- Which is better - a well or an Abyssinian well

- Where construction is possible

- Well Creation Technology

- Drilling

- Blocking with a headstock with a substock

- Stuffing headstock with plug

- Barbell driving

- Independent development of the Abyssinian well

- Filter design

- Well construction technology

- Technical capability

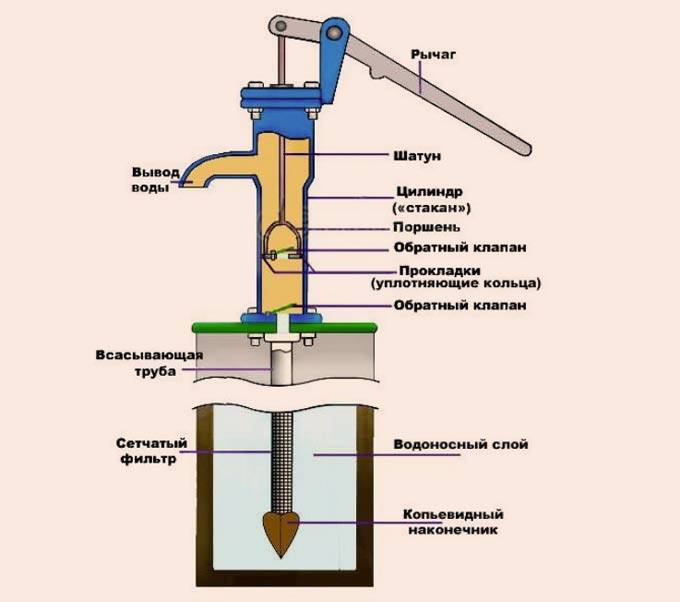

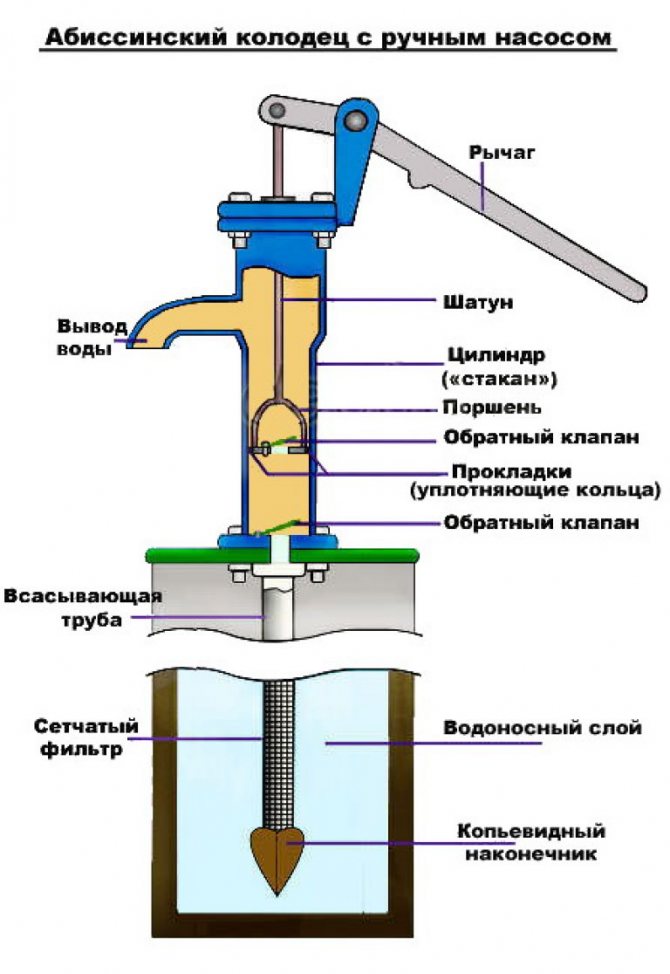

- Operating principle

- Barrel manufacturing technology

- How to build an Abyssinian well

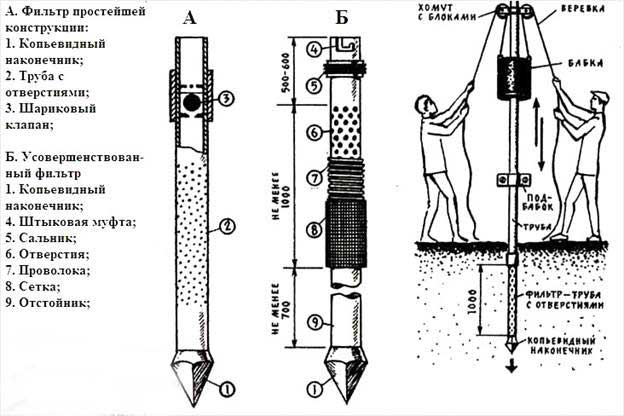

- How to make a filter

- Drilling technology

- "Arrangement of the device"

- Can't do without a woman

- Gentle drilling method

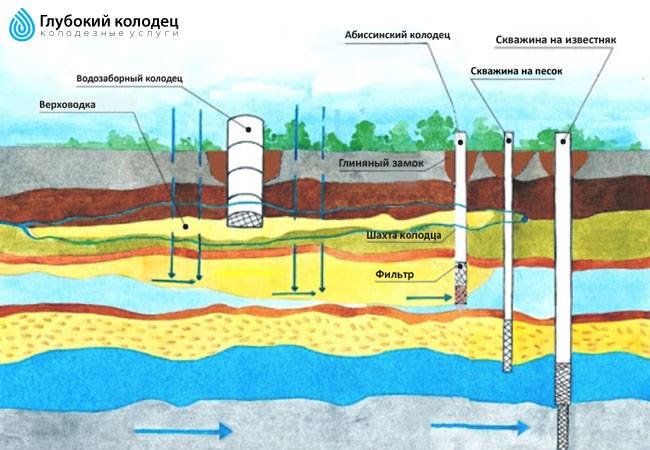

Which is better - a well or an Abyssinian well

Ordinary wells are still often used in suburban areas. The construction of this facility is the cheapest option for water supply. The whole complex of works on digging such a structure with a depth of 12 m will cost about 65-70 thousand rubles. At the same time, digging one ring in heavy clay soil costs 15 thousand rubles.

The advantages of wells include:

- comparative cheapness of construction;

- uninterrupted water supply;

- ease of operation;

- service duration.

The disadvantage is the small volume of water supplied, the possibility of contamination with perch water, the need for regular cleaning and disinfection.

The construction of the Abyssinian structure will take less time. It can be arranged in the basement or other type of room.The water from such a well is cleaner, since foreign objects and perched water are not allowed into it. It can be used without purification. The Abyssinian well has a fairly high productivity. The service life of the structure sometimes reaches 30 years.

Where construction is possible

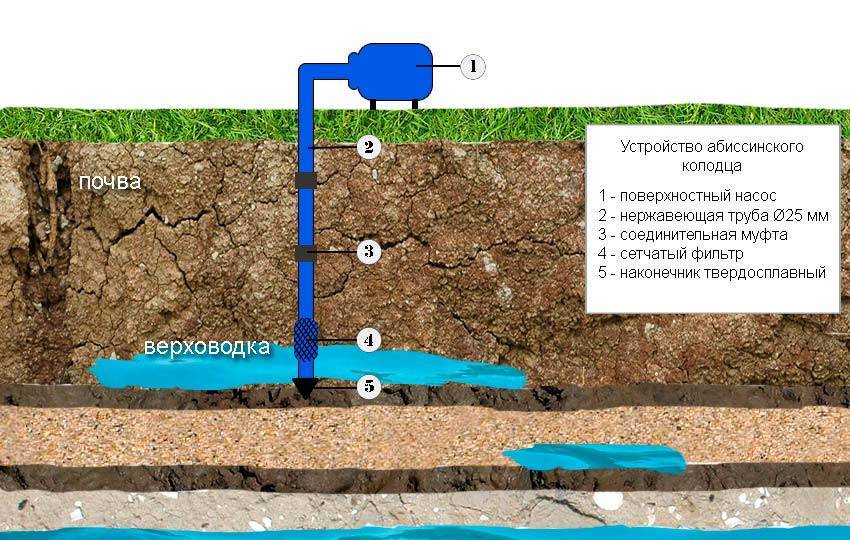

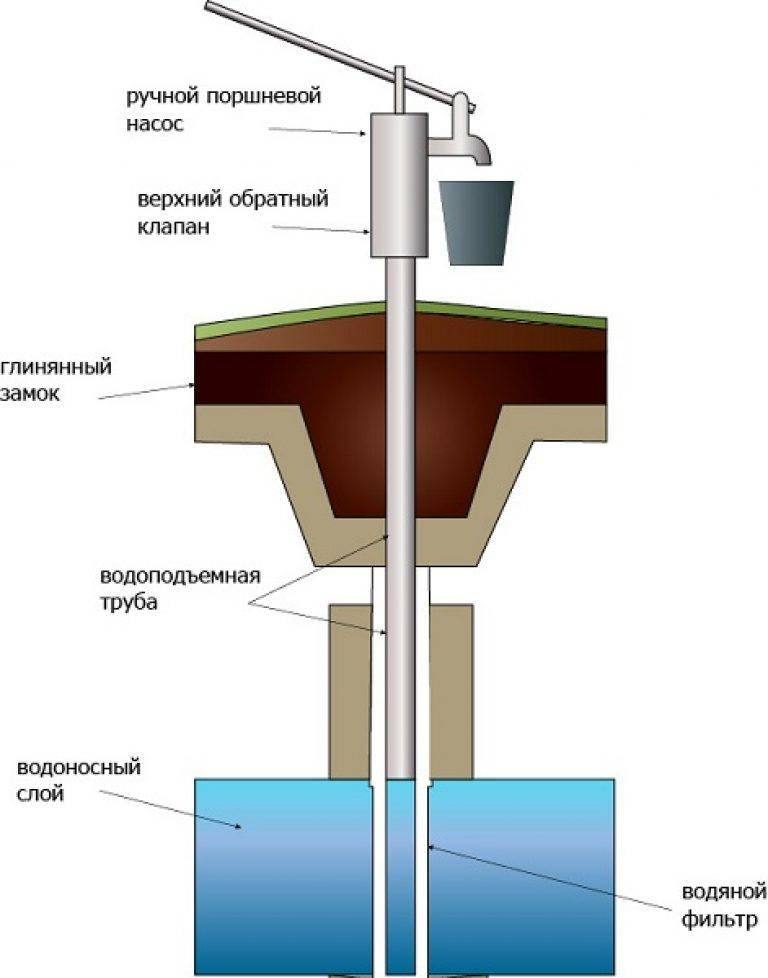

It is necessary to arrange such a well in areas where the aquifer is within 4–8 m of depth or in places where there is sufficient pressure in the aquifer up to 15 meters, which can raise water to a depth of 7–8 meters. If the water from the reservoir rises a little below 8 m, then you can simply install the pump, deepening it into the ground.

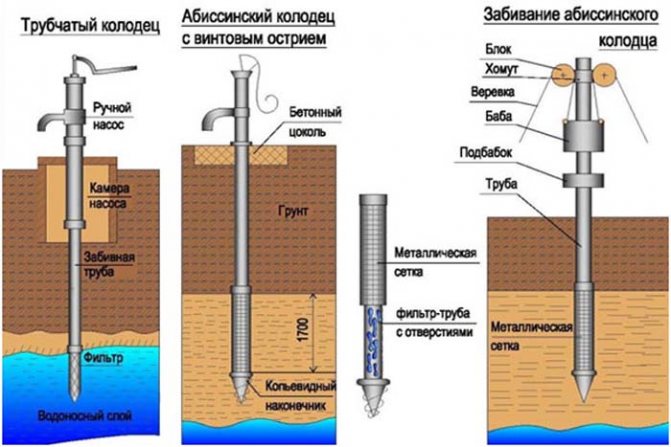

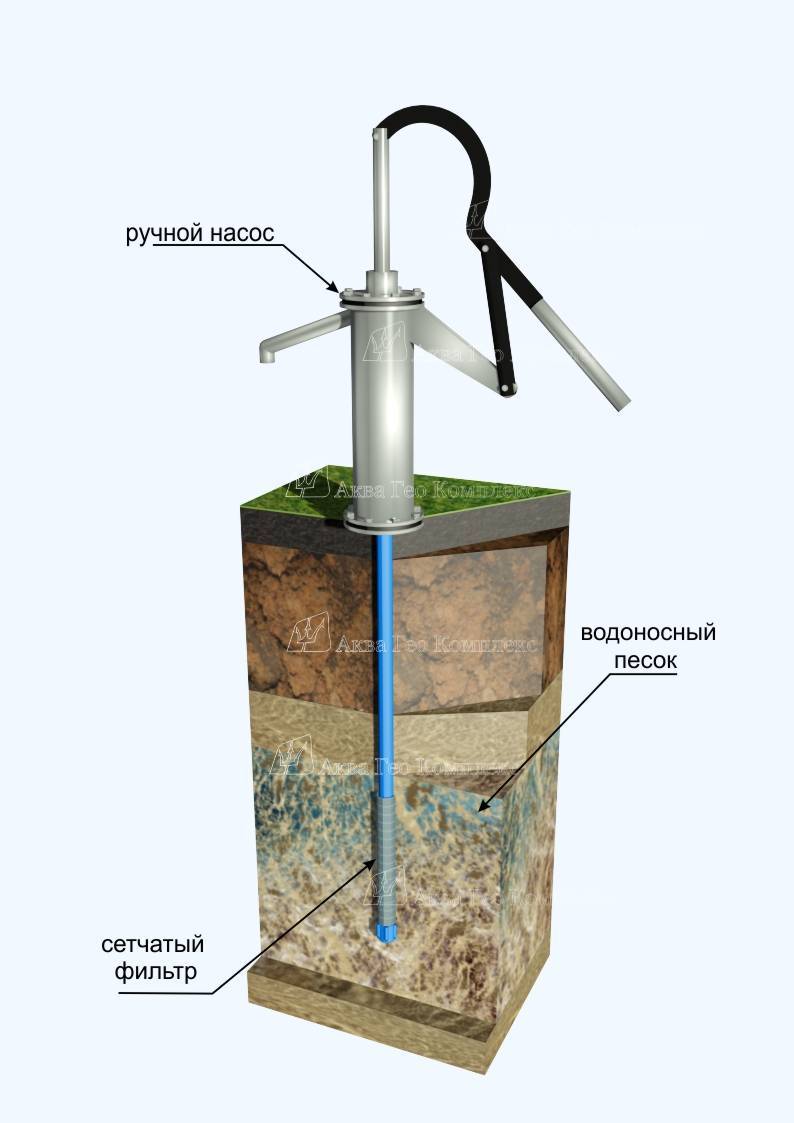

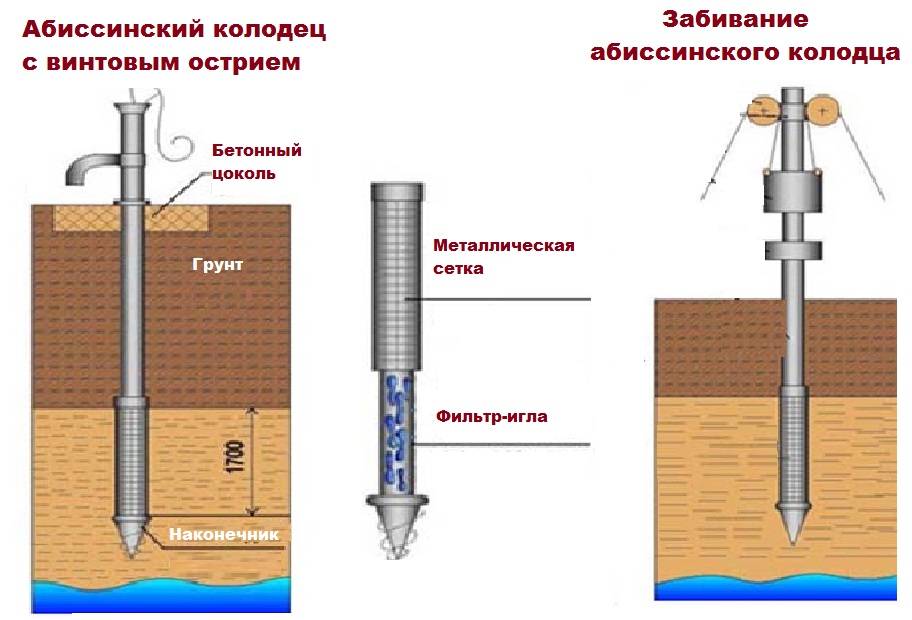

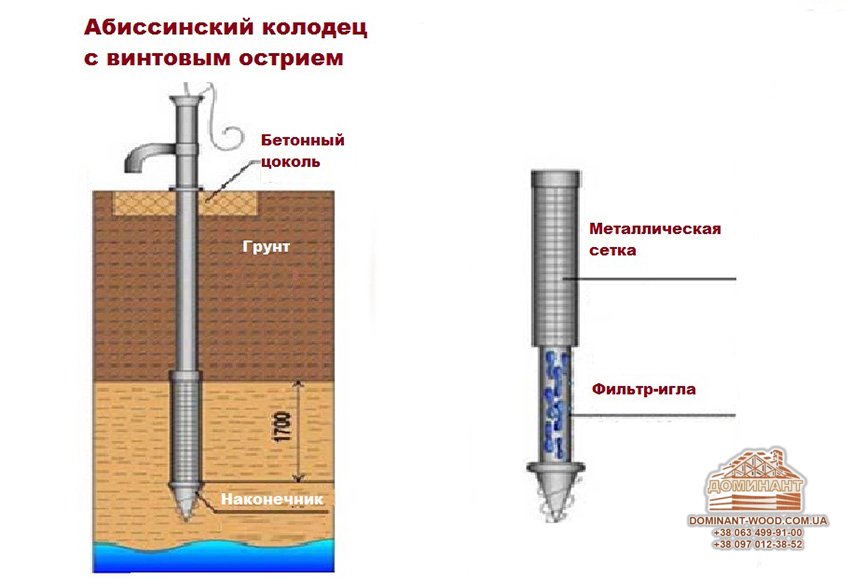

The main part of the Abyssinian well is a perforated pipe with a head (wedge tip) and a filter. The tip should be 20-30 mm larger in diameter. It is advisable to make the filter from metal, the same as the material from which the pipe is made: this will reduce the level of electrochemical corrosion. Holes 6–8 mm in diameter are drilled in the pipe with a diameter of 0.6–0.8 m along the length of the pipe. In this section of the pipe, a wire is wound with a gap of 1–2 mm for free passage of water. After winding, the wire is soldered to the pipe in several places and at the ends of the wire. After that, with the help of soldering, a mesh of plain weaving made of non-ferrous metal or stainless steel is fixed.

Various devices are used to deepen the pipes, but it is better to first dig a hole of 0.5-1.5 m, and then drill a well 1-1.5 m. so that the pipe does not move when plugged.

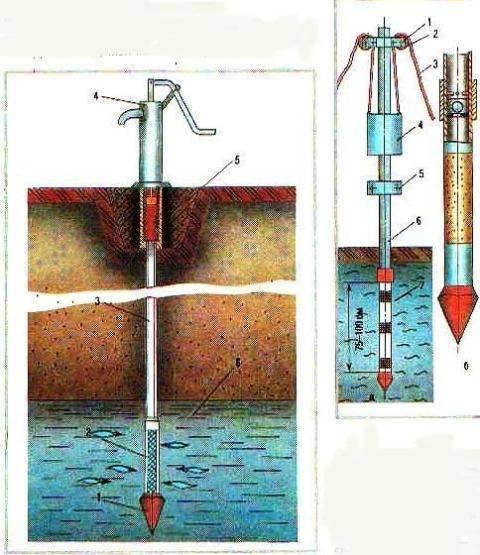

Often a pile driver is used to deepen pipes, but other devices can be used.Deepening the well pipe with a metal rod with a diameter of 16-22 mm inserted into the pipe consists in raising the rod 1 m high and applying sharp, vertical blows to the tip. As a result, almost all the load falls on the tip. You can lengthen the rod as the well deepens, or you can fix the flexible cable at the top of the metal rod. This method is called shock-rope.

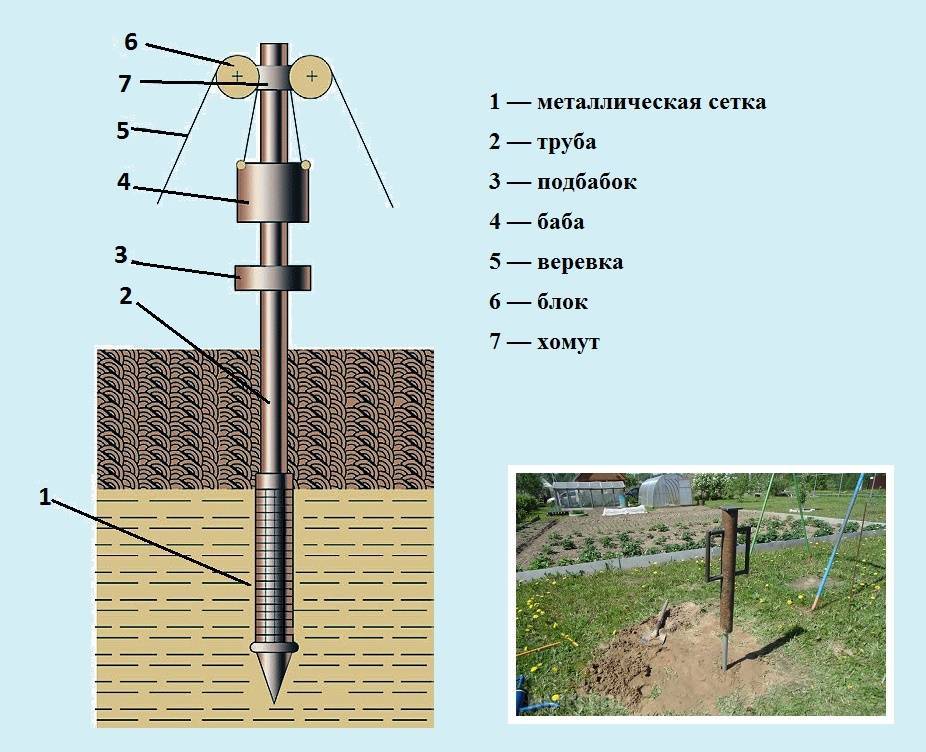

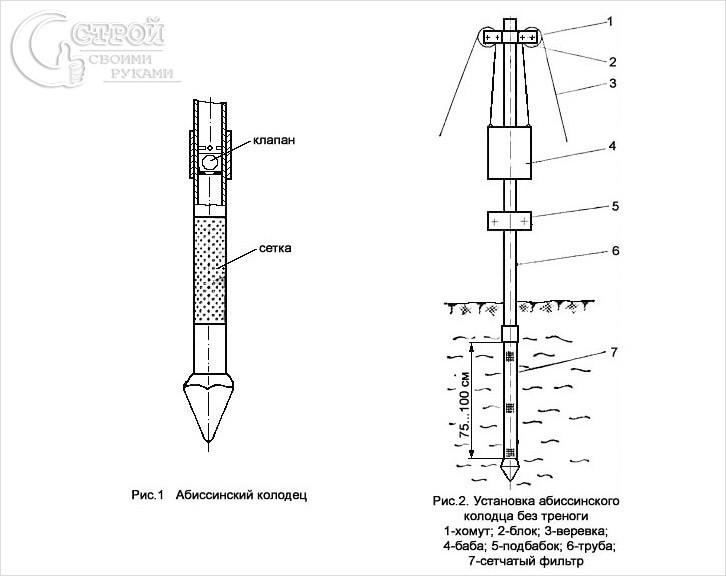

The technology for deepening pipes for an Abyssinian well is as follows: it is necessary to use a headstock weighing 25–30 kg, this device is lifted up by the handles and lowered sharply, the impact load should fall on the nozzle attached to the sub-pipe. When deepening the well, the nozzle is moved up the pipe and, if necessary, another pipe is screwed on.

If the depth of the aquifer is unknown, then when the pipe is clogged by 4 - 5 m, periodically check if water has appeared. If you have a thin aquifer and it is not known how deep it is, then you can clog the pipe below and not get water.

If the Abyssinian well is installed in clay soils, then the filter mesh can become very dirty, and you may not understand that you have fallen into the aquifer. In this case, it’s better not to rush, and when even a minimal amount of water appears in the well, you need to pump it, and if possible, rinse the filter every 0.5 m. To do this, use an electric pump, insert a hose into the pipe and wash the mesh with clean water.

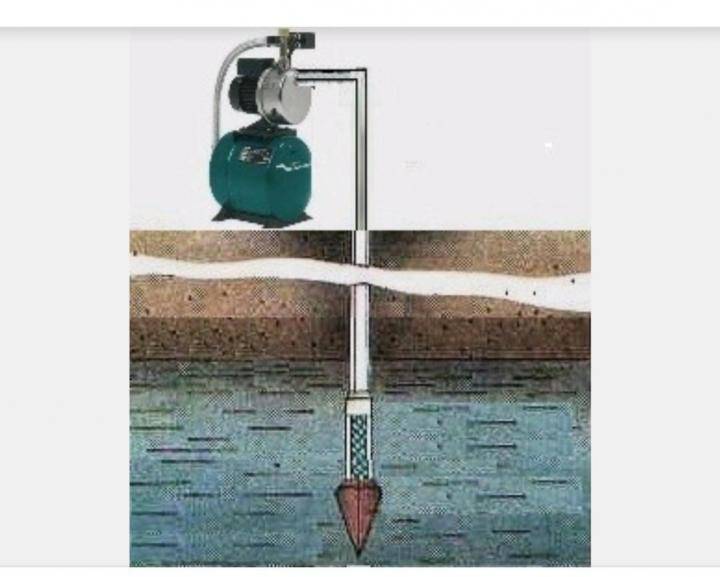

An electric self-priming pump is used to lift the water. You can also use a piston pump. After installing the pump and pumping the well, a clay castle is arranged around the pipe and a blind area is made of concrete.The time required to build an Abyssinian tube well is about 5-10 hours, and in most cases depends on the nature of the soil and the depth of the aquifer.

The Abyssinian well will serve 10-30 years, the period depends on the aquifer, the quality of the work and the material used. Water can be pumped continuously from the well for several hours, the productivity of the well is usually 1-3 cubic meters. water per hour.

Well Creation Technology

The Abyssinian well is equipped in two ways: by driving or drilling a well. To implement the first method, the so-called driving woman is used, and in the process of work, water is periodically poured into the pipe. At the moment when the water abruptly goes into the ground, the pipe is dug another 50 cm, and then the pump is mounted. The driving method is good when you create a well yourself, but this method is not without drawbacks. First, if a boulder gets in the way of the pipe, the needle can completely deteriorate. Secondly, when clogging the well, you can skip the aquifer.

The second method, which involves drilling a well, requires the help of craftsmen and the involvement of special equipment, but when implementing this method, you are guaranteed to find water in the well.

There are several ways to clog a well-needle:

- With the help of a sliding headstock and a tailstock - a special part that tightly covers the pipe and does not slip down. In the process of driving the needle, the worker lifts the headstock and forcefully lowers it down to the substock. The part is gradually moved up the pipe and worked in the same way until an aquifer is found.

- The second method of creating an Abyssinian well is driving with a headstock with a plug.In such a case, the blow falls on the upper part of the pipe, while the plug is installed at the end in order to protect the thread from damage. This method is good because it allows you to use the maximum impact force.

- You can also hammer a well with a rod. In this case, there is no danger of bending the pipe, and the process itself is easier and faster. The driving rod can be made from a hexagon or a round rod. Separate parts of the bars are twisted together using a threaded connection. In order for the rod to be removed from the ground after work is completed, its length must be greater than the depth of the aquifer.

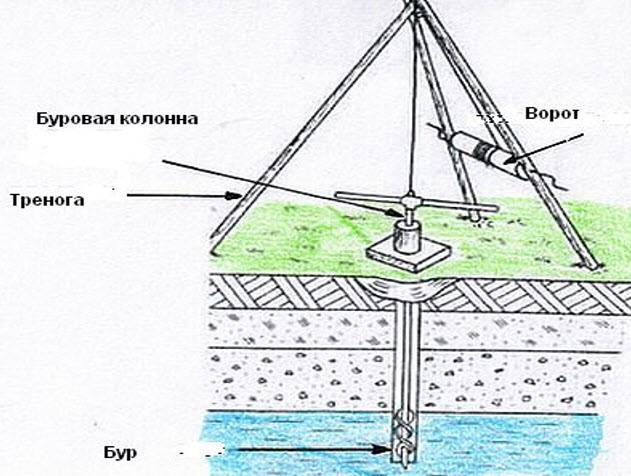

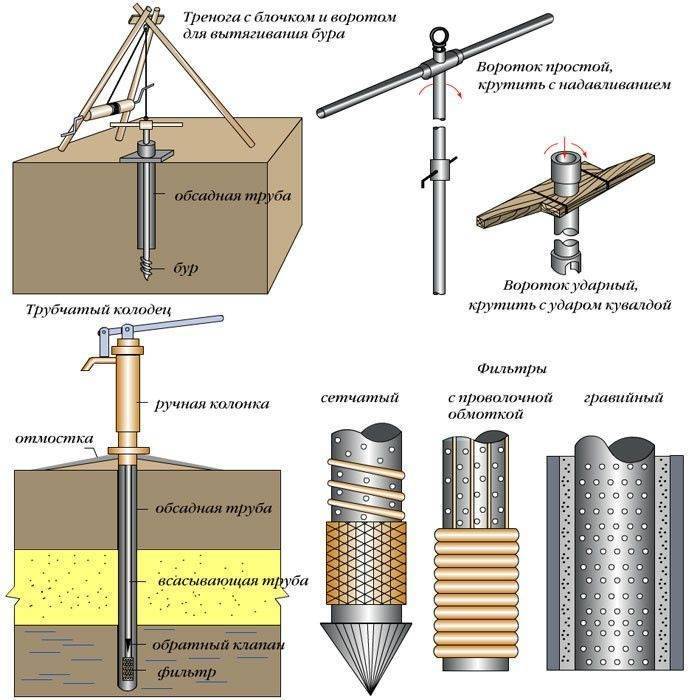

Drilling

This method is often used to pass the soil to the quicksand, as the water-saturated sandy layer is called, which, due to its friability, can crumble immediately after the drill advances in it. To avoid this, well drilling is combined with casing immersion.

Boers for the production of abassinian well needle can be welded in the home workshop. It is optimal to use two modifications:

- a frame drill, which is a U-shaped structure, and is used to pass through a dense clay layer,

- frame drill with a cylinder, which is installed inside the frame and serves to collect and subsequent evacuation of soil from the channel.

The drilling technology is quite simple - the passage of soil layers is carried out sequentially, with a gradual build-up of the working part with rods.At the stage of drilling with a drill with a cylinder, it is better to use a winch (purchased or assembled independently from a starter and a cable, equipped with restrictive washers and installed on a stand). Such a device will make it easy to remove the drill, rods and soil accumulated in the cylinder from the channel, which together give a considerable weight.

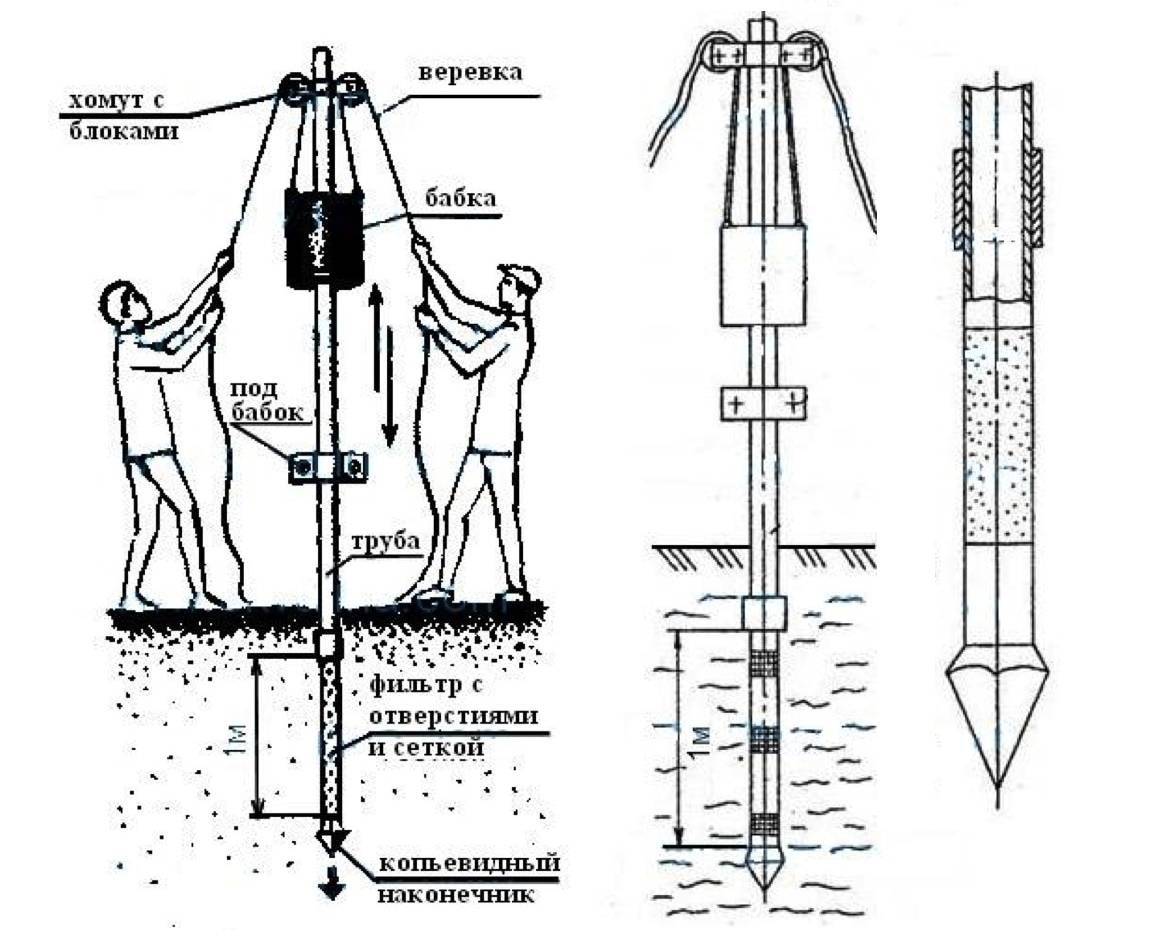

Blocking with a headstock with a substock

A subhead is a cone-shaped element fixed to the rod with a thrust washer. A simple design allows you to achieve maximum efficiency.

The headstock sliding along the rod, falling after lifting, gives off energy to the subheadstock, due to which the rod enters the ground. In order to avoid damage, the tailstock cone must be made of a stronger material than the headstock. The thrust washer prevents the cone from flying off the rod, even with very strong impacts. On the contrary, at this time he "sits down" even more firmly.

Stuffing headstock with plug

To implement this method, they use not a sliding bar, but a headstock. To protect the thread of the rod, a plug is installed in the upper part. It is recommended to use grandmas from 30 kg and more.

Barbell driving

Rod driving equipment - hexagonal rods, the diameter of which allows them to be placed in the column. Each of them is supplied with a thread for increasing the length (internal on one side and external on the other). For reliable fastening, the length of threaded sections must be at least 2 cm. The process of driving a casing pipe immersed in a drilled well consists in throwing a rod into the rod cavity.

Independent development of the Abyssinian well

You can make an Abyssinian well with your own hands using a simple home-made installation.To perform the work, it is necessary to prepare the following tools and materials:

- electric drill;

- grinder;

- welding installation;

- sledgehammer and hammer;

- set of gas keys;

- a water pipe in sections of 150 cm each;

- cast-iron couplings - for driving pipes, steel - for connection;

- steel wire 0.3 mm thick and mesh (galoon weaving) for the filter;

- sealant for joints;

- check valve;

- pump equipment.

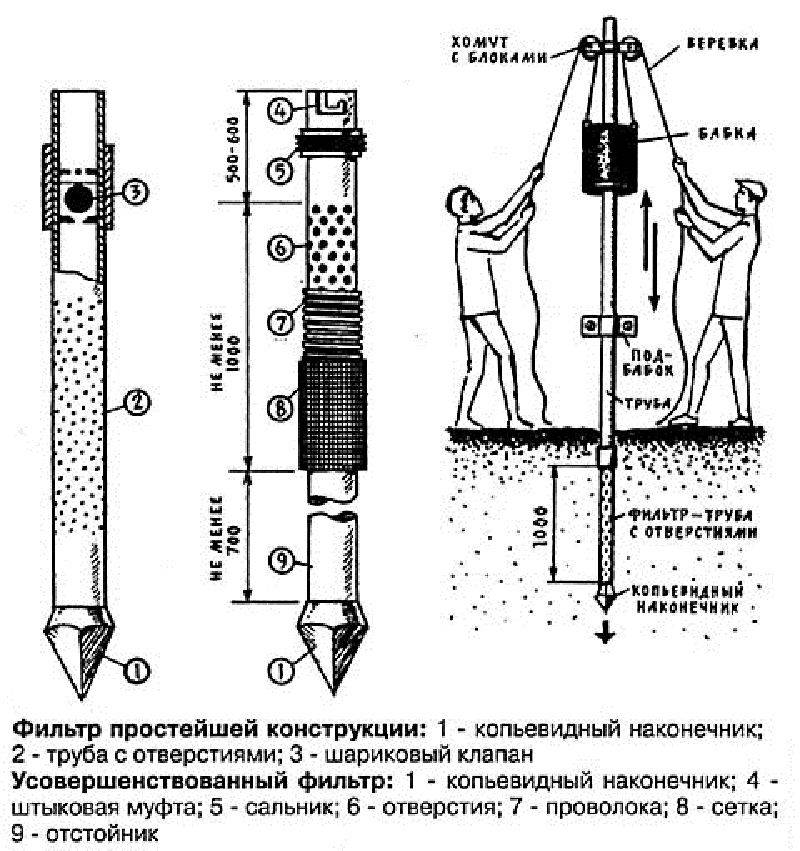

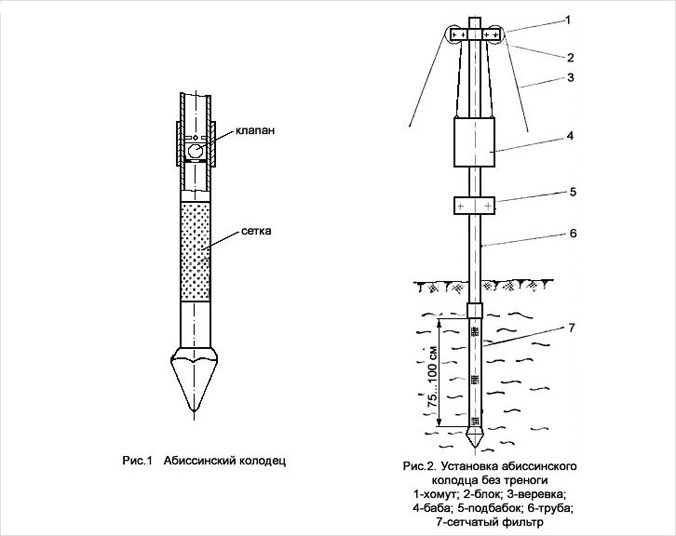

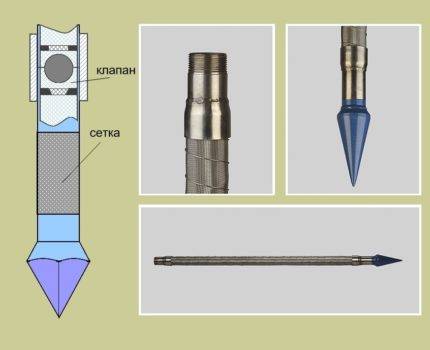

Filter design

A tip with a filter is made from a small piece of pipe (length up to 85 cm), to which a cone-shaped tip is welded. Small holes are made on the surface of the tip for water supply. A wire and a stainless steel mesh are wound onto the pipe with additional fixation on metal clamps in increments of 9 cm.

Well construction technology

The process of driving a pipe into sandy soil is quite simple, but requires a little skill. Experts recommend performing work on the arrangement of a well of this type in the following order:

- A garden drill drills a shaft of the required depth and diameter. The optimal depth of the structure is determined by the sound method - the passage of clay soils does not create noise, a strong rattle is felt in sandy soils of a large fraction, and a slight rustle in sandy soils of a fine fraction.

- A water intake pipe is being installed with a phased connection of the segments with metal couplings. Work is carried out until a wet sandy layer appears. Next, a depth check is performed - a small volume of liquid is fed into the casing. If the liquid seeps quickly - the depth is suitable, if with delays - it is necessary to deepen the pipe by 50 cm.

- Filter installation.A pipe section with a homemade filter is mounted using threaded couplings. The finished structure is immersed to the bottom to the sand layer, and a cast-iron coupling is screwed in the upper part.

- Next, the check valve and pumping equipment are installed. All elements must form a single sealed structure, otherwise the finished water supply system will not function effectively. To seal joints and increase the strength of the connecting elements, you can additionally use linseed hemp or oil-based paint.

- At the end of the work, the hydraulic structure is pumped to obtain clean drinking water. First, an air plug passes, then a cloudy liquid, after which purified water appears.

- To protect the water intake point from the penetration of pollution and runoff into the mine, it is recommended to concrete a small area around the structure. It should rise above the top level of the soil by 5–8 cm.

Video about the technology of arranging a homemade well-needle.

The main advantage of wells is the reliability of structures and the safety of the arrangement. In addition, they are durable, practical and easy to use.

A do-it-yourself equipped Abyssinian well can be located in a summer cottage, in a garage or cellar. The construction of such a hydraulic structure does not require expensive equipment, and all work can be done independently without the involvement of contractors.

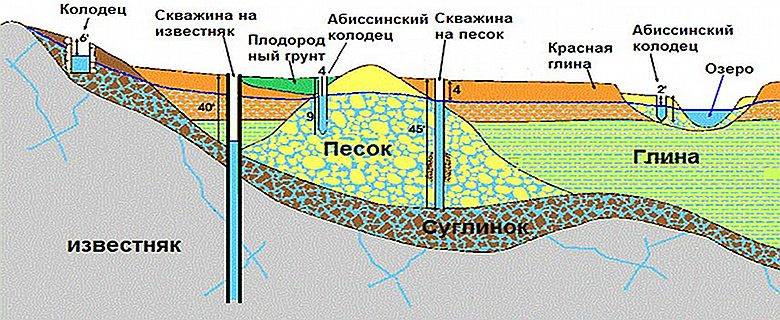

Technical capability

The depth limitations of the Abyssinian well are due to the use of a vacuum pump. A surface pump will not be able to lift water from a depth of more than 8 meters.

In a significant part of the territory of Russia, the aquifer is shallow.Most often it is just 5-8 meters, which makes the construction of Abyssinian wells quite appropriate.

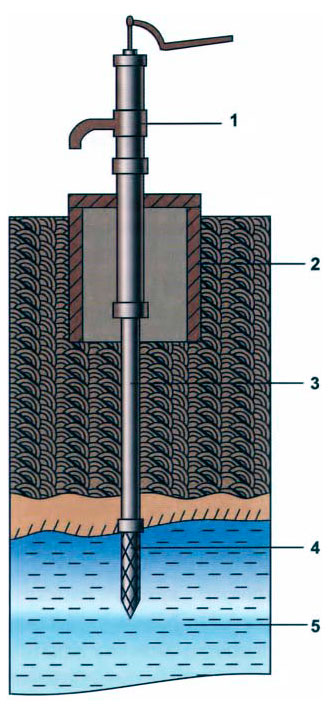

Scheme of placement of the Absiinsky well on the ground

Problems arise due to the presence of thick layers of clay, which is not possible to break through. You can move on to more expensive drilling that allows you to overcome such obstacles, but you can try to punch a well in another place.

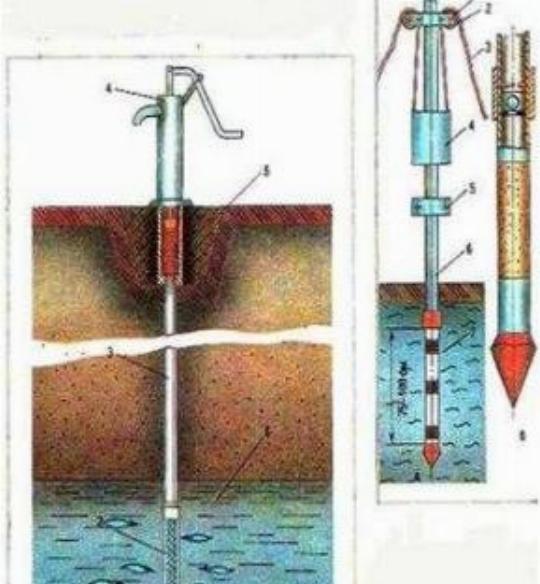

Operating principle

Soil piercing method

Soil piercing method

to the aquifer was invented centuries ago in northern Africa.

The wide shafts of wells in the oases were covered with sand, collapsed due to soil erosion.

Creation and cleaning of well shafts

required a lot of time and human resources.

The Abyssinian version of the well made it possible to get water anywhere at minimal cost.

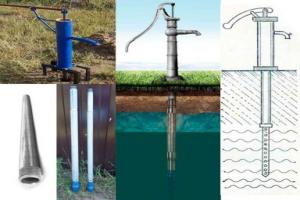

For the construction of wells of this type, steel pipes with a diameter of one and a half inches are used (see the video on how to properly drill a well for water).

A sharp tip is attached to the end of the first pipe

, which pierces the soil, allowing the pipes to lower, and subsequently plays the role of a filter.

A vacuum pump is attached to the last section of the pipe, with the help of which water rises from the aquifer.

This design, in fact, is a well. When there is a shortage of water in one well, another one is created at some distance.

Despite the small cost, creating a well may not work. The simple technology, however, requires a certain level of water in the pipes after the aquifer is punctured.

The minimum level must be at least 8 meters

. Otherwise, the water will be expelled faster than it is coming from the water reservoir.

Average depth of Abyssinian wells

is 10 to 15 meters. But it all depends on the specific soil and the depth of the water veins.

The very principle of the device is designed to use the first clean layer of water (). A dozen and a half meters of sand and loam well filter ground and sedimentary waters.

Determine the level of water occurrence

can be from neighbors or with the help of measurement drilling. In some cases, Abyssinian wells are lowered to a depth of 20-30 meters.

Thick layers of gravel, compressed sandstone and large boulders will not allow you to puncture the soil. In these cases, they look for another place on the site.

INTERESTING FACT

. The soil consists of layers of different rocks arranged one above the other.

Depending on the geological features of the area, these can be:

- gravel,

- dolomite,

- limestone,

- sand.

Splits of different origin

, voids, cracks are filled with groundwater. The water layer is limited by two layers of clay.

Barrel manufacturing technology

There are no Abyssinian wells in industrial production. The manufacture of the installation is ordered in the workshop or made by hand.

To facilitate immersion in the ground, the lower edge of the first rod is equipped with a spear-shaped tip, its diameter in the wide part is 3-5 cm larger than the diameter of the main pipe, the length is about 10-15 cm

In order to make a well, a needle will need:

- Thick-walled pipes VGP, in the marking of which it is indicated "reinforced". The optimal size of the outer diameter of the rolled pipe is from 25 to 40 mm. It should be remembered that the thicker the trunk, the more difficult it is to drive it into the ground, and the thickness of the pipe will not affect the flow rate of the well.

- Steel tip machined on a lathe. The length of the part is 10-12 cm, Ø is 1-2 cm more than the Ø of the pipe, so that the friction of the soil against the trunk does not slow down the driving process. The tip may be conical or pyramidal, but not welded from wedge-shaped pipe cuts.

- Steel mesh of dense galloon weaving, necessary for the installation of an additional filter. It will prevent the ingress of fine grains of sand and even clay suspension.

For the manufacture of the barrel, it is better to purchase a seamless pipe, which will definitely not crack when driven. The pipe must be cut into segments of approximately 1.2 - 1.5 m. In the drilling business, they are called rods.

The indicated dimensions are recommended based on the greatest ease of use. The specific length of the segments in the indicated interval depends on the expected depth of the working. It is desirable that one of them be 1 m for the final penetration into the water carrier.

A check valve in the form of a ball or plate prevents the outflow of water extracted by the pump into the well needle after stopping the electromechanical or manual pump

The extension of the barrel is carried out as the projectile deepens, it is carried out by successively winding up the sections of the VGP pipe.

To make connections along the edges of the segments, 7 turns of plumbing threads are cut and steel couplings are used. The connections are hermetically sealed, plumbing tow is placed in the thread.

It is not difficult to completely manufacture and install an Abyssinian well with your own hands, but if temporary operation is planned, it is wiser to rent a pile driver

A tip is welded to the first segment of the future column and equipped with a primitive filter - this is the water intake part.Holes Ø 8 - 10 mm are drilled in the starting section of the pipe so that the elements of the specified perforation are arranged in a certain checkerboard pattern.

Drilling holes begin, stepping back from the bottom edge of about 15 cm with a similar goal of maintaining strength indicators. At the junction of the first link of the column with the next rod, a check valve of the pumping system is installed.

Most often it is a ball that passes water only towards the pump.

Step 1: Before drilling a needle hole, you need to stock up on a tool. The total footage of the drill pipe string should be 2–3 m more than the estimated depth of the aquifer. To facilitate the drilling process and to organize a pit under the mouth of the mine, it is desirable to dig a pit

Step 2: If there are boulders and large pebbles in the geological section of the drilling site, it is advisable to stock up on drills with a chisel function

Step 3: Before starting drilling, it is necessary to check the screwing of couplings with drill pipes and their quantity. If the section is composed of sand and gravel deposits, the Abyssinian well can be started with a pipe equipped with a strainer and a cone-shaped tip. If it is not planned to install pumping equipment in the pit, it is better to protect the upper link of the drill string with a casing pipe, the cavity of which must be filled with sand or ASG

Installing a hand pump at the wellhead of the needle will reduce the cost of arranging the source to the limit

How to build an Abyssinian well

To build a structure, you can use one of two methods:

Zabivny.For driving structures into the ground, they usually use a “driving woman”. In this case, you need to constantly pour water into the pipe. After a sharp departure of water into the soil, the structure deepens another half a meter, then the installation of the water pump can begin.

Construction of the Abyssinian well

The driving method for creating an Abyssinian well is great, but there are a number of dangers. The main one is the probability of passing by the aquifer.

In addition, when a stone is encountered at a great depth, the structure can be completely damaged.

Small diameter drilling. This method guarantees the presence of water in the well, but its use requires special equipment.

To build a well, you must purchase:

- Drill and grinder.

- Hammer and sledgehammer.

- A couple of gas keys.

- Pancakes from the rod from 20 to 40 kg, for clogging the pipe.

- Welding machine.

- Garden drill with a diameter of 15 cm.

- Pipes: From 3 to 10 meters - ½ inch, 1 meter - ¾ inch.

- 1 inch well pipe, in 1-1.5 m pieces with short threads on each side.

- Bolts and nuts for 10.

- Grid made of stainless steel galloon weaving P48, 1 m long and 16 cm wide.

- Automobile collars of 32 standard sizes.

- Couplings: steel, for connecting pipes and cast iron 3 - 4 pieces, for clogging pipes.

- Wires two meters with a diameter of 0.2 - 0.3 mm.

- Pumping station, HDPE pipes, check valve and couplings.

How to make a filter

For the manufacture of the filter, an inch pipe is needed, which is approximately 110 cm long, a tip is welded to it in the form of a cone - a needle for an Abyssinian well.In its absence, you can simply flatten the end of the pipe with a sledgehammer. Next, you need to do:

- With a grinder, slots are cut on both sides of the pipe at a length of 80 cm through 1.5 - 2 cm, the size of the slot is from 2 to 2.5 cm. In this case, the overall strength of the pipe should not be compromised.

- A wire is wound onto the pipe.

- After that, a mesh is applied to it and fixed with clamps after 8 - 10 cm. The photo shows ready-made filters for the Abyssinian well.

Prepared well filters

In America, unlike the Russian Federation, for example, filter for such a well manufactured with an internal mesh and wire above and below the mesh.

Drilling technology

The instruction indicates that the drilling process is as follows:

- With the help of a garden drill, the soil is drilled.

- The structure is built up from pipes: ½ inch pipes are interconnected with ¾ inch pipe couplings and 10 bolts. Holes must be pre-drilled at the fixing points.

- The process of drilling a well continues until the appearance of wet sand flowing down from the surface of the drill. Further drilling does not make sense - wet sand will return back to the well.

- The pipe with the filter is clogged.

- Pipe sections are connected to the filter by means of couplings. FUM tape is screwed onto the thread.

- Then such a design with a filter from pipes is lowered to the sand, a cast-iron coupling is screwed on top of it.

- Pancakes are laid on this coupling from the rod. An axis is passed through their center, along which pancakes will slide and clog the pipe. The axle is made from a piece of pipe 1.5 meters long and ½ inch in diameter with a bolt at the end.

Installation scheme of the Abyssinian well

- From each hit with a pancake, the pipe sinks several centimeters.

- After passing from the sand level by half a meter, you need to pour some water into the pipe. If she disappears, the sand has accepted her.

"Arrangement of the device"

The design, invented a long time ago, has not changed very much since that time. Maybe because for some time the Abyssinian wells were forgotten. There are 2 ways to achieve the goal - driving method and drilling. No, there are more, but these are the most popular.

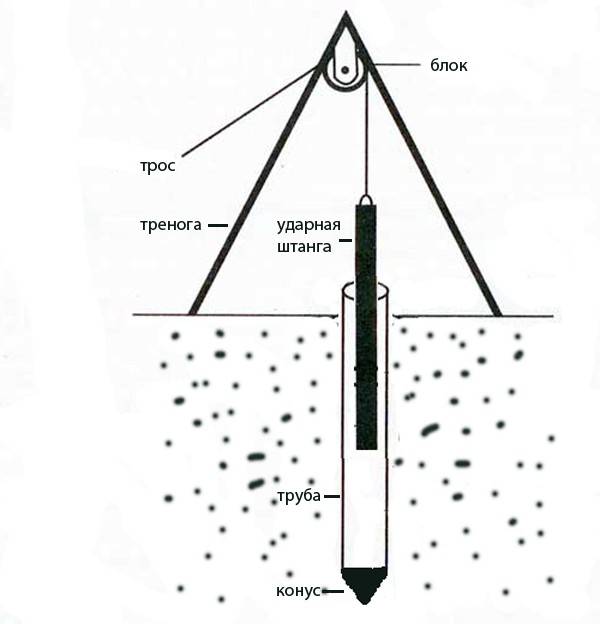

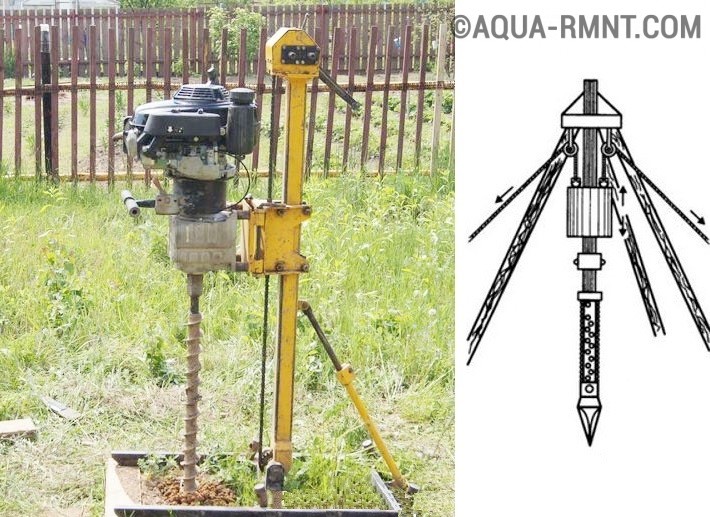

Can't do without a woman

This rather simple device consists of two main parts.

- Drill projectile. This is a sharp cone-tip that cuts the ground, and the trunk is a pipe, which is built up during work as it deepens into the soil.

- A pile driver is a part that includes a metal tripod and a heavy (concrete) projectile. The top of the first element is equipped with two blocks through which strong ropes (cables) are pulled. A load is tied to them, which is called a “construction woman”.

By pulling the ropes, the heavy-weight projectile is lifted to the very top of the tripod. Then they are released, as a result, the woman falls on the podbabok - a kind of anvil, which is securely fixed on a piece of pipe. This is a 2 piece clamp. Its surface area is greater than that of the bottom of the projectile.

As a result of such actions, the trunk gradually goes into the soil. When one section of the pipe is immersed in the ground, the bollard is removed, a new one is screwed to the trunk, then the clamp is fixed on it again. Such work is carried out until the aquifer is reached by the stackable pipe. It is not only opened, but also deepened into the layer by at least a meter. Experts recommend crossing it by 2/3, but an amateur driller is unlikely to know the exact dimensions of the aquifer.

To periodically check for the appearance of water in the trunk, a rather simple folk invention is used - a large nut fixed horizontally on the cord. When it comes into contact with water, any builder will definitely hear a rather loud slap. Another test option is pouring water into the barrel. If she suddenly disappeared abruptly, then the goal has been achieved.

It is also important to determine when to stop drilling. This is done according to the speed of penetration. When they reach the aquifer, it increases

And falls again when the spear plunges into the clay

When they reach the aquifer, it increases. And falls again when the spear plunges into the clay.

The advantage of the method is a fairly quick work and getting the desired Abyssinian well. There is also a minus, this is an increased load on threaded connections. If they are damaged, the loss of tightness is inevitable, so the water will become unsuitable for domestic use.

Gentle drilling method

This type of work is more difficult, so it is better to use compact drilling rigs, but there is a home-made design that greatly facilitates the work. It consists of:

- tripod with collar;

- block at the top.

The drilling projectile is taken out of the ground with the help of a block, a cable and a winch. In this case, the pipeline is not threatened by the loss of integrity. The Abyssinian well is made using a special drill - auger - a steel pipe with blades welded in a spiral. Rotating, the projectile is deepened into the ground. After it goes to the full depth, it is removed, the soil between the blades is removed, and the operation is continued. Pipes can be threaded or fastened with studs.

Since the latter method is much more labor intensive, and the process will take a lot of time, most people prefer the first method. Self-made structures are advised to use only if there is one hundred percent confidence in the proximity of water.