- How baths are chosen

- Let's look at the basic requirements!

- Quality material - durable bathtub

- Features of cast iron, acrylic and steel

- Cast iron

- Steel

- Acrylic

- Installing an acrylic bath

- No. 8. Cast iron bath manufacturers

- Cast iron bathtubs

- Advantages and disadvantages

- Bath massage systems

- Conclusions and useful video on the topic

- Results

How baths are chosen

Most articles list the advantages of certain products in a matter-of-fact and dry manner and, based on technical parameters, give categorical advice.

But it is better to do it differently - to see what exactly is important for the bath users themselves and, based on real opinions, to voice recommendations on the type and material of the product. What are people looking for when choosing plumbing?

Let's look at the basic requirements!

- Comfort in use. ("Better cast iron - it is warmer").

- Color. (“The acrylic bathtub was ordered to match the color of the tiles”).

- Price. (“Unfortunately, there was not enough money for fashionable and expensive acrylic, so we bought high-quality cast iron”).

- Quality. (“Good cast-iron bathtubs have such hardness of enamel that axes have fallen into them during repairs, and there are no traces”).

- Ease of maintenance. (“There will be savings with acrylic - you don’t need to buy bathroom cleaners. All the plaque is simply washed off with water”).

- Hassle-free installation. (“The husband installed the cast-iron bath without any problems”).

- Convenience of delivery.(“The acrylic was easily lifted up to our fifth floor.”)

- Dimensions and design. (“The only good thing about acrylic bathtubs is the size.”)

Opinions are equally divided - and still there is no clarity which bathroom is better: acrylic or cast iron. So, it is worth evaluating the objectivity of user statements!

Quality material - durable bathtub

The main requirements for plumbing are long-term comfortable use without loss of performance and aesthetic qualities. If we evaluate the baths in this particular perspective, then cast iron will most likely be in the lead. After all, its main characteristics include:

- Service life - up to 40-50 years;

- Good heat capacity - water cools slowly, about a degree in 10-15 minutes;

- High strength - the material does not deform, is not damaged and practically does not wear out.

The “weak link” of cast-iron bathtubs is considered, but it is worth clarifying that in high-quality products from well-known manufacturers, there are practically no problems with enamel. Only after many years of service may there be slight abrasion and loss of luster, but by this time you will probably just want to update the bath.

As for acrylic, its characteristics for the same indicators are as follows:

- Service life - about 20 years;

- The heat capacity is slightly higher than cast iron - cooling by one degree Celsius occurs in half an hour.

- Poor impact resistance, offset by simple repairs;

It is also very important when choosing an acrylic bathtub to look at the type of reinforcement used, which is made or fiberglass based or polyurethane composite.The first option is not only dangerous due to the evaporation of excess styrene used in the production, but also has a tendency to form microcracks with subsequent destruction of the material.

This type of defect in acrylic bathtubs cannot be restored. With a polyurethane composite, there are no such problems, and the bathtub lasts for many years without any signs of wear.

The price, which is determined primarily by quality, does not differ much from “competitors”:

- Cast iron - 8-20 thousand rubles and more;

- Acrylic - 9-25 thousand rubles and more.

Also, when discussing materials, it is worth noting some more points laid down at the production stage:

- Dimensions;

- The form;

- Color.

According to these indicators, cast iron definitely loses, since it is produced in a standard rectangular shape in white. Acrylic, due to the excellent plasticity of the material, has almost no restrictions on shape and size. In addition, plastic is easily colored in mass, that is, the color palette for bathtubs is very wide.

Summing up the material characteristics and their cost, taking into account all the user parameters in this group, it can be noted that acrylic surpasses cast iron in design at a similar price and with a slight lag in technical data.

Features of cast iron, acrylic and steel

Bathtubs are made not only from the materials mentioned above, but also from wood, marble, glass, faience and copper. However, it is this trinity that is most popular due to consumer qualities.

Cast iron

An alloy of iron and carbon with a content of the latter from 2.14% to 6.67% - that's what cast iron is. Plumbing products have been produced from it since the 19th century. The material is hard, but brittle due to the high percentage of carbon.Resistant to corrosion even under conditions of constant exposure to oxygen and moisture at the same time (rust forms more on the surface, it is reluctant to penetrate inside). Demonstrates good casting qualities. Fonts made of this alloy are usually powder coated on the outside and several layers of enamel on the inside.

A cast-iron bath is one of the symbols of Soviet life, each apartment was equipped with such a product. Russian manufacturers are still making them., but in a much larger range. The aesthetics of modern domestic cast iron fonts has changed for the better, just look at the products of the Novokuznetsk brand "Universal" or OJSC "Kirov Plant".

Pig-iron bathtub Universal Sibiryachka

Pig-iron bathtub Universal Sibiryachka

Foreign goods are represented in this niche by the Spanish firm Roca, the Finnish Timo, the French Jacob Delafon and many others. Retro fans will be interested in the offers of the Italian company Magliezza - classic-style fonts, as well as antique legs and faucets for them.

Cast iron bath Magliezza Julietta

Cast iron bath Magliezza Julietta

| pros | Minuses |

|

|

Steel

Another iron-carbon alloy, but containing less carbon than cast iron. This gives the material flexibility, ductility, reduces brittleness. Stainless steel rivals cast iron in terms of corrosion resistance and does not require a coating.Bathtubs made of structural steel are protected from external influences by enamel.

Due to its flexibility, the material lends itself well to stamping, which allows you to diversify the choice of shapes. In addition to the usual ovals and rectangles, corner models are produced, round, polygonal and asymmetric. The prestige rating in this segment is headed by Europeans: the German company Kaldewei, the Portuguese BLB and the constant nominee of all sanitary tops Roca. Among domestic products stand out the lines of steel fonts Reimar, Antika and Donna Vanna, manufactured by OJSC VIZ.

Steel bath Kaldewei Conoduo.

Steel bath Kaldewei Conoduo.

| pros | Minuses |

|

|

Acrylic

The third material is an acrylic resin based polymer. To achieve the desired strength, the products are reinforced with fiberglass. By adding pigments and fillers, plastic is given various colors and textures, including the so-called cast marble. At a temperature of about 100°C (the exact figure depends on the composition), the material softens, and as it cools, it hardens again. This makes it possible to give the fonts any shape from standard or corner to the most bizarre, allowing you to choose a model for a specific design. Dignity smoothly flows into a disadvantage: acrylic plumbing warps from too hot water.

According to many experts, the top three responsible for the production of the best polymer baths are the Polish company Cersanit, the Czech Ravak, and again Roca.Also noteworthy are the products of the German company Villeroy & Boch, which has patented its own kind of acrylic - quartz. The difference of this material is higher strength. Of the Russian manufacturers, it is worth noting the Aquanet company.

Villeroy & Boch My Art bathtub in quartz.

Villeroy & Boch My Art bathtub in quartz.

| pros | Minuses |

|

|

Installing an acrylic bath

The process of installing an acrylic bathtub is complex and high-tech. Even minor errors during installation can lead to the fact that the life of the plumbing product is significantly reduced. To prevent this from happening, you need to follow the instructions below.

Acrylic bath device

Table: Step by step installation instructions

Steps, photo

Description of actions

Step one

Like any other installation procedure, the installation of an acrylic bathtub should begin with the preparation and unpacking of all structural parts. During the assembly process, the dimensions indicated in the instructions must be observed, especially the distance from the first pair of legs to the drain hole. The standard size is 17 cm. Turn the tub over and make a mark of this size on the bottom and draw a transverse line along it. Attach the leg guide to the outer part of the bottom of the tub and mark the attachment points with a pencil. Repeat the procedure on the other side of the product.

step two

Using a 3 mm metal drill, make holes in the acrylic for the brackets.The depth of the holes should not exceed 6 mm. Otherwise, you risk making a hole in the new tub. To prevent this, wrap electrical tape around the drill at a distance of about 5-6 mm from the sharp end of the drill.

Step Three

Having collected all the brackets included in the kit and the guides, mount the structure on the fasteners on the outside of the bath. In this case, self-tapping screws are used.

Step Four

Assemble all legs before installing the tub. There are various frame designs, and the legs themselves may also differ, but as a rule, there are no problems with their installation. They need to be screwed into place in the bottom of the bath. This procedure does not require a level.

Step Five

Install the siphon, strictly following the diagram attached to the acrylic bath. There are many types of siphons, so there are different ways to install them. The only common step is to check all the necessary gaskets and tightness at their installation sites. If burrs are found, they must be removed. Otherwise, leaks may occur.

Step Six

Transfer the bath to the room and put it in its place

This must be done with extreme caution - do not collapse or damage the installed siphon. Use a building level to level the bathtub

Adjust the feet to the level reading by screwing or unscrewing them. After doing this procedure with the first pair, repeat it for the second. Align the diagonals (to do this, lay a long rule diagonally, and a building level on top).

step seven

After leveling, you need to install special hooks to prevent the bathtub from turning over. The set contains 3 dowels with hooks. One hook should be attached to the wall at the end of the tub, and the other two hooks on the other side. Depending on the type of hook, the installation method may vary slightly. For example, they can be attached using one or more dowels. Having fixed the dowels in their places, check them for strength.

Step eight

Install the tub on the hooks and connect the siphon to the sewer drain. All joints with walls must be carefully treated with a sealant. Alternatively, you can install a skirting board.

Step nine

After you have managed to install the bath, be sure to check it for leaks. To do this, you should take a full bath of water and wait. Carefully inspect all joints. You can also put a sheet of paper or a piece of rag under the siphon - this way you will notice even a minimal leak. If everything is normal and your bath is not leaking, then you can safely use it.

Step ten

If the frame is not included in the kit or it is not provided for by the design itself, then the bath can be installed on bricks. To do this, you need to install bath on a special brick masonry. It is advisable to use only red bricks to prevent mold. Be sure to leave a couple of inches of space between the bottom of the tub and the foam padding.

Installation of an acrylic bathtub on a frame. Varieties of frames for different forms of fonts

No. 8. Cast iron bath manufacturers

The topic of cast iron bath manufacturers requires more detailed consideration.It should be noted that it is better to give preference to products of famous brands that have modern production, monitor the quality of products at every stage of production, use the best materials and constantly replenish collections with new models.

Among foreign manufacturers, the most popular are the cast-iron bathtubs of the Spanish company Roca. Spanish Novial baths, Italian Artex and Castalia, Finnish Timo and Portuguese RECOR are also in demand. The products of Chinese manufacturers are rarely of high quality (often they save on cast iron and apply enamel by painting rather than sintering in a furnace), but even here there are exceptions. A prime example is the Goldman baths.

The products of domestic manufacturers will cost much cheaper, but at the same time they are practically not inferior in quality, and in design they are already almost catching up with European counterparts. Let's highlight the cast-iron bathtubs produced by Plant Universal and Kirovsky Zavod.

In any case, do not hesitate to ask for documents that confirm the quality of the bath.

Cast iron bathtubs

For hundreds of years, people have been using cast iron bathtubs because of the strength and reliability of the material. Until now, cast iron has not gone out of fashion, because by applying enamel you can “ennoble” it, giving it a more aesthetic appearance. Enamel is applied in several layers at once, which makes cast-iron products incredibly beautiful. As a rule, manufacturers provide their customers with not only glossy, but also matte cast iron bathtubs.

Cast iron bath

Thanks to the silver ions added to the enamel during painting, there is a natural purification of the water that you collect in the bath.Such a trick can be found in many models, but not all, because the addition of silver ions significantly increases the final cost of the accessory. Of course, like all plumbing fixtures, cast iron baths have their pros and cons.

Beautiful cast iron bath

Advantages and disadvantages

The main advantages of cast iron include:

- ease of care;

- noise reduction;

- thermal conductivity;

- high resistance to mechanical damage;

- strength;

- long service life (from 50 years).

A cast iron bath is able to maintain a high temperature of water for a long time. This reduces the cost of subsequent heating and significantly improves the comfort of taking water procedures. Also cast iron bath is very a durable product that is difficult to damage even with a sledgehammer. Due to its large weight, the bathtub always stands firmly in place.

Cast iron bath - photo

It takes a lot of effort to damage the surface of the cast iron, and the resulting damage can be easily restored. As a result, a cracked or chipped bathtub can last for many more years. All bursts and sounds are perfectly absorbed by cast iron. Also, to care for him and maintain the coating in its original form, you do not need to make any special efforts. Over the years, cast iron changes color and loses its luster. To restore the original appearance of the bath, a special bath paint-epoxy will help. Even temperature changes will not be able to affect this. But, despite the large number of advantages, the cast-iron bath still has some disadvantages.

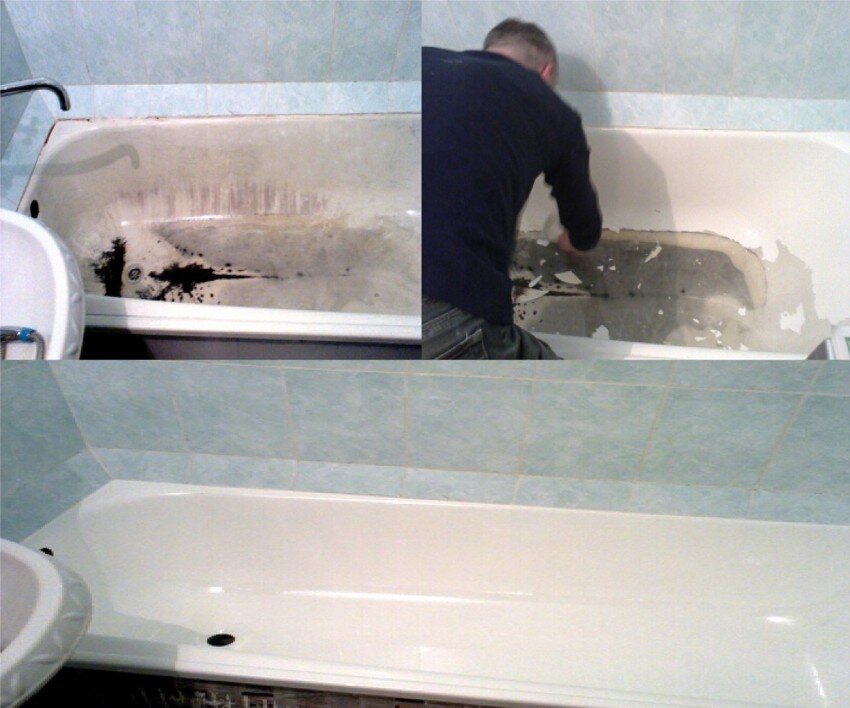

Cast iron bath restoration - before and after

The list of disadvantages of cast iron includes:

- high slipperiness of the coating, which can cause various injuries during the adoption of water procedures;

- insufficient variety in the choice of the form of the product;

- great weight.

A cast iron bath is comparable in weight to a stone one

The weight of a conventional bath can exceed 120 kg, which often creates some problems during installation and transportation. Cast iron bathtubs are usually very large and have a triangular or rectangular shape. Such a design solution does not always fit into apartments with small bathrooms. In addition, a triangular bath can even spoil the appearance of the room - such a nuance should be taken into account when choosing a material.

Cast iron bathtub custom sizes

Cast iron bathtub HAITI, with handles

Cast iron bath Recor

Bath massage systems

In modern baths, systems are installed for three types of water massage: hydro-, aero- and turbomassage. These systems are mounted, as a rule, on bathtubs made of acrylic, quartz and steel.

Hydromassage

A hydromassage system is a system of nozzles and hoses through which water moves under high pressure, driven by a pump. As a rule, a system for adjusting the pressure of the jet is provided, and the number of nozzles is determined by the size of the bath.

Air massage

The air massage system is similar to the hydro massage system, but has one significant difference - the working tool for massage is not a jet of water, but air bubbles, the intensity of which is adjustable.

Turbomassage

The turbomassage system is a combined type of aero and hydromassage. Basically, this system is installed in such types of baths as a jacuzzi.Two hoses are supplied to the nozzles at once, through which both water and air lend themselves. This feature allows you to use the system both in combination and separately for each type of massage, if desired.

Conclusions and useful video on the topic

Comparison of the technical and practical qualities of sanitary ware for an informed choice of a bathtub made of innovative acrylic or traditional cast iron:

Cast iron bowl selection criteria:

How to choose wisely good acrylic bath?

It is believed that acrylic bathtubs are ideal for high-rise buildings - they are easy to transport, easy to install. Among them, you can easily choose a model for the smallest bathroom. Cast iron bowls are better suited for a private house or cottage.

However, these are only the recommendations of practitioners. Both options have advantages and disadvantages. The elegance of acrylic or the practicality of cast iron: the final choice is up to the buyer.

Are you looking for a practical, beautiful and durable bath? Or do you have experience with cast iron or acrylic plumbing? Please share with readers your impressions of using different types of baths, ask questions and participate in discussions. The comment form is located below.

Results

We have tabulated the criteria given earlier, for each first place the material receives 2 points, for the second - 1 point, for the third - 0 points.

| Criterion | Cast iron bathtubs | Steel baths | Acrylic bathtubs |

| Ease of installation | 2 | 1 | |

| The weight | 1 | 2 | |

| Care | 2 | 1 | |

| Damage resistance | 2 | 1 | |

| Variety of forms | 1 | 2 | |

| Variety of sizes | 1 | 2 | |

| Life time | 2 | 1 | |

| maintainability | 1 | 1 | 2 |

| Ease of use | 2 | 1 | 2 |

| Price | 2 | 1 | |

| Outcome | 9 | 12 | 12 |

Although cast iron bathtubs were the last in our ranking, they were the first in such important performance qualities as resistance to damage, service life, ease of maintenance and ease of use. Therefore, if price, weight and ease of installation do not matter to you, you are an adherent of classical forms, then you should choose cast-iron bathtubs, otherwise it is better to take acrylic bowls. Steel bathtubs are somewhat of a cheap compromise, with average performance in almost all evaluation criteria. Set your priorities wisely and choose the best option for you.

![How to choose a bath: 5 points + and - [acrylic - steel - cast iron]](https://fix.housecope.com/wp-content/uploads/3/d/9/3d97b2b9dd98c348a7ffa0690dc22e7b.jpeg)

![How to choose a bath: 5 points + and - [acrylic - steel - cast iron]](https://fix.housecope.com/wp-content/uploads/3/f/c/3fc1f5cff1c237641a19b845dfd68c88.jpeg)