- Well Creation Technology

- Drilling

- Blocking with a headstock with a substock

- Stuffing headstock with plug

- Barbell driving

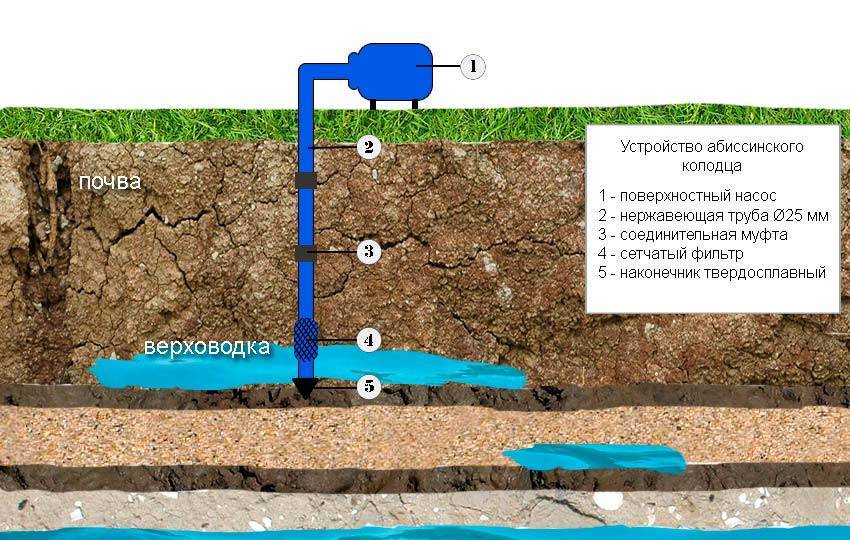

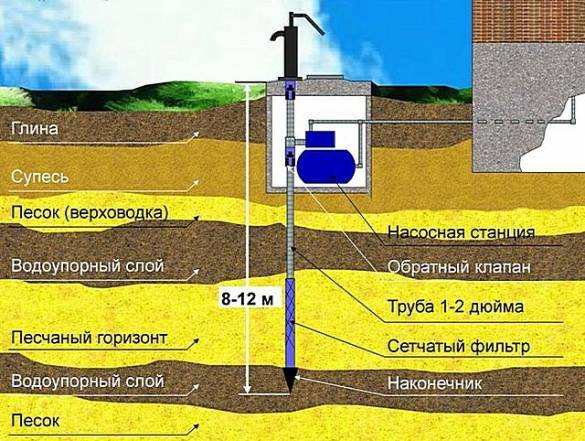

- Arrangement of the Abyssinian well

- Principles of operation of the Abyssinian well

- Where construction is possible

- Arrangement of the Abyssinian well

- Abyssinian well equipment

- Abyssinian pumps

- Stainless steel well needle

- Plastic filter for Abyssinian well

- Hand drill for the first layer

- Set for a well a needle

- Criteria for choosing an Abyssinian well

- Pros and cons of the Abyssinian well

- Well benefits

- Well Disadvantages

- What to consider before making a decision?

- Potential Obstacles

- Hydrogeological "amateur activity"

- Making a filter for an Abyssinian well

- Well from Ethiopia - start construction

Well Creation Technology

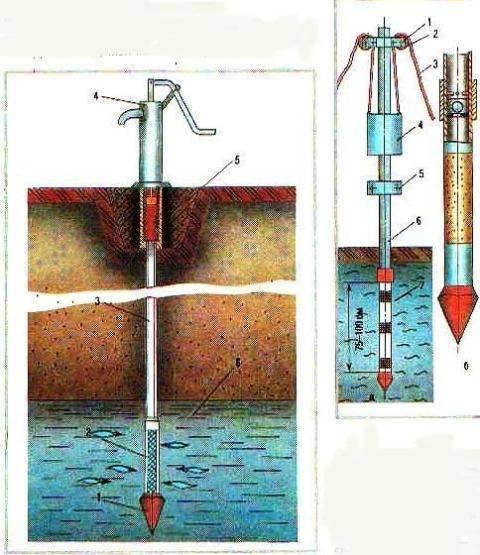

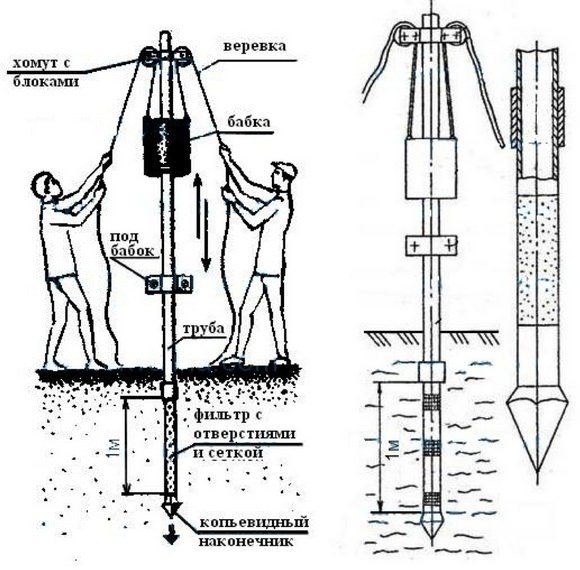

The Abyssinian well is equipped in two ways: by driving or drilling a well. To implement the first method, the so-called driving woman is used, and in the process of work, water is periodically poured into the pipe. At the moment when the water abruptly goes into the ground, the pipe is dug another 50 cm, and then the pump is mounted. The driving method is good when you create a well yourself, but this method is not without drawbacks. First, if a boulder gets in the way of the pipe, the needle can completely deteriorate.Secondly, when clogging the well, you can skip the aquifer.

The second method, which involves drilling a well, requires the help of craftsmen and the involvement of special equipment, but when implementing this method, you are guaranteed to find water in the well.

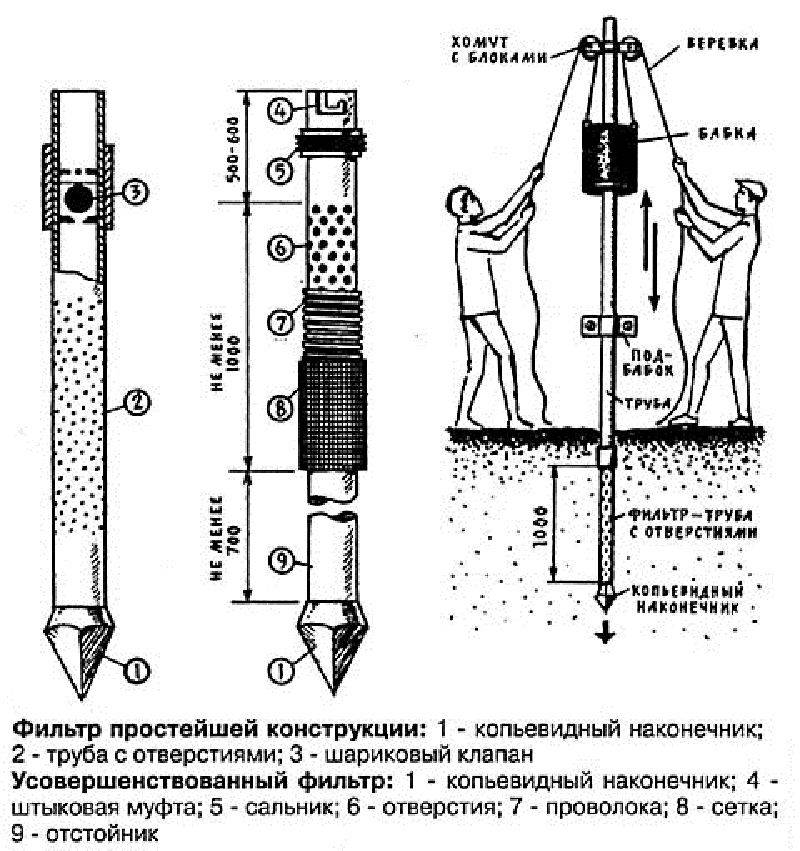

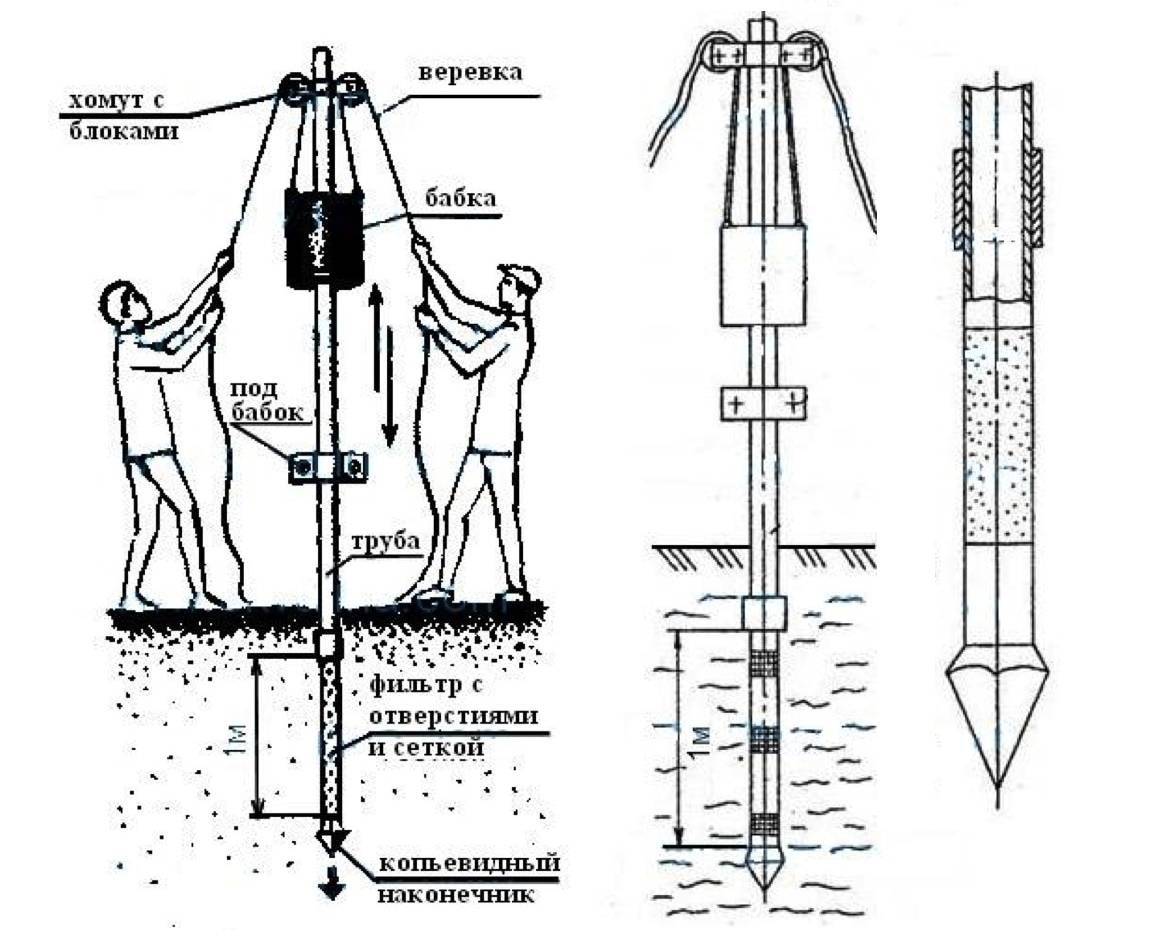

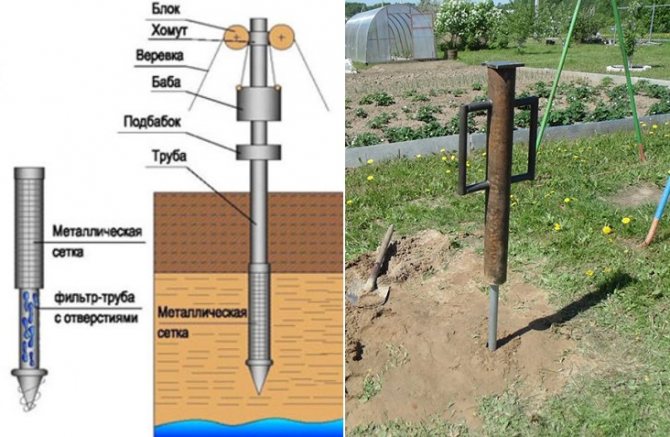

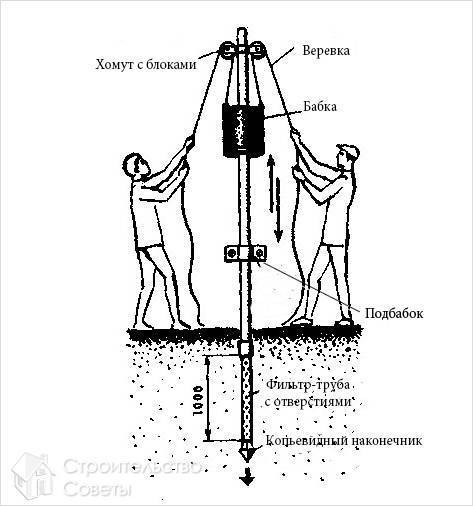

There are several ways to clog a well-needle:

- With the help of a sliding headstock and a tailstock - a special part that tightly covers the pipe and does not slip down. In the process of driving the needle, the worker lifts the headstock and forcefully lowers it down to the substock. The part is gradually moved up the pipe and worked in the same way until an aquifer is found.

- The second method of creating an Abyssinian well is driving with a headstock with a plug. In such a case, the blow falls on the upper part of the pipe, while the plug is installed at the end in order to protect the thread from damage. This method is good because it allows you to use the maximum impact force.

- You can also hammer a well with a rod. In this case, there is no danger of bending the pipe, and the process itself is easier and faster. The driving rod can be made from a hexagon or a round rod. Separate parts of the bars are twisted together using a threaded connection. In order for the rod to be removed from the ground after work is completed, its length must be greater than the depth of the aquifer.

Drilling

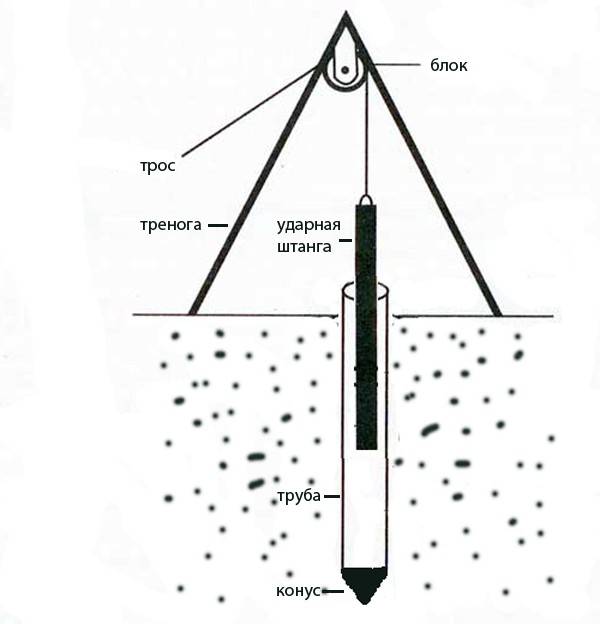

This method is often used to pass the soil to the quicksand, as the water-saturated sandy layer is called, which, due to its friability, can crumble immediately after the drill advances in it. To avoid this, well drilling is combined with casing immersion.

Drills for the production of the Abassinian well needles can be welded in a home workshop. It is optimal to use two modifications:

- a frame drill, which is a U-shaped structure, and is used to pass through a dense clay layer,

- frame drill with a cylinder, which is installed inside the frame and serves to collect and subsequent evacuation of soil from the channel.

The drilling technology is quite simple - the passage of soil layers is carried out sequentially, with a gradual build-up of the working part with rods. At the stage of drilling with a drill with a cylinder, it is better to use a winch (purchased or assembled independently from a starter and a cable, equipped with restrictive washers and installed on a stand). Such a device will make it easy to remove the drill, rods and soil accumulated in the cylinder from the channel, which together give a considerable weight.

Blocking with a headstock with a substock

A subhead is a cone-shaped element fixed to the rod with a thrust washer. A simple design allows you to achieve maximum efficiency.

The headstock sliding along the rod, falling after lifting, gives off energy to the subheadstock, due to which the rod enters the ground. In order to avoid damage, the tailstock cone must be made of a stronger material than the headstock. The thrust washer prevents the cone from flying off the rod, even with very strong impacts. On the contrary, at this time he "sits down" even more firmly.

Stuffing headstock with plug

To implement this method, they use not a sliding bar, but a headstock. To protect the thread of the rod, a plug is installed in the upper part. It is recommended to use grandmas from 30 kg and more.

Barbell driving

Rod driving equipment - hexagonal rods, the diameter of which allows them to be placed in the column.Each of them is supplied with a thread for increasing the length (internal on one side and external on the other). For reliable fastening, the length of threaded sections must be at least 2 cm. The process of driving a casing pipe immersed in a drilled well consists in throwing a rod into the rod cavity.

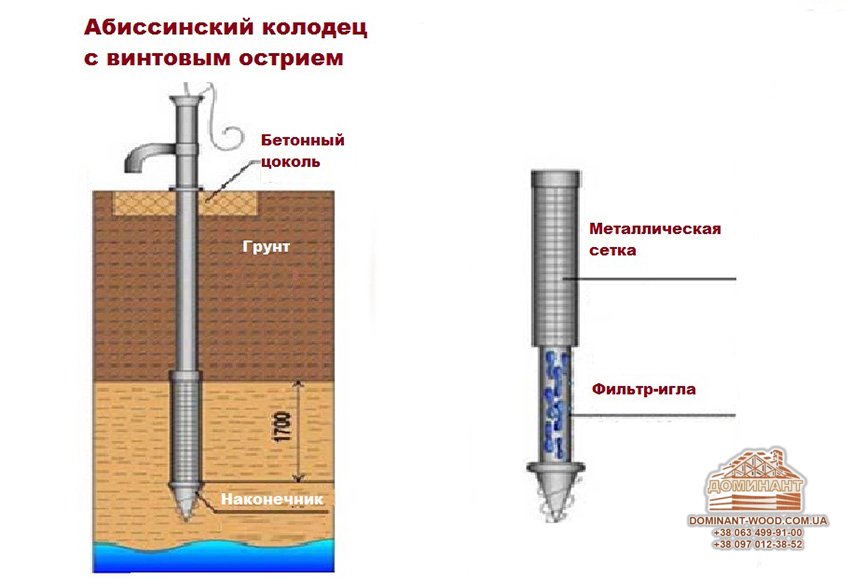

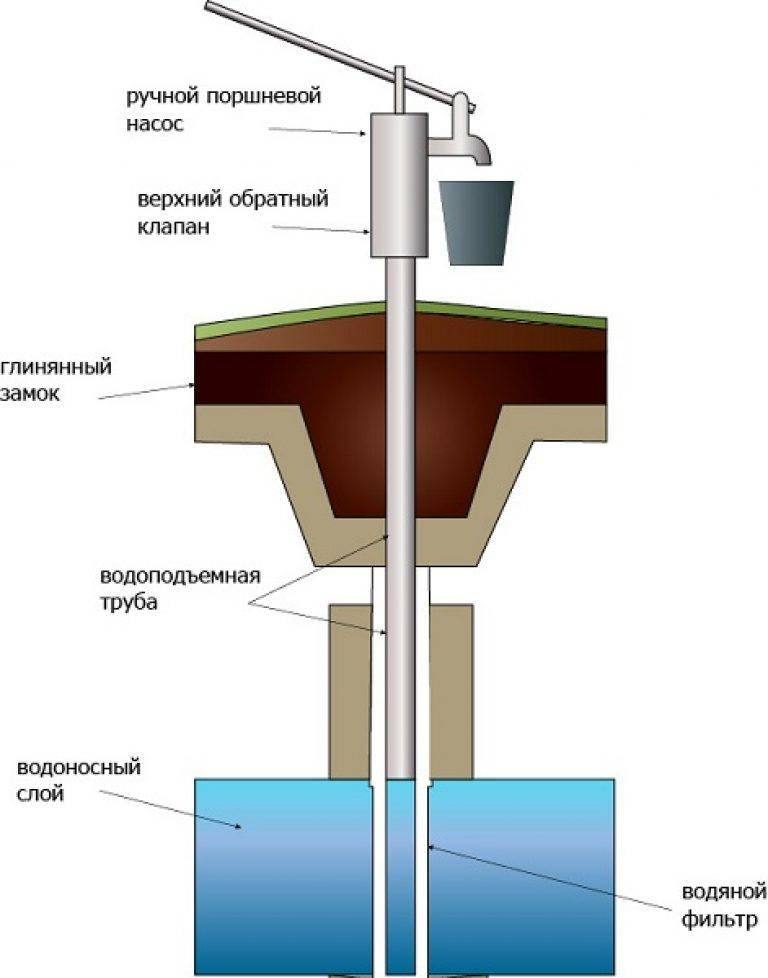

Arrangement of the Abyssinian well

After the work with the well is completed, the structure is a pipe sticking out of the ground.

In order for it to become an autonomous and full-fledged source of water supply, a number of works should be carried out:

- We fall asleep with gravel all the space near the pipe.

- A blind area is made on top of the gravel: this concrete platform is located slightly above the ground level at the well.

This design will prevent atmospheric moisture from entering the place of intake, as well as protect the pipe from negative external influences.

The rise of water from the Abyssinian well can be carried out with a traditional hand pump mounted on the head of the pipe. If the site is electrified, this work can be greatly facilitated. The depth of the source is usually small, a surface pump is enough to raise the water. Its inlet pipe is placed in the pipe to the water level. A special filter mesh is installed at the end of the hose.

Ensuring year-round operation of the Abyssinian well

If you plan to use your Abyssinian well permanently, then it must be equipped accordingly. The low temperature in the upper layers of the earth is the main problem in the operation of wells and pumps in cold weather. It can cause damage to both pumping equipment and water supply pipelines.

If you plan to use your Abyssinian well permanently, then it must be equipped accordingly. The low temperature in the upper layers of the earth is the main problem in the operation of wells and pumps in cold weather. It can cause damage to both pumping equipment and water supply pipelines.

To protect the pipeline and the pump from freezing, they must be placed either in special containers - caissons, or in rooms with a positive temperature.

The role of a caisson can be a buried capital structure (below the freezing level of the soil), or it can be a buried structure made of plastic or iron, made in the form of a barrel.

The lower edge of the caisson should be below the freezing line of the soil - the water supply pipeline of the dwelling should also be at the same level. The caisson may have an additional layer made of a sealing material that is not afraid of soil exposure. The water supply pipeline itself can have an autonomous heating system (using a heating cable), or have a reliable insulating layer.

What conclusion can be drawn from the above?

-

- Self-construction of both the well itself and the infrastructure necessary for servicing is within the power of people even with little building skills.

- Such a well can become a source of autonomous water supply for a house at a relatively low cost.

- For domestic needs, water can be used without treatment, but for drinking water it must be subjected to additional purification.

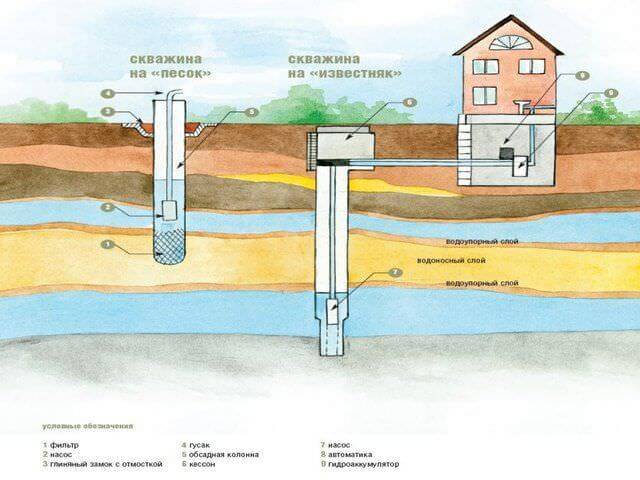

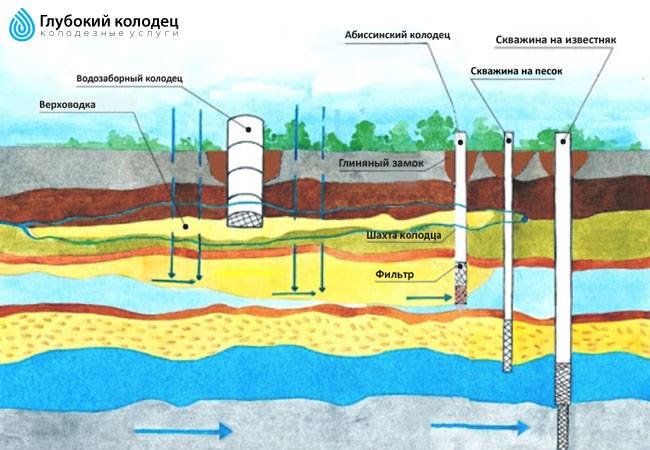

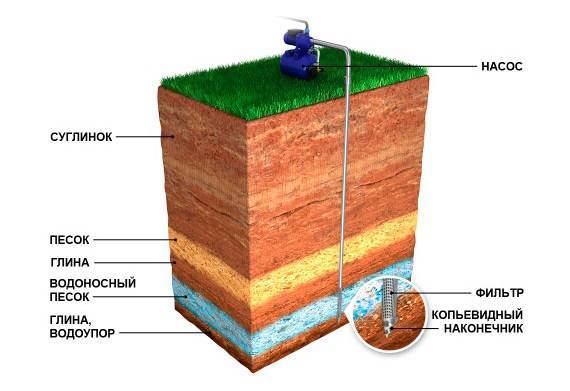

Principles of operation of the Abyssinian well

In the 60s. 19th century during the war in Abyssinia (Ethiopia), the American engineer Norton proposed to the British army a primitive design, called the "Abyssinian well". The device did not require much time to install, it was just as quickly dismantled and transferred to another place, but water was produced in the desert. A hand pump was used for lifting, now electric ones are predominantly installed.

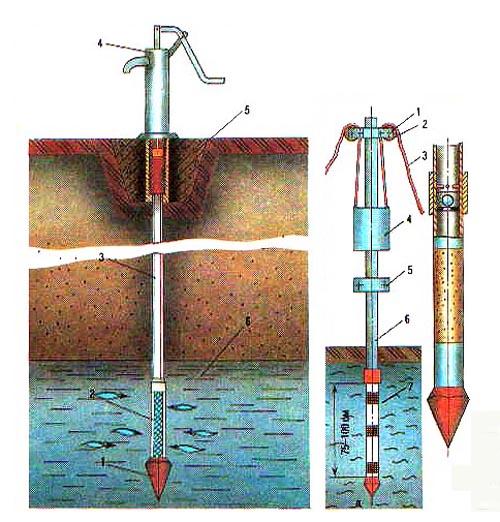

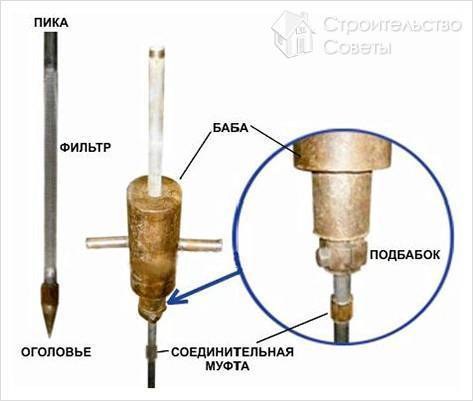

This is not a well in the classical sense, but a barrel of pipes with a filter and a tip immersed in the ground. The first element is used to purify water from coarse particles, now it will be improved so that fine sand fractions will not pass through. The tip is long, gradually tapering towards the end, the trunk itself, along with it - a kind of needle for a well - a suitable shape for hammering into the ground.

To understand what an Abyssinian well is, you need to imagine how it was made. The classic method is hammering, it is most often used by independent craftsmen. You can bring in a manual or mechanical drilling rig, but this is a special technique that will have to be rented or hired, which will increase the budget. The pipes are plugged until the tip penetrates the aquifer.

It is necessary to understand what an Abyssinian well is, so as not to expect too much from it. The well-needle opens the closest aquifers, technical water is not used for human consumption without additional purification. The site is watered with it, used for construction, bath water supply and other household needs.

When summer residents hear about the Abyssinian well, what it is, not everyone knows. After getting acquainted with the device, it is often decided to build it. As an option for water supply, when the site is just being equipped, it is quite acceptable.

Watch a video about the features of the Abyssinian well device and its differences from a conventional well:

Where construction is possible

It is necessary to arrange such a well in areas where the aquifer is within 4–8 m of depth or in places where there is sufficient pressure in the aquifer up to 15 meters, which can raise water to a depth of 7–8 meters. If the water from the reservoir rises a little below 8 m, then you can simply install the pump, deepening it into the ground.

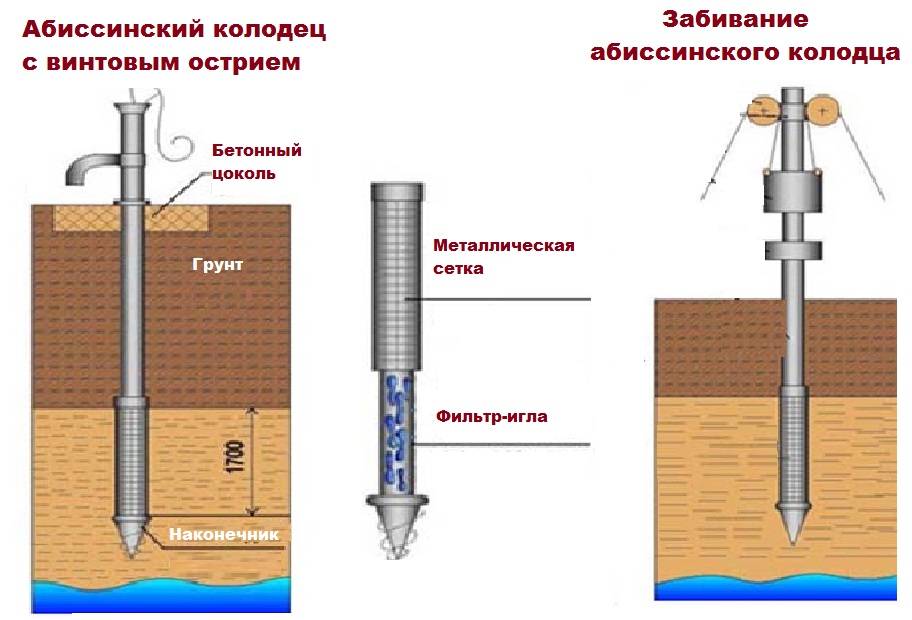

The main part of the Abyssinian well is a perforated pipe with a head (wedge tip) and a filter. The tip should be 20-30 mm larger in diameter. It is advisable to make the filter from metal, the same as the material from which the pipe is made: this will reduce the level of electrochemical corrosion. Holes 6–8 mm in diameter are drilled in the pipe with a diameter of 0.6–0.8 m along the length of the pipe. In this section of the pipe, a wire is wound with a gap of 1–2 mm for free passage of water. After winding, the wire is soldered to the pipe in several places and at the ends of the wire. After that, with the help of soldering, a mesh of plain weaving made of non-ferrous metal or stainless steel is fixed.

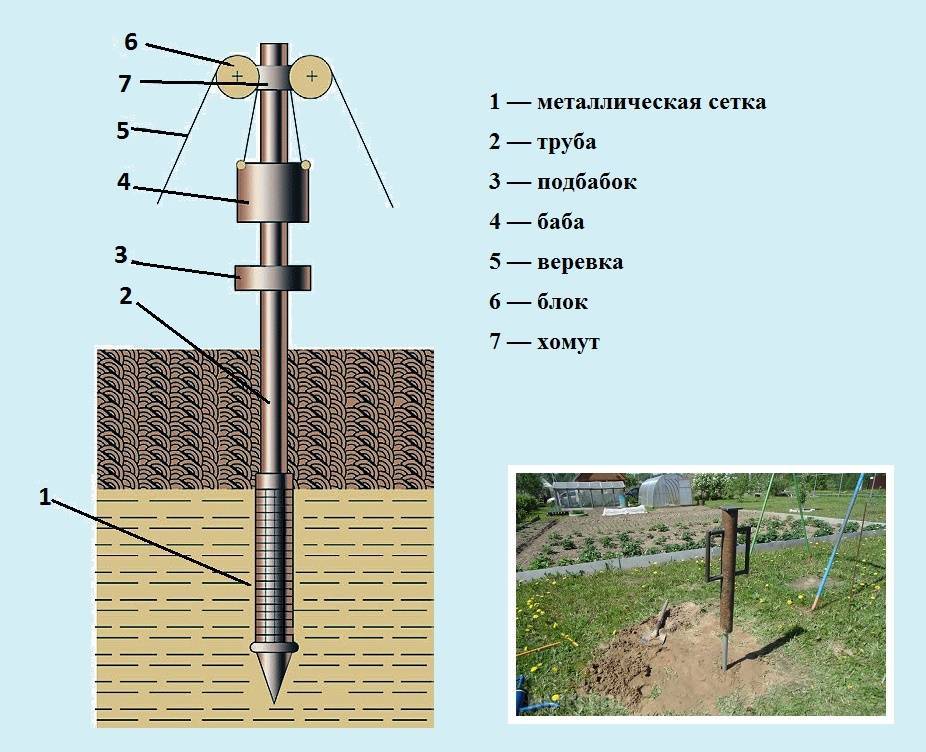

Various devices are used to deepen the pipes, but it is better to first dig a hole of 0.5-1.5 m, and then drill a well 1-1.5 m. so that the pipe does not move when plugged.

Often a pile driver is used to deepen pipes, but other devices can be used. Deepening the well pipe with a metal rod with a diameter of 16-22 mm inserted into the pipe consists in raising the rod 1 m high and applying sharp, vertical blows to the tip. As a result, almost all the load falls on the tip. Can the rod be extended as you deepen wells, or you can fix a flexible cable at the top of a metal rod. This method is called shock-rope.

The technology for deepening pipes for an Abyssinian well is as follows: it is necessary to use a headstock weighing 25–30 kg, this device is lifted up by the handles and lowered sharply, the impact load should fall on the nozzle attached to the sub-pipe. When deepening the well, the nozzle is moved up the pipe and, if necessary, another pipe is screwed on.

If the depth of the aquifer is unknown, then when the pipe is clogged by 4 - 5 m, periodically check if water has appeared. If you have a thin aquifer and it is not known how deep it is, then you can clog the pipe below and not get water.

If the Abyssinian well is installed in clay soils, then the filter mesh may become very dirty, and you may not understand that you have hit to the aquifer. In this case, it’s better not to rush, and when even a minimal amount of water appears in the well, you need to pump it, and if possible, rinse the filter every 0.5 m. To do this, use an electric pump, insert a hose into the pipe and wash the mesh with clean water.

An electric self-priming pump is used to lift the water. You can also use a piston pump. After installing the pump and pumping wells around the pipe arrange a clay castle and make a blind area of concrete. The time required to build an Abyssinian tube well is about 5-10 hours, and in most cases depends on the nature of the soil and the depth of the aquifer.

The Abyssinian well will serve 10-30 years, the period depends on the aquifer, the quality of the work and the material used.Water can be pumped continuously from the well for several hours, the productivity of the well is usually 1-3 cubic meters. water per hour.

Arrangement of the Abyssinian well

The source works only in summer. During the cold season, the Abyssinian well is not intended for operation. Sometimes the structure has to be re-drilled. Therefore, the arrangement of the source should not be expensive.

Abyssinian well equipment

The arrangement is reduced to the installation of a hand pump - a pump at the outlet of the pipe from the ground. Hand pumps can be left in the winter with minimal risk of loss due to theft or vandalism.

Or make in the house to enjoy the winter.

If an electric surface pump is needed to raise water, then after work, it is better not to leave it, but to take it into the house. To avoid theft, it is more convenient to use the variant of the well not with a cap, but with a lid.

This is what an Abyssinian well looks like with a cap on the mouth:

Abyssinian pumps

When choosing a pump, how the Abyssinian well was built is not important. Depth matters

A pumping station for the Abyssinian well is not required; for structures less than 10 meters deep, choose a surface pump.

Two pumps, for the same depth, do not work the same way. Although they may have much in common, different well pumps are installed differently.

Centrifugal pumps work by suction through the rotation of an internal fan. These are standard workhorse pumps because they cost less than other types.

Centrifugal pumps are installed in a mechanical housing, on the surface of the well, and not inside the well. This makes maintenance more convenient.But the catch is that centrifugal pumps don't produce enough suction to work in a deep well.

Consider a centrifugal pump for an Abyssinian well if it is drilled to a depth of no more than 10 meters.

Price of surface centrifugal pump:

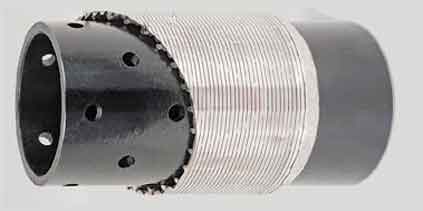

Stainless steel well needle

The filter for the Abyssinian well with metal pipes can be made independently. But without the skills of working with metal, it is cheaper to buy ready-made.

The filter is the basis of the source: a high-quality tip for an Abyssinian well gives a normal flow rate. Perforation is 30% of the pipe surface, not less than one meter in length. The minimum outer diameter of the pipes is 34 mm.

- The capacity of the wellpoint is increased by winding the perforated frame with wire in a spiral with an indent of 1 centimeter. This increases the flow of fluid to the perforation.

- From above, the needle for the well is wrapped with a network of galloon weaving. We solder the grid with tin, lead is not good. The task of the grid is to retain fine sand.

- On top of the mesh, we braid the wellpoint with a wire with an indent of 5-10 millimeters. This will create a gap between the soil and the wall of the needle when driven into the water carrier.

The frame, mesh and winding wire are needed from stainless steel. Copper, brass and galvanization will quickly become unusable. The filter, made of stainless steel, contains another advantage: it can withstand acid washing. Any filter element will crust over after a few years, and a needle with glandular waters clogs three times faster. Then it will be necessary to wash the Abyssinian with chemical reagents.

Plastic filter for Abyssinian well

It is much easier to make a borehole filter made of polypropylene pipes. Pipes and filters made of HDPE (nPVC) have been working for more than 50 years, and do not overgrow.

Video how to make a plastic filter for the Abyssinian well with your own hands:

Hand drill for the first layer

An auger bit for an Abyssinian well will be required to pass the first meters of soil. It will be difficult to drill the entire well with a drill; it will be difficult to pull the auger from the ground from a depth of 2 meters. And to make a lifting tripod with a winch for the Abyssinian is impractical.

In addition, a sandy layer begins at a depth, into which it is better to hammer a needle than to remove sand with an auger.

The sandy walls are not strong and begin to crumble inside the trunk.

A burr can be made from a garden or fishing drill. To do this, you need to increase the auger with additional sections of tubes up to a length of 2 meters.

If the sand layer starts closer to the surface, the drill does not need to be extended.

The price of a garden drill on Yandex Market:

Set for a well a needle

For self-drilling, they sell a ready-made kit for the Abyssinian well.

The set includes:

- The filter is a needle.

- Couplings, for fastening sections.

- Threaded pipes.

The price of the kit depends on the number and diameter of pipes. Metal pipes are made of stainless steel or galvanized. Stainless steel kits are 10-20% more expensive than galvanized ones.

Criteria for choosing an Abyssinian well

Any country dweller, before starting the construction of an Abyssinian well, must find out if it suits him. After all, the Abyssinian is a shallow well (up to about 10 m), and it is placed in watered sand of large and medium fractions.If the water-bearing layer is lower, for example, at a depth of 12-15 m, then you need to think carefully whether it is worth making an “igloo”. The reason is that a self-priming pumping station will not lift water through a pipe if the distance from the top of the well to the water surface exceeds 8-9 m.

Maximum water intake depth specified in the technical characteristics of the pumping station.

One of the options for solving the problem of a deeper aquifer can be the construction of an Abyssinian and the installation of a pumping station in the underground, basement or well.

Alefandr User

I have a well was dug in the area 15 rings, but not much water. In fact, the level is kept only on the last ring. This is about 500 liters, which is completely insufficient for the normal supply of a large family. I don't want to deepen the well with repair rings. I think to score an Abyssinian right in the well. The question is, is it a working idea or not?

In such a situation, in order not to throw money away, you need to act according to the following algorithm:

- We learn the flow rate and depth of neighboring wells.

- We find out whether the wells were drilled in sand or limestone.

If about 5-7 m remains on the sand and up to the water-bearing sandy layer, then you can try to hammer in the “needle”. If the sand is below 10 m, then the pump will not be able to lift water from that depth.

In addition, it must be taken into account that if the pump is placed in a well above a water surface, then in the event of seasonal fluctuations in the level, the station may be flooded. Secondly, if it is necessary to maintain the pump and the “needle”, for example, airing the Abyssinian, you will have to climb into the well to eliminate the problem.

Therefore, if there is not enough water in the well, but at least one ring is collected during the night, it makes sense to deepen the source by another 1-2 m.For example, using instead of repair rings a plastic HDPE pipe with a wall thickness of 6-8 mm, the desired diameter and with stiffeners. It also does not make sense to install the Abyssinian in clay or in solid layers of soil, the "needle" simply will not work.

Therefore, we first find out what kind of soil is on the site, and only then do we choose the source of water supply.

You can find out about the structure of the soil and the depth of the aquifer by asking neighbors who have wells: at what depth is the water from the surface, and were there any problems when digging. For example, workers ran into a thick layer of clay or ran into a quicksand. A hint may be the wide distribution of active Abyssinians in a village or village.

The second way is to conduct exploratory drilling, for example, to find out the type of soil and choose the design of the foundation. The results can say a lot about the possibility Abyssinian well construction.

dmp-best User

I want to make an Abyssinian well on the site. The question is whether it will suit me if the soil on the site is the following.

As can be seen from the borehole passport, water-saturated sand of medium size lies at a depth of ten meters. Those. the best option for the “needle”, but at a depth of 4.5 m there is fine sand saturated with water with gravel inclusions. And gravel and stones are a serious obstacle to clogging the Abyssinian well, because. the tip of the “needle” may break, the filter mesh may be peeled off, the pipes will bend or the fittings will burst. The way out is to drill a "needle".

Pros and cons of the Abyssinian well

Starting the arrangement of a well-needle, it is important to consider all its pros and cons

Well benefits

The positive properties of wells include:

- Ease of organization with your own hands.

- Versatility and practicality.

- Small dimensions.

- Ease of repair and scheduled maintenance.

- Mobility.

It will take no more than 1 day to organize a hydraulic structure. The preparation of equipment and the drilling process do not require external assistance. At the same time, if during driving you encounter a cobblestone or other hard rock, you can quickly dismantle the device and move it to a more favorable area.

Well Disadvantages

The key disadvantages of the equipment are:

- Low flow rate compared to a traditional well.

- Loss of productivity during the dry season.

- Probability of collision with obstacles.

If you need to connect a house in which a large family lives to the water supply, the needle well option is not suitable. However, such a well will be a good auxiliary system, supplying a sufficient amount of fluid for technical needs.

What to consider before making a decision?

Arrangement of the Abyssinian well is not possible in any territory.

Potential Obstacles

Restrictions relate to the type of soil, the depth of the aquifer in a particular area, the quality and quantity of water.

- The soil of the site is the first possible stumbling block. Making an Abyssinian well is not difficult if the soil is sandy - light and pliable. Work with clay heavy soil looks completely different, it will already require considerable effort. The worst option is a rocky area full of large boulders. In this case, in order to save nerve cells, it is better to immediately abandon this idea.

- The first aquifer is another potential obstacle. The depth of this formation should not exceed 8 m.Otherwise, it will be very difficult to raise the water, a powerful pump will be required, and this operation will be beyond the power of a manual device. Therefore, at first it is better for the owner of the site to ask the neighbors what the depth of the horizon is in this area. Or check it yourself - with the help of a rope with a load and someone else's well.

- Compliance of water with sanitary standards. Before planning the construction of the "Abyssinian" you need to make sure the quality of the water. The first aquifer is the most vulnerable layer. It can be spoiled by carelessly built cesspools in the neighborhood, nearby factories, factories, nitrates and pesticides, which are generously sprinkled on the fields. Therefore, a sample taken from neighboring wells in late spring is best taken for bacteriological and chemical analysis at the SES.

- Well flow rate. This is the maximum volume of water received from the well per hour. This indicator depends only on the saturation of the aquifer. The possible volume is 0.5-4 m3 per hour, but specific figures can be found in one case - if the neighbors have already built a similar Abyssinian structure.

If all checks gave a positive result, then we can assume that there are no serious "contraindications" for installing an Abyssinian needle.

Hydrogeological "amateur activity"

In some cases, difficulties arise in determining how close the water horizon is to the surface. To understand whether the site is suitable for an Abyssinian well, it is enough independently carry out small hydrogeological works - carefully explore the area.

The territory is suitable for an "Ethiopian" structure if:

- it is located in the lowland;

- moisture-loving plants with deep roots settled on it (for example, nettle, burdock, coltsfoot, reed, hops);

- not more than 500 m away, sources of drinking water were found - barrels, springs or key ponds, springs.

Making a filter for an Abyssinian well

The duration of the well and the quality of the water supplied to the site largely depends on technical characteristics of the filter and technological features of its manufacture. This is especially significant when the quality of the water source in the soil is low.

The device has the following requirements:

- the whip must have a steel tip made of solid material and attached by threading or welding;

- the base of the cone attached to the pipe must be larger than the outer dimension of the pipe by the thickness of the filter + 10 mm to ensure that its integrity is maintained;

At the bottom of the pipe, a structural element is created for the intake and filtration of water from the aquifer. To do this, stepping back 0.5 m from the end, drill a system of holes with a diameter of 6-10 mm in a checkerboard pattern with a step of 50 mm. The total height of the intake part can vary between 0.5 - 1.0 m.

Note! To increase the degree of purification of water from solid inclusions, the size of which is otherwise assumed to be equal to twice the value of the cross section of the perforation, it is required to make a filter element. The filter can be a fixed stainless steel mesh with a cell of 2 mm (a smaller section can quickly become silted) and / or a wound wire with an anti-corrosion coating or a design with an appropriate pitch of turns;

The filter can be a fixed stainless steel mesh with a cell of 2 mm (a smaller section can quickly become silted) and / or a wound wire with an anti-corrosion coating or a design with an appropriate pitch of turns;

The filter element is fastened with wire twists or soldering using tin solder that does not contain lead, which can poison water.

The prepared section of the pipe is wrapped with stainless steel wire with a diameter of 1.5 mm in the form of a spiral winding, trying not to close the holes in the pipe. A stainless steel mesh with small diameter holes is wound over the wire in two layers, which is fixed to the pipe with clamps.

The mesh or wire on the “needle” filter holds the sand and the already purified water enters the pipe.

The mesh or wire on the “needle” filter holds the sand and the already purified water enters the pipe.

In order to provide better filtration and reduce the size of suspensions in the water, a geotextile tape is wound over the steel mesh, which is also fixed with clamps. The figure shows the stages of manufacturing a filter on a steel pipe device.

Abyssinian well filter: on top - a pipe with holes; in the center - a pipe with holes and winding wire; below - a pipe with holes, wire and mesh.

Abyssinian well filter: on top - a pipe with holes; in the center - a pipe with holes and winding wire; below - a pipe with holes, wire and mesh.

Additionally, after installing the steel wellpoint to the required depth, corresponding to the occurrence of the aquifer, a plastic pipe can be placed inside the pipe, equipped with a filter similar to that described above. This will ensure the high quality of water obtained from the Abyssinian well and long-term uninterrupted operation of the device.

Well from Ethiopia - start construction

A well-needle is a drill string that is buried in the ground along impact drilling technologies without the use of a casing pipe.This technique is almost never used in professional drilling. But to create a summer cottage water intake point with your own hands, it is ideal.

The essence of this work is as follows. You need to break through the ground using pipes with a section of about 1-1.5 inches to the depth of the water layer. To achieve this, attach a thin tip to the end of the tubular. It is due to such a simple device that a well-needle is created.

Fine tip attached to the pipe

To equip an Abyssinian well, you will need a set of different pipes (it is not necessary to purchase new products, already used ones are quite suitable), a welding unit, a sledgehammer, a garden drill, a stainless galloon mesh, a wire with a cross section of about 0.25 mm, a hammer, clamps, a drill, grinder, a pump operating on the principle of creating a vacuum, special couplings.

With your own hands, you make a well according to the algorithm below. First, take an ordinary garden drill and use half-inch pipes 1–2 m long to build it up. Let us explain what is meant by this operation. You need to use bolts and couplings made from 3/4 inch pipes to create a special design. And then attach it to the drill.

The structure of the pipes should be as tight as possible. If this recommendation is not followed, the design will not be able to fulfill its task. The required tightness of the joints of pipes is achieved by sealing them with paint (oil), silicone compounds, sanitary flax.

At the end of the homemade design, install a special filter in the form of a needle.It makes the produced water clean, protects the well from silting and helps the drill to break through the soil. It is desirable to make the filter from pipe sections that were used to create the structure. Then between its elements there will be no reaction of electrochemical corrosion.

In the next section, we talk in detail about how to make a filter for the Abyssinian well. Study it carefully.