- What is a well-needle?

- Conditions for the construction of the Abyssinian well

- What is better a well or an Abyssinian well?

- The choice between a well or a well

- What is the difference between a well and a well

- Advantages of the Abyssinian well

- Cons of the Abyssinian well

- Pros of a well

- Cons of a well

- So what is better for a house - a well or a well?

- "Arrangement of the device"

- Can't do without a woman

- Gentle drilling method

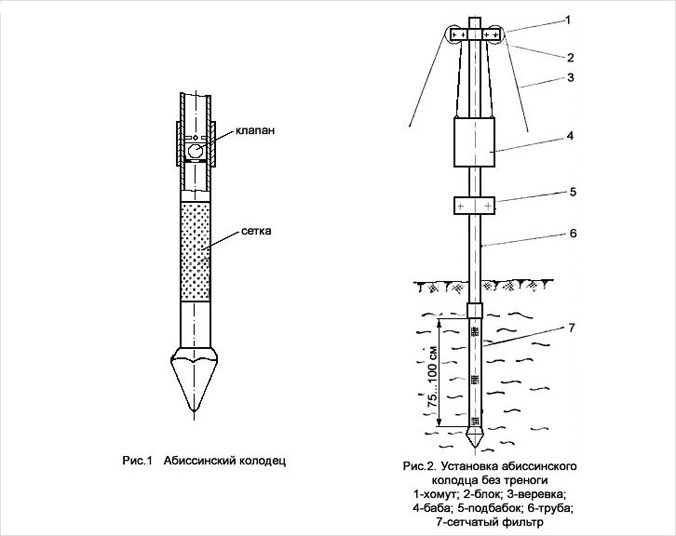

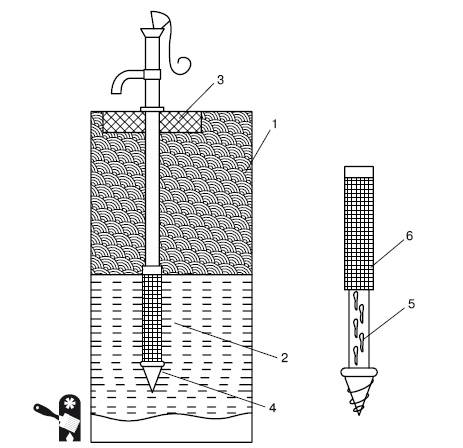

- The Abyssinian well consists of details:

- Preparation of the necessary materials

- What is an Abyssinian well?

- How to choose the right place?

What is a well-needle?

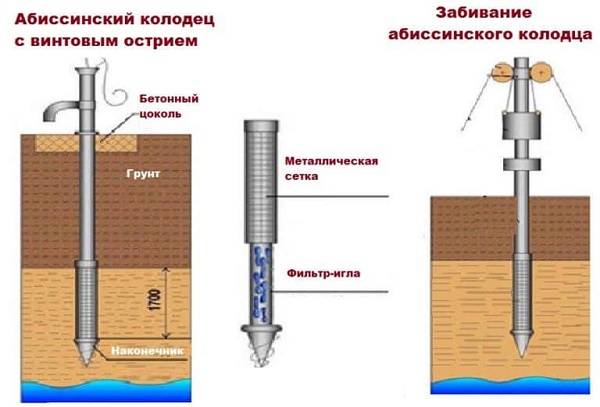

Such a structure got its name due to its specific design - the end of a metal pipe with a diameter of 5 ± 2.5 cm, driven into the ground, is equipped with a metal tip of a conical shape, due to which it enters the ground like a needle. The tip with a smaller angle improves the patency, and the massive structure (solid material) will ensure the removal of stones and the deviation of the conduit from massive obstacles.

Needle on the Abyssinian well

In order for water to get from the aquifer into the closed cavity, holes with a diameter of 10 ± 2 mm are drilled in the wall of the first hammered lash in increments of 5.5 ± 0.5 cm, which can be additionally wrapped with a fine stainless steel mesh.The filter element, which keeps sand from penetrating inside, is fixed using spot welding or several turns of wire wound over and twisted together.

It is obvious that the tip, which is equipped with a well-needle, must have a larger base diameter than the outer size of the sections driven into the ground. This is necessary so that the resistance of the layers does not lead to a displacement of the mesh and does not expose holes through which soil and sand will get inside. Since the point should be removable, it should have the following design features:

- The item is a solid cone, obtained by turning a steel blank, the cross-sectional size of which is 10 ± 2 mm larger than the cross-sectional dimension of the lash.

- Inside, an elongated thread is made, the depth of which is 1.5 - 2 of the outer dimensions of the pipes.

- From the base of the cone to the thread, a cylindrical groove is made 5–6 mm wide and with a diameter equal to the corresponding size of the screwed whip.

A similar Abyssinian well is equipped by twisting the sections together using special elongated couplings and gradually deepening them by driving in with a sledgehammer manually or with a heavy impact tool mounted on a guide ("headstock").

When impacting a pipe assembly, the following negative results are possible:

- section curvature - is prevented by using thick-walled gas pipes;

- bend in the area of the coupling joint, leakage is prevented by the use of elongated couplings with cylindrical grooves;

- jamming of the thread of the upper lash, on which the impact action is performed, is compensated by the use of a special replaceable nozzle made of a material with a lower hardness;

- deviation of the column from the vertical position - which can be prevented by using a guide vane and headstock.

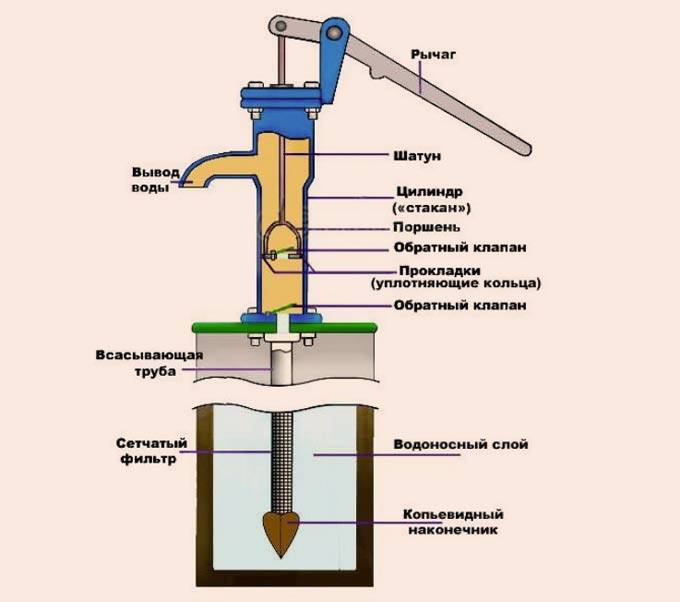

Water can also be obtained using a hand column, thereby doing without electricity.

The well, obtained by driving a pipe needle, was the prototype of modern workings, is still used by the military on campaigns or by private traders in the country as a quick and cheap method of extraction, thanks to which water can be obtained within 5-8 hours after the start of work. A pump is installed on top of the last clogged lash and the aquifer is pumped up, for which it is initially required to fill in water and displace the air plug.

Conditions for the construction of the Abyssinian well

For the device of the Abyssinian well, the ardent desire of the owner of the site, supported by knowledge of the design of the water intake, is not enough. Before starting work, it is necessary to find out whether the geological conditions are suitable for the construction of a needle well.

Soils lying in the ground differ in physical and mechanical properties: in density, structure, hardness parameters, etc. Drillers have a classification according to the so-called "drillability" of rocks.

For sandstone and sand, for example, different types of tools and drilling methods are used. Rocky sandstone is drilled with a core barrel with a hard-alloy bit, and water-bearing sands are lifted by the shock-rope method using a bailer.

The installation of the Abyssinian well cannot be carried out when the occurrence of limestone (1), sandstone (2) is close to the surface, clay deposits (3) and sands (4) are optimal for work.

The installation of the Abyssinian well cannot be carried out when the occurrence of limestone (1), sandstone (2) is close to the surface, clay deposits (3) and sands (4) are optimal for work.

According to the totality of physical and mechanical properties, together with the drillability of the rocks, they are conditionally divided into:

- Solid or rocky. They are able to split, crush, gradually collapse when drilling at high speed and pressure. Hard rocks are represented in the upper part of the deposits by limestones, sandstones, marls, dolomites, etc.

- Plastic. They are easily or relatively easy to cut with a knife and drilling tool, including the Abyssinian wellhead. Plastic representatives include clays, loams, and sandy loams with a high plasticity number.

- Loose. They do not keep their shape, because. are made up of unconnected particles. When saturated with water, some dusty species can "float". The free-flowing variety includes sands of all categories by size, gravel-pebble, gruss-rubbly and similar deposits.

At the disposal of home craftsmen who want to work on the device of the Abyssinian well, there is no drilling tool for sinking all of the listed types of soil. Independent drillers will be able to cross only plastic and loose categories. It is impossible to crush hard rock with the tip of an Abyssinian well.

Sedimentary deposits are ideal for the device and normal operation of the Abyssinian well: gravel, crushed stone, pebbles with aggregate, sands, sandy loams, loams (+)

Sedimentary deposits are ideal for the device and normal operation of the Abyssinian well: gravel, crushed stone, pebbles with aggregate, sands, sandy loams, loams (+)

You should not try to break a large boulder: it is better to move a little and start working there again. Moreover, the dismantling of the water intake device is carried out many times faster than installation.

In addition to restrictions on drillability, the height of the water table affects the possibility of constructing a well-needle. The fact is that extracting it from a thin-barrel mine can only be entrusted to surface pumping equipment. Most brands of surface pumps are ready to lift water from a depth of no more than 8 m.

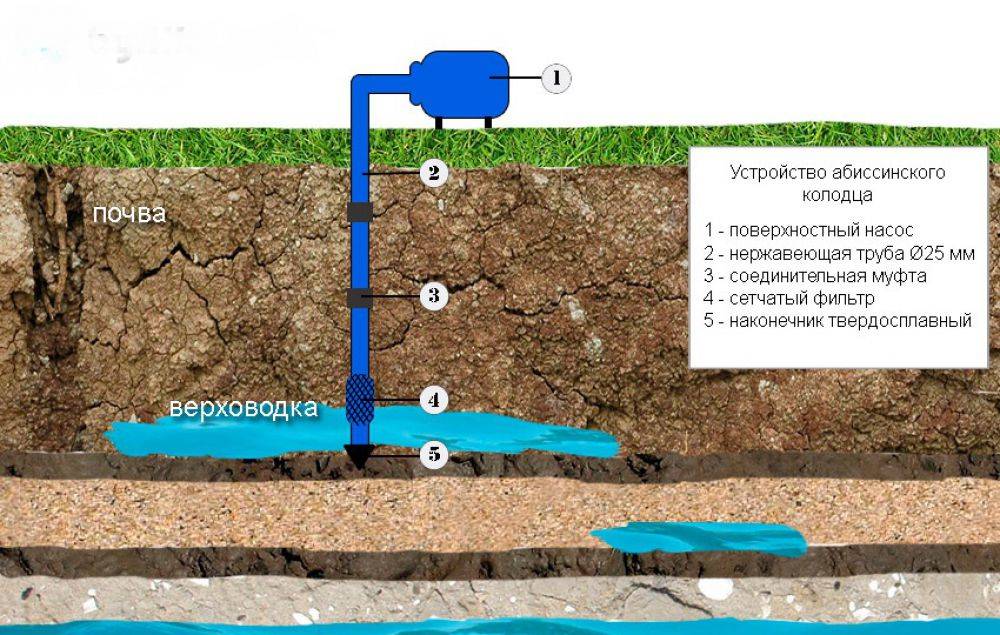

For pumping water from a well-needle, surface pumping equipment is used, which extracts water from an average depth of 8-10 m.

Even if the suction depth is indicated in the data sheet as about 10 m, we must not forget about the standard pressure losses in the barrel and that the pump usually also transports water along a horizontal section.

Every 10 m of horizontal movement takes away 1 m from the suction depth. In addition, surface pumps are strongly recommended to be located in enclosed spaces, and they are often removed from the place of water intake.

If, apart from the Abyssinian well, there is absolutely no way out, and the depth of the appearance of water in nearby wells is fixed at 12–15 m from the surface of the earth, then to raise the water, you should stock up on an airlift or a hand pump capable of pumping water from the indicated depth.

To pump water from a depth of more than 15 - 20 m, you can use an airlift, which, in addition to transporting water, saturates it with oxygen.

An alternative option for adapting the water intake needle to an unsuitable groundwater level is to install a pit. Before driving the column into the ground, a pit is dug about a meter deep, a width convenient for working with a shovel in it. The driving of the rods then begins from the bottom of the pit. The pump in such situations is installed in a pit.

If the groundwater in the area lies lower than the maximum suction depth of the pump, a pit is built and pumping equipment is located in it

If the groundwater in the area lies lower than the maximum suction depth of the pump, a pit is built and pumping equipment is located in it

What is better a well or an Abyssinian well?

Regular supply of clean water is one of the most important conditions for meeting the vital and domestic needs of a person.

The choice between a well or a well

Residents of urban apartment buildings are usually supplied with water by centralized communications, but the owner of private housing constructions has to equip everything on their own.

Drilling an Abyssinian well in the house

At the same time, the question often arises which source of water should be preferred: a traditional well or an Abyssinian well.

digging a well

Although both the well and the well serve the same purpose, both of them have fundamental differences, and they are not only in the price of arrangement. So what is actually better, a well or a well?

What is the difference between a well and a well

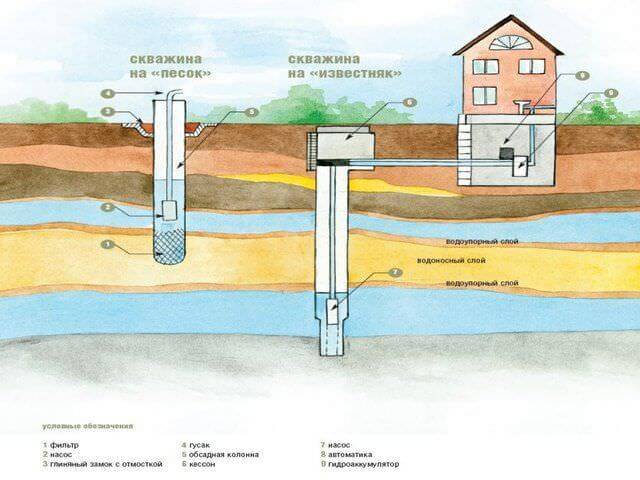

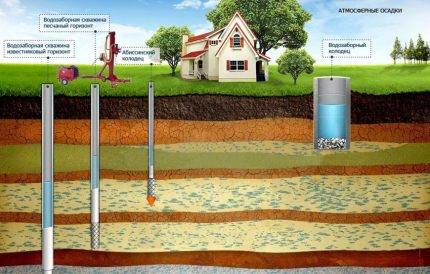

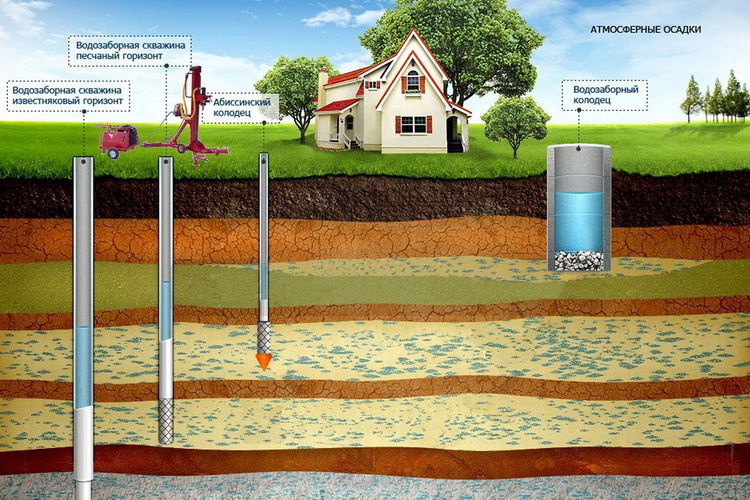

A well is a hydraulic structure in the form of a vertical shaft, often dug by hand, while a well is a relatively narrow and deep hole drilled in the rock with a special tool.

The inner world of the well

Outwardly, the wells differ from wells in their larger diameter and shallower depth, although some of them, for example, the famous Karakum wells, can have a depth of more than 200 meters.

The inner world of the Abyssinian well

Also, wells, unlike wells, are equipped with special casing pipes that prevent soil shedding and contamination of well water with surface water. Wells and wells differ in the way water is raised.

Pumping water from a well is almost always done using an electric, less often a manual pump, but you can raise water from a well using a conventional drum.

See also: Abyssinian well hand pump

Advantages of the Abyssinian well

Arrangement of the Abyssinian well is the easiest and most affordable way to provide yourself with drinking water.

Hammer drilling method

Since the depth of Abyssinian wells rarely exceeds 12 meters, drilling does not require special mechanized equipment, which significantly reduces financial costs - the arrangement of such a turnkey well will cost 2-3 times cheaper than a concreted well.

For drilling wells of this type, permits are not required, it can be located in any convenient place (in the yard, garage, basement of a residential building), if necessary, an electric pump can be connected to it. The service life of an Abyssinian well is 10-30 years.

Cons of the Abyssinian well

The geological features of the area can become a serious obstacle to drilling the Abyssinian well.

Firstly, shallow aquifers lie unevenly, which does not exclude the possibility of skipping the desired layer even by experienced drillers.

Secondly, drilling of Abyssinian wells may become impossible in soils with a deep clayey or rocky layer, in arid areas. In any case, the quality of water from an Abyssinian well is lower than from an artesian one.

Pros of a well

decorative well

If we compare the well with the Abyssinian well, then the main advantage of the first will be its versatility.The service life of the well is more than 50 years, in addition, due to the wide mouth, it is much easier to carry out preventive and repair work on shallow wells.

Cons of a well

While the arrangement of the Abyssinian well is sometimes a matter of one day, digging a well requires much more effort, and often financial investments.

See also: Well for home - what, where, how?

The risk of contamination of well water with biological materials is an order of magnitude higher than well water: garbage can get into the well through an open mouth, perched water can get through the walls.

It should also be noted that due to the slow filling of the well, its performance may be limited.

Well repair

Repair of deep (more than 20 meters) wells, as a rule, is associated with certain difficulties.

So what is better for a house - a well or a well?

An unambiguous answer, which is better, a well or a well, cannot be given, since everything here depends on the goals, equipment and needs of the owner.

However, the use of more technological ways of water supply, which are drilling wells, is considered preferable.

Wells provide cleaner water, they are productive, easy to maintain, they can be drilled in any place, they do not require the obligatory equipment of special superstructures.

You can order drilling of the Abyssinian well in our organization. We offer reasonable prices, high quality of work performed, but you can purchase all the components necessary for well equipment from us.

"Arrangement of the device"

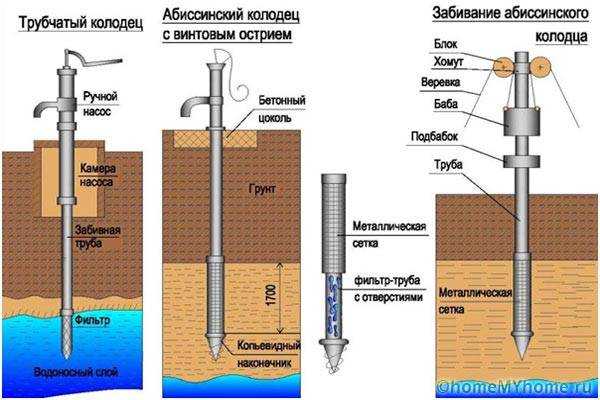

The design, invented a long time ago, has not changed very much since that time. Maybe because for some time the Abyssinian wells were forgotten.There are 2 ways to achieve the goal - driving method and drilling. No, there are more, but these are the most popular.

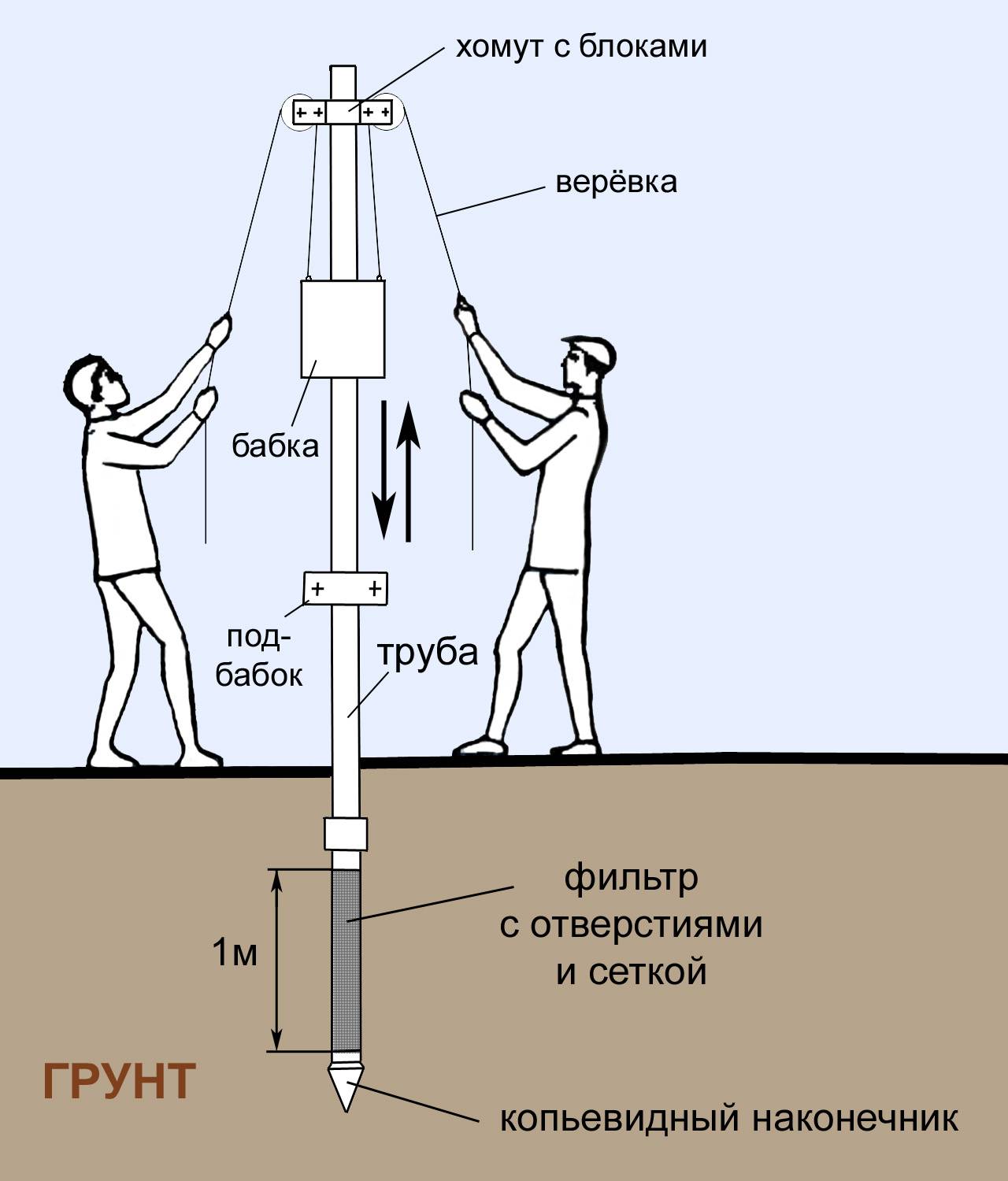

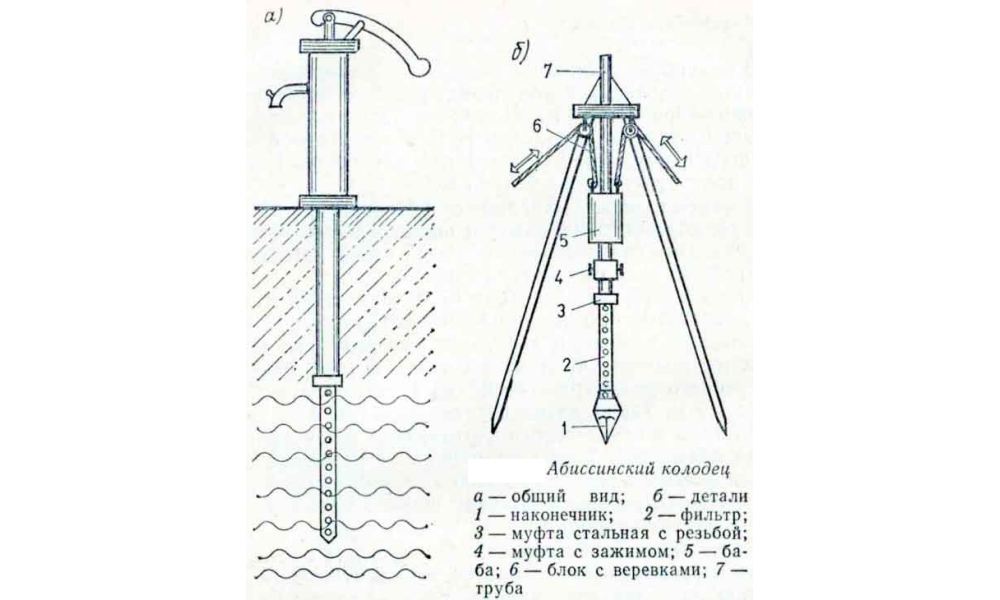

Can't do without a woman

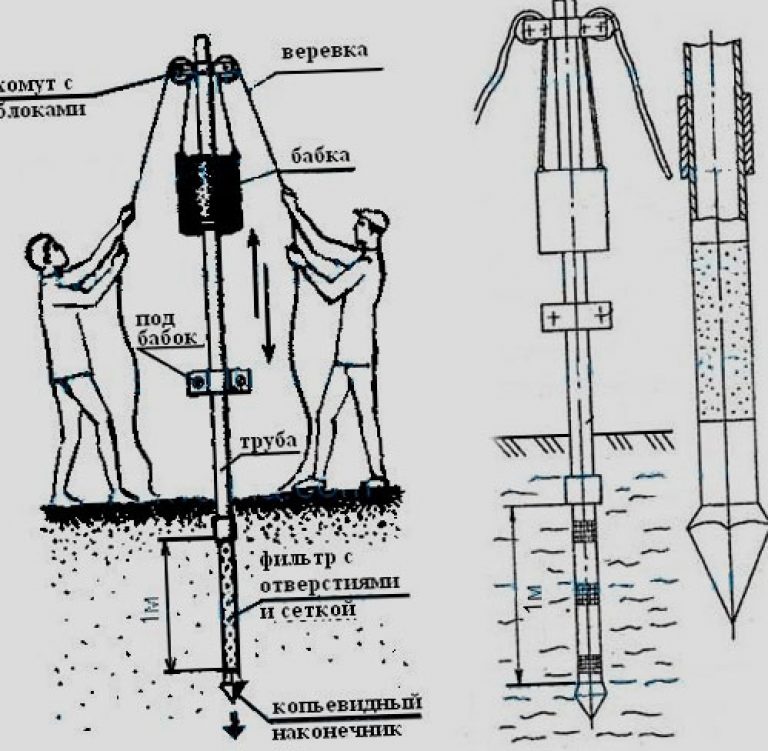

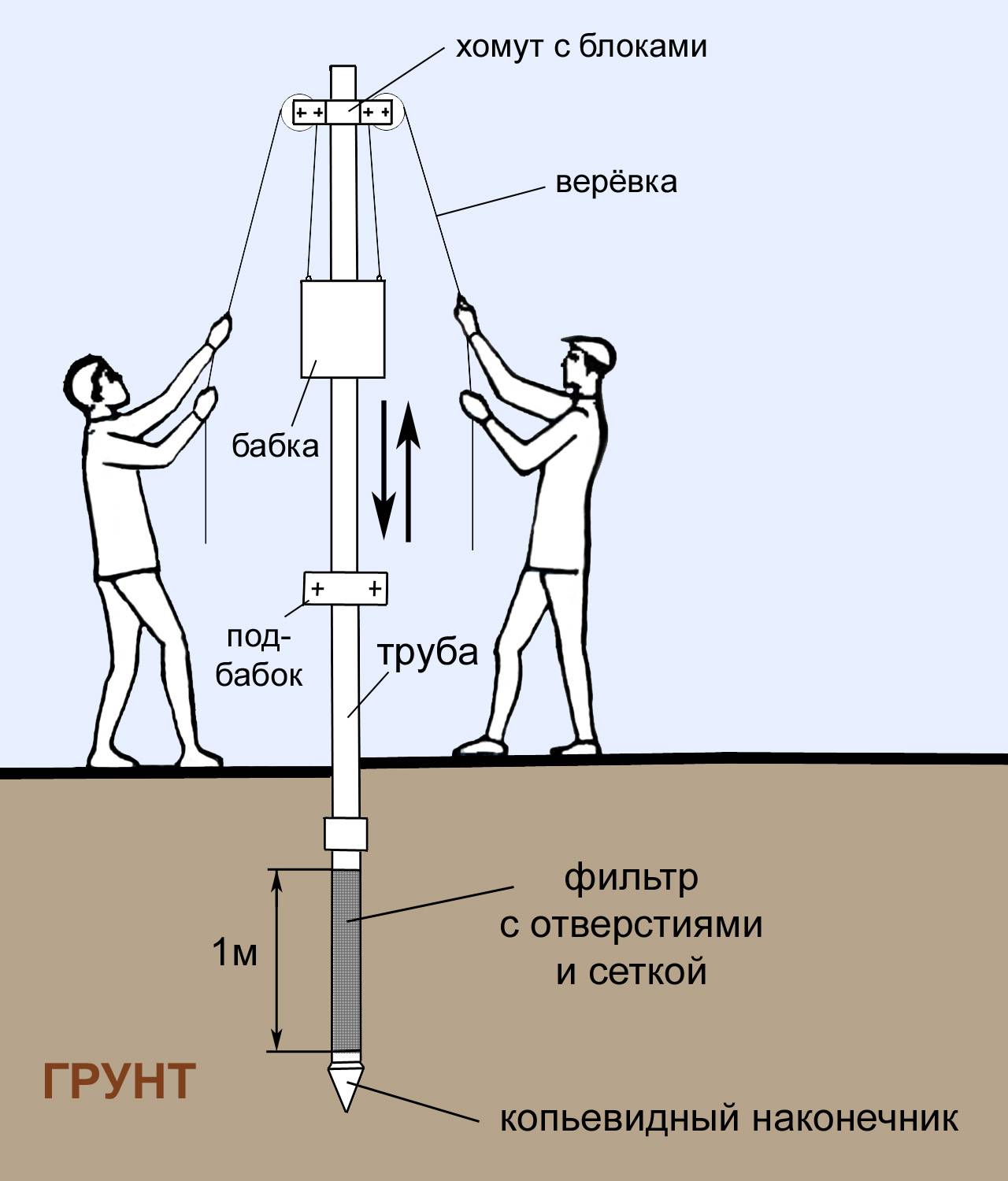

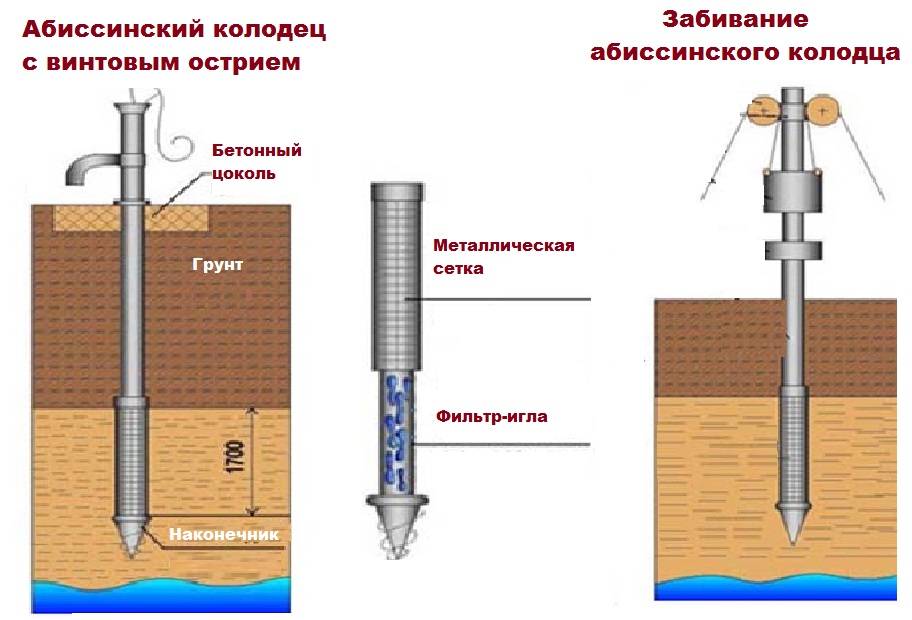

This rather simple device consists of two main parts.

- Drill projectile. This is a sharp cone-tip that cuts the ground, and the trunk is a pipe, which is built up during work as it deepens into the soil.

- A pile driver is a part that includes a metal tripod and a heavy (concrete) projectile. The top of the first element is equipped with two blocks through which strong ropes (cables) are pulled. A load is tied to them, which is called a “construction woman”.

By pulling the ropes, the heavy-weight projectile is lifted to the very top of the tripod. Then they are released, as a result, the woman falls on the podbabok - a kind of anvil, which is securely fixed on a piece of pipe. This is a 2 piece clamp. Its surface area is greater than that of the bottom of the projectile.

As a result of such actions, the trunk gradually goes into the soil. When one section of the pipe is immersed in the ground, the bollard is removed, a new one is screwed to the trunk, then the clamp is fixed on it again. Such work is carried out until the aquifer is reached by the stackable pipe. It is not only opened, but also deepened into the layer by at least a meter. Experts recommend crossing it by 2/3, but an amateur driller is unlikely to know the exact dimensions of the aquifer.

To periodically check for the appearance of water in the trunk, a rather simple folk invention is used - a large nut fixed horizontally on the cord. When it comes into contact with water, any builder will definitely hear a rather loud slap.Another test option is pouring water into the barrel. If she suddenly disappeared abruptly, then the goal has been achieved.

It is also important to determine when to stop drilling. This is done according to the speed of penetration. When they reach the aquifer, it increases

And falls again when the spear plunges into the clay

When they reach the aquifer, it increases. And falls again when the spear plunges into the clay.

The advantage of the method is a fairly quick work and getting the desired Abyssinian well. There is also a minus, this is an increased load on threaded connections. If they are damaged, the loss of tightness is inevitable, so the water will become unsuitable for domestic use.

Gentle drilling method

This type of work is more difficult, so it is better to use compact drilling rigs, but there is a home-made design that greatly facilitates the work. It consists of:

- tripod with collar;

- block at the top.

The drilling projectile is taken out of the ground with the help of a block, a cable and a winch. In this case, the pipeline is not threatened by the loss of integrity. The Abyssinian well is made using a special drill - auger - a steel pipe with blades welded in a spiral. Rotating, the projectile is deepened into the ground. After it goes to the full depth, it is removed, the soil between the blades is removed, and the operation is continued. Pipes can be threaded or fastened with studs.

Since the latter method is much more labor intensive, and the process will take a lot of time, most people prefer the first method. Self-made structures are advised to use only if there is one hundred percent confidence in the proximity of water.

The Abyssinian well consists of details:

- tip

- filter

- threaded steel coupling

- clutch with clamp

- woman

- rope block

- pipe

The installation technology of the Abyssinian well is simple. Any man can handle it.

Be sure to consider two main conditions.

First, the aquifer must be about nine meters below the soil surface. You can find out about this from your neighbors who have wells. Secondly, the soil should be sandy or have a composition of coarse sand and gravel. Otherwise, you will not be able to break through the stony soil without the involvement of special equipment. Next, stock up on the basic elements for the Abyssinian well: Rubber seal. Fine mesh filter. Hardened steel tip. Assemble the main - a collection pipe that supplies water. Coupling for jumpers of pipe sections. Pump for manual evacuation of the piston mechanism. Water intake valve. Then we carry out the skeleton for the Abyssinian well. The supporting structure of the Abyssinian well is made using a one to two inch pipe. This structure is then driven into the ground.

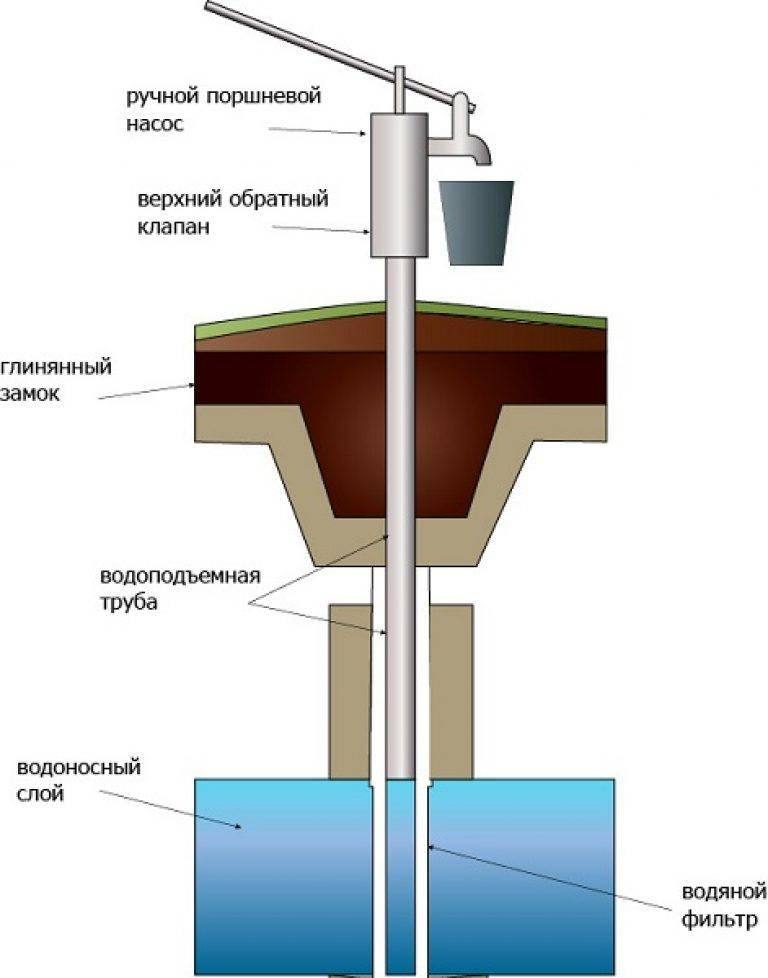

An important condition is that the downhole pipe must be of a larger diameter than the well pipes. If this is not done, then moving the pipes to a depth will become impossible.

The sequence of work with pipes. In the place chosen for the well, it is necessary to select soil in a hole with a diameter of one meter. The first pipe, the main, is driven into the ground with the help of a cast-iron woman or rod strikes. Later, it is screwed into the ground with the help of a frame drill. In this case, it is necessary to constantly extract the rock. After installing the first section of the pipe, it should be strengthened in the pit, the earth around it should be tamped, adding soil. On the lower segment, the end of which has a thread, the next pipe segment is screwed on. Then the next one is screwed on and so on.The total length of the pipes corresponds to the depth of the water reservoir. When the filter goes down to the water vein, the water in the mine rises by one meter. For primary water filtration on the pipe, it is necessary to drill holes of 10 mm in a checkerboard pattern, with an indent of half a meter. More often it is impossible - we lose strength. A cone-shaped sharp tip is screwed onto the edge of the lower pipe, 200-300 mm long with slots for water. Next, the perforated pipe should be wrapped with stainless wire, after which a stainless steel or plastic mesh should be applied - this is a filter that does not allow fine sand to pass through. It is necessary to solder the metal mesh with a special flux or tin solder that does not contain lead. Water poisoning should not be used. Sealed gaskets should be used at the junctions of the pipes, otherwise water will leak, which will certainly affect the efficiency of the well. To ensure sufficient strength at the pipe joints, it is necessary to use linen hemp impregnated with oil paint. The final technological processes for creating the Abyssinian well: We wash the clay filter under pressure. At the upper end of the pipe we install a water pump, which helps to raise water from the depths of the earth and pump out the top layer until it is completely clarified. We fix the pump with a flange on the casing pipe or with a threaded connection. During installation, you must constantly monitor the water level. When the water rises, you should think about the tightness of the pipe connection, which can be broken due to depressurization or clogging of the well. Steel couplings with high-quality threads should be installed.In order to prevent sewage from mixing with drinking water, it is necessary to build a well on a concrete foundation, which will rise above the surface of the earth.

Preparation of the necessary materials

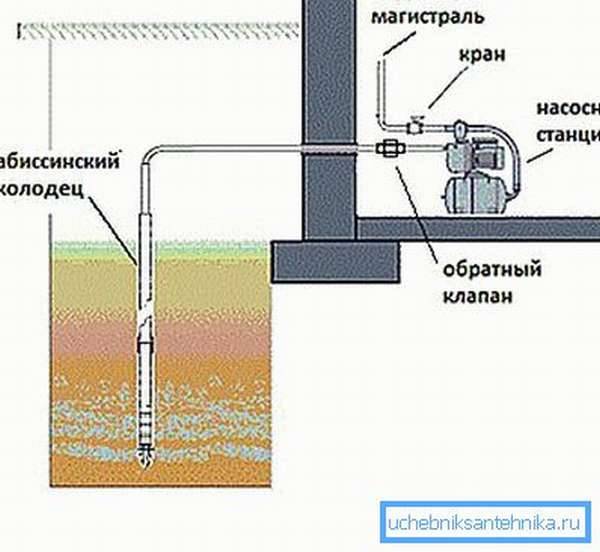

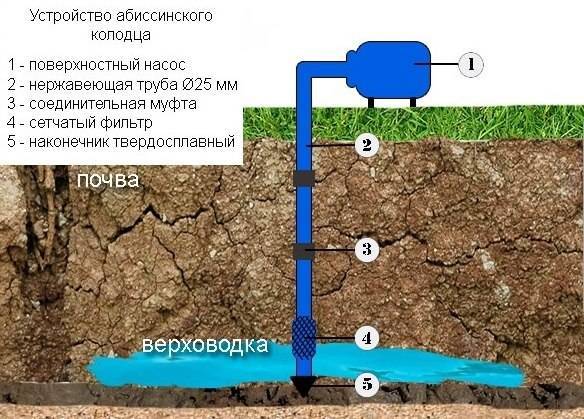

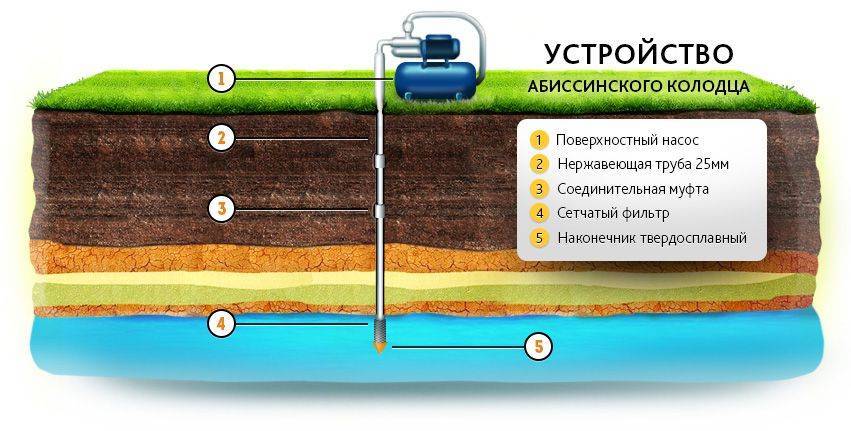

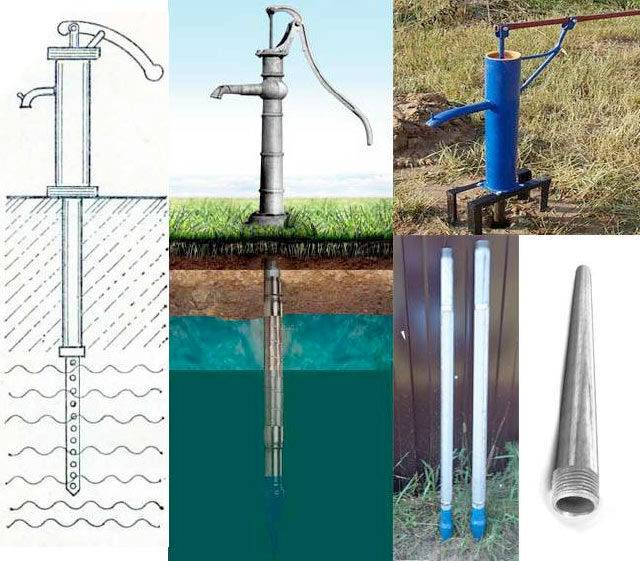

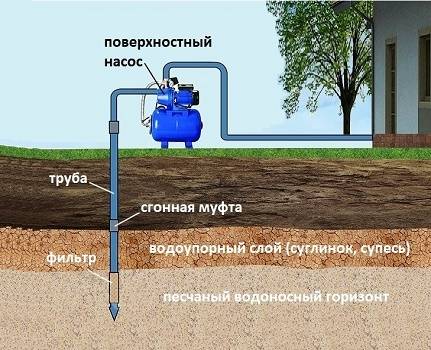

The design of the Abyssinian well is extremely simple and consists of a set of metal pipes 1-2 m long, interconnected with couplings, a filter pipe in the lower part for water intake and a pump on the soil surface.

Abyssinian well device

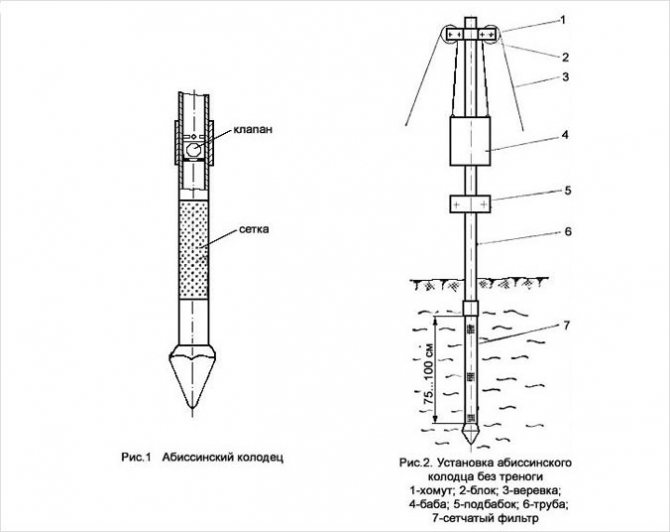

Step 1. Pipes are preferably galvanized or stainless steel for corrosion protection, pipe diameter is 1-1½ inches (approximately 2.5-3.8 cm). Copper pipes are not suitable because of the softness of the metal, besides, copper is able to give free ions to water, poisoning it. On pipes, except for the lowest one, external threads are cut on both sides.

Pipe kit

Step 2. Perforation is performed in the lower pipe, which is a water intake with a filter. The length of the perforated part is 700-1000 mm. The diameter of the holes is 8-10 mm, the center distance between the holes is 50 mm. The holes are staggered. Over the perforated part, stainless wire is wound according to the scheme.

Abyssinian well wire filter

Instead of wire, you can use a fine-mesh harpoon or plain weave made of stainless steel. The mesh is tightly wrapped around the perforated part of the pipe and soldered at all joints.

Pipe filter

At the upper end of the pipe, a thread is cut for connection to the coupling.

Step 3. A spear-shaped tip made of hardened steel is welded to the lower end of the pipe, which facilitates clogging of the well.The diameter of the tip at the junction with the pipe should be 15-20 mm larger than the diameter of the pipe - this makes it easier to pass through the ground when driving.

Welded tip

Step 4. The number of pipes in the kit depends on the expected depth of the well. They are connected using a threaded coupling, flax or fluoroplastic thread is wound on the thread for strength. It is preferable to take thick-walled couplings, with a wall thickness of 5 mm - such products are stronger.

Couplings for connecting pipes

Step 5. To drive pipes into the ground, a hard-alloy drive-in tip is made. The tip has an internal thread and is screwed onto the next section of the pipe.

driving tip

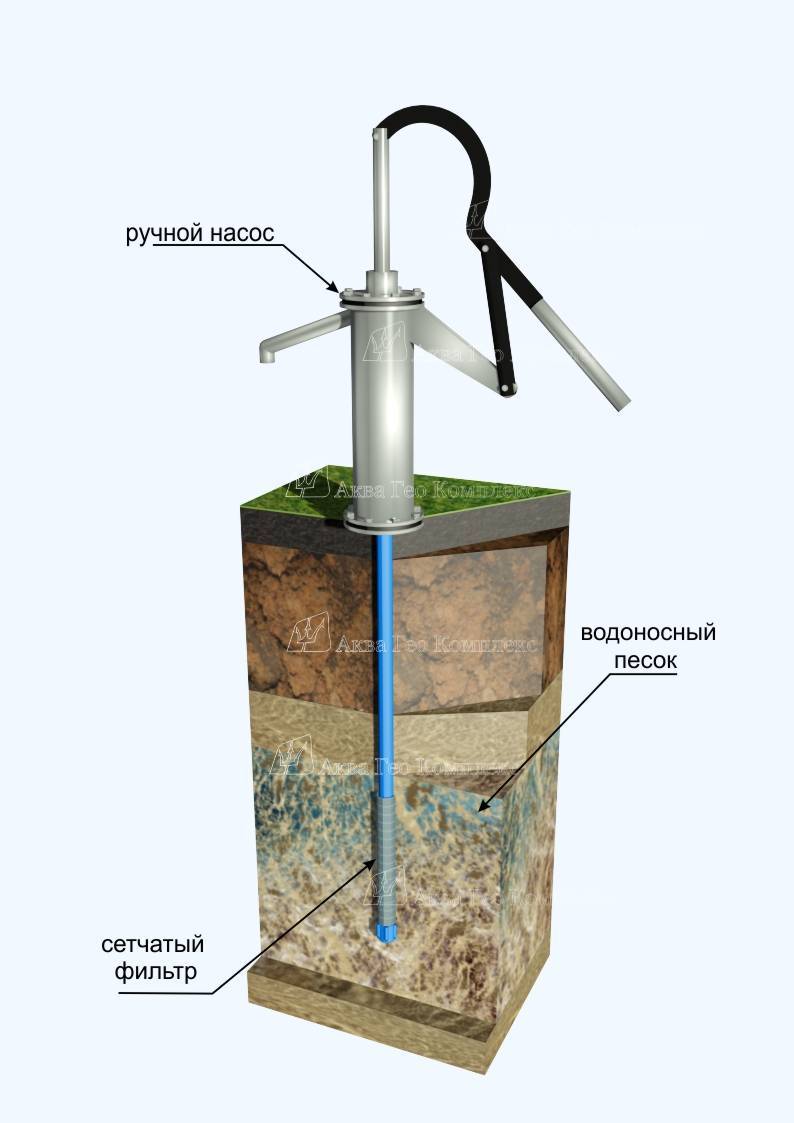

Step 6 Pipes are clogged with a sledgehammer or headstock. The headstock is a steel cylinder in which a hole is drilled slightly larger than the diameter of the pipe used. The striking surface inside the cylinder conforms to the conical shape of the striking tip in order to center the strike. From below, a removable ring is attached to the headstock according to the diameter of the pipe in order to avoid distortions when clogging. The headstock on both sides is equipped with handles for lifting.

grandma

Step 7. Sometimes the headstock is made with a through hole, in this case, instead of the impact tip, a substock is used, which is attached to the pipe at a convenient height. In this case, the blow does not occur at the end of the pipe, which reduces the chances of bending it when passing through dense layers of soil.

Drawings of devices for clogging the Abyssinian well

To facilitate the lifting of the headstock, a collar with blocks is made. In this case, the headstock is lifted together from two sides through the blocks, it falls under its own weight.

Clogging an Abyssinian well with a headstock with a subheadstock

Step 8For primary pumping of the well and cleaning it from sand, it is recommended to use a hand pump. If in the future you plan to install a pumping station, you can not buy a hand pump, but rent it.

Hand pump

Step 9. When placing pumping equipment in a caisson, after installing the well, it is necessary to dig a pit for its (caisson) installation. The depth of an uninsulated caisson should be greater than the level of soil freezing.

Caisson for a well

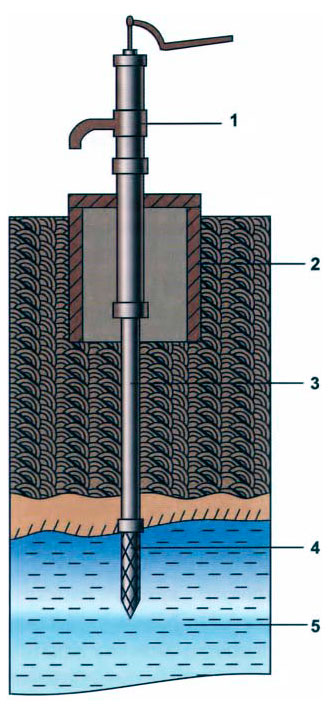

What is an Abyssinian well?

Abyssinian well

they call several iron pipes up to 9 m long, connected by couplings, through which water from the well rises to the surface with the help of a pump. The last pipe has a pointed tip. Hence the second name of such a structure - a well-needle. At its very bottom, a filter is installed - a pipe with drilled holes, wrapped with a special mesh that traps sand and small impurities up to 0.25 mm.

artesian well

Unlike a conventional well, the arrangement of which requires extensive earthworks, the Abyssinian well is drilled much faster and requires much less material costs and physical effort. Moreover, the water in it (especially in spring) is much cleaner - after all, riding water and drains do not get into it. After a thorough cleaning and washing of such a well, the water in it will be similar to spring water.

How to choose the right place?

This type of well is dangerous because the water can be contaminated by sewage. Therefore, it is necessary to choose a place for a well as far as possible from any zones where there are abundant drains. The distance from the septic tank must be at least 20 meters. This is with fine-grained soil, which perfectly purifies water.If the soil is coarse-grained, the distance increases by another 2 times.

If the question arose of how to make an Abyssinian well with your own hands so that the water in it is clean and safe, you need to know that the depth of the well should be at least 4 meters. If the water went earlier, this means that it is soil water, which contains many dangerous impurities.