- Overview of manufacturers and prices

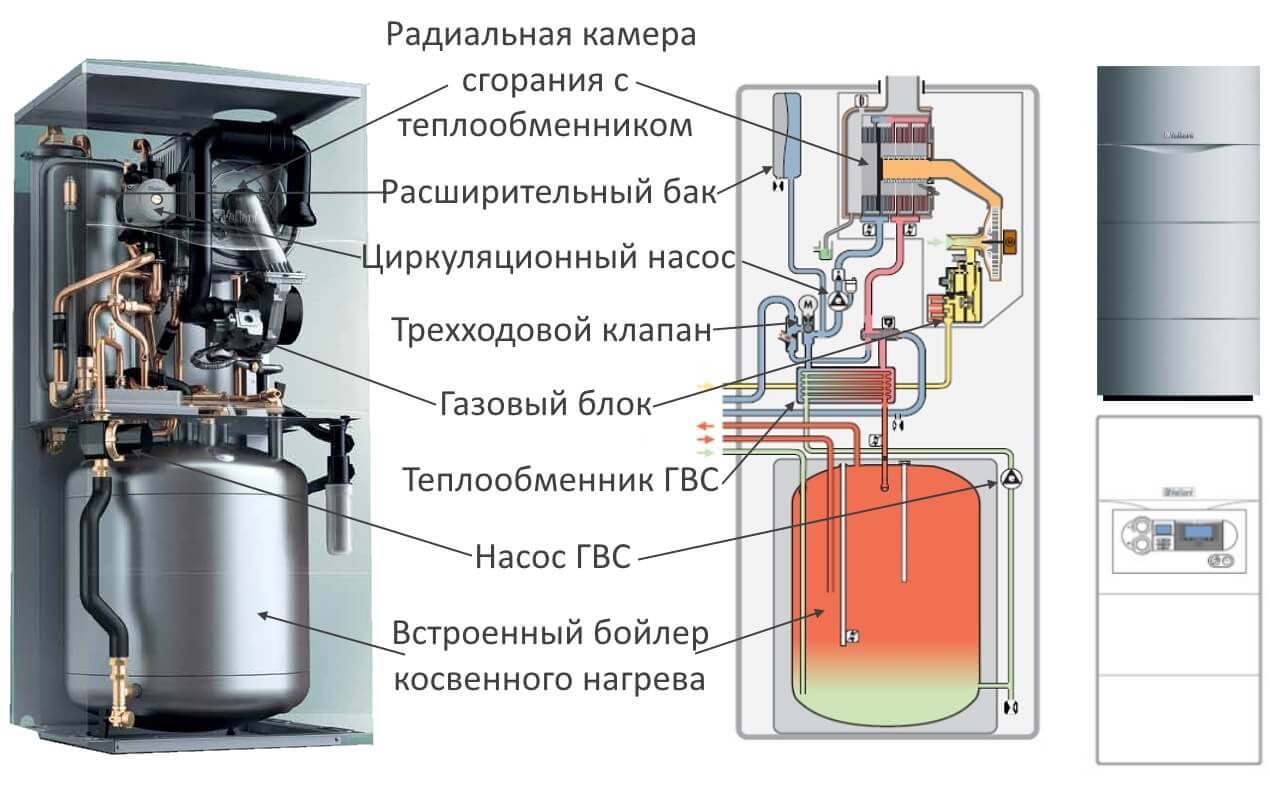

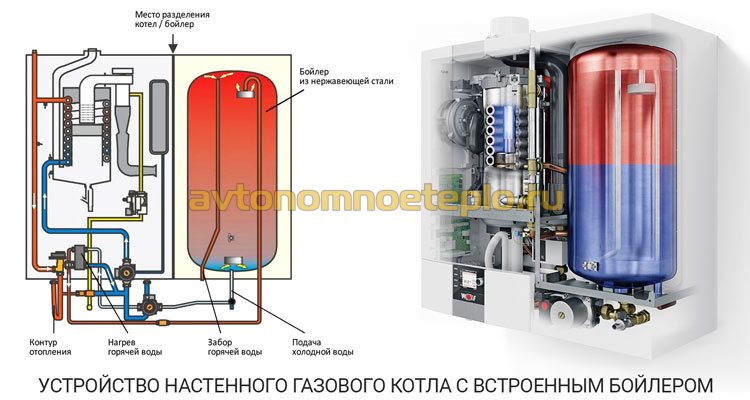

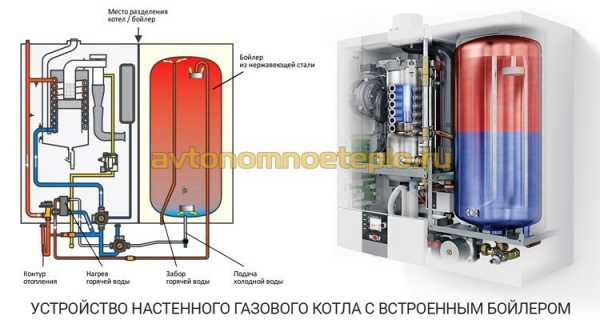

- How wall-mounted gas boilers work with a built-in indirect heating boiler

- How does a mounted gas boiler with a built-in boiler work

- Choosing a wall-mounted heating boiler with an internal boiler

- Rating of brands of boilers with an integrated boiler

- The cost of a boiler with a built-in boiler

- What is layered water heating?

- Choice according to area

- A few words about the performance of the boiler

- Which option is suitable for a large area?

- How to eliminate the shortcomings of hot water supply from the second circuit of a gas boiler

- Operation of the stratified boiler

- Choice of a floor-standing gas boiler with an integrated boiler

- Calculation of the required boiler power

- Which brand of boiler with an internal boiler is better

- Floor-standing boiler with an internal boiler - pros and cons

Overview of manufacturers and prices

An interesting line of double-circuit gas boilers with a built-in boiler is the Italian manufacturer Baxi. Popular floor and wall models such as:

- Baxi Slim 2.300i;

- Baxi SLIM 2.300Fi;

- Baxi NUVOLA 3 COMFORT 240Fi;

- Baxi NUVOLA 3 280B40i;

- Baxi NUVOLA 3 COMFORT 280i.

Most gas boilers are equipped with electronic self-diagnosis systems, flame control, overheating protection and other safety modules.There is electronic ignition, the possibility of switching to liquefied gas, a programmable timer, etc. Prices vary in the region of 1500-2000 dollars.

Dual circuit Baxi gas boilers with a built-in boiler are compact in size, attractive external design, convenient control panel and the ability to automatically control the operation of the equipment

Gas boilers from another popular Italian manufacturer, Ferroli, are no less in demand. Most often, buyers choose models:

- Ferroli DIVAtop 60 F 32;

- Ferroli DIVAtop 60 F 24;

- Ferroli DIVAtop 60 C 32;

- Ferroli PEGASUS D 30 K 130;

- Ferroli PEGASUS D 40 K 130.

These gas double-circuit boilers are varied in terms of power and type of installation (floor and wall), but all are distinguished by increased corrosion resistance and a convenient control panel with an LCD monitor. Outside, the heat exchanger is covered with a layer of aluminum anti-corrosion composition, inside there is an ionization electrode for protection against electro-chemical processes. Almost all models are equipped with electric ignition, two control microprocessors, pump blocking protection etc. Cost gas double-circuit boilers Ferroli varies in a fairly wide range: from 1200 to 3000 dollars.

Double-circuit gas boilers of the Italian manufacturer Ferrolli are well known on the market. Their main feature is European quality standards and increased reliability.

Nova Florida double-circuit gas boilers, which appeared on the market relatively recently - in 1992, are distinguished by high quality. It is a trademark of the Italian company Fondital

Most often, buyers pay attention to the models:

- Nova Florida Libra Dual Line Tech BTFS

- Nova Florida Libra Dual Line Tech BTFS 28

- Nova Florida Libra Dual Line Tech BTFS 32

- Nova Florida Pegasus Compact Line Tech KBS 24

Compact wall-mounted boilers of this brand are relatively inexpensive: $ 1200-1500. The price of more powerful models can be $ 2500-3000. Methane or liquefied gas can be used to operate the boilers. The equipment has a high degree of electrical protection, the control panel is equipped with a convenient LCD monitor. It is possible to automatically control the operation of the boiler using room and external temperature sensors.

Cast iron floor gas boilers are usually cheaper and are equipped with a single-level burner. To regulate the operation of such a boiler, it is necessary to install a mixing unit into which an automatic three-way valve is built. As a result, the savings will be minimal. Good opportunities for reducing heating costs are provided by condensing models, which use the energy generated during the condensation of steam.

A heating gas boiler with a boiler in a private house can be installed provided that there is a main gas pipeline passing in the immediate vicinity of the building. Natural gas is the most common and cost-effective fuel in our country.

Modern manufacturers of gas equipment for domestic needs offer consumers the following types of such devices:

- Single-circuit - boilers are intended exclusively for heating small spaces.

- Dual-circuit - perfectly cope with the performance of two functions for space heating and for heating running water.

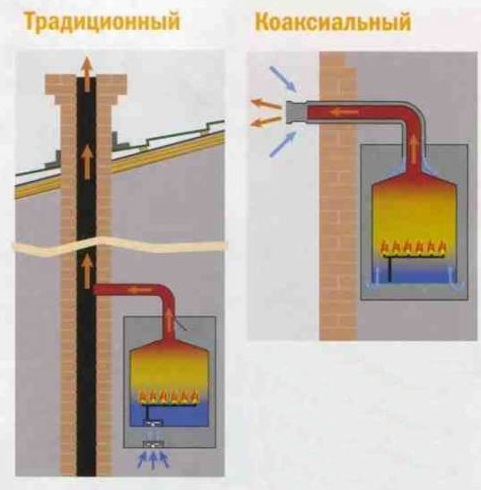

Modern gas boilers manufactured by manufacturers of domestic and foreign industries also differ from each other according to the principle of gas supply.

So, for example, some models of boilers can successfully operate with natural fuel supply methods, while the combustion products are removed through the chimney. Correct operation of this type of equipment is possible only if there is a constant presence of fresh air in the room, which will ensure the maintenance of the combustion process.

Other types of gas boilers are additionally equipped with forced (coaxial) output of gas combustion products. In this case, the air is supplied from the street, and the combustion products of the fuel are also removed there.

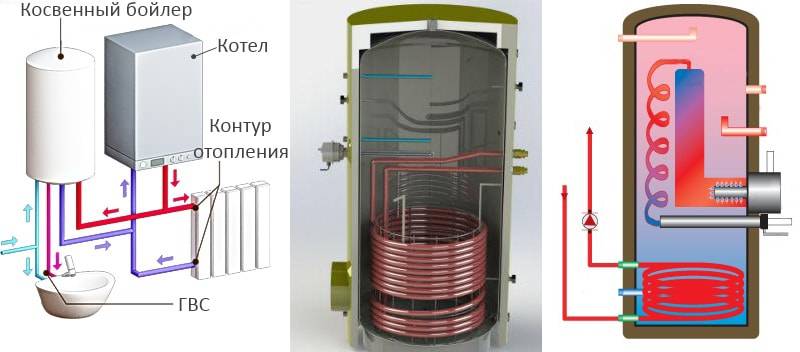

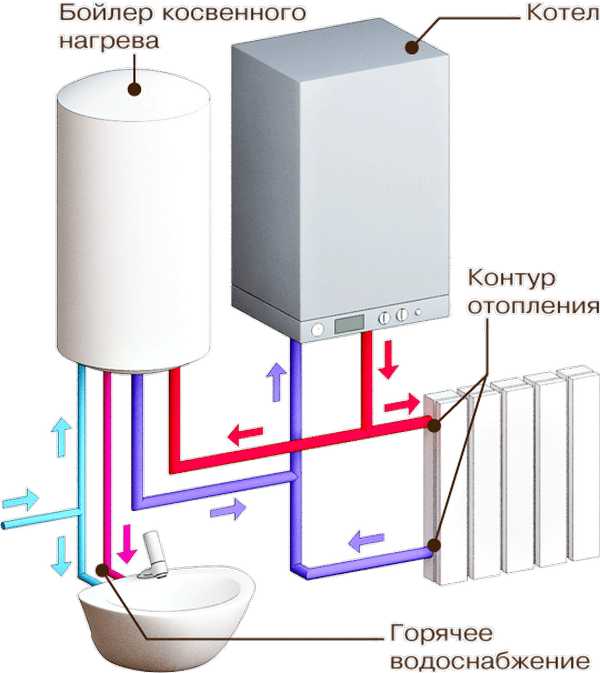

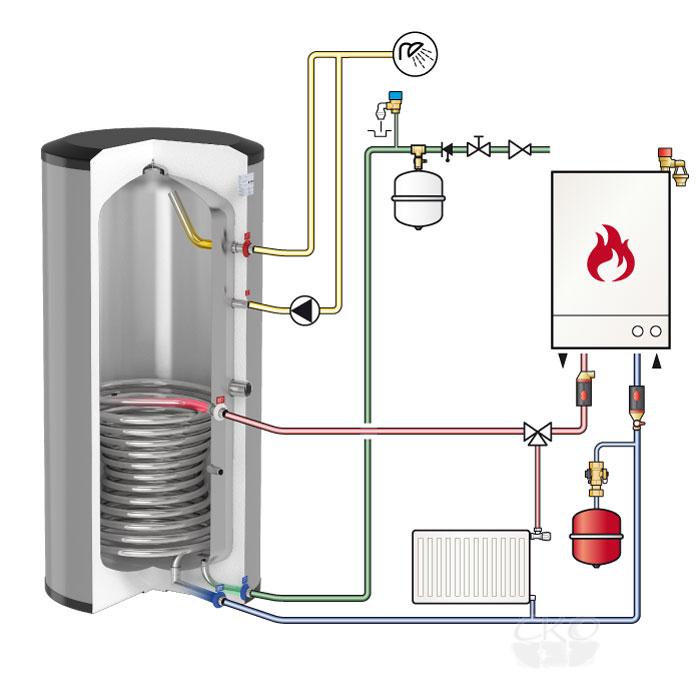

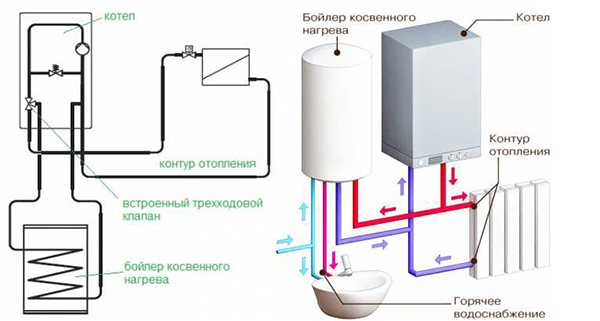

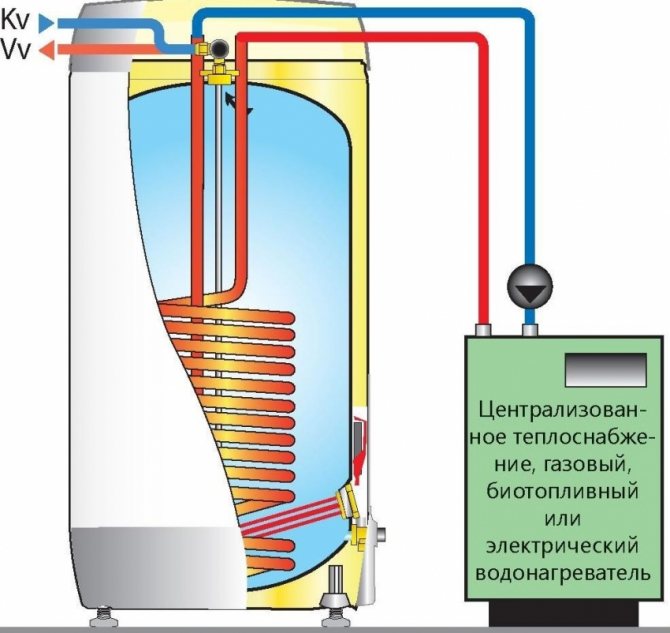

How wall-mounted gas boilers work with a built-in indirect heating boiler

How does a mounted gas boiler with a built-in boiler work

- The primary and secondary heat exchangers operate continuously.

- The boiler maintains a constant liquid heating temperature. A coil is installed inside the boiler, through which hot water circulates. Layer-by-layer heating of the liquid is carried out.

- After opening the water supply tap, hot water is immediately supplied to the consumer, displaced by cold liquid entering the boiler.

- The type of combustion chamber - the consumer is offered gas boilers with an open and closed combustion chamber:

- Atmospheric, connected to a standard classic chimney.

- In turbo boilers with a closed combustion chamber, smoke removal and air intake from the street is carried out through a coaxial chimney.

- The volume of the storage tank - the built-in indirect heating boiler, depending on the selected model and its power, has a capacity of 10 to 60 liters. There are boilers with a larger capacity, but, as a rule, they are made in a floor version.

An indirect heating boiler is equipped with gas heating equipment with a power of over 25 kW. In boilers with lower productivity, the storage tank is usually not installed.

Choosing a wall-mounted heating boiler with an internal boiler

- The volume of the storage boiler - the capacity of the tank depends on how much hot water will be available. For a large family, it is better to choose models with a storage capacity of at least 40 liters.

- Throughput - the technical documentation clearly stipulates how much hot water the boiler can heat within 30 minutes. The heating temperature is indicated as 30°C.

- Power - accurate heat engineering calculations will be made by a consultant of a company selling heating equipment. With self-selection of equipment, use the formula 1 kW = 10 m². To the result obtained, add a margin of 20-30% for hot water supply.

- Protection of the boiler and storage tank - boilers equipped with 2-3 degrees of protection against scale, which is the main reason for the failure of the storage tank, are considered the best.

Rating of brands of boilers with an integrated boiler

- Italy - Baxi, Immergas, Ariston, Sime

- Germany - Wolf, Buderus

- France - Chaffoteaux, De Dietrich

- Czech Republic – Protherm, Thermona

- US and Belgium co-production - ACV

The cost of a boiler with a built-in boiler

- Manufacturer - Czech, German and Austrian boilers, take the lead in terms of cost among analogues manufactured by factories located in other EU countries.

- Power - a 28 kW Baksi boiler, an Italian manufacturer, will cost approximately 1800 €, and for a 32 kW unit, you will have to pay 2200 €.

- Type of combustion chamber - models with a closed burner device using the condensing principle of heating the coolant are the most expensive. Atmospheric counterparts are 5-10% cheaper.

- Bandwidth and storage capacity. Wall-mounted gas boilers for heating and hot water heating with a built-in boiler, capable of heating 14 l / min, will cost approximately 1600 €. Analogues, with a capacity of 18 l / min, already cost 2200 €.

Advantages of boilers with built-in boiler

- Possibility of heating water even during peak periods. A double-circuit boiler, at low water pressure, does not go into operation. The gas supply opens when a certain intensity of liquid circulation in the pipeline is reached. Water heating in the boiler is carried out in advance when there is a normal pressure in the system.

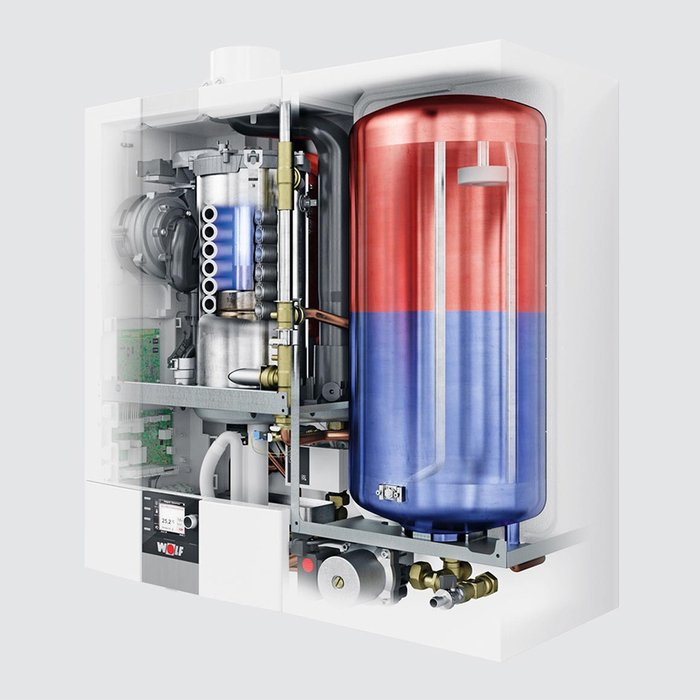

- Compactness - all gas mounted heating boilers with a built-in storage boiler are small in size, which allows them to be placed in any utility and domestic premises used as a boiler room.

- Instant supply of hot water - the boiler is connected to the recirculation system. After heating the water in the tank, a constant temperature is maintained. Hot water starts flowing from the water supply faucet a few seconds after opening.

- Simple installation - the device of the boiler in the boiler is made in such a way that the consumer does not need to additionally configure the operation of the unit.It is enough to supply electricity to the automation, gas to the burner and a pipeline to the supply and return pipes of the water supply system located on the body.

Cons of built-in boilers in boilers

- High price.

- Boiler susceptibility to failure as calcium deposits build up.

In DHW mode, the boiler consumes approximately 30% less gas. Therefore, the cost of purchasing the unit pays off in the first few heating seasons.

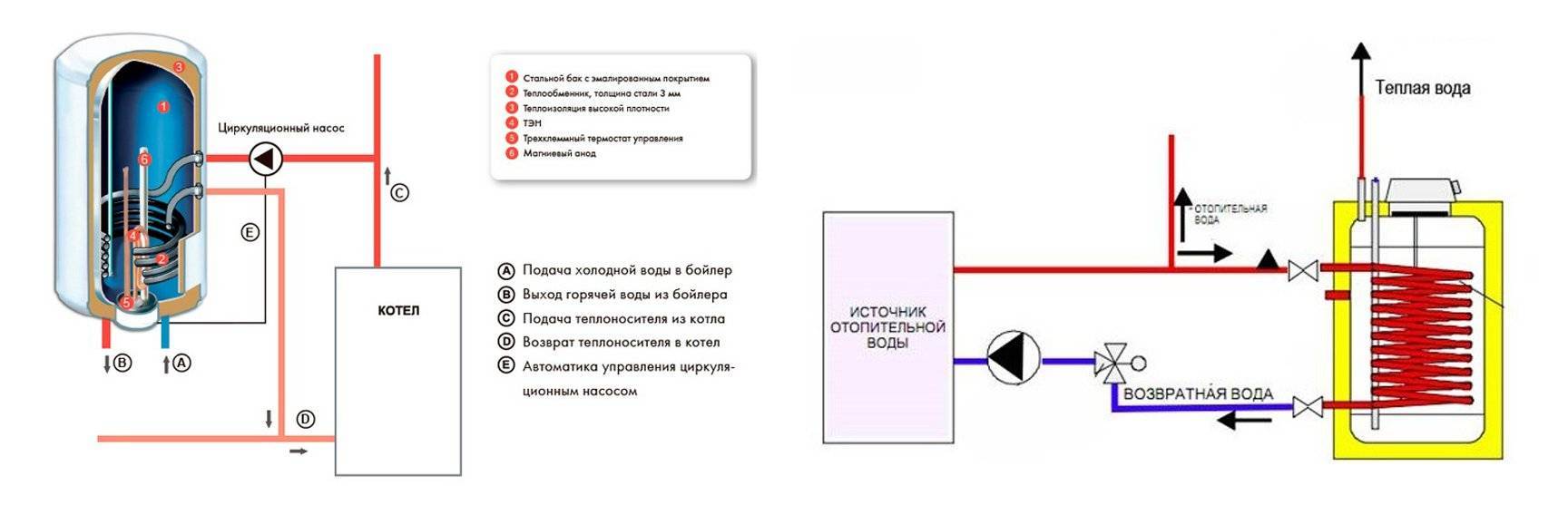

What is layered water heating?

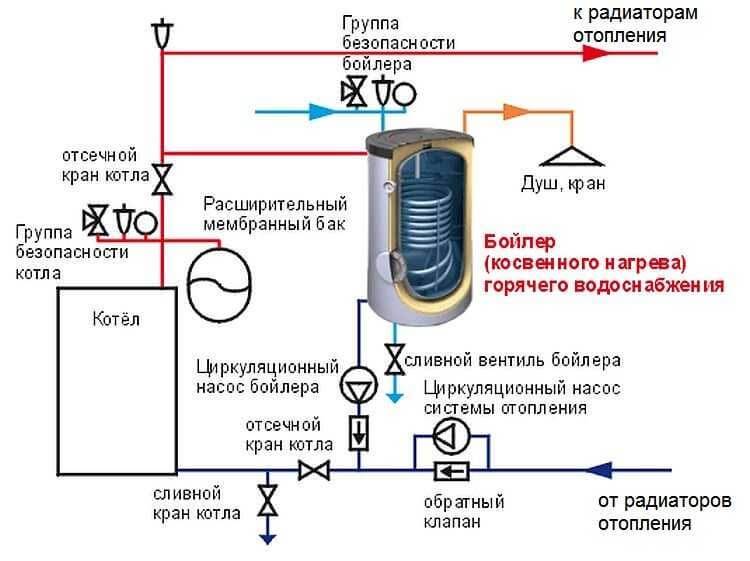

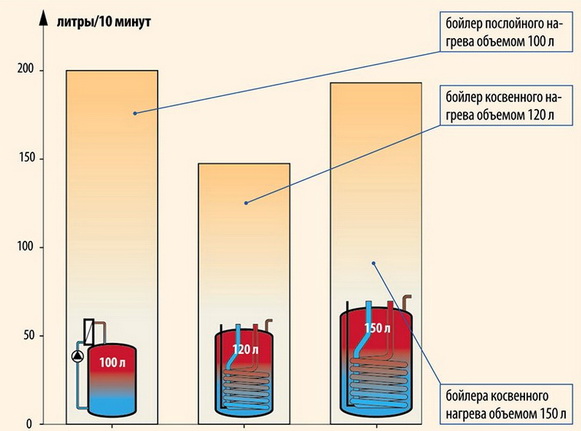

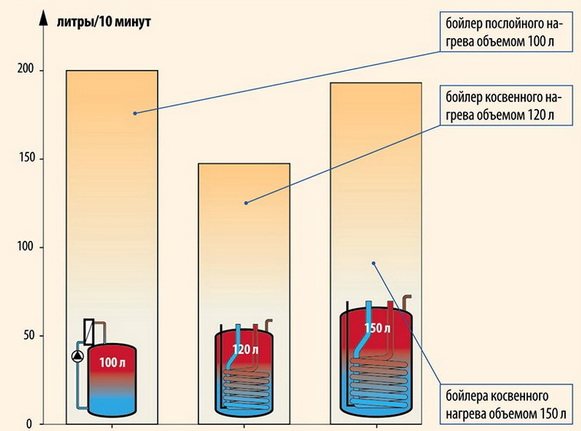

There are two types of boilers that can work with boilers - with indirect or layered heating. In an indirect heating boiler, the water will heat up longer, and much more. So, when using layered heating, a shower can be taken after 5 minutes, and indirect heating will allow this to be done no earlier than 20 minutes after the boiler is turned on.

There are two types of boilers that can work with boilers - with indirect or layered heating. In an indirect heating boiler, the water will heat up longer, and much more. So, when using layered heating, a shower can be taken after 5 minutes, and indirect heating will allow this to be done no earlier than 20 minutes after the boiler is turned on.

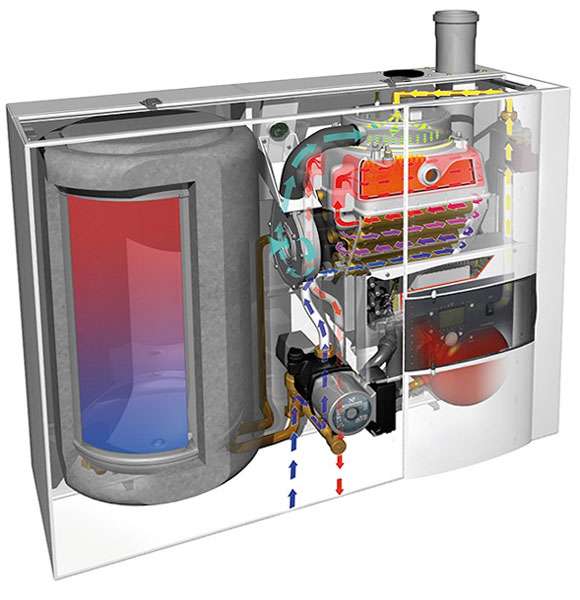

In double-circuit boilers with stratified boilers heating water is heated by instantaneous water heater. Most often it is a plate radiator, but there are also other designs, for example, a pipe in a pipe. Heat transfer occurs from the heated coolant to cold tap water. The streams are separated by a thin sheet of metal, so that heat transfer is very efficient.

For condensing boilers, an additional heat exchanger has proven to be advantageous, as helps the condensation of water vapor containing the so-called. latent heat of combustion products. But this is more true for double-circuit, and not for single-circuit condensing boilers.

Water is supplied to the stratified heating boilers from the instantaneous water heater, i.e. already hot.That is why such boilers are able to prepare hot water faster than indirect heating boilers, where you have to wait until the entire tank is heated. The difference is more noticeable after a break in the operation of the boiler.

The advantage of stratified heating boilers is that the hot water entering the tank occupies the top layer, while at the bottom it can remain cool. Stratification makes it possible to get hot water from the tap already 5 minutes after turning on the boiler. In boilers paired with an indirect heating boiler, you will have to wait at least 20 minutes until the internal heat exchanger heats up a large amount of water. You have to wait longer also because with indirect heating, the water is heated from below, as a result of which it is constantly mixed due to convection.

Of course, the indirect heating time depends on the size of the heat exchanger, the capacity of the boiler and the power of the burner. So, the fastest water will heat up with a large boiler power and a large heat exchanger. However, the larger the heat exchanger, the less space remains in the boiler for water, and the high power of the boiler will be due to the fact that the burner will often turn off in heating mode, and, accordingly, will work faster.

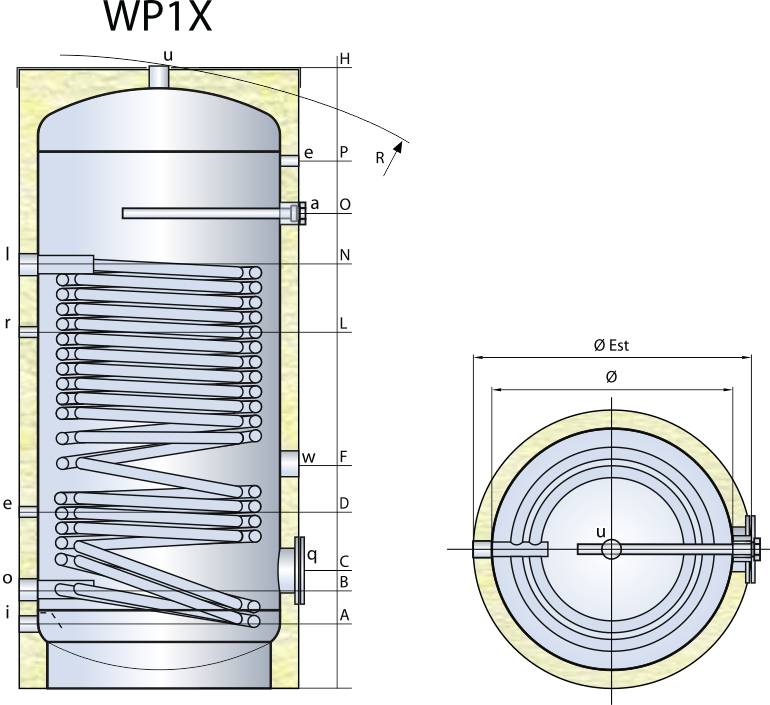

Layered boilers do not have a heat exchanger, so their entire internal volume (with the exception of thermal insulation, if any) is occupied by water. It is estimated that stratified heating boilers are 1.5 times more productive than indirect heating boilers. This means that layer-by-layer heating, among other things, saves space. Thus, if it is not possible to allocate a boiler room in the house, then double-circuit boilers with a layered heating boiler are the most reasonable solution.

Layered boilers do not have a heat exchanger, so their entire internal volume (with the exception of thermal insulation, if any) is occupied by water. It is estimated that stratified heating boilers are 1.5 times more productive than indirect heating boilers. This means that layer-by-layer heating, among other things, saves space. Thus, if it is not possible to allocate a boiler room in the house, then double-circuit boilers with a layered heating boiler are the most reasonable solution.

Why do you need a boiler at all? This question is often asked by people who are far from the topic, but they do not always receive an exhaustive answer to it. A boiler of any type increases the comfort of using hot water. So, a double-circuit boiler with a boiler is able to provide a large and stable pressure of hot water at several points of water intake, while a similar boiler, but without a boiler, when the second tap is turned on, will not have time to heat the water to the desired temperature with the same pressure. In addition, there are situations when a small pressure of hot water is needed. Boilers in this case will cope with the task, and in instantaneous water heaters, the lower limit of pressure is limited.

As for the dimensions of double-circuit boilers with layered heating boilers, there are compromises here. The smallest boiler has a volume of only 20 liters. It can even have a wall-mounted double-circuit boiler, not much larger in size than a similar boiler without a boiler.

A floor-standing boiler with a built-in boiler looks like a refrigerator. You can even find a place for it in the kitchen. Of course, small boilers will not provide many taps at the same time, so they need to be selected taking into account the peak consumption of hot water. A large boiler will also be needed in order to serve a modern shower panel with hydromassage or quickly take a hot bath. A boiler capable of such tasks must contain 250-300 liters of water, which means it must be separate. The maximum volume of built-in boilers is 100 liters.

Speaking about the comfort of using hot water, one cannot fail to mention such an important point as the distance from the boiler to the draw-off point.If it exceeds 5 m, then the DHW system must be circulating, otherwise it will take a long time to wait for hot water.

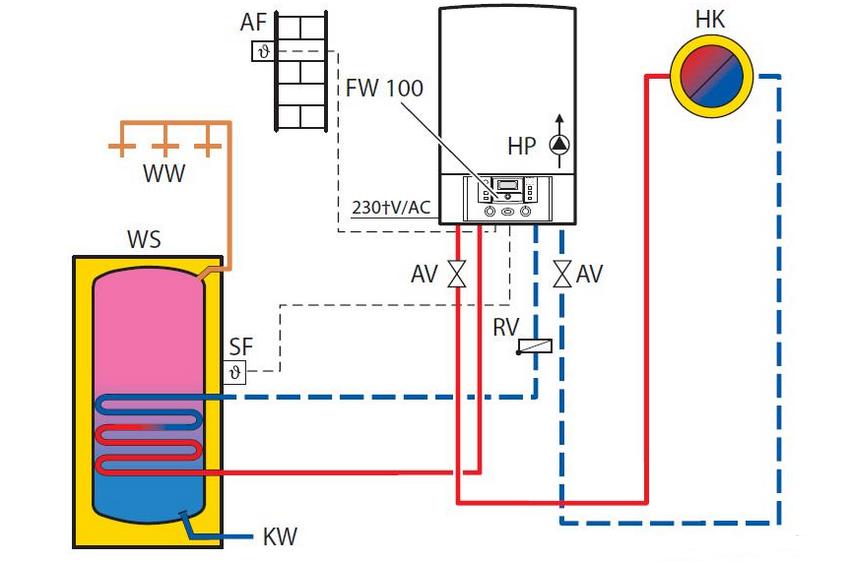

Choice according to area

Tying several types of heating will save

- heating area.

- Need for hot water.

- Type of energy carrier.

- The size of the equipment, the presence or absence of a separate room.

- heat exchanger material.

The main determining parameter is the area: regardless of the type of water-heating heat exchanger, every 10 m2 requires no less than 1 kW of boiler power, and in the presence of a second circuit, 15-20% more. layer-by-layer heating sufficient at hot water consumption up to 1.5 l/min and no circulation. But when a large family lives (3 people or more) and hot water is taken from several points, it is more profitable to install a tubular heat exchanger (ideally with indirect heating). The average consumption rate of hot water per person is 100 liters per day, it is this value that is recommended to focus on when choosing a water heater.

With gas connected, there are no problems, this is the cheapest way to heat water for radiators and consumer needs. But in its absence, electric, solid and liquid fuel units are used as the main source of heat, and the question of the expediency of the second circuit becomes open. It is not recommended to combine an electric boiler with an indirect heating boiler, this only leads to an increase in costs. When using a solid fuel boiler, it is almost impossible to control the temperature of the water in the secondary circuit, and the inertia of such a system does not allow hot water to be obtained at any time.

In the absence of a separate room, a floor or wall-mounted gas boiler with a closed combustion chamber and forced flue gas removal should be installed. They are found in a double-circuit design and produce an average of 1-12 liters per hour. But such models have a power limit; they are not suitable for a heated room area of more than 180 m2. All other types of gas equipment are located in non-residential premises with organized ventilation.

A few words about the performance of the boiler

When choosing a boiler, it is important to correctly evaluate its performance. Often the manufacturer indicates only the initial performance, which is taken into account with a full tank of hot water.

For the consumer, it is more important to take into account the performance that the boiler produces with a regular flow of water. This figure is significantly lower than the original performance.

Another important point that affects performance is the increase in temperature. The lower this indicator, the longer the boiler will work, and the less breakdowns there will be. Indicating the performance of the boiler, manufacturers are guided by various growth data. In general, the rule should be followed: the greater the power of the equipment and the volume of the boiler, the more productive the equipment.

More information about choosing gas heating boiler presented in the video:

We bring to your attention an online calculator for selecting a boiler, depending on the characteristics of your room:

Which option is suitable for a large area?

Experts believe that for a large house hot water system, a tubular heat exchanger is preferable to a plate heat exchanger.Since the distance from the heater to the point of water intake can be considerable, it is necessary to wait quite a long time until the cold water drains. The problem is solved with the help of a recycling system. This is a section of the plumbing system, through which hot water circulates between the heater and the point of analysis constantly, maintaining the set temperature. Such a device cannot be used with a plate heat exchanger, since mineral deposits will form on the plates very intensively.

In a small house, the size of the equipment is important. The best choice can be a compact boiler, in which a large tubular heat exchanger is inserted

In this case, the pipes are placed in a spiral along the entire height of the boiler in order to quickly heat the entire volume of water at once. The efficiency is increased by the correct arrangement of the coil, for example, in the form of two parallel spirals. Such a device allows you to comfortably use even a small boiler, with a volume of only 10-20 liters.

Vaillant gas double-circuit boilers - the best combination of quality and reasonable price. This heating equipment has long been known and enjoys well-deserved popularity.

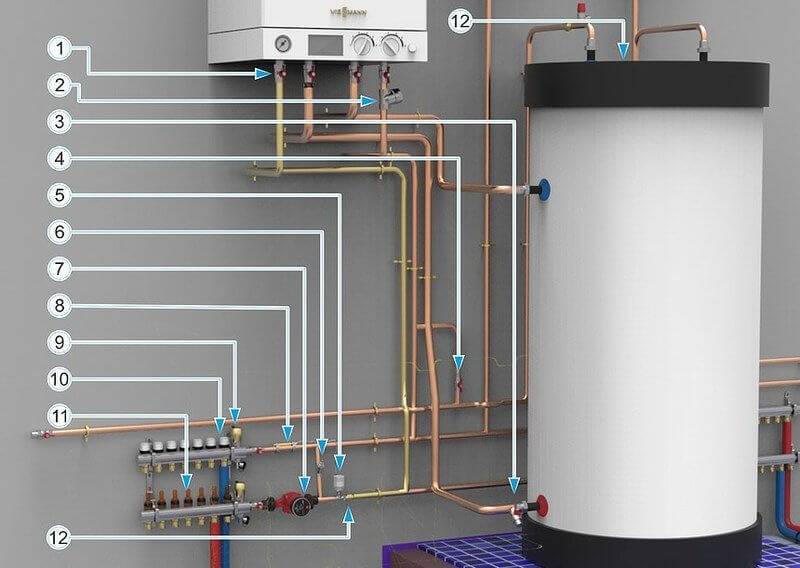

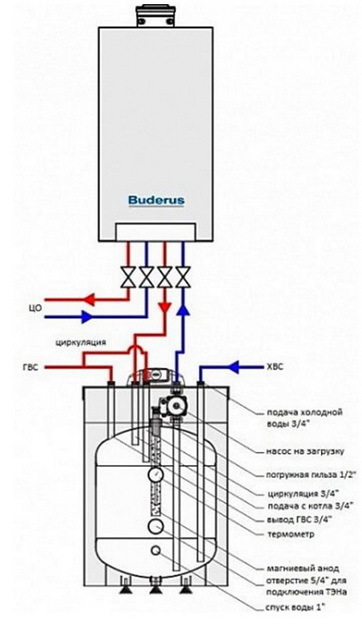

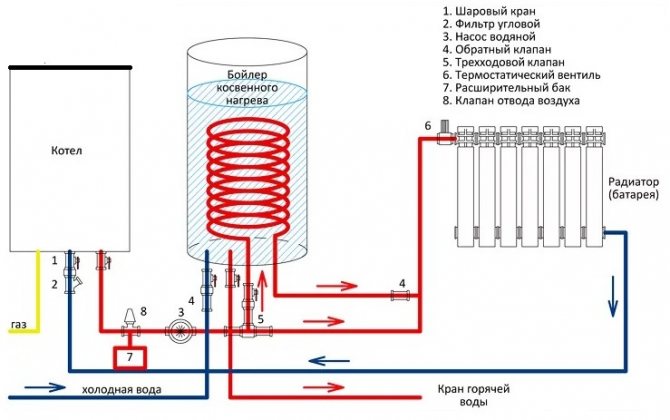

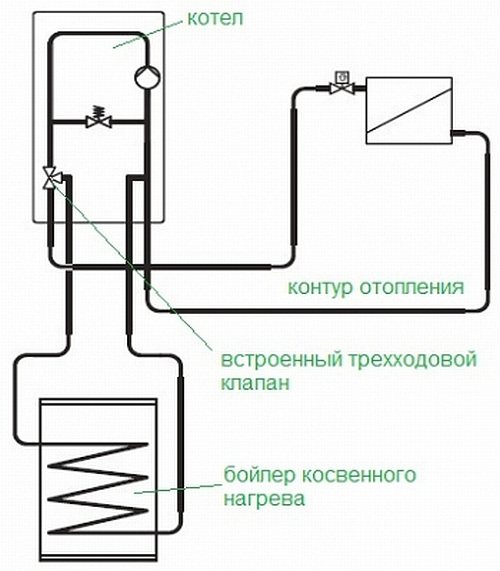

How to eliminate the shortcomings of hot water supply from the second circuit of a gas boiler

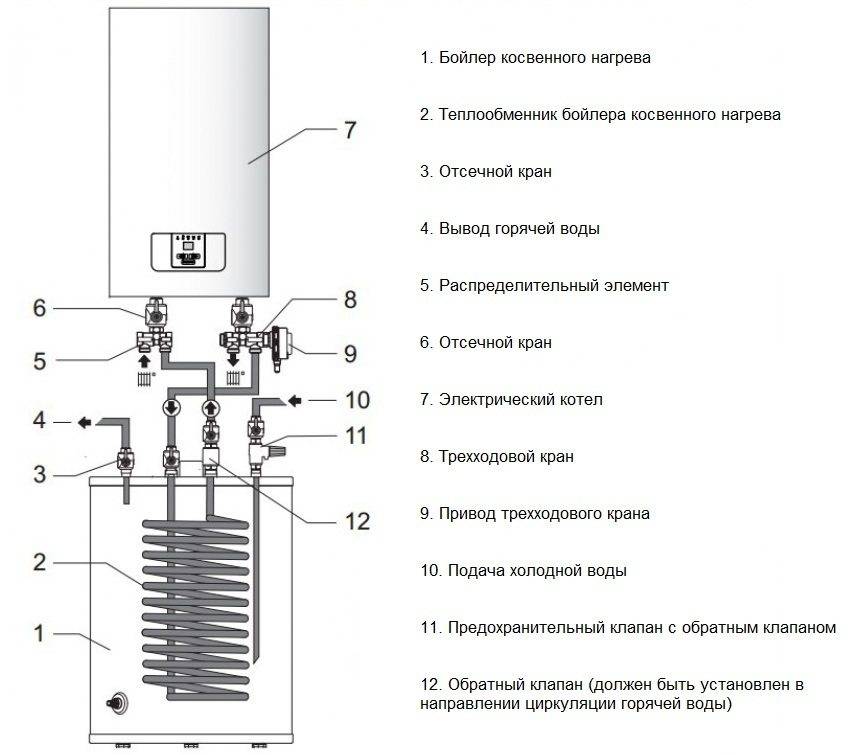

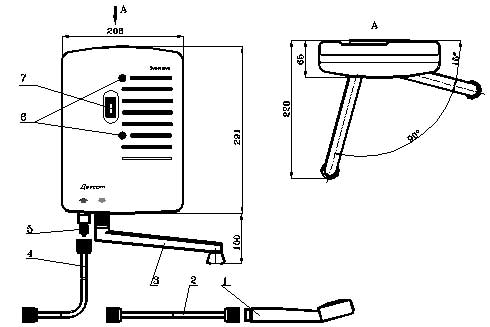

Obviously, to equalize the water temperature, you need to use a storage boiler. Craftsmen have long adapted to include in the hot water supply network from double-circuit boiler is also electric boiler. An exemplary scheme is shown in the figure.

Scheme - how to connect an electric boiler to a double-circuit boiler

As a result, the taps have a stable temperature of hot water. But at the same time:

- The boiler still turns on every time and threatens to break.

- A high consumption of electricity, since cold water also enters the boiler, and hot water is stored for a long time.

- The overall cost of the system and its bulkiness have increased without a fundamental change in quality - half-measures.

Another typical way out of the situation is to forget about the existence of the second circuit, and on the first one turn on the indirect heating boiler and the control circuit for it - effectively, but expensive.

Not so long ago, another solution was found in the form of a layered heating boiler.

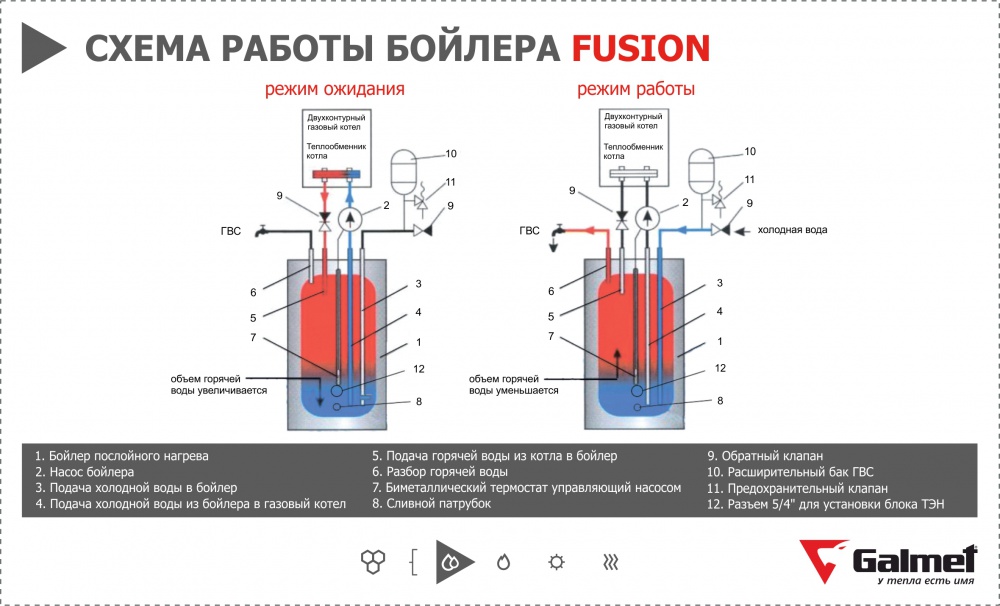

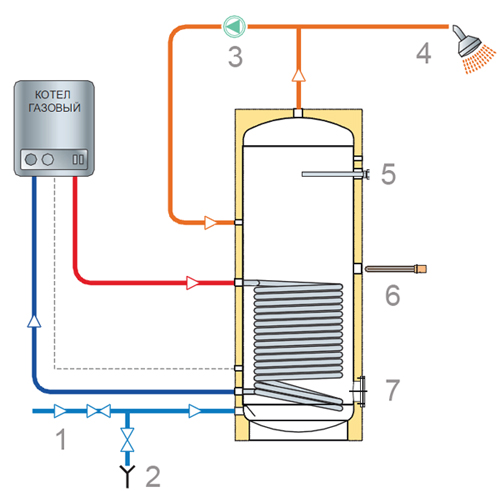

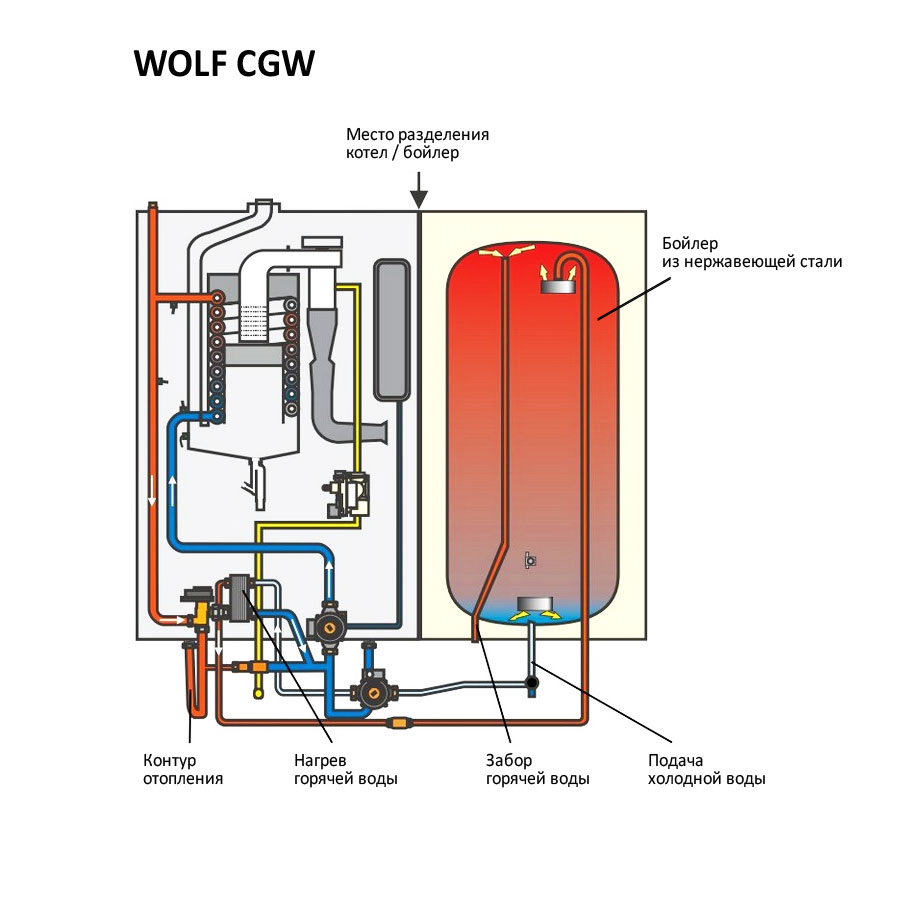

Operation of the stratified boiler

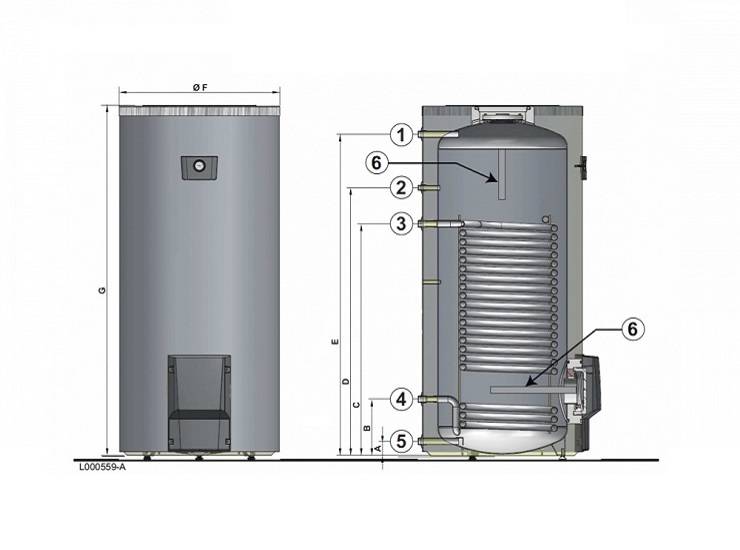

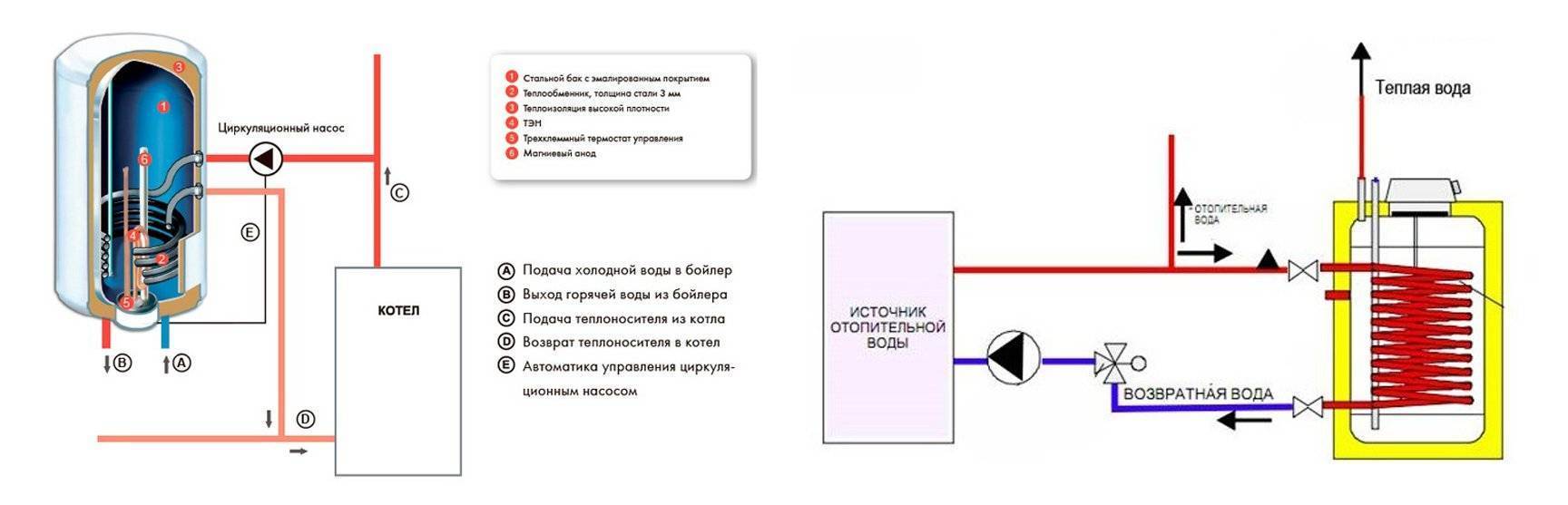

A layered heating boiler is a thermally insulated pressure tank with a conventional anode inside to prevent corrosion, and with several pipes for supplying and taking water, brought out to different heights inside the tank.

Many stratified boilers are also equipped with an integrated circulation pump. Consider how a layered boiler is connected and how it works.

- Cold water is supplied to the bottom of the tank, it displaces the hot water, which goes to the tap through the water intake at the very top of the tank.

- The circulation pump turns on when the water is cold, takes it from the bottom and distills it little by little through the boiler. Water is heated in the boiler and enters the upper part of the tank, where it can immediately be supplied to the tap.

- Turning on the pump is controlled by automation, the sensor of which monitors the temperature, or rather, the thickness of the hot layer at the top of the tank. As soon as there is not enough hot water, the pump turns on. But the heating temperature is set only approximately, it is determined by the pump performance, which can be adjusted.

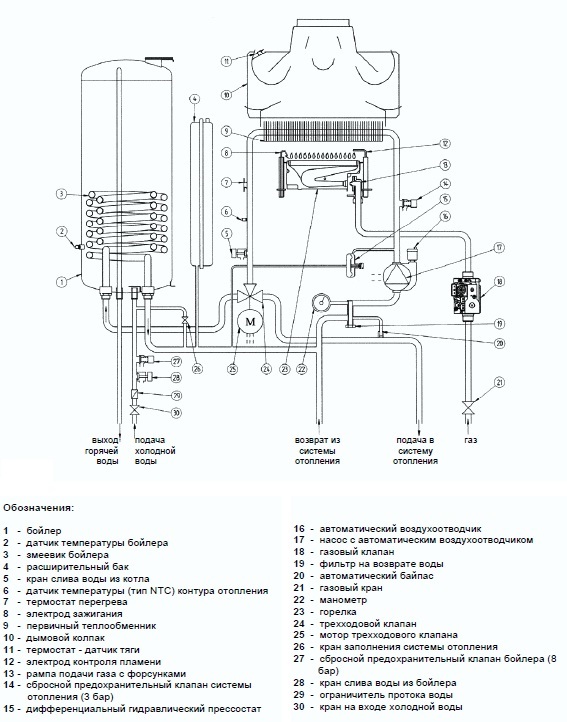

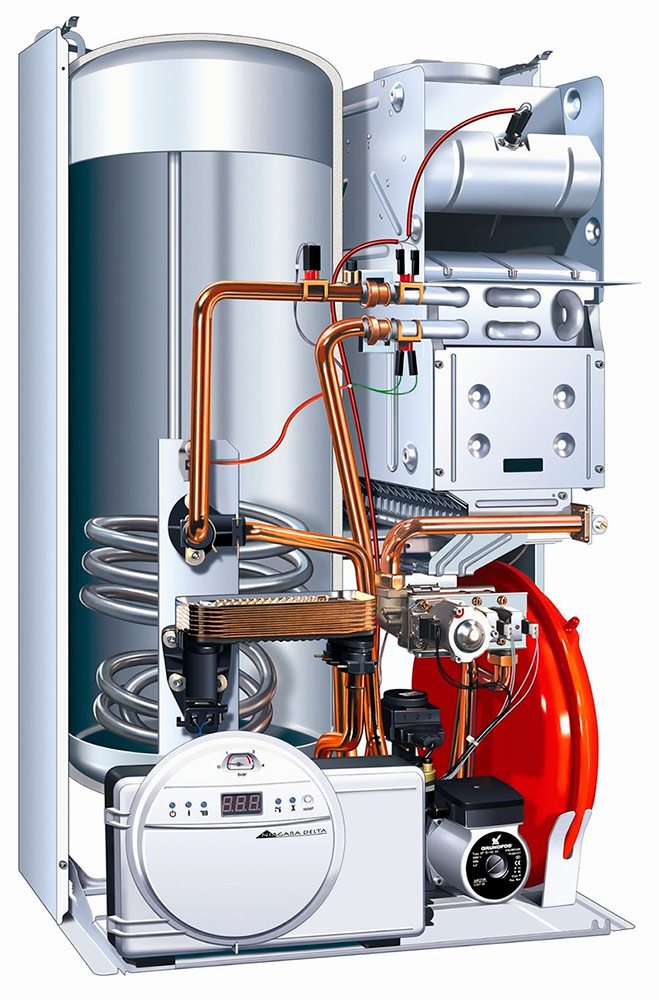

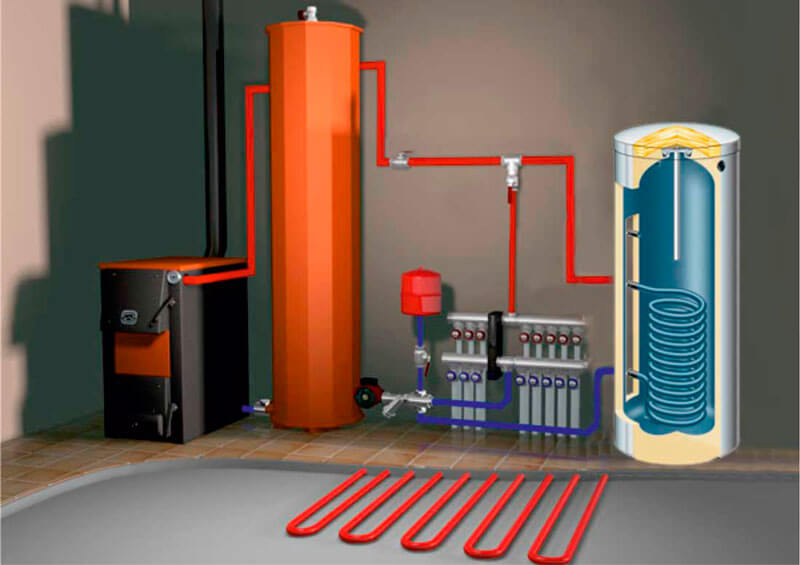

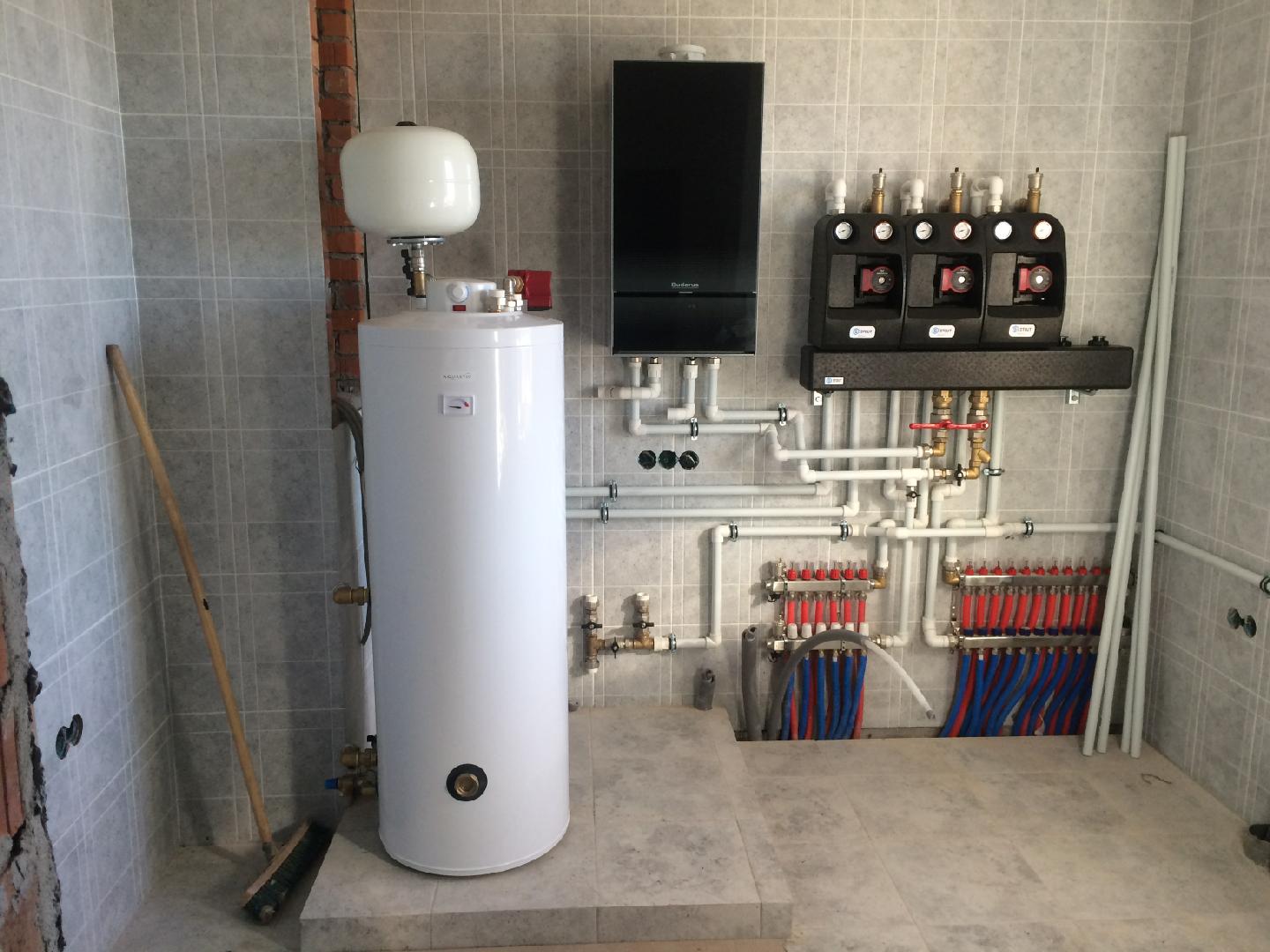

Choice of a floor-standing gas boiler with an integrated boiler

When choosing a 2-circuit boiler with an integrated storage tank-water heater, take into account the thermal characteristics and the principle of operation used. According to their internal structure, the following models are distinguished:

- Atmospheric boilers - have an open combustion chamber. When working, they burn the air from the room. Installation requirements are high.

Condensing boilers - accumulate the heat of flue gases through targeted condensate formation. They have efficiency up to 108%.

Turbocharged models - a closed combustion chamber, complemented by a turbine that pumps air pressure. The device uses forced intake of air masses and removal of combustion products.

After selecting the boiler according to the type of work, the required power and throughput are calculated.

Calculation of the required boiler power

During the calculations of a two-circuit unit with a built-in storage tank, two operating parameters are taken into account:

- Required power for space heating.

Reserve capacity for hot water supply.

Boiler volume.

The first parameter is calculated using a simple formula, 1 kW = 10 m². So, for a house of 100 m², you will need a 10 kW heater. An additional 30% is added for DHW heating. The volume of the built-in tank varies from 40-60 liters for domestic boiler equipment, up to 500 liters, in industrial units.

A properly selected boiler provides peak hot water needs (simultaneous consumption from all taps installed in the house). It is possible to install an additional free-standing container, the required volume.

Which brand of boiler with an internal boiler is better

A floor double-circuit gas heating boiler with an indirect heating boiler is offered by foreign manufacturers. You can facilitate the selection of a suitable boiler by distributing the most popular models according to a territorial basis:

- Germany:

- bosch Condens,

- Vaillant ecoCOMPACT,

wolf CGS.

Italy:

- Baxi Slim,

Ferroli Pegasus,

Beretta Fabula,

SIME Bitherm,

Immergas Hercules.

Sweden: Electrolux FSB.

Slovakia: Protherm Bear.

In order for the model you like to please with a long period of flawless operation, before buying, you should pay attention to the following:

- Adaptation to domestic operating conditions - in the EU and the Russian Federation, different parameters of main gas pressure, water quality for hot water supply, etc.

Type of connected heating system - condensing boilers are installed for low-temperature heating and are optimally suited for connection to underfloor heating.

The presence of a service center near the house is another significant plus. The official representation of the company that sold the boiler guarantees that if the heat generator breaks down, it will not be necessary to wait several months until the necessary spare parts are delivered from abroad.

Assistance in choosing a suitable boiler will be provided by a consultant from a company selling heating equipment.

Floor standing boiler with internal boiler - pros and cons

Floor double-circuit gas heating boilers with an internal boiler are distinguished by the following advantages:

- Fast supply of hot water to the user.

Reduced fuel consumption compared to boiler equipment operating in the flow heater mode.

Possibility of switching to summer mode, when only DHW is operating without a heating circuit.

Easy installation and maintenance.

Low requirements for the installation of a boiler with a boiler.

The operation of heat generators with a built-in storage tank revealed several disadvantages:

- High price.

Energy dependence - automation sensitive to voltage drops, often fails. During installation, a voltage stabilizer, grounding, etc. are additionally connected. To ensure continuous heating during a power outage, install a UPS.

Difficult installation, if necessary, connect a recirculation system. Installation of the boiler itself is no more complicated than a classic heat generator. The problem is the conduct of the recirculating water supply.

With proper installation, the boiler remains operational for the entire period of operation declared by the manufacturer. Installation work must be carried out by a qualified and licensed person.