efficiency of thermostats, which is also the reason for reducing heating costs.

- The powder coating simplifies the maintenance of the batteries, eliminating the need for periodic painting.

- There are models that can withstand high pressure.

- All this is combined with a relatively low price.

But such products also have several disadvantages that you need to know about before buying:

- In prefabricated devices, rubber sealing elements are used, which makes it impossible to use antifreeze as a coolant.

- Low protection against corrosive processes. To extend the operating period, it is necessary that the water has a neutral acidity and does not contain abrasive particles that can damage the protective film.

- Inside the heater, air may accumulate, to bleed which it is necessary to equip the battery with an air vent.

- The weak point of such a battery is the threaded connections.

Nevertheless, for the most part, the properties and features of aluminum heaters make them ideal for heating systems.

Copper radiators

Copper radiators compare favorably with other heating devices in that their contours are made of a seamless copper pipe without the use of other metals.

The appearance of copper radiators is suitable only for fans of industrial design, so manufacturers complete thermal appliances with decorative screens made of wood and other materials.

A pipe with a diameter of up to 28 mm is complemented by copper or aluminum fins and decorative protection made of solid wood, thermoplastics or composite materials. This option provides efficient heating of the room due to the unique heat transfer of non-ferrous metals. By the way, in terms of thermal conductivity, copper is more than 2 times ahead of aluminum, and steel and cast iron - 5-6 times. Having a low inertia, a copper battery provides rapid heating of the room and allows the use of temperature control equipment.

In terms of its thermal conductivity, copper is second only to silver, with a significant margin ahead of other metals.

The plasticity inherent in copper, corrosion resistance and the ability to contact polluted coolant without harm make it possible to use copper batteries in apartments in high-rise buildings. It is noteworthy that after 90 hours of operation, the inner surface of the copper radiator is covered with an oxide film, which further protects the heater from interaction with aggressive substances. The disadvantage of copper radiators is only one - too high a cost.

Comparative table of technical characteristics of copper and copper-aluminum radiators

Crimping and working pressure

When choosing aluminum heating radiators, you should pay attention to which companies are valued better by consumers, and what pressure and operating pressure the device has. How to find out these values? They are registered in the passport to the model

The operating pressure is the pressure that the battery can withstand daily. For aluminum, it is equal to the value - from 10 to 15 atmospheres.

Aluminum batteries are actively used in private houses and cottages. This is advisable, since the boilers in such buildings create a working pressure of about 2 atmospheres. In an apartment, it is better to use devices made of a different material, since the working pressure in it can reach up to 30 atmospheres.

Crimping pressure is an indicator that characterizes what maximum pressure the device can withstand for a short time. In the fall, it is planned to carry out pressure testing in the apartments, at which time the working pressure increases by 2 times. That is why it is recommended to opt for models that have a supply of crimping pressure.

Cast iron radiators

Cast iron batteries have been used in residential heating systems for more than 100 years and, so far, no type of heating device has surpassed them in terms of corrosion resistance and durability. Possessing high heat dissipation, cast-iron "accordions" are perfectly suited for operation in the expanses of the former CIS.

In the event of an emergency shutdown of heat supply, the "cast iron" will store the accumulated heat for a long time and continue to heat the air. He is not afraid of critical pressure drops, water hammer and poor quality of the coolant. Hard alkaline water with air pockets and rust particles does not have such a detrimental effect on cast iron batteries as on other heating devices, and their price is much lower. All the mentioned advantages still encourage many of our fellow citizens to purchase these particular radiators as heating appliances.

The disadvantages include inexpressive design, bulkiness and high inertia, due to which they cannot be used in modern heating systems with thermoregulation. But in a modern interpretation, thermal appliances have become more stylish and attractive, while retaining amazing strength and durability.

Unlike the bulky "accordions" of the Soviet era, modern cast-iron radiators are a model of design and style. As for exclusive models, many of them can be attributed to works of art.

Having familiarized yourself with the technical characteristics and other features of modern cast-iron radiators, you will no longer be able to drop them from the scales when choosing.

Summary table of cast iron radiators

The average service life is 35-40 years, in reality, many radiators have been working since the 50s of the last century. Calling the shortcomings of cast iron thermal appliances, everyone remembers the bulkiness and heavy weight, completely forgetting about the high thermal inertia. But the last factor is very important, given the general trend towards saving heat, and, as a result, the use of thermostatic flow controllers in heating circuits.

In conjunction with a cast-iron radiator, even the most high-tech thermostat will not be able to work - the whole reason is the high thermal inertia of the heater

Calculation by area

This is the simplest technique that allows you to roughly estimate the number of sections needed to heat a room. Based on many calculations, the norms for the average heating power of one square of the area were derived. To take into account the climatic features of the region, two norms were prescribed in SNiP:

- for the regions of central Russia, it is necessary from 60 W to 100 W;

- for areas above 60 °, the heating rate per square meter is 150-200 watts.

Why is there such a large range in the norms? In order to be able to take into account the materials of the walls and the degree of insulation. For houses made of concrete, the maximum values \u200b\u200bare taken, for brick houses, you can use average values. For insulated houses - the minimum. Another important detail: these standards are calculated for the average ceiling height - no higher than 2.7 meters.

How to calculate the number of radiator sections: formula

Knowing the area of \u200b\u200bthe room, multiply its rate of heat consumption, which is most suitable for your conditions. Get the total heat loss of the room. In the technical data for the selected radiator model, find the heat output of one section. Divide the total heat loss by the power, you get their number. It's not difficult, but to make it clearer, let's give an example.

An example of calculating the number of radiator sections according to the area of the room

Corner room 16 m 2, in the middle lane, in a brick house. Batteries with a thermal power of 140 watts will be installed.

For a brick house, we take heat losses in the middle of the range. Since the room is angular, it is better to take a larger value. Let it be 95 watts. Then it turns out that 16 m 2 * 95 W = 1520 W are required to heat the room.

Now we count the number of radiators for heating this room: 1520 W / 140 W = 10.86 pcs. We round up, it turns out 11 pieces. How many sections of radiators will need to be installed.

The calculation of heating batteries per area is simple, but far from ideal: the height of the ceilings is not taken into account at all. With a non-standard height, a different technique is used: by volume.

Working pressure types

The documents attached to aluminum radiators indicate not only the power of the product and its working pressure, but also the pressure, and sometimes the maximum allowable pressure, that the product can withstand without violating its functional purpose. In the variety of these values, given in tabular form, it is easy for an ignorant person to get confused.

Operating pressure is the pressure that will be maintained in the heating system and appliances during operation. The permissible value in aluminum radiators is 10-15 atmospheres.

It is not recommended to use such batteries in apartments with a centralized heating system, since in such a design the working pressure can be several times higher than the norm.

In some cases, it is necessary to have information about the value of the crimping pressure. Before starting the heating system, it is tested for tightness. To do this, the design is supplied with a pressure exceeding the working one, which makes it possible to identify malfunctions and, in their absence or after correction, guarantee its high-quality operation.

The pressure value indicates how high the water level can rise. A pressure of one atmosphere can lift a column of water 10 meters high.

When buying batteries for an apartment with a centralized heating system, it is necessary to take into account the allowable operating pressure margin, since utilities, for one reason or another, sometimes supply water to the system with very high pressure.

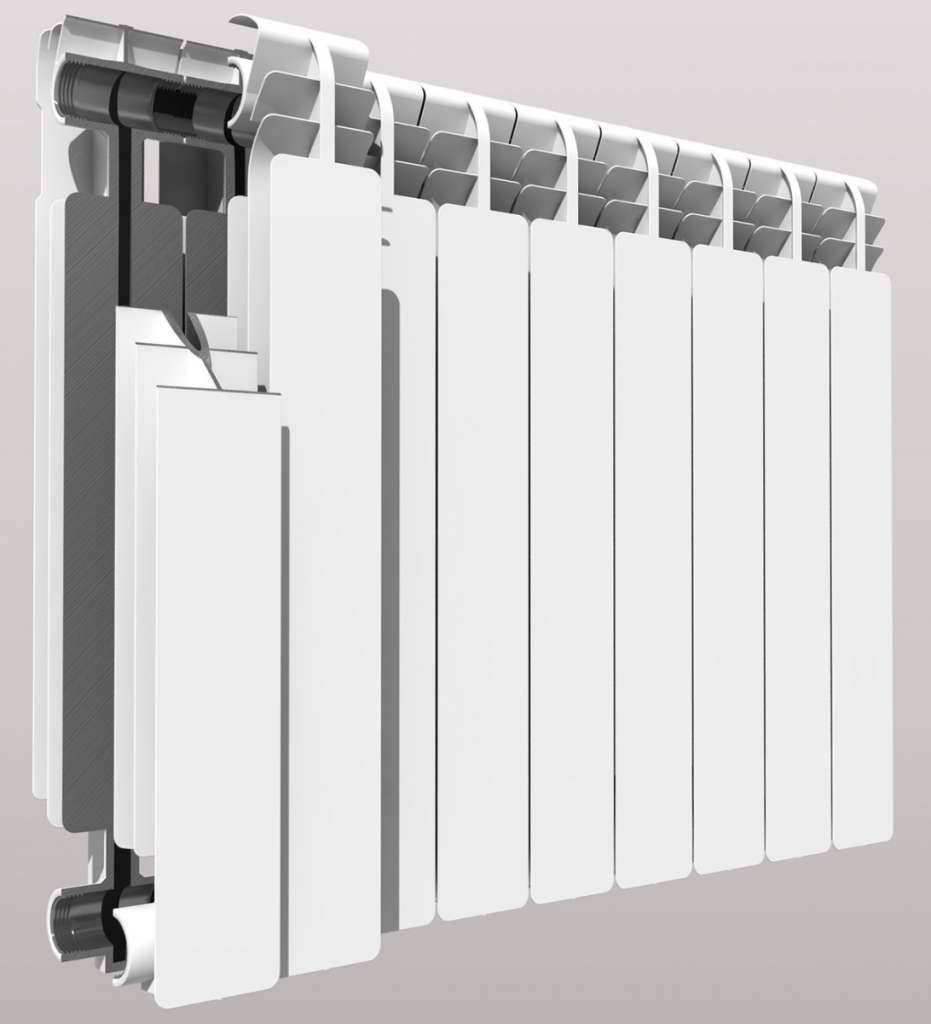

Structural features

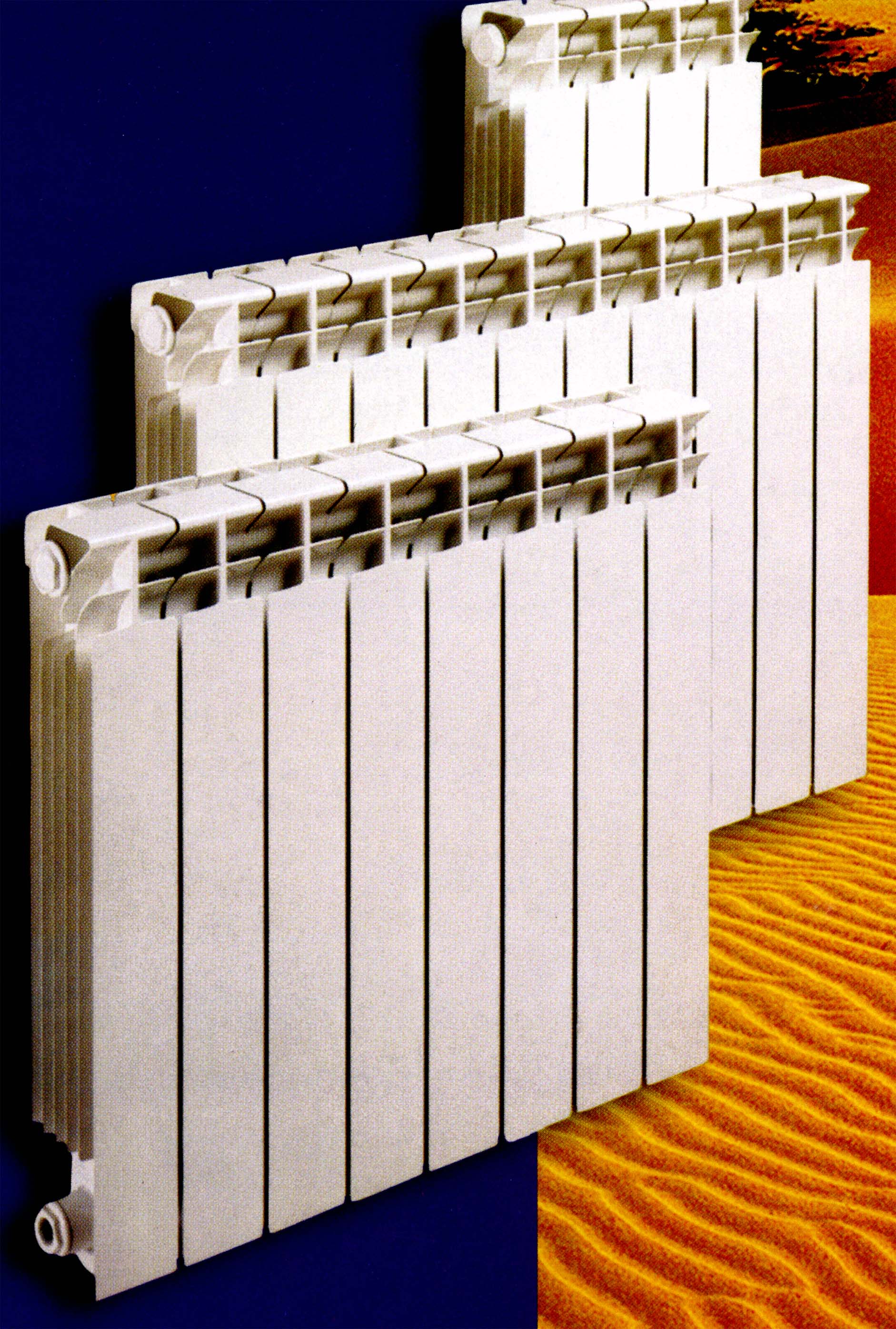

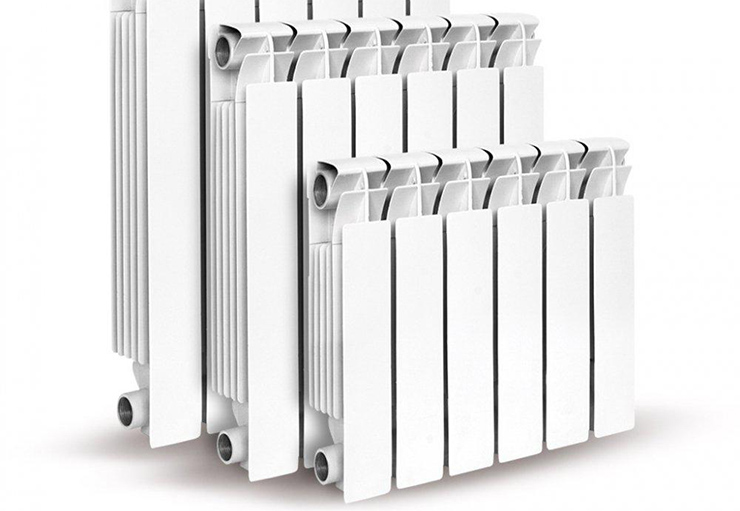

To understand which aluminum heating radiators are best for an apartment, you should know what to look for when choosing them. Most often, models are used, the center distance of which is 500 mm.

The presented parameter indicates that the distance between the upper and lower radiator manifolds is 500 mm. In this case, the vertical dimension of these batteries is 580 mm.

The choice of the number of sections of heating radiators is determined based on how much heat you need to receive. Our calculator for calculating heating radiators will help you calculate this.

It is important to note that the heat exchange of products occurs both with the help of convection and due to radiation, and during their installation from the floor and window sill it is necessary to maintain a distance of more than 100 mm. If you cannot maintain the specified distance, you should purchase smaller batteries and put more sections.

For walls with a large glass area, it is better to choose options whose size between the central parts of the collectors is 200 mm. They are also suitable if you have low window sills in your room. There are also non-standard aluminum radiators, the size of which does not exceed 800 mm. If we talk about the number of sections, then most often there are 10 of them, while each weighs up to 1.5 kg.

Heat dissipation of one section

Today, the range of radiators is large. With the external similarity of the majority, thermal performance can vary significantly. They depend on the material from which they are made, on the dimensions, wall thickness, internal section and on how well the design is thought out.

Therefore, to say exactly how many kW in 1 section of an aluminum (cast-iron bimetallic) radiator can only be said in relation to each model. This information is provided by the manufacturer. After all, there is a significant difference in size: some of them are high and narrow, others are low and deep.The power of sections of the same height of the same manufacturer, but different models, may differ by 15-25 W (see the table below STYLE 500 and STYLE PLUS 500) . Even more tangible differences can be between different manufacturers.

Technical characteristics of some bimetallic radiators

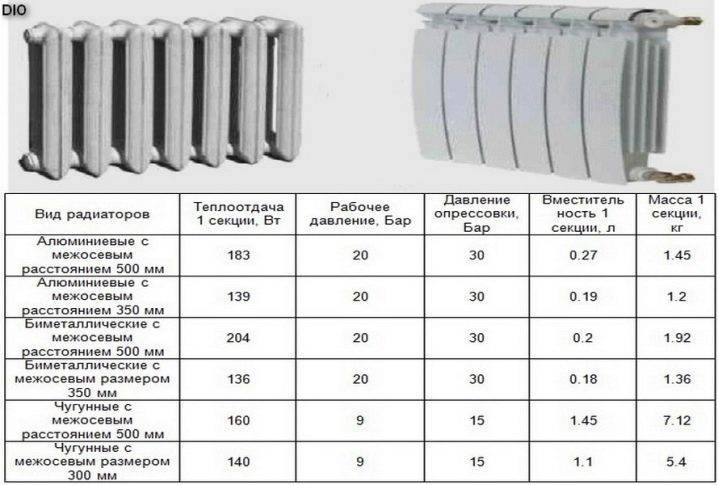

Please note that the heat output of sections of the same height can have a noticeable difference. However, for a preliminary assessment of how many sections of batteries are needed for space heating, we deduced the average values of thermal power for each type of radiator

They can be used for approximate calculations (data are given for batteries with a center distance of 50 cm):

Nevertheless, for a preliminary assessment of how many sections of batteries are needed for space heating, we deduced the average values of thermal power for each type of radiator. They can be used for approximate calculations (data are given for batteries with a center distance of 50 cm):

- Bimetallic - one section emits 185 W (0.185 kW).

- Aluminum - 190 W (0.19 kW).

- Cast iron - 120 W (0.120 kW).